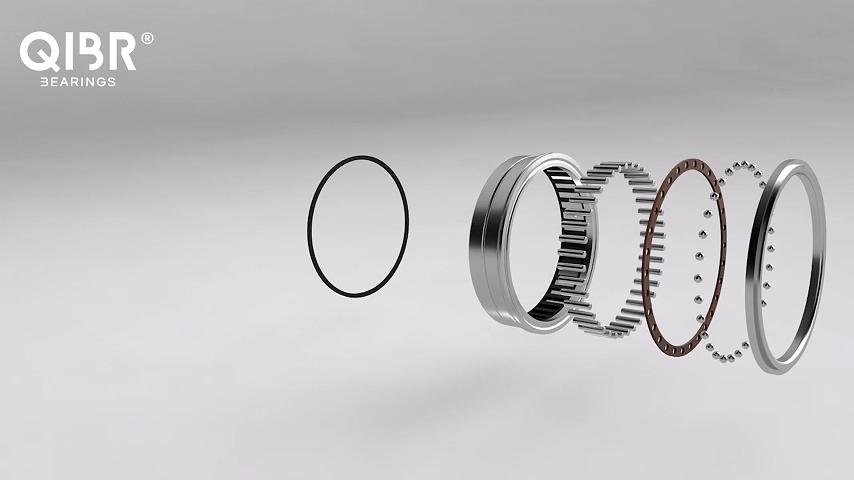

Image may differ from product. See technical specification for details.

Search for the bearing model you need

| NO. | Product | Product Number | Diameter under rollers (Fw) | Outer diameter (D) | Width (C) | Mass | Reference speed |

|---|---|---|---|---|---|---|---|

| 1 |

|

NKX 10 ZTN | 10 mm | 19 mm | 23 mm | 0.036 kg | 9500 rpm |

| 2 |

|

NKX 10 TN | 10 mm | 19 mm | 23 mm | 0.034 kg | 9500 rpm |

| 3 |

|

NKX 12 Z | 12 mm | 21 mm | 23 mm | 0.04 kg | 9000 rpm |

| 4 |

|

NKX 12 | 12 mm | 21 mm | 23 mm | 0.038 kg | 9000 rpm |

| 5 |

|

NKX 15 Z | 15 mm | 24 mm | 23 mm | 0.047 kg | 8500 rpm |

| 6 |

|

NKX 15 | 15 mm | 24 mm | 23 mm | 0.044 kg | 8500 rpm |

| 7 |

|

NKX 17 Z | 17 mm | 26 mm | 25 mm | 0.055 kg | 8500 rpm |

| 8 |

|

NKX 17 | 17 mm | 26 mm | 25 mm | 0.053 kg | 8500 rpm |

| 9 |

|

NKX 20 Z | 20 mm | 30 mm | 30 mm | 0.09 kg | 7500 rpm |

| 10 |

|

NKX 20 | 20 mm | 30 mm | 30 mm | 0.083 kg | 7500 rpm |

| 11 |

|

NKX 25 Z | 25 mm | 37 mm | 30 mm | 0.13 kg | 6300 rpm |

| 12 |

|

NKX 25 | 25 mm | 37 mm | 30 mm | 0.13 kg | 6300 rpm |

| 13 |

|

NKX 30 Z | 30 mm | 42 mm | 30 mm | 0.14 kg | 6000 rpm |

| 14 |

|

NKX 30 | 30 mm | 42 mm | 30 mm | 0.14 kg | 6000 r/min |

| 15 |

|

NKX 35 | 35 mm | 47 mm | 30 mm | 0.16 kg | 5600 rpm |

| 16 |

|

NKX 35 Z | 35 mm | 47 mm | 30 mm | 0.17 kg | 5600 rpm |

| 17 |

|

NKX 40 Z | 40 mm | 52 mm | 32 mm | 0.21 kg | 5000 rpm |

| 18 |

|

NKX 40 | 40 mm | 52 mm | 32 mm | 0.2 kg | 5000 rpm |

| 19 |

|

NKX 45 Z | 45 mm | 58 mm | 32 mm | 0.27 kg | 4500 rpm |

| 20 |

|

NKX 45 | 45 mm | 58 mm | 32 mm | 0.25 kg | 4500 rpm |

| 21 |

|

NKX 50 Z | 50 mm | 62 mm | 35 mm | 0.3 kg | 4300 rpm |

| 22 |

|

NKX 50 | 50 mm | 62 mm | 35 mm | 0.28 kg | 4300 rpm |

| 23 |

|

NKX 60 Z | 60 mm | 72 mm | 40 mm | 0.38 kg | 3600 rpm |

| 24 |

|

NKX 60 | 60 mm | 72 mm | 40 mm | 0.36 kg | 3600 rpm |

| 25 |

|

NKX70 Z | 70 mm | 85 mm | 40 mm | 0.52 kg | 3400 rpm |

| 26 |

|

NKX 70 | 70 mm | 85 mm | 40 mm | 0.5 kg | 3400 rpm |

Features and advantages of QIBR needle roller bearing and thrust ball combination bearing, thrust bearing with cage

QIBR needle roller bearing and thrust ball combination bearing, thrust bearing with cage solves multiple key problems in various fields, mainly reflected in the following aspects:

1. Compound load bearing capacity

This combination bearing can bear radial and axial loads at the same time, and is suitable for complex environments where two loads act at the same time during work, especially applications that need to bear torque and radial force.

2. Save space and simplify design

Since this combination bearing bears radial and axial loads at the same time, it is usually not necessary to use multiple bearings in the design to share different types of loads, thereby saving installation space.

In some compact designs, the use of this combination bearing can greatly simplify the assembly process, reduce the number of parts, and reduce manufacturing and maintenance costs.

3. Strong adaptability

Needle roller bearing and thrust ball combination bearing, thrust bearing with cage can adapt to complex working environments, can work normally under high load, vibration, impact and other conditions, and adapt to load changes in different directions.

4. Improve overall stability

The structural design of the combined bearing can effectively reduce the deviation or vibration of moving parts and enhance overall stability.

The performance improvement and solution of QIBR needle roller bearing and thrust ball combined bearing, thrust bearing with cage

1. Improved materials

Selection of high-performance materials: Using materials with higher hardness, wear resistance and corrosion resistance can significantly improve the durability and stability of bearings.

2. Optimized cage design

Cage structure optimization: Optimize the cage structure design to achieve better needle roller arrangement and uniform load distribution. Improving the cage structure can reduce the mutual collision of needle rollers and improve operating stability and efficiency.

3. Improved lubrication performance

High-efficiency lubricating materials: Use grease or lubricating oil that is more suitable for high temperature and high pressure environments to ensure that the lubricating oil can maintain stable performance under long-term work, thereby reducing bearing friction and improving durability.

4. Improved precision

Precision machining technology: By improving manufacturing accuracy and reducing the error between bearing components, ensure that the contact between needle rollers and cages is more uniform and stable. This can not only improve the performance of the bearing, but also extend the service life and reduce noise and vibration.

Main application areas of QIBR needle roller bearings and thrust ball combined bearings, thrust bearings with cages

1. Automatic transmission

Transmission: Needle roller bearings can withstand large radial loads, and thrust ball bearings can withstand axial loads. Therefore, combined bearings are often used in transmission components in automobile transmissions to help support and reduce friction and improve work efficiency.

2. Agricultural machinery

In agricultural machinery, such as tractors, seeders and harvesters, transmission devices often require high load bearing and compact design. Needle roller bearings and thrust ball combined bearings can meet these requirements. Due to the relatively harsh working environment of agricultural machinery, the high durability and load-bearing capacity of combined bearings are very suitable for this application.

3. Reducer

Reducers usually need to handle radial and axial loads at the same time, so combined bearings have important applications in this type of equipment.

4. Machine tool equipment

Combined bearings are also widely used in machine tool equipment, especially in situations where they need to withstand high radial loads and large axial loads. It can effectively reduce vibration, reduce noise, and improve production efficiency and machine tool precision.