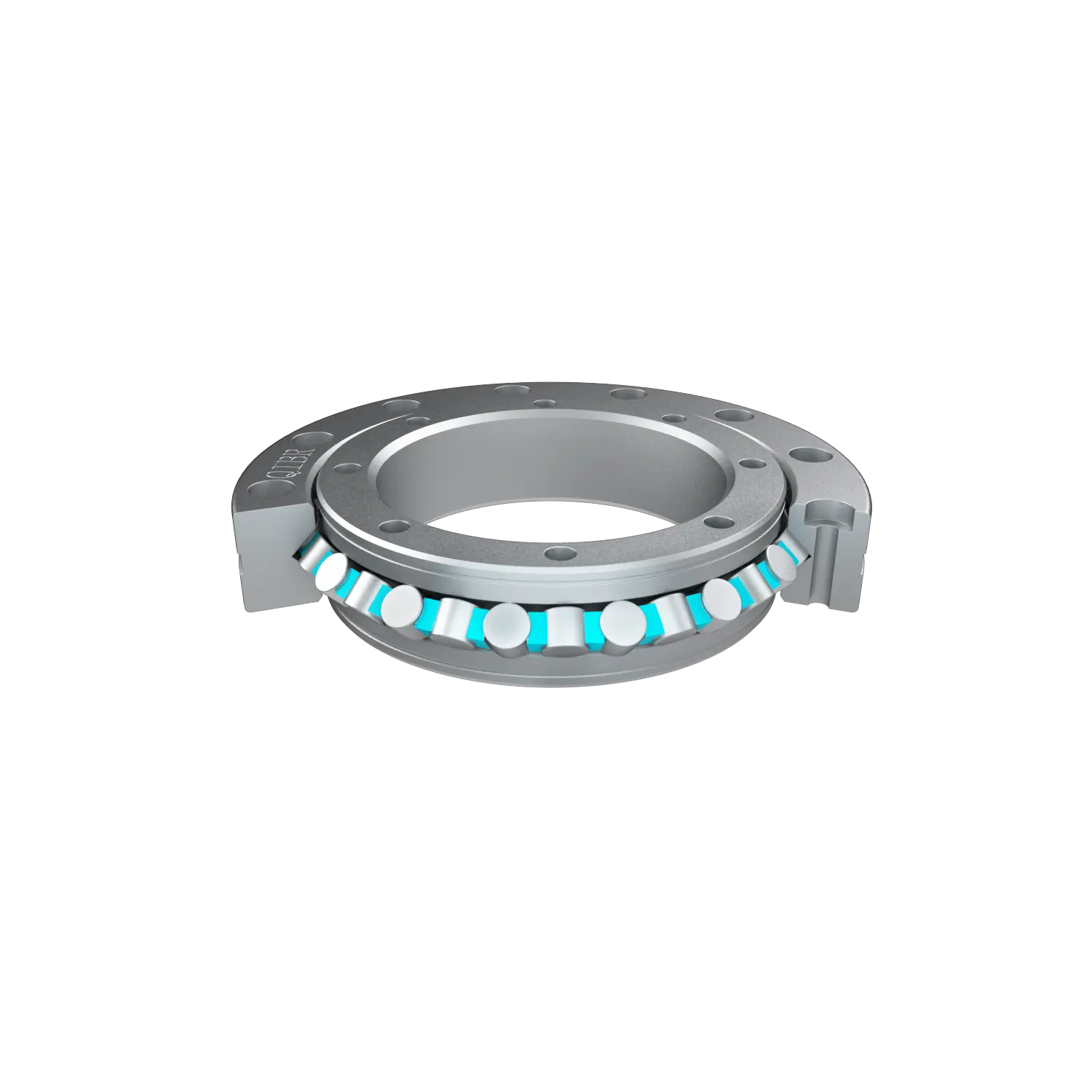

QRU 148(G)

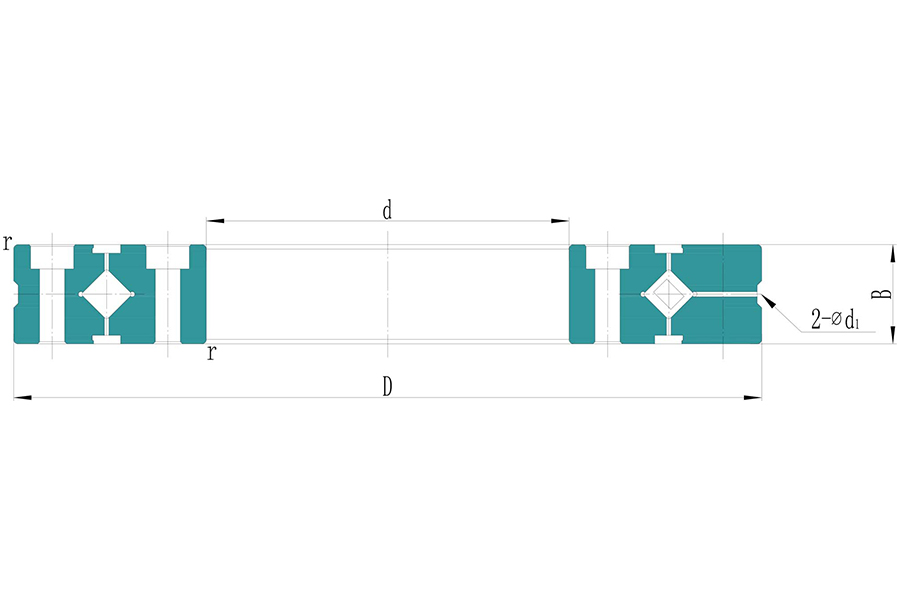

- Inner Diameter(d)

- 90mm

- Outer Diameter(D)

- 210

- Roller Pitch Circle Diameter(dp)

- 147.5mm

Specifications

RU Seris - QRU 148(G)

QRU 148(G) Crossed Cylindrical Roller Bearing Product Features and Advantages

High load capacity: It can withstand large radial and axial loads and is suitable for high-load application scenarios.

Small size and large load: The cross-arranged rollers can effectively distribute the load, and the bearing provides greater load capacity at a smaller size.

Low friction: The contact surface between the cylindrical roller and the raceway is large, the friction coefficient is low, and energy loss and heat generation are reduced.

High precision: The bearing structure is optimized to improve the rotation accuracy of the bearing and is suitable for applications requiring high precision.

Application: It has a wide range of applications in industrial robots, machine tools and CNC machine tools, aerospace, medical equipment, optical instruments, IC manufacturing equipment and other fields.

QIBR - QRU 148(G) Crossed Cylindrical Roller Bearing Optimization

High-performance materials: The bearing material can be replaced according to the working requirements of the bearing, such as stainless steel, silicon-manganese steel, etc.

Structural optimization: The one-piece inner ring and outer ring are designed with mounting holes, without flanges and bearing seats, and easy to install.

Sealing structure: The sealing structure can be selected according to the working environment of the bearing, such as FKM/fluoro rubber seals for high temperature resistance, hydrogenated nitrile rubber (HNBR) seals for low temperature resistance, and polyetheretherketone (PEEK) seals for chemical resistance, to ensure the heat resistance, oil resistance, and chemical resistance under different working conditions.

Grease replacement: QIBR technicians can recommend grease according to the working conditions of the bearing or replace grease according to customer needs, such as Mobil, Shell, SKF, Fuchs and other brands.

More customization: QIBR can design and optimize the bearing structure and process according to customer requirements for drawings and bearings.

QIBR - QRU 148(G) Crossed cylindrical roller bearing quality control

Dimension measurement: Use a variety of professional high-precision instruments to measure multiple dimensions of the bearing, with the highest accuracy of up to 0.001mm.

Rotation accuracy: Use a micrometer to measure small flaws or deviations on the bearing surface, with a measurement accuracy of up to 0.001mm.

Hardness measurement: Use a hardness tester to measure the surface hardness of the bearing, with a measurement accuracy of up to ±0.5HRC.

Metallographic analysis: Analyze the internal metallographic structure of the metal through a professional metallographic microscope.

Geometric tolerance: Use a profilometer to measure the bearing geometry and relative position.

Noise monitoring: Use a vibration meter to monitor the vibration during operation and obtain noise data.

Raw material control: Purchase steel and parts from suppliers certified by ISO 14001 to ensure product stability while promoting sustainable development.

Features & Benefits

Cross roller bearings are commonly used in various applications where high precision, rigidity, and load-bearing capacity are required. Some of the key applications include: Machine tools: it is extensively used in machine tool spindles, rotary tables, and indexing heads due to their ability to provide high rigidity and accuracy, allowing for precise machining operations. Robotics: These bearings are essential components in robotic arms and joints, enabling smooth and precise movement while supporting heavy loads. Medical equipment: Cross roller bearings are used in medical imaging equipment such as CT scanners and MRI machines, where they support rotating components with high precision and stability. Aerospace: In aerospace applications, cross roller bearings are employed in aircraft landing gear, flight control systems, and satellite antennas, where they must withstand extreme conditions and provide reliable performance. Semiconductor manufacturing: Cross roller bearings are used in semiconductor manufacturing equipment, such as wafer handling robots and lithography machines, where they play a crucial role in ensuring precise positioning and alignment of components. Precision instruments: These bearings find applications in various precision instruments, including metrology equipment, optical devices, and measuring instruments, where they contribute to high accuracy and stability.