QIBR and the German planetary gear manufacturer have reached a cooperation agreement regarding spherical roller bearings

- Industry

- Industrial Manufacturing

- Location

- Germany

- Goals

- Increased lifespan of spherical roller bearings

Products used

QIBR and the German planetary gear manufacturer have reached a cooperation agreement regarding spherical roller bearings

Maximize profitability by reducing downtime of customer equipment

Customer Introduction:

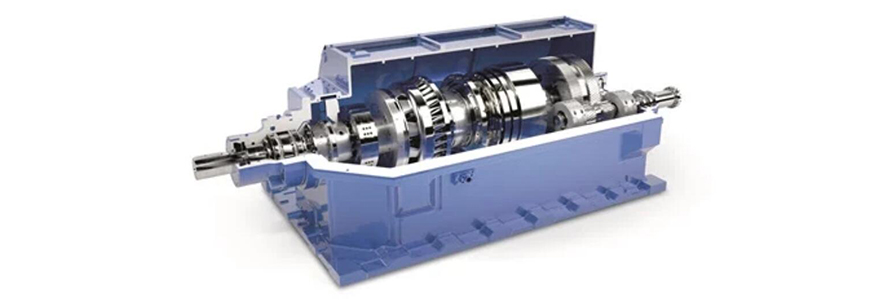

Their company was founded in Eisenach in 1926. Since its founding, it has specialized in the development of innovative and high-quality gearboxes, which are manufactured and assembled at its own plant. They are a third-generation family business. For decades, they have established and maintained long-standing, intensive partnerships with foreign customers.

a) Challenge (Existing Issues and Why They Haven't Been Solved)

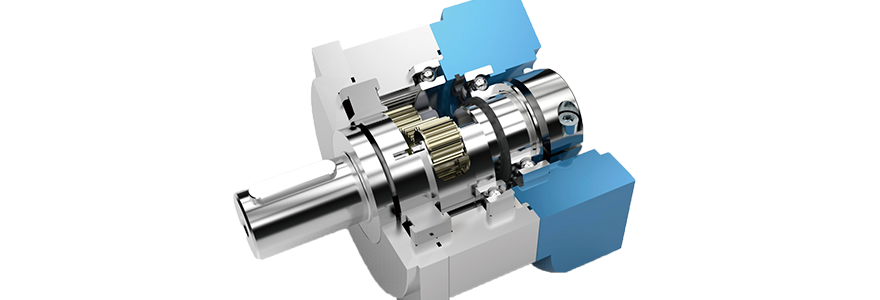

Misalignment and single-row loading frequently occur in industrial gearboxes, impacting the lifespan of bearings. As a result, spherical roller bearings are widely used in industrial gearboxes. However, the non-misalignment life of spherical roller bearings is relatively low, which leads to frequent bearing replacements and increased downtime for industrial gearboxes.

b) Solution (How QIBR Solves the Problem)

QIBR has conducted comprehensive technical optimizations to address the non-misalignment issue of spherical roller bearings:

- Material Optimization: High-quality alloy steel is selected, with carburizing and quenching applied to the outer race to achieve a surface hardness of 680-840 HV and a hardening depth of 0.3-0.35 mm. The needle rollers undergo overall quenching with a hardness of HRC 61-65. Washers are also quenched entirely with a hardness of 664-840 HV. The surface of the eccentric wheel undergoes carburizing and quenching, with a cylindrical surface hardness of 680-840 HV and a hardening depth of 0.4-0.5 mm. This ensures appropriate hardness levels to enhance wear resistance and extend service life.

- Precision Machining: Advanced mechanical equipment and high-precision machining techniques are employed for precise spherical grinding of bearings, roller grinding, and forming of retainers. This improves dimensional and shape accuracy, thereby enhancing the smooth operation of the bearings.

- Quality Control: Strict adherence to product quality control processes includes quality inspection of raw materials, monitoring of process stages, and comprehensive testing of finished products. Advanced quality inspection equipment such as coordinate measuring machines and X-ray flaw detectors are utilized to ensure bearings meet high standards in dimensions and performance.

- Manufacturing Process Optimization: Cold rolling and optimized heat treatment processes are employed to enhance bearing hardness, wear resistance, strength, and stability, further extending the bearing's operational lifespan.

c) Results

- The misalignment issue of spherical roller bearings has been optimized.

- The lifespan and stability of the bearings have been improved.

- Downtime due to bearing failures has been reduced.

- The overall operational efficiency of industrial gearboxes has been enhanced.

- Maintenance costs and uncertainties in the production process for customers have been reduced

Customer Testimonials

QIBR's technical experts provided us with highly optimized products and solutions, conducting precise analysis and improvements on the low non-misalignment lifespan of spherical roller bearings in our industrial gearboxes. By optimizing the material and process of the bearings, they reduced downtime due to failures. The improvements in QIBR's spherical roller bearings significantly enhanced the stability and operational efficiency of our equipment, reduced downtime, and lowered maintenance costs, effectively addressing the high damage rate caused by bearing misalignment. Compared to traditional industrial gearboxes, the lifespan has been significantly increased.

We will continue to choose QIBR's professional products and services to support our production needs.

We will continue to choose QIBR's professional products and services to support our production needs.