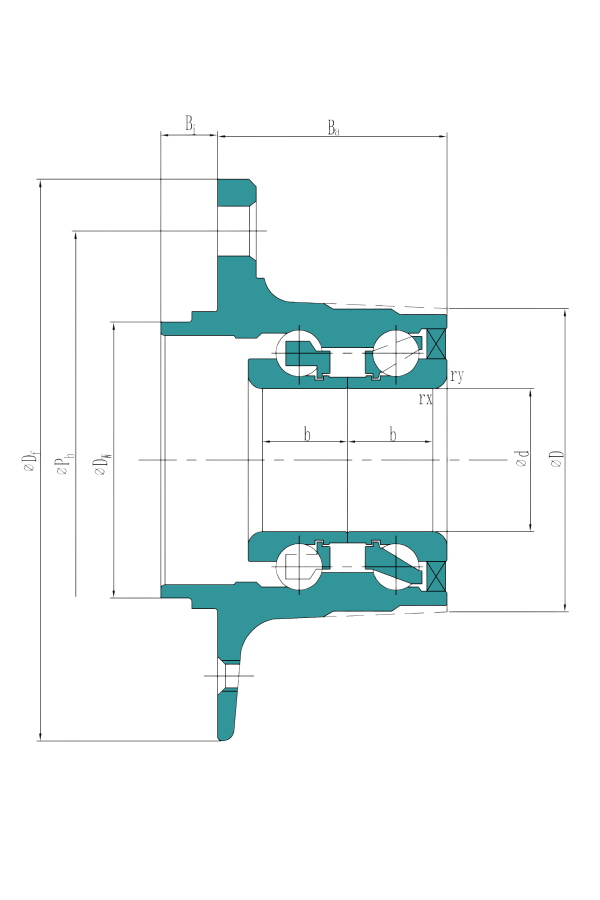

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh,DIN / VDEh

Inner diameter (d)

28mm-54mm

Outer diameter (D)

62.5mm-96mm

Mass

1.02kg-2.18kg

Material

GCr15, 52100, 100Cr6, SUJ2

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

Automobile wheels

| NO. | Product | Product Number | Inner diameter (d) | Mass | Outer diameter (D) | Width of outer ring (B) |

|---|---|---|---|---|---|---|

| 1 |

|

28BWK16A-Y-2+X3 F | 28 mm | 1.5 kg | 66.4 mm | 67.9 mm |

| 2 |

|

28BWK16A-Y-2+X4 F | 28 mm | 1.5 kg | 66.4 mm | 67.9 mm |

| 3 |

|

ZA-28BWK19B-Y-2CP-01 | 28 mm | 1.5 kg | 62.5 mm | 66 mm |

| 4 |

|

ZA-28BWK20A-Y-2CP-01 | 28 mm | 1.683 kg | 62.5 mm | 66 mm |

| 5 |

|

ZA-30BWK21 D-Y-A-01 E | 30 mm | 1.09 kg | 67.4 mm | 67.8 mm |

| 6 |

|

ZA-32BWK08A-Y-2-01 H | 32 mm | 2.18 kg | 72 mm | 69.5 mm |

| 7 |

|

ZA-32BWK04B-Y-2-01 E | 32 mm | 1.59 kg | 78 mm | 60.3 mm |

| 8 |

|

32BWK09-Y-2CP17-01 E | 32 mm | 1.9 kg | 78 mm | 69.3 mm |

| 9 |

|

32BWK10-Y-2CP17-01 H | 32 mm | 2.06 kg | 78 mm | 75.3 mm |

| 10 |

|

ZA-28BWK12-Y-CP4*01 | 28 mm | 1.05 kg | 65 mm | 51.8 mm |

| 11 |

|

ZA-30BWK17A-Y-2CP-01 | 30 mm | 1.2 kg | 66 mm | 51.8 mm |

| 12 |

|

ZA-30BWK10-G-3-Y--01 | 30 mm | 1.02 kg | 66 mm | 51.8 mm |

| 13 |

|

ZA-35BWK04-Y-2CA15** | 35 mm | 1.05 kg | 69 mm | 53 mm |

| 14 |

|

ZA-38BWK01J-Y-2CA-01 | 38 mm | 1.35 kg | 87.4 mm | 58 mm |

| 15 |

|

ZA-43BWK03D-Y-2CA-01 | 43 mm | 1.22 kg | 83 mm | 42.5 mm |

| 16 |

|

ZA-/H0/50KWH01M-Y-01 | 50 mm | 1.5 kg | 86 mm | 55 mm |

| 17 |

|

ZA-/H0/50KWH02A-Y-01 | 50 mm | 1.5 kg | 84 mm | 55 mm |

| 18 |

|

ZA-/H0/52KWH01-Y--01 | 52 mm | 1.8 kg | 91 mm | 53 mm |

| 19 |

|

ZA-54KWH01M-Y-2CA-01 | 54 mm | 2 kg | 96 mm | 50.9 mm |

| 20 |

|

ZA-54KWH02D-Y-2CA-01 | 54 mm | 2 kg | 90 mm | 59 mm |

Characteristics and advantages of second-generation hub bearings:

Integrated design: Second-generation hub bearings typically integrate multiple functional modules. For instance, the outer ring includes a flange designed to secure the bearing, allowing it to be easily mounted onto the wheel axle and fastened with nuts. This design greatly simplifies vehicle maintenance.

Higher load capacity: Compared to first-generation hub bearings, the optimized design of second-generation bearings allows them to handle greater loads, making them especially popular in high-performance vehicles.

Improved sealing technology: These bearings are equipped with highly efficient sealing systems to prevent dust, moisture, and other contaminants from entering the bearing cavity, enhancing durability and stability.

Enhanced durability and longevity: Using more wear-resistant materials and advanced lubrication technologies increases the lifespan of second-generation bearings, reducing the need for frequent replacements and maintenance.

Lightweight design: Modern materials and precision engineering make second-generation hub bearings lighter and more efficient, cutting vehicle weight and boosting fuel economy and driving performance.

Applications:

Second-generation hub bearings are widely used in modern automobiles, trucks, motorcycles, and other transportation systems. They are exceptionally prominent in high-performance, off-road, and electric cars.

Development trends:

As the automotive industry focuses more on environmental protection, energy efficiency, and high performance, hub-bearing technology is evolving to meet the ever-changing needs of modern vehicles. Overall, the second-generation hub bearing represents a significant advancement in automotive bearing technology, enhancing reliability and performance and meeting the complex demands of modern vehicles.