Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN/VDEh,DIN/VDEh

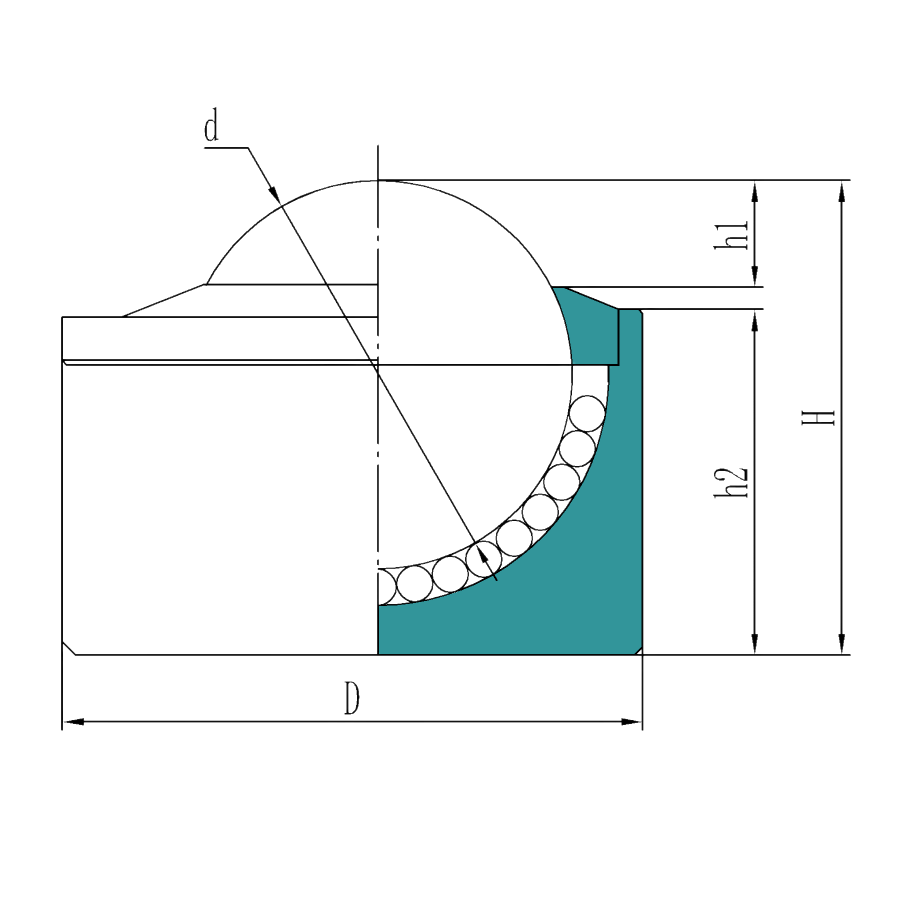

Main ball diameter (d)

8mm-60mm

Outer diameter (D)

12mm-100mm

Weight

0.006kg-3.600kg

Structures

main ball, shell

Brand

QIBR/OEM/Neutral

Material

Carbon steel, Bearing steel, GCr15, 440 Stainless steel, 304 Stainless steel, Plastic

ODM/OEM

Support

Applications

electronics, hardware, machinery, chemical industry,transmission systems, feeding systems, processing systems, processing machinery and packaging machinery auxiliary equipment.

| NO. | Product | Product Number | Main ball diameter (d) | Material | MAX loading capacity | Outer diameter (D) | Loading capacity | Weight |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

KSM-8 | 8 mm | BS/CS | 8 kg | 12 mm | 5 kg | 0.006 kg |

| 2 |

|

KSM-8 | 8 mm | SS/SS | 5 kg | 12 mm | 3 kg | 0.006 kg |

| 3 |

|

KSM-10 | 10 mm | BS/CS | 20 kg | 16 mm | 15 kg | 0.028 kg |

| 4 |

|

KSM-10 | 10 mm | SS/SS | 15 kg | 16 mm | 10 kg | 0.028 kg |

| 5 |

|

KSM-12 | 12 mm | BS/CS | 35 kg | 22 mm | 30 kg | 0.035 kg |

| 6 |

|

KSM-12 | 12 mm | SS/SS | 25 kg | 22 mm | 20 kg | 0.035 kg |

| 7 |

|

KSM-15 | 15.875 mm | BS/CS | 70 kg | 24 mm | 60 kg | 0.050 kg |

| 8 |

|

KSM-15 | 15.875 mm | SS/SS | 40 kg | 24 mm | 30 kg | 0.050 kg |

| 9 |

|

KSM-22 | 22.2 mm | BS/CS | 200 kg | 36 mm | 180 kg | 0.190 kg |

| 10 |

|

KSM-22 | 22.2 mm | SS/SS | 120 kg | 36 mm | 100 kg | 0.190 kg |

| 11 |

|

KSM-25 | 25.4 mm | BS/CS | 250 kg | 37 mm | 200 kg | 0.210 kg |

| 12 |

|

KSM-25 | 25.4 mm | SS/SS | 150 kg | 37 mm | 130 kg | 0.210 kg |

| 13 |

|

KSM-30 | 30.16 mm | BS/CS | 350 kg | 44 mm | 300 kg | 0.340 kg |

| 14 |

|

KSM-30 | 30.16 mm | SS/SS | 240 kg | 44 mm | 190 kg | 0.340 kg |

| 15 |

|

KSM-38 | 38.1 mm | BS/CS | 450 kg | 54 mm | 400 kg | 0.650 kg |

| 16 |

|

KSM-38 | 38.1 mm | SS/SS | 300 kg | 54 mm | 280 kg | 0.650 kg |

| 17 |

|

KSM-45 | 45 mm | BS/CS | 550 kg | 62 mm | 500 kg | 0.960 kg |

| 18 |

|

KSM-45 | 45 mm | SS/SS | 360 kg | 62 mm | 320 kg | 0.960 kg |

| 19 |

|

KSM-60 | 60 mm | BS/CS | 1600 kg | 100 mm | 1400 kg | 3.600 kg |

| 20 |

|

KSM-60 | 60 mm | SS/SS | 800 kg | 100 mm | 550 kg | 3.600 kg |

Features and advantages of QIBR universal ball bearing KSM series

1. Multi-directional load-bearing capacity

The biggest feature of QIBR universal ball bearing KSM series is that it can withstand loads from different directions, especially radial and axial loads. This bearing can provide stable support at multiple angles and is suitable for equipment that needs to withstand complex mechanical effects.

2. High flexibility and freedom

QIBR universal ball bearing KSM series can rotate in multiple directions and has high flexibility. It allows a certain angle change between the inner and outer rings to adapt to complex movement requirements. Due to this degree of freedom, it is particularly suitable for applications that require angle adjustment.

3. Low friction

QIBR universal ball bearing KSM series has lower friction resistance than traditional sliding bearings, which can effectively reduce energy loss and heat accumulation. Therefore, universal ball bearings can maintain high operating efficiency.

4. High load-bearing capacity

QIBR universal ball bearing KSM series is usually designed with multiple rolling elements that can roll between the inner and outer rings of the bearing to disperse the load pressure. In this way, it can still maintain smooth operation under higher load conditions and has a strong load-bearing capacity.

The performance improvement and solutions of QIBR universal ball bearing KSM series

1. Material Improvement

High-strength materials: Use higher-strength steel or alloy materials to improve the bearing's load-bearing capacity and wear resistance. Especially under high load and high temperature environments, high-quality materials can significantly increase the bearing's service life.

2. Optimization of lubrication technology

The use of high-performance lubricants or greases can reduce friction and reduce wear. For universal ball bearings operating under high temperature, high speed and harsh conditions, the selection of high-temperature lubricants and highly adaptable synthetic greases can help improve operating stability.

3. Design Optimization

The optimized design of rolling elements: Increase the number of rolling elements, or improve the load-bearing capacity and reduce the friction coefficient by improving the size and shape of the rolling elements, thereby improving the bearing's performance.

4. Improved surface finish

Optimize the surface finish of the inner and outer rings and rolling elements of the bearing, reduce the friction coefficient, and reduce energy loss during operation, thereby improving operating efficiency.

Main application areas of QIBR universal ball bearing KSM series

1. Steering system

In the steering system of some models, universal ball bearings are used to connect the steering wheel and the wheel to allow the angle of the wheel to change during the steering process.

2. Agricultural machinery

Universal ball bearings in agricultural machinery are mainly used to connect tractors and agricultural machinery, especially when the power output of the tractor is connected to other agricultural machinery, it can withstand large angle and torque changes to ensure the stability of power transmission.

3. Industrial machinery

In some high-angle conveyor belt systems, universal ball bearings can be used to connect different parts to meet the movement requirements in the production line.

4. Automation equipment

Many automated machines and devices require universal ball bearings to ensure stable power transmission between parts.