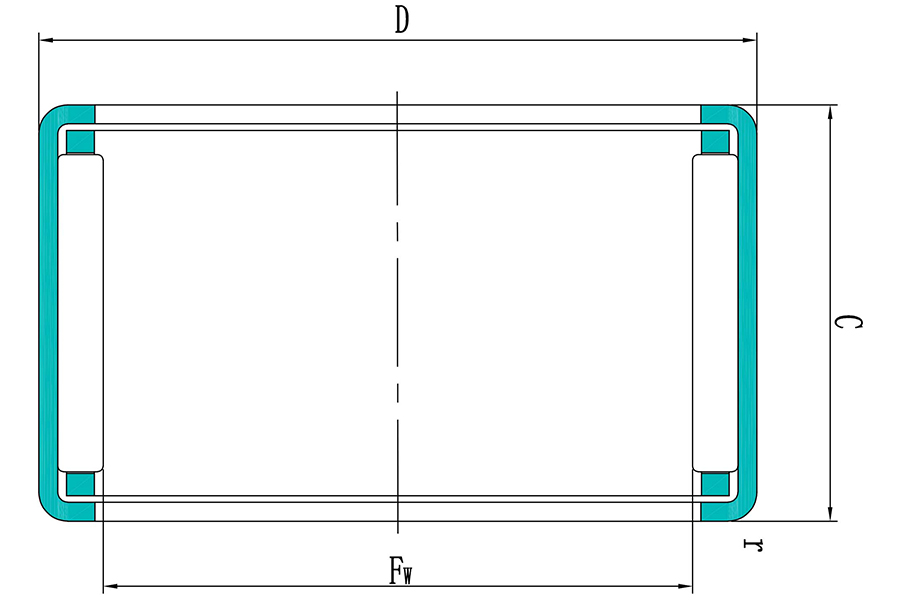

HK0509

- Diameter under rollers(Fw)

- 5mm

- Outside diameter of needle roller complement(Ew)

- 9mm

- Width needle roller and cage assembly(U)

- 9mm

Specifications

Drawn Cup Needle Roller Bearings Seris - HK0509

HK0509 Needle Roller Bearing Features and Advantages

High load capacity: Needle bearings can withstand significant axial and radial loads, making them suitable for various heavy machinery and equipment.

High Precision: The manufacturing precision of needle bearings is high, with low rotational inertia, enabling high-precision operation.

Low Friction Coefficient: With a low friction coefficient, needle bearings effectively reduce frictional resistance during operation, minimizing energy loss.

Compact Structure and Lightweight: The overall structure is compact and lightweight, making it suitable for support structures with limited radial installation space.

Application: Needle roller bearings have a wide range of applications in industries such as automotive, aerospace, industrial machinery, construction and agricultural equipment, home appliances, shipbuilding, and medical devices.

QIBR - HK0509 Needle Roller Bearing Optimization

Structural Optimization: Adjusting the arrangement of needles or the contact angle based on customer requirements and bearing operating conditions.

Cage Material: Material selection for the cage can be customized based on customer needs, including low carbon steel, stainless steel, PA66, etc.

High-Performance Materials: Choosing suitable materials based on customer requirements, such as DC03M, C15Mn, 16MnCr5, etc.

Heat Treatment: Carburizing or carbonitriding and quenching treatment of the outer ring and cage according to the bearing's operating conditions.

More customization: QIBR can design and optimize bearings based on customer operating conditions and requirements.

QIBR - HK0509 Needle Roller Bearing Quality Control

Dimension measurement: Using various high-precision instruments to measure multiple dimensions of the bearings, achieving a maximum precision of 0.001mm.

Rotation accuracy: Measuring small defects or deviations on the bearing surface with a micrometer, with a measurement precision of up to 0.001mm.

Hardness measurement: Surface hardness is measured using a hardness tester, with an accuracy of ±0.5HRC.

Metallographic analysis: Internal metallographic structure is analyzed using a professional metallographic microscope.

Geometric tolerance: A contour gauge measures the bearing's geometric shape and relative position.

Noise monitoring: A vibration meter monitors vibration during operation to obtain noise data.

Raw material control: Steel and parts are sourced from ISO 14001-certified suppliers, ensuring product stability while promoting sustainable development.

Features & Benefits

Needle roller bearings are used in various applications across different industries due to their high load-carrying capacity and compact design.