Image may differ from product. See technical specification for details.

Search for the bearing model you need

Material

52100

Applications

Bearing Manufacturing, Automotive and Medical Devices

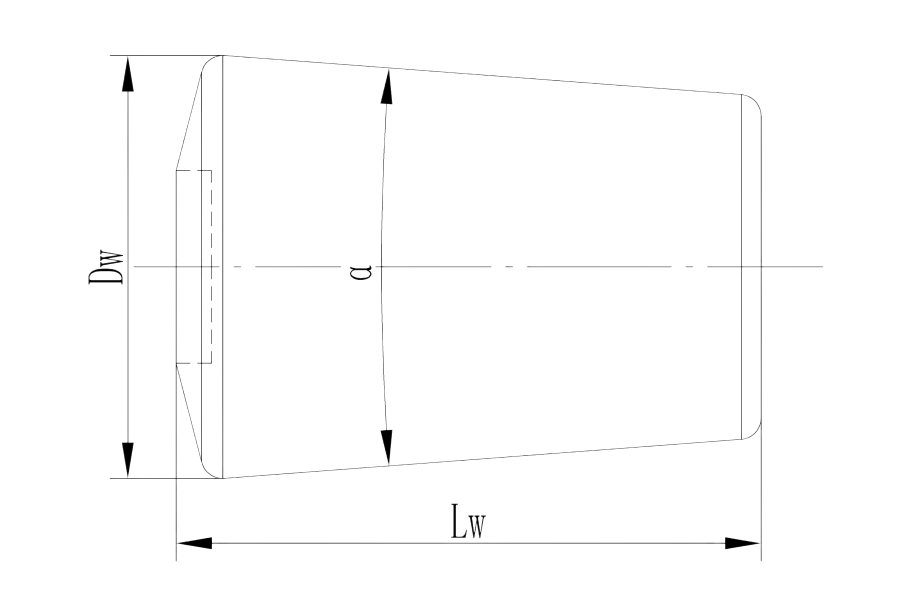

Diameter (Dw)

5.612mm-49.2mm

Length (Lw)

8.45mm-90.59mm

Mass

0.0014kg-1.18kg

| NO. | Product | Product Number | Diameter (Dw) | Length (Lw) | Mass |

|---|---|---|---|---|---|

| 1 |

|

Tapered Roller 5.612x8.45x4° | 5.612 mm | 8.45 mm | 0.00146 kg |

| 2 |

|

Tapered Roller 6.631x10.08x4° | 6.631 mm | 10.08 mm | 0.00242 kg |

| 3 |

|

Tapered Roller 6.799x10.92x4° | 6.799 mm | 10.92 mm | 0.00274 kg |

| 4 |

|

Tapered Roller 8.111x11.64x4° | 8.111 mm | 11.64 mm | 0.00420 kg |

| 5 |

|

Tapered Roller 9.437x12.47x4° | 9.437 mm | 12.47 mm | 0.00615 kg |

| 6 |

|

Tapered Roller 10.5x13.09x4° | 10.5 mm | 13.09 mm | 0.00803 kg |

| 7 |

|

Tapered Roller 10.833x13.9x4° | 10.833 mm | 13.9 mm | 0.00906 kg |

| 8 |

|

Tapered Roller 12.439x14.99x4° | 12.439 mm | 14.99 mm | 0.01300 kg |

| 9 |

|

Tapered Roller 13.493x15.4x4° | 13.493 mm | 15.4 mm | 0.01570 kg |

| 10 |

|

Tapered Roller 14.903x16.63x4° | 14.903 mm | 16.63 mm | 0.02080 kg |

| 11 |

|

Tapered Roller 15.043x17.69x4° | 15.043 mm | 17.69 mm | 0.02240 kg |

| 12 |

|

Tapered Roller 15.238x18.54x4° | 15.238 mm | 18.54 mm | 0.02400 kg |

| 13 |

|

Tapered Roller 16.858x19.25x4° | 16.858 mm | 19.25 mm | 0.03060 kg |

| 14 |

|

Tapered Roller 17.939x19.46x4° | 17.939 mm | 19.46 mm | 0.03530 kg |

| 15 |

|

Tapered Roller 19.127x21.97x4° | 19.127 mm | 21.97 mm | 0.04510 kg |

| 16 |

|

Tapered Roller 20.328x22.78x4° | 20.328 mm | 22.78 mm | 0.05290 kg |

| 17 |

|

Tapered Roller 21.479x25.19x4° | 21.479 mm | 25.19 mm | 0.06510 kg |

| 18 |

|

Tapered Roller 22.62x25.7x4° | 22.62 mm | 25.7 mm | 0.07380 kg |

| 19 |

|

Tapered Roller 23.929x28.33x4° | 23.929 mm | 28.33 mm | 0.09100 kg |

| 20 |

|

Tapered Roller 24.935x29.625x4° | 24.935 mm | 29.625 mm | 0.10300 kg |

| 21 |

|

Tapered Roller 26.82x29.18x4° | 26.82 mm | 29.18 mm | 0.11800kg |

| 22 |

|

Tapered Roller 30.96x32.151x4° | 30.96 mm | 32.151 mm | 0.17500 kg |

| 23 |

|

Tapered Roller 33.28x33.679x4° | 33.28 mm | 33.679 mm | 0.21200 kg |

| 24 |

|

Tapered Roller 6.973x8.92x4° | 6.973 mm | 8.92 mm | 0.00241kg |

| 25 |

|

Tapered Roller 7.811x9.93x4° | 7.811 mm | 9.93 mm | 0.00337 kg |

| 26 |

|

Tapered Roller 8.216x10.75x4° | 8.216 mm | 10.75 mm | 0.00402 kg |

| 27 |

|

Tapered Roller 9.982x12.28x4° | 9.982 mm | 12.28 mm | 0.00682 kg |

| 28 |

|

Tapered Roller 10.987x13.42x4° | 10.987 mm | 13.42 mm | 0.00903 kg |

| 29 |

|

Tapered Roller 12.383x15.45x4° | 12.383 mm | 15.45 mm | 0.01320 kg |

| 30 |

|

Tapered Roller 12.662x16.81x4° | 12.662 mm | 16.81 mm | 0.01490 kg |

| 31 |

|

Tapered Roller 14.17x18.12x4° | 14.17 mm | 18.12 mm | 0.02020 kg |

| 32 |

|

Tapered Roller 15.65x19.77x4° | 15.65 mm | 19.77 mm | 0.02690 kg |

| 33 |

|

Tapered Roller 17.102x21.5x4° | 17.102 mm | 21.5 mm | 0.03500 kg |

| 34 |

|

Tapered Roller 18.533x21.76x4° | 18.533 mm | 21.76 mm | 0.04180 kg |

| 35 |

|

Tapered Roller 20.068x24.08x4° | 20.068 mm | 24.08 mm | 0.05420 kg |

| 36 |

|

Tapered Roller 22.958x27.5x4° | 22.958 mm | 27.5 mm | 0.08100 kg |

| 37 |

|

Tapered Roller 24.501x27.636x4° | 24.501 mm | 27.636 mm | 0.09340 kg |

| 38 |

|

Tapered Roller 25.722x29.35x4° | 25.722 mm | 29.35 mm | 0.10900 kg |

| 39 |

|

Tapered Roller 27.182x31.93x4° | 27.182 mm | 31.93 mm | 0.13200 kg |

| 40 |

|

Tapered Roller 30.47x33.272x4° | 30.47 mm | 33.272 mm | 0.16400 kg |

| 41 |

|

Tapered Roller 33.869x34.73x4° | 33.869 mm | 34.73 mm | 0.22600 kg |

| 42 |

|

Tapered Roller 39.4x42.427x4° | 39.4 mm | 42.427 mm | 0.37200kg |

| 43 |

|

Tapered Roller 6.74x11.95x3°10' | 6.74 mm | 11.95 mm | 0.00300 kg |

| 44 |

|

Tapered Roller 21.9x22.98x10° | 21.9 mm | 22.98 mm | 0.05490 kg |

| 45 |

|

Tapered Roller 17x31.33x3°30' | 17 mm | 31.33 mm | 0.04930 kg |

| 46 |

|

Tapered Roller 15.092x33.6x2°30' | 15.092 mm | 33.6 mm | 0.04230 kg |

| 47 |

|

Tapered Roller 15.687x32.09x2°30' | 15.687 mm | 32.09 mm | 0.04400 kg |

| 48 |

|

Tapered Roller 17x33.09x2°28' | 17 mm | 33.09 mm | 0.05370 kg |

| 49 |

|

Tapered Roller 8.88x12.07x8°40' | 8.88 mm | 12.07 mm | 0.00466 kg |

| 50 |

|

Tapered Roller 11.649x15.21x8°40' | 11.649 mm | 15.21 mm | 0.01020 kg |

| 51 |

|

Tapered Roller 13.158x16.75x8°40' | 13.158 mm | 16.75 mm | 0.01440 kg |

| 52 |

|

Tapered Roller 14.575x17.82x8°40' | 14.575 mm | 17.82 mm | 0.01890 kg |

| 53 |

|

Tapered Roller 15.931x18.3x8°40' | 15.931 mm | 18.3 mm | 0.02350 kg |

| 54 |

|

Tapered Roller 17.291 x20.63x8°40' | 17.291 mm | 20.63 mm | 0.03100 kg |

| 55 |

|

Tapered Roller 18.801x21.76x8°40' | 18.801 mm | 21.76 mm | 0.03880 kg |

| 56 |

|

Tapered Roller 20.36x22.89x8°40' | 20.36 mm | 22.89 mm | 0.04810 kg |

| 57 |

|

Tapered Roller 21.671x24.41x8°40' | 21.671 mm | 24.41 mm | 0.05810 kg |

| 58 |

|

Tapered Roller 23.182x25.44x8°40' | 23.182 mm | 25.44 mm | 0.06960 kg |

| 59 |

|

Tapered Roller 25.981x27.88x8°40' | 25.981 mm | 27.88 mm | 0.09640 kg |

| 60 |

|

Tapered Roller 18.6x25.32x8° | 18.6 mm | 25.32 mm | 0.04360 kg |

| 61 |

|

Tapered Roller 21x26.37x8° | 21 mm | 26.37 mm | 0.05880 kg |

| 62 |

|

Tapered Roller 5.311x10.84x3°50' | 5.311 mm | 10.84 mm | 0.00160 kg |

| 63 |

|

Tapered Roller 6.73x12.31x3°50' | 6.73 mm | 12.31 mm | 0.00300 kg |

| 64 |

|

Tapered Roller 6.846x13.7x3° | 6.846 mm | 13.7 mm | 0.00353 kg |

| 65 |

|

Tapered Roller 8.575x16.94x3° | 8.575 mm | 16.94 mm | 0.00685 kg |

| 66 |

|

Tapered Roller 9.328x16.68x3°16' | 9.328 mm | 16.68 mm | 0.00799 kg |

| 67 |

|

Tapered Roller 8.575x16.06x3° | 8.575 mm | 16.06 mm | 0.00650 kg |

| 68 |

|

Tapered Roller 9.775x17.28x3° | 9.775 mm | 17.28 mm | 0.00920 kg |

| 69 |

|

Tapered Roller 11.5x20.58x3° | 11.5 mm | 20.58 mm | 0.01510 kg |

| 70 |

|

Tapered Roller 11.5x19.58x3° | 11.5 mm | 19.58 mm | 0.01440 kg |

| 71 |

|

Tapered Roller 12.82x21.58x3° | 12.82 mm | 21.58 mm | 0.01980 kg |

| 72 |

|

Tapered Roller 14.05x24.09x3° | 14.05 mm | 24.09 mm | 0.02650 kg |

| 73 |

|

Tapered Roller 15.38x27.05x3° | 15.38 mm | 27.05 mm | 0.03560 kg |

| 74 |

|

Tapered Roller 17.94x31.12x3° | 17.94 mm | 31.12 mm | 0.05580 kg |

| 75 |

|

Tapered Roller 22.8x38.8x3° | 22.8 mm | 38.8 mm | 0.11300 kg |

| 76 |

|

Tapered Roller 25.68x47.007x3° | 25.68 mm | 47.007 mm | 0.17200 kg |

| 77 |

|

Tapered Roller 28x50.131x3° | 28 mm | 50.131 mm | 0.21900 kg |

| 78 |

|

Tapered Roller 26x52.575x2° | 26 mm | 52.575 mm | 0.20200 kg |

| 79 |

|

Tapered Roller 7.25x13.54x4° | 7.25 mm | 13.54 mm | 0.00380 kg |

| 80 |

|

Tapered Roller 8.195x14.48x4° | 8.195 mm | 14.48 mm | 0.00520 kg |

| 81 |

|

Tapered Roller 9.542x17.34x4° | 9.542 mm | 17.34 mm | 0.00846 kg |

| 82 |

|

Tapered Roller 10.631x16.49x4° | 10.631 mm | 16.49 mm | 0.01020 kg |

| 83 |

|

Tapered Roller 10.91x16.94x4° | 10.91 mm | 16.94 mm | 0.01100 kg |

| 84 |

|

Tapered Roller 12.516x18.45x4° | 12.516 mm | 18.45 mm | 0.01580 kg |

| 85 |

|

Tapered Roller 13.682x21.21x4° | 13.682 mm | 21.21 mm | 0.02170 kg |

| 86 |

|

Tapered Roller 15.078x23.13x4° | 15.078 mm | 23.13 mm | 0.02870 kg |

| 87 |

|

Tapered Roller 15.218x23.81x4° | 15.218 mm | 23.81 mm | 0.03010 kg |

| 88 |

|

Tapered Roller 15.427x23.86x4° | 15.427 mm | 23.86 mm | 0.03100 kg |

| 89 |

|

Tapered Roller 17.068x23.85x4° | 17.068 mm | 23.85 mm | 0.03830 kg |

| 90 |

|

Tapered Roller 18.233x27.56x4° | 18.233 mm | 27.56 mm | 0.05010 kg |

| 91 |

|

Tapered Roller 19.477x31.4x4° | 19.477 mm | 31.4 mm | 0.05460 kg |

| 92 |

|

Tapered Roller 20.628x33.48x4° | 20.628 mm | 33.48 mm | 0.07740 kg |

| 93 |

|

Tapered Roller 21.85x35.99x4° | 21.85 mm | 35.99 mm | 0.09320 kg |

| 94 |

|

Tapered Roller 23x38.52x4° | 23 mm | 38.52 mm | 0.11000 kg |

| 95 |

|

Tapered Roller 24.329x42.01x4° | 24.329 mm | 42.01 mm | 0.13400 kg |

| 96 |

|

Tapered Roller 25.307x45.72x4° | 25.307 mm | 45.72 mm | 0.15700 kg |

| 97 |

|

Tapered Roller 27.165x49.191x4° | 27.165 mm | 49.191 mm | 0.19500 kg |

| 98 |

|

Tapered Roller 29.54x53.699x4° | 29.54 mm | 53.699 mm | 0.25100 kg |

| 99 |

|

Tapered Roller 31.693x56.9x4° | 31.693 mm | 56.9 mm | 0.30700 kg |

| 100 |

|

Tapered Roller 36.592x67.88x4° | 36.592 mm | 67.88 mm | 0.48600 kg |

Application: Used in medical equipment, food processing equipment and other applications that require corrosion resistance.

3. Carburizing steel

Composition: Carburizing steel containing elements such as chromium and nickel is usually used, such as 20CrNi4A, etc.

Features: The core is soft and the surface is hard, which is suitable for bearing applications under impact load environment.

Application: It is suitable for applications requiring high strength, wear resistance and fatigue resistance.

Characteristics of tapered rollers

Strong load-bearing capacity: Tapered roller bearings have a large contact area and can withstand large radial loads.

Low friction: Due to the principle of rolling friction, tapered roller bearings have less friction and higher efficiency than sliding bearings.

High precision: Some high-precision tapered rollers can be used in high-speed and precision equipment.

When selecting tapered rollers, the following factors need to be considered:

Load requirements: Select the appropriate specifications according to the load size required.

Speed requirements: When running at high speed, choose rollers made of materials that are suitable for high speeds.

Temperature and environment: Select appropriate materials and sealing methods according to the temperature and pollution conditions of the working environment.

Lubrication: Reasonable lubrication can reduce friction and extend the service life of bearings.