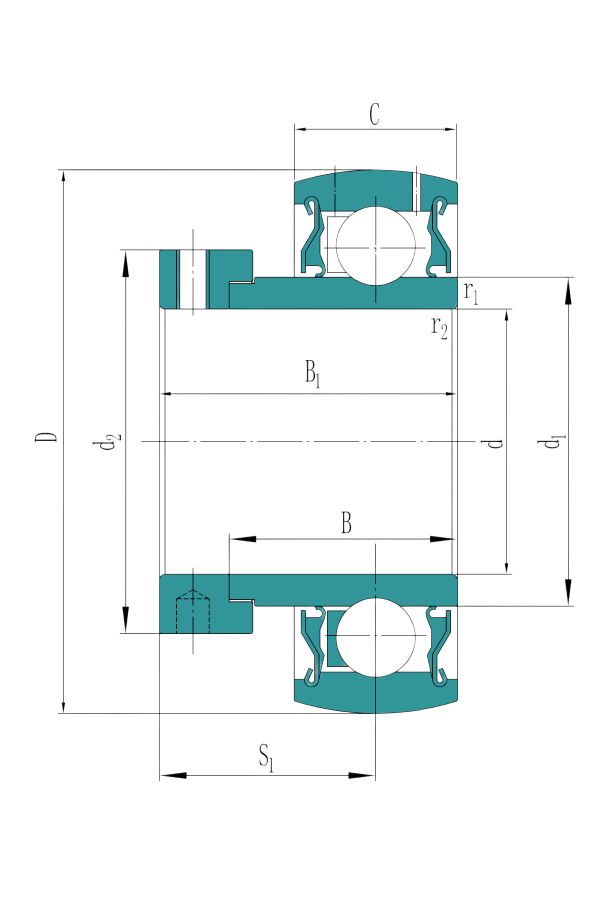

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Material

52100, 100Cr6, SUJ2, stainless steel

Inner diameter

12.7mm-100mm

Outer diameter

40mm-215mm

Weight

0.09kg-12.18kg

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

Conveyor systems, agricultural machinery, food processing equipment, textile machinery, ect

| NO. | Product | Product Number | Basic dynamic load rating | Basic static load rating | Bore | Mass | Outer diameter (D) | Width inner ring (B) |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

YET 203-008 | 9.56 KN | 4.75 KN | 1/2 inch(12.7mm) | 0.13 kg | 40 mm | 19.1 mm |

| 2 |

|

YET 204-012 | 12.7 KN | 6.55 KN | 3/4 inch(19.05 mm) | 0.17 kg | 47 mm | 21 mm |

| 3 |

|

YEL 204-012-2F | 12.7 KN | 6.55 KN | 3/4 inch(19.05 mm) | 0.21 kg | 47 mm | 34.2 mm |

| 4 |

|

YET 205-100 | 14 KN | 7.8 KN | 1 inch(25.4 mm) | 0.19 kg | 52 mm | 21.5 mm |

| 5 |

|

YELAG 205-100 | 14 KN | 7.8 KN | 1 inch(25.4 mm) | 0.23 kg | 52 mm | 34.9 mm |

| 6 |

|

YEL 205-100-2F | 14 KN | 7.8 KN | 1 inch(25.4 mm) | 0.24 kg | 52 mm | 34.9 mm |

| 7 |

|

YET 206-102 | 19.5 KN | 11.2 KN | 1-1/8 inch(28.575 mm) | 0.34 kg | 62 mm | 23.8 mm |

| 8 |

|

YELAG 206-102 | 19.5 KN | 11.2 KN | 1-1/8 inch(28.575 mm) | 0.4 kg | 62 mm | 36.5 mm |

| 9 |

|

YEL 206-102-2F | 19.5 KN | 11.2 KN | 1-1/8 inch(28.575 mm) | 0.41 kg | 62 mm | 36.5 mm |

| 10 |

|

YET 206-103 | 19.5 KN | 11.2 KN | 1-3/16 inch(30.163 mm) | 0.32 kg | 62 mm | 23.8 mm |

| 11 |

|

YELAG 206-103 | 19.5 KN | 11.2 KN | 1-3/16 inch(30.163 mm) | 0.37 kg | 62 mm | 36.5 mm |

| 12 |

|

YEL 206-103-2F | 19.5 KN | 11.2 KN | 1-3/16 inch(30.163 mm) | 0.38 kg | 62 mm | 36.5 mm |

| 13 |

|

YET 206-104 | 19.5 KN | 11.2 KN | 1-1/4 inch(31.75 mm) | 0.3 kg | 62 mm | 23.8 mm |

| 14 |

|

YET 207-104 | 25.5 KN | 15.3 KN | 1-1/4 inch(31.75 mm) | 0.51 kg | 72 mm | 25.4 mm |

| 15 |

|

YELAG 207-104 | 25.5 KN | 15.3 KN | 1-1/4 inch(31.75 mm) | 0.6 kg | 72 mm | 37.6 mm |

| 16 |

|

YEL 207-104-2F | 25.5 KN | 15.3 KN | 1-1/4 inch(31.75 mm) | 0.61 kg | 72 mm | 37.6 mm |

| 17 |

|

YET 207-105 | 25.5 KN | 15.3 KN | 1-5/16 inch(33.338 mm) | 0.49 kg | 72 mm | 25.4 mm |

| 18 |

|

YET 207-106 | 25.5 KN | 15.3 KN | 1-3/8 inch(34.925 mm) | 0.46 kg | 72 mm | 25.4 mm |

| 19 |

|

YELAG 207-106 | 25.5 KN | 15.3 KN | 1-3/8 inch(34.925 mm) | 0.54 kg | 72 mm | 37.6 mm |

| 20 |

|

YEL 207-106-2F | 25.5 KN | 15.3 KN | 1-3/8 inch(34.925 mm) | 0.55 kg | 72 mm | 37.6 mm |

| 21 |

|

YET 207-107 | 25.5 KN | 15.3 KN | 1-7/16 inch(36.513 mm) | 0.44 kg | 72 mm | 25.4 mm |

| 22 |

|

YELAG 207-107 | 25.5 KN | 15.3 KN | 1-7/16 inch(36.513 mm) | 0.5 kg | 72 mm | 37.6 mm |

| 23 |

|

YEL 207-107-2F | 25.5 KN | 15.3 KN | 1-7/16 inch(36.513 mm) | 0.51 kg | 72 mm | 37.6 mm |

| 24 |

|

YET 208-108 | 30.7 KN | 19 KN | 1-1/2 inch(38.1 mm) | 0.64 kg | 80 mm | 29.7 mm |

| 25 |

|

YELAG 208-108 | 30.7 KN | 19 KN | 1-1/2 inch(38.1 mm) | 0.74 kg | 80 mm | 42.8 mm |

| 26 |

|

YEL 208-108-2F | 30.7 KN | 19 KN | 1-1/2 inch(38.1 mm) | 0.76 kg | 80 mm | 42.8 mm |

| 27 |

|

YET 209-111 | 33.2 KN | 21.6 KN | 1-11/16 inch(42.863 mm) | 0.73 kg | 85 mm | 30.2 mm |

| 28 |

|

YELAG 209-111 | 33.2 KN | 21.6 KN | 1-11/16 inch(42.863 mm) | 0.84 kg | 85 mm | 42.8 mm |

| 29 |

|

YEL 209-111-2F | 33.2 KN | 21.6 KN | 1-11/16 inch(42.863 mm) | 0.86 kg | 85 mm | 42.8 mm |

| 30 |

|

YET 209-112 | 33.2 KN | 21.6 KN | 1-3/4 inch(44.45 mm) | 0.69 kg | 85 mm | 30.2 mm |

| 31 |

|

YELAG 209-112 | 33.2 KN | 21.6 KN | 1-3/4 inch(44.45 mm) | 0.8 kg | 85 mm | 42.8 mm |

| 32 |

|

YEL 209-112-2F | 33.2 KN | 21.6 KN | 1-3/4 inch(44.45 mm) | 0.81 kg | 85 mm | 42.8 mm |

| 33 |

|

YELAG 210-115 | 35.1 KN | 23.2 KN | 1-15/16 inch(49.213 mm) | 0.94 kg | 90 mm | 49.2 mm |

| 34 |

|

YEL 210-115-2F | 35.1 KN | 23.2 KN | 1-15/16 inch(49.213 mm) | 0.95 kg | 90 mm | 49.2 mm |

| 35 |

|

YEL 211-200-2F | 43.6 KN | 29 KN | 2 inch(50.8 mm) | 1.5 kg | 100 mm | 55.6 mm |

| 36 |

|

YEL 211-203-2F | 43.6 KN | 29 KN | 2-3/16 inch(55.563 mm) | 1.25 kg | 100 mm | 55.6 mm |

| 37 |

|

YET 212-207 | 52.7 KN | 36 KN | 2-7/16 inch(61.913 mm) | 1.25 kg | 110 mm | 36.7 mm |

| 38 |

|

YEL 212-207-2F | 52.7 KN | 36 KN | 2-7/16 inch(61.913 mm) | 1.6 kg | 110 mm | 61.9 mm |

| 39 |

|

HC201-8 | 12800 N | 6600 N | 1/2 inch | 0.29 kg | 1.8504 inch | 1.3465 inch |

| 40 |

|

HC202-9 | 12800 N | 6600 N | 9/16 inch | 0.26 kg | 1.8504 inch | 1.3465 inch |

| 41 |

|

HC202-10 | 12800 N | 6600 N | 5/8 inch | 0.26 kg | 1.8504 inch | 1.3465 inch |

| 42 |

|

HC203-11 | 12800 N | 6600 N | 11/16 inch | 0.25 kg | 1.8504 inch | 1.3465 inch |

| 43 |

|

HC204-12 | 12800 N | 6600 N | 3/4 inch | 0.21 kg | 1.8504 inch | 1.3465 inch |

| 44 |

|

HC205-13 | 14000 N | 7850 N | 13/16 inch | 0.30 kg | 2.0472 inch | 1.374 inch |

| 45 |

|

HC205-14 | 14000 N | 7850 N | 7/8 inch | 0.29 kg | 2.0472 inch | 1.374 inch |

| 46 |

|

HC205-15 | 14000 N | 7850 N | 15/16 inch | 0.27 kg | 2.0472 inch | 1.374 inch |

| 47 |

|

HC205-16 | 14000 N | 7850 N | 1 inch | 0.25 kg | 2.0472 inch | 1.374 inch |

| 48 |

|

HC206-17 | 19450 N | 11250 N | 1-1/16 inch | 0.42 kg | 2.4409 inch | 1.437 inch |

| 49 |

|

HC206-18 | 19450 N | 11250 N | 1-1/8 inch | 0.39 kg | 2.4409 inch | 1.437 inch |

| 50 |

|

HC206-19 | 19450 N | 11250 N | 1-3/16 inch | 0.37 kg | 2.4409 inch | 1.437 inch |

| 51 |

|

HC206-20 | 19450 N | 11250 N | 1-1/4 inch | 0.34 kg | 2.4409 inch | 1.437 inch |

| 52 |

|

HC207-20 | 25700 N | 15200 N | 1-1/4 inch | 0.65 kg | 2.8346 inch | 1.4803 inch |

| 53 |

|

HC207-21 | 25700 N | 15200 N | 1-5/16 inch | 0.61 kg | 2.8346 inch | 1.4803 inch |

| 54 |

|

HC207-22 | 25700 N | 15200 N | 1-3/8 inch | 0.58 kg | 2.8346 inch | 1.4803 inch |

| 55 |

|

HC207-23 | 25700 N | 15200 N | 1-7/16 inch | 0.56 kg | 2.8346 inch | 1.4803 inch |

| 56 |

|

HC208-24 | 29500 N | 18100 N | 1-1/2 inch | 0.78 kg | 3.1496 inch | 1.685 inch |

| 57 |

|

HC208-25 | 29500 N | 18100 N | 1-9/16 inch | 0.74 kg | 3.1496 inch | 1.685 inch |

| 58 |

|

HC209-26 | 32700 N | 20900 N | 1-5/8 inch | 0.89 kg | 3.3465 inch | 1.685 inch |

| 59 |

|

HC209-27 | 32700 N | 20900 N | 1-11/16 inch | 0.84 kg | 3.3465 inch | 1.685 inch |

| 60 |

|

HC209-28 | 32700 N | 20900 N | 1-3/4 inch | 0.80 kg | 3.3465 inch | 1.685 inch |

| 61 |

|

HC210-29 | 35000 N | 23200 N | 1-13/16 inch | 1.09 kg | 3.5433 inch | 2 inch |

| 62 |

|

HC210-30 | 35000 N | 23200 N | 1-7/8 inch | 1.03 kg | 3.5433 inch | 2 inch |

| 63 |

|

HC210-31 | 35000 N | 23200 N | 1-15/16 inch | 0.97 kg | 3.5433 inch | 2 inch |

| 64 |

|

HC210-32 | 35000 N | 23200 N | 2 inch | 0.91 kg | 3.5433 inch | 2 inch |

| 65 |

|

HC211-32 | 43300 N | 29200 N | 2 inch | 1.46 kg | 3.937 inch | 2.185 inch |

| 66 |

|

HC211-33 | 43300 N | 29200 N | 2-1/16 inch | 1.38 kg | 3.937 inch | 2.185 inch |

| 67 |

|

HC211-34 | 43300 N | 29200 N | 2-1/8 inch | 1.31 kg | 3.937 inch | 2.185 inch |

| 68 |

|

HC211-35 | 43300 N | 29200 N | 2-3/16 inch | 1.23 kg | 3.937 inch | 2.185 inch |

| 69 |

|

HC212-36 | 47700 N | 32800 N | 2-1/4 inch | 1.73 kg | 4.3307 inch . | 2.437 inch |

| 70 |

|

HC212-37 | 47700 N | 32800 N | 2-5/16 inch | 1.78 kg | 4.3307 inch | 2.437 inch |

| 71 |

|

HC212-38 | 47700 N | 32800 N | 2-3/8 inch | 1.71 kg | 4.3307 inch | 2.437 inch |

| 72 |

|

HC212-39 | 47700 N | 32800 N | 2-7/16 inch | 1.77 kg | 4.3307 inch | 2.437 inch |

| 73 |

|

HC213-40 | 57200 N | 40000 N | 2-1/2 inch | 1.80 kg | 4.7244 inch | 2.7008 inch |

| 74 |

|

HC213-41 | 57200 N | 40000 N | 2-9/16 inch | 2.23 kg | 4.7244 inch | 2.7008 inch |

| 75 |

|

HC214-42 | 62100 N | 44800 N | 2-5/8 inch | 2.29 kg | 4.9213 inch | 2.7008 inch |

| 76 |

|

HC214-43 | 62100 N | 44800 N | 2-11/16 inch | 2.48 kg | 4.9213 inch | 2.7008 inch |

| 77 |

|

HC214-44 | 62100 N | 44800 N | 2-3/4 inch | 2.36 kg | 4.9213 inch | 2.7008 inch |

| 78 |

|

HC215-45 | 66200 N | 49300 N | 2-13/16 inch | 2.94 kg | 5.1181 inch | 2.9528 inch |

| 79 |

|

HC215-46 | 66200 N | 49300 N | 2-7/8 inch | 2.81 kg | 5.1181 inch | 2.9528 inch |

| 80 |

|

HC215-47 | 66200 N | 49300 N | 2-15/16 inch | 2.54 kg | 5.1181 inch | 2.9528 inch |

| 81 |

|

HC215-48 | 66200 N | 49300 N | 3 inch | 2.5 kg | 5.1181 inch | 2.9528 inch |

| 82 |

|

HC305-13 | 22400 N | 11500 N | 13/16 inch | 0.49 kg | 2.4409 inch | 1.374 inch |

| 83 |

|

HC305-14 | 22400 N | 11500 N | 7/8 inch | 0.48 kg | 2.4409 inch | 1.374 inch |

| 84 |

|

HC305-15 | 22400 N | 11500 N | 15/16 inch | 0.46 kg | 2.4409 inch | 1.374 inch |

| 85 |

|

HC305-16 | 22400 N | 11500 N | 1 inch | 0.44 kg | 2.4409 inch | 1.374 inch |

| 86 |

|

HC306-17 | 26500 N | 14900 N | 1-1/16 inch | 0.71 kg | 2.8346 inch | 1.437 inch |

| 87 |

|

HC306-18 | 26500 N | 14900 N | 1-1/8 inch | 0.68 kg | 2.8346 inch | 1.437 inch |

| 88 |

|

HC306-19 | 26500 N | 14900 N | 1-3/16 inch | 0.66 kg | 2.8346 inch | 1.437 inch |

| 89 |

|

HC307-20 | 33300 N | 19100 N | 1-1/4 inch | 0.87 kg | 3.1496 inch | 1.500 inch |

| 90 |

|

HC307-21 | 33300 N | 19100 N | 1-5/16 inch | 0.83 kg | 3.1496 inch | 1.500 inch |

| 91 |

|

HC307-22 | 33300 N | 19100 N | 1-3/8 inch | 0.80 kg | 3.1496 inch | 1.500 inch |

| 92 |

|

HC307-23 | 33300 N | 19100 N | 1-7/16 inch | 0.77 kg | 3.1496 inch | 1.500 inch |

| 93 |

|

HC308-24 | 40600 N | 23700 N | 1-1/2 inch | 1.17 kg | 3.5433 inch | 1.626 inch |

| 94 |

|

HC308-25 | 40600 N | 23700 N | 1-9/16 inch | 1.13 kg | 3.5433 inch | 1.626 inch |

| 95 |

|

HC309-26 | 48600 N | 28900 N | 1-5/8 inch | 1.54 kg | 3.937 inch | 1.689 inch |

| 96 |

|

HC309-27 | 48600 N | 28900 N | 1-11/16 inch | 1.49 kg | 3.937 inch | 1.689 inch |

| 97 |

|

HC309-28 | 48600 N | 28900 N | 1-3/4 inch | 1.44 kg | 3.937 inch | 1.689 inch |

| 98 |

|

HC310-29 | 62000 N | 38000 N | 1-13/16 inch | 2.00 kg | 4.3307 inch | 1.937 inch |

| 99 |

|

HC310-30 | 62000 N | 38000 N | 1-7/8 inch | 1.95 kg | 4.3307 inch | 1.937 inch |

| 100 |

|

HC310-31 | 62000 N | 38000 N | 1-15/16 inch | 1.88 kg | 4.3307 inch | 1.937 inch |

Features and advantages of QIBR insert bearings with an eccentric locking collar (inch shafts)

QIBR insert bearings with an eccentric locking collar (inch shafts) solve several key problems in various fields, particularly in the following aspects:

1. Self-aligning ability

The insert bearing has a self-aligning function. It consists of an inner ring, outer ring, rolling elements, and cage. The spherical shape of the outer ring allows the bearing to accommodate certain axial and radial errors. Even when the shaft is not perfectly aligned during installation, the bearing can still function properly, reducing damage caused by installation errors.

2. High load capacity

Insert bearings can typically bear large radial loads and certain axial loads, making them suitable for heavy-duty machinery.

3. Durability and reliability

Due to their structural characteristics, insert bearings are wear-resistant and impact-resistant, showing strong reliability in unfavorable working conditions (such as dusty or humid environments).

4. Correcting shaft misalignment

When the shaft is eccentric or not fully aligned, the bearing with an eccentric locking ring can partially correct these issues, ensuring smooth operation of the equipment.

Performance improvements and solutions for QIBR insert bearings with an eccentric locking collar (inch shafts)

1. Material improvement

High-performance materials: Using high-strength, high-wear-resistant materials such as ceramics, advanced alloy steels, and stainless steel can significantly improve the durability and load-bearing capacity of insert bearings.

Surface treatment: Surface treatments like carburizing, nitriding, chrome plating, and hardening can enhance the bearing's wear resistance, corrosion resistance, and fatigue strength.

2. Precision improvement

High-precision manufacturing: Advanced processing technologies such as CNC machining and precision grinding improve the bearing’s processing accuracy, leading to smoother operation and lower noise.

High-precision fit: Improving the fit accuracy between the inner and outer rings of the insert bearing ensures the flexibility and stability of the bearing's rotation, reducing friction and wear.

Sealing performance improvement

3. Efficient sealing

More efficient sealing structures, such as double-lip seals or skeleton seals, can effectively prevent dust and dirt from entering the bearing, reducing contamination and extending its service life.

Sealing materials: Using heat-resistant, wear-resistant, and corrosion-resistant sealing materials ensures bearing reliability in harsh environments.

4. Load capacity enhancement

Optimized design: By optimizing the geometry of insert bearings, such as increasing the contact area and adopting a stronger outer ring structure, their load-bearing capacity is improved, enhancing the bearing's ability to withstand loads.

Main application areas of QIBR insert bearings with an eccentric locking collar (inch shafts)

1. Agricultural machinery

Insert bearings are commonly used in agricultural machinery such as tractors, seeders, harvesters, etc. These machines are often subject to high loads and may experience axial or radial misalignment, making the self-aligning feature of insert bearings very suitable for this environment.

2. Construction machinery

Insert bearings are widely used in construction machinery such as cranes, excavators, and concrete mixers. Construction machinery often operates in high-load and high-impact environments, and the high load capacity and self-aligning features of insert bearings help equipment run more smoothly.

3. Automotive industry

In automotive suspension systems, wheel axles, and steering components, insert bearings are widely used. Insert bearings can withstand reverse impact forces and lateral forces from the tires and suspension systems, making them ideal for automotive applications.

4. Conveying equipment

Insert bearings are widely used in various conveying equipment such as conveyor belts, belt conveyors, and roller conveyors. Insert bearings can adapt to load variations in conveying equipment and axial misalignment caused by long-term operation of the equipment.