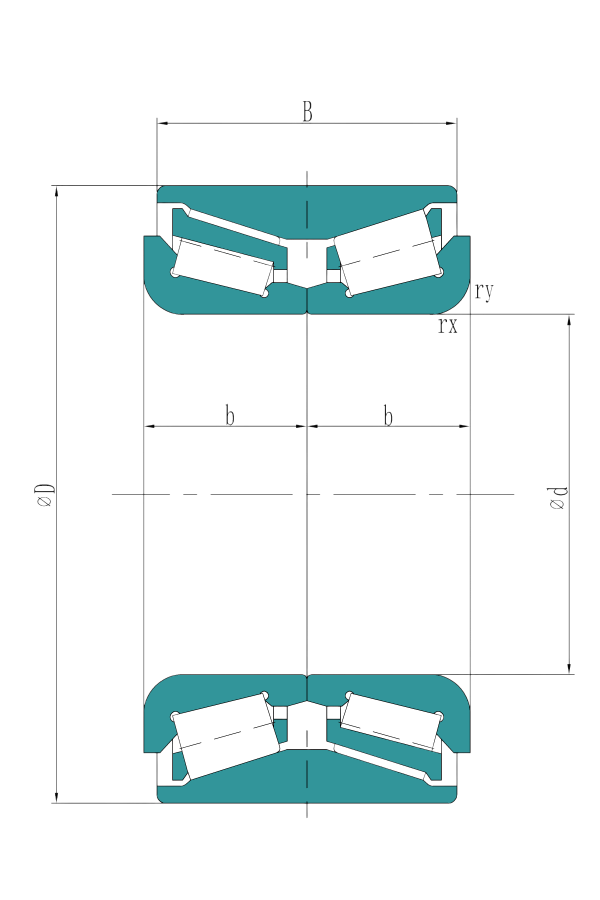

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh,DIN / VDEh

Inner diameter (d)

28mm-49mm

Outer diameter (D)

58mm-88mm

Mass

0.45kg-1.47kg

Material

GCr15, 52100, 100Cr6, SUJ2

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

Automobile wheels

| NO. | Product | Product Number | Inner diameter (d) | Mass | Outer diameter (D) | Width of outer ring (B) |

|---|---|---|---|---|---|---|

| 1 |

|

ZA-28BWD03ACA51** | 28 mm | 0.45 kg | 58 mm | 42 mm |

| 2 |

|

ZA-28BWD05ACA30** | 28 mm | 0.48 kg | 58 mm | 44 mm |

| 3 |

|

ZA-28BWD05BCA30**S01 | 28 mm | 0.48 kg | 58 mm | 44 mm |

| 4 |

|

ZA-28BWD01ACA60** | 28 mm | 0.53 kg | 61 mm | 42 mm |

| 5 |

|

ZA-30BWD01A-A-CA8-01 | 30 mm | 0.58 kg | 63 mm | 42 mm |

| 6 |

|

ZA-32BWD05CA105** | 32 mm | 0.83 kg | 72 mm | 45 mm |

| 7 |

|

ZA-32BWD07A1CA15** | 32 mm | 0.9 kg | 73 mm | 40 mm |

| 8 |

|

ZA-34BWD11CA57** | 34 mm | 0.46 kg | 64 mm | 37 mm |

| 9 |

|

ZA-34BWD09ACA75** | 34 mm | 0.55 kg | 68 mm | 37 mm |

| 10 |

|

ZA-35BWD14CA62** | 35 mm | 0.45 kg | 65 mm | 37 mm |

| 11 |

|

ZA-35BWD19E-JB-5CA01 | 35 mm | 0.5 kg | 65 mm | 37 mm |

| 12 |

|

ZA-35BWD26CA68*-01 E | 35 mm | 0.54 kg | 66 mm | 37 mm |

| 13 |

|

ZA-/HO/35BWD07CA6-01 | 35 mm | 0.5 kg | 68 mm | 30 mm |

| 14 |

|

ZA-35BWD07ACA108** | 35 mm | 0.49 kg | 68 mm | 30 mm |

| 15 |

|

ZA-35BWD07CA123** | 35 mm | 0.49 kg | 68 mm | 30 mm |

| 16 |

|

ZA-/HO/35BWD16C-01 E | 35 mm | 0.58 kg | 68 mm | 36 mm |

| 17 |

|

ZA-35BWD06ACA125** | 35 mm | 0.55 kg | 72 mm | 31 mm |

| 18 |

|

ZA-35BWD01CCA38** | 35 mm | 0.6 kg | 72 mm | 34 mm |

| 19 |

|

ZA-36BWD01BCA60** | 36 mm | 0.57 kg | 72 mm | 34 mm |

| 20 |

|

37BWD07B-A-CA11-01 E | 37 mm | 0.628 kg | 72 mm | 37 mm |

| 21 |

|

ZA-38BWD21CA53** | 38 mm | 0.59 kg | 70 mm | 38 mm |

| 22 |

|

ZA-38BWD09ACA120** | 38 mm | 0.51 kg | 71 mm | 30 mm |

| 23 |

|

ZA-38BWD22LCA96** | 38 mm | 0.61 kg | 71 mm | 39 mm |

| 24 |

|

ZA-38BWD12CA133** E | 38 mm | 0.57 kg | 72 mm | 33 mm |

| 25 |

|

ZA-38BWD12CA145** E | 38 mm | 0.57 kg | 72 mm | 33 mm |

| 26 |

|

ZA-38BWD26E1CA6-02 E | 38 mm | 0.67 kg | 73 mm | 40 mm |

| 27 |

|

ZA-/HO/38BWD15A-JB01 | 38 mm | 0.65 kg | 74 mm | 33 mm |

| 28 |

|

ZA-38BWD01A1-A--05 E | 38 mm | 0.6 kg | 74 mm | 33 mm |

| 29 |

|

ZA-38BWD24CA78** | 38 mm | 0.65 kg | 74 mm | 33 mm |

| 30 |

|

ZA-38BWD10BCA41** | 38 mm | 0.69 kg | 74 mm | 40 mm |

| 31 |

|

ZA-38BWD27ACA68**S01 | 38 mm | 0.7 kg | 74 mm | 40 mm |

| 32 |

|

ZA-38BWD27ACA75**S01 | 38 mm | 0.7 kg | 74 mm | 40 mm |

| 33 |

|

ZA-/HO/38BWD23A-JB01 | 38 mm | 0.85 kg | 76 mm | 43 mm |

| 34 |

|

ZA-38BWD18CA138 | 38 mm | 0.81 kg | 80 mm | 33 mm |

| 35 |

|

ZA-39BWD02D-A-CA1-01 | 39 mm | 0.5 kg | 68 mm | 37 mm |

| 36 |

|

ZA-39BWD01JCA70** | 39 mm | 0.6 kg | 72 mm | 37 mm |

| 37 |

|

ZA-39BWD05CA58** | 39 mm | 0.66 kg | 74 mm | 39 mm |

| 38 |

|

ZA-40BWD16CA103** | 40 mm | 0.59 kg | 74 mm | 34 mm |

| 39 |

|

ZA-/HO/40BWD15A-JB01 | 40 mm | 0.65 kg | 74 mm | 36 mm |

| 40 |

|

ZA-40BWD06A-JB-5CA01 | 40 mm | 0.7 kg | 74 mm | 40 mm |

| 41 |

|

ZA-40BWD06D-JB-5CA01 | 40 mm | 0.7 kg | 74 mm | 40 mm |

| 42 |

|

ZA-40BWD06JCA85** E | 40 mm | 0.63 kg | 74 mm | 40 mm |

| 43 |

|

ZA-40BWD12CA88** E | 40 mm | 0.71 kg | 74 mm | 42 mm |

| 44 |

|

ZA-40BWD12FCA88** | 40 mm | 0.71 kg | 74 mm | 42 mm |

| 45 |

|

ZA-40BWD17DCA116** | 40 mm | 0.71 kg | 75 mm | 39 mm |

| 46 |

|

ZA-40BWD17ECA116** | 40 mm | 0.71 kg | 75 mm | 39 mm |

| 47 |

|

ZA-40BWD05CA60** | 40 mm | 0.71 kg | 76 mm | 38 mm |

| 48 |

|

ZA-40BWD07ACA85** | 40 mm | 0.68 kg | 80 mm | 34 mm |

| 49 |

|

ZA-40BWD14CA80** | 40 mm | 0.77 kg | 80 mm | 34 mm |

| 50 |

|

ZA-/HO/42BWD06--02 E | 42 mm | 0.65 kg | 76 mm | 35 mm |

| 51 |

|

ZA-42KWD08AU42C-01LB | 42 mm | 0.82 kg | 80 mm | 38 mm |

| 52 |

|

ZA-42BWD22ACA12-01 E | 42 mm | 0.87 kg | 80 mm | 44 mm |

| 53 |

|

ZA-42BWD11CA56** | 42 mm | 0.86 kg | 80 mm | 45 mm |

| 54 |

|

ZA-42KWD10U42CA-01LB | 42 mm | 0.92 kg | 82 mm | 40 mm |

| 55 |

|

ZA-43KWD07AU42C-01LB | 43 mm | 0.86 kg | 77 mm | 41.5 mm |

| 56 |

|

ZA-43BWD14A1CA69** | 43 mm | 0.76 kg | 79 mm | 38 mm |

| 57 |

|

ZA-/HO/43BWD13A-01 E | 43 mm | 0.85 kg | 79 mm | 45 mm |

| 58 |

|

ZA-43BWD03CA133** | 43 mm | 0.96 kg | 80 mm | 45 mm |

| 59 |

|

ZA-43BWD06BCA133** | 43 mm | 0.94 kg | 82 mm | 45 mm |

| 60 |

|

ZA-44BWD02ACA96-01 E | 44 mm | 0.81 kg | 82.5 mm | 37 mm |

| 61 |

|

45BWD14JCA117** E | 45 mm | 0.92 kg | 83 mm | 44 mm |

| 62 |

|

ZA-45BWD03CA101** | 45 mm | 0.85 kg | 84 mm | 39 mm |

| 63 |

|

ZA-45BWD16CA103** E | 45 mm | 0.9 kg | 84 mm | 39 mm |

| 64 |

|

ZA-45BWD07BCA78-01 E | 45 mm | 0.93 kg | 84 mm | 40 mm |

| 65 |

|

ZA-45BWD12J1CA8-01 E | 45 mm | 0.9 kg | 84 mm | 40 mm |

| 66 |

|

ZA-45BWD10ACA86** | 45 mm | 0.99 kg | 84 mm | 45 mm |

| 67 |

|

ZA-45BWD15BCA98-01 E | 45 mm | 0.95 kg | 85 mm | 41 mm |

| 68 |

|

ZA-45BWD17CA84** | 45 mm | 1.1 kg | 86 mm | 45 mm |

| 69 |

|

ZA-47KWD02AU42C-01LB | 47 mm | 1.47 kg | 88 mm | 55 mm |

| 70 |

|

ZA-48BWD02A2CA97** | 48 mm | 0.92 kg | 86 mm | 40 mm |

| 71 |

|

ZA-49BWD02-A-CA10-01 | 49 mm | 1.01 kg | 84 mm | 50 mm |

| 72 |

|

ZA-49BWD03CA153** E | 49 mm | 1.13 kg | 88 mm | 48 mm |

Characteristics and advantages of first-generation hub bearings:

Single rolling element design: Early hub bearings typically employed either balls or rollers as rolling elements. These designs were relatively simple, consisting of an inner ring, an outer ring, and rolling elements.

Disassembly and maintenance: Traditional hub bearings require regular maintenance and lubrication. During usage, disassembly for inspection was often necessary. Over time, wear on the balls or rollers could degrade bearing performance, ultimately necessitating replacement.

Installation method: Early hub bearings were installed using external tools to assemble the bearing and wheel. Precise alignment was crucial to ensure compatibility between the hub and the bearing.

Material: These bearings were typically manufactured using steel or other alloy materials, known for their strength and durability.

Maintenance requirements: Regular lubricating oil or grease was needed to reduce friction and extend service life. Insufficient lubrication or prolonged excessive wear could lead to bearing failure, affecting vehicle operation.

Applications:

First-generation hub bearings were widely used in early automobiles and agricultural machinery.

Development trends:

With advancements in automotive technology, hub bearings have evolved through multiple generations. Second and third-generation hub bearings now feature optimized designs, offering improved performance and reliability. However, first-generation hub bearings remain used in some small and medium-sized vehicles, particularly in cost-sensitive models.

In summary, with its efficient design and reliable performance, the first-generation hub bearing laid the foundation for advancements in the automotive industry. It continues to play a significant role in certain modern vehicles.