YRTS395

- Mass(kg)

- 33

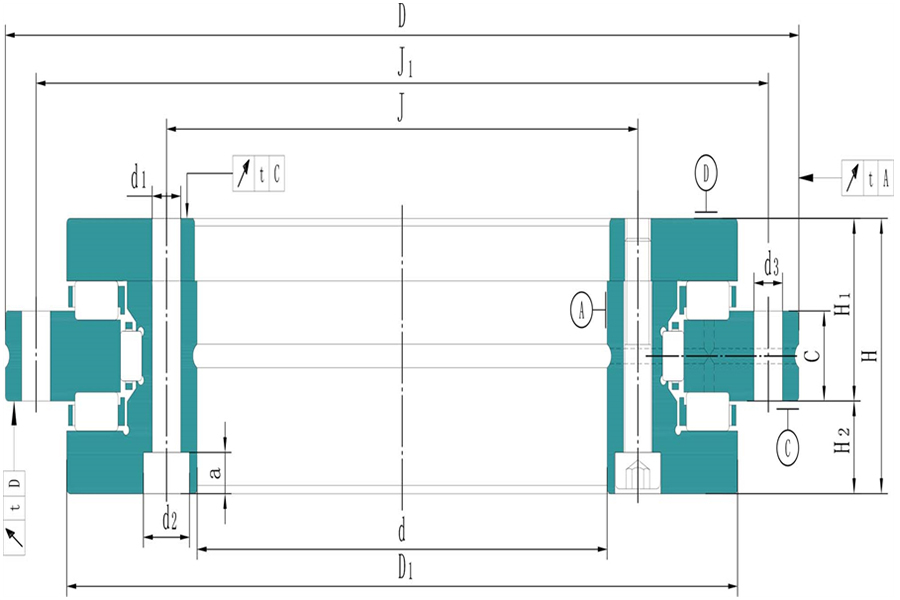

- Inner Diameter (d)

- 395

- Outer Diameter (D)

- 525

Specifications

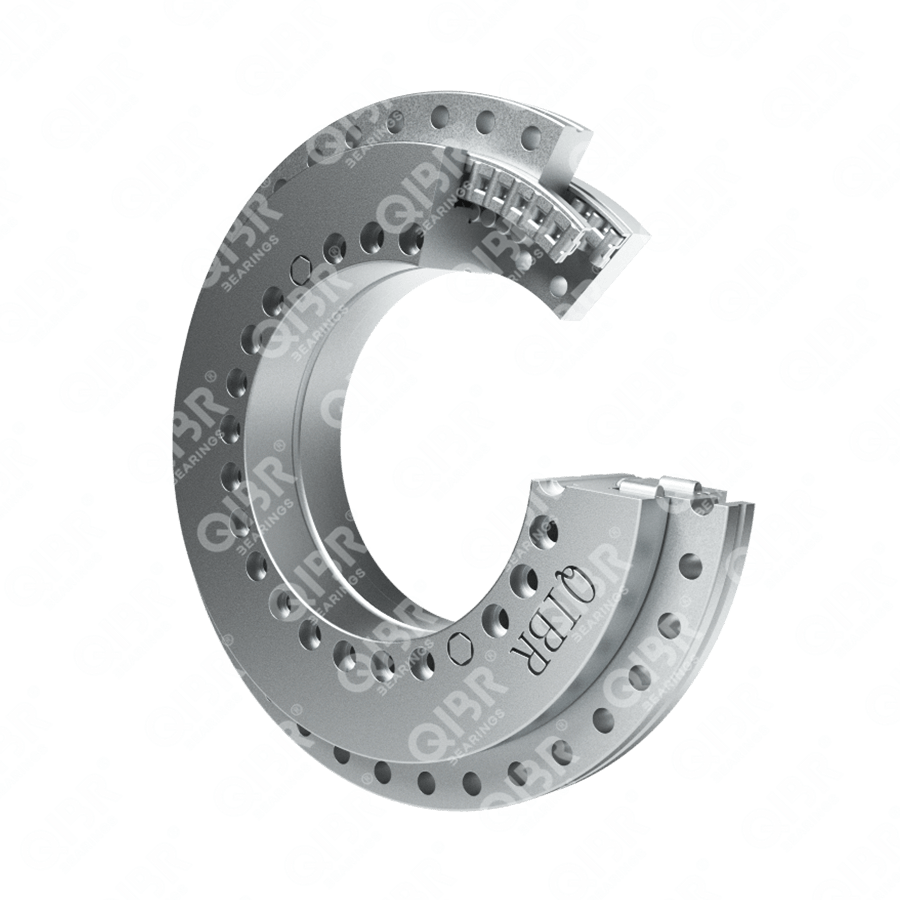

YRTS Seris - YRTS395

YRTS395 YRT Turntable Bearings Features and Advantages

High load capacity: YRT turntable bearings can withstand axial loads, radial loads, and overturning moments, making them suitable for high-load applications.

High Precision: The dimensional accuracy is at P5 level, and the rotational accuracy is at P4 level, ensuring high rotational precision.

Superior Rigidity: These bearings exhibit higher stiffness when subjected to overturning moments, maintaining good performance under high load conditions.

Low Operating Noise: They generate low noise during operation, making them ideal for use in noise-sensitive environments.

Application: YRT turntable bearings are widely used in precision rotary tables, vertical grinding machines, indexing heads, gear hobbing machines, CNC machine tools, radar systems, and high-precision medical equipment.

QIBR - YRTS395 YRT Turntable Bearings Optimization

High-performance materials: The bearing materials can be replaced based on different working conditions, such as GCr15, GCr15SiMn, S165M, etc.

Cage Material: The cage material can be replaced according to customer requirements, such as using 20# steel, brass, or polyamide nylon.

Grease Replacement: The grease can be substituted with other lubricants, such as Mobilith SHC 220 or Shell Gadus S2 V220.

Grease replacement: QIBR technicians can recommend grease according to the working conditions of the bearing or replace grease according to customer needs, such as Mobil, Shell, SKF, Fuchs and other brands.

More customization: QIBR can design and optimize bearings based on customer specifications and operational requirements.

QIBR - YRTS395 YRT Turntable Bearings quality control

Dimension measurement: Various high-precision instruments are used to measure multiple dimensions of the bearings, achieving a maximum accuracy of 0.001mm.

Rotation accuracy: A dial gauge is employed to measure small defects or deviations on the bearing surface, with measurement accuracy reaching 0.001mm.

Hardness measurement: The surface hardness of the bearings is measured using a hardness tester, with an accuracy of ±0.5HRC.

Metallographic analysis: Professional metallographic microscopes are used to analyze the internal metallographic structure of the metal.

Geometric tolerance: A profile projector is used to measure the geometric shape and relative position of the bearings.

Noise monitoring: Vibration monitors are utilized to track the vibration conditions during operation, providing noise data.

Raw material control: Steel and components are sourced from suppliers with ISO 14001 certification, ensuring product stability while promoting sustainable development.

Features & Benefits

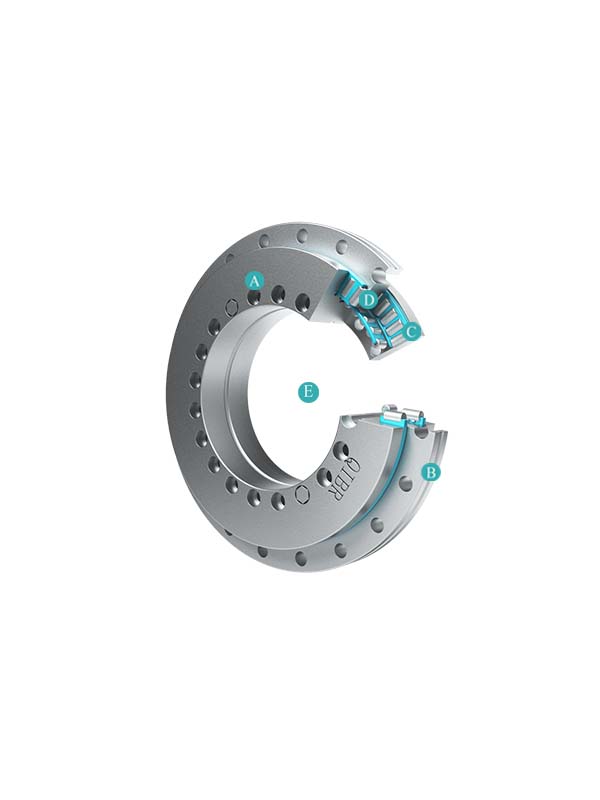

YRT turntable bearing is a slewing mechanism with an outer ring rotating and an inner ring supporting. It is mainly divided into three series: YRT type, YRTS type, and YRTM type. These three series bearings have the same installation dimensions, but have different internal structures and similar performance. YRT series bearings are composed of three rows of rollers. Two rows of axial rollers ensure stable axial load-bearing capacity. One row of radial rollers ensures that the bearing can withstand radial force and overturning moment. It is suitable for axial load-bearing slewing mechanisms.