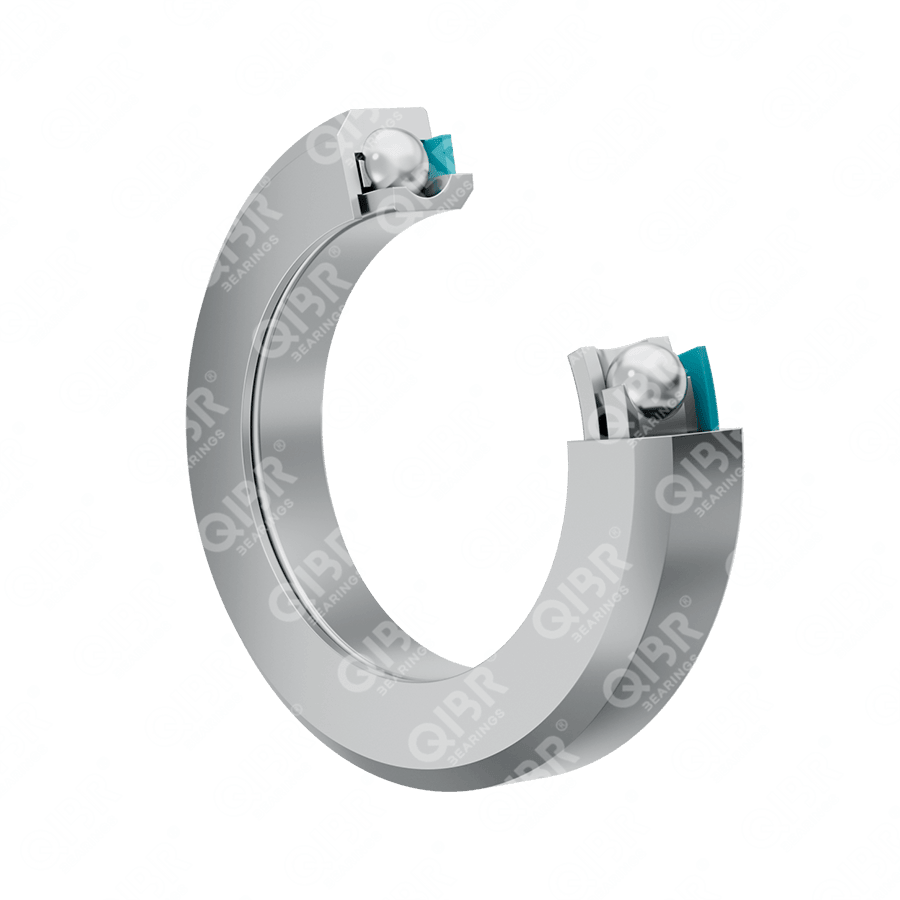

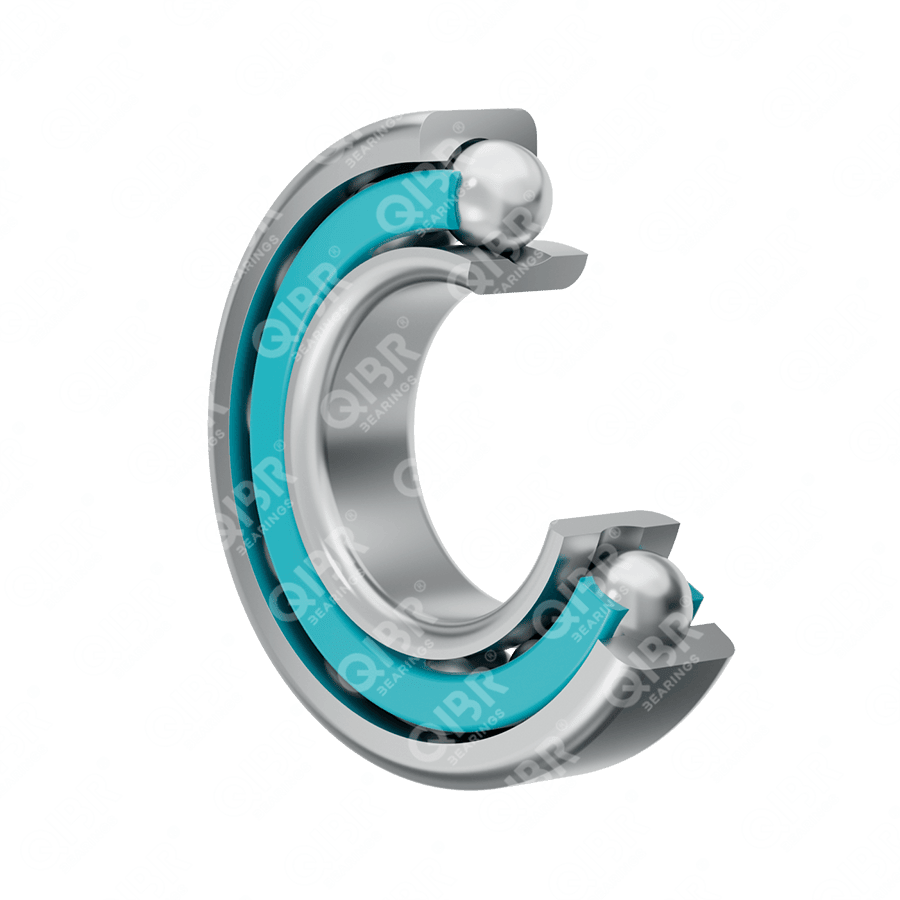

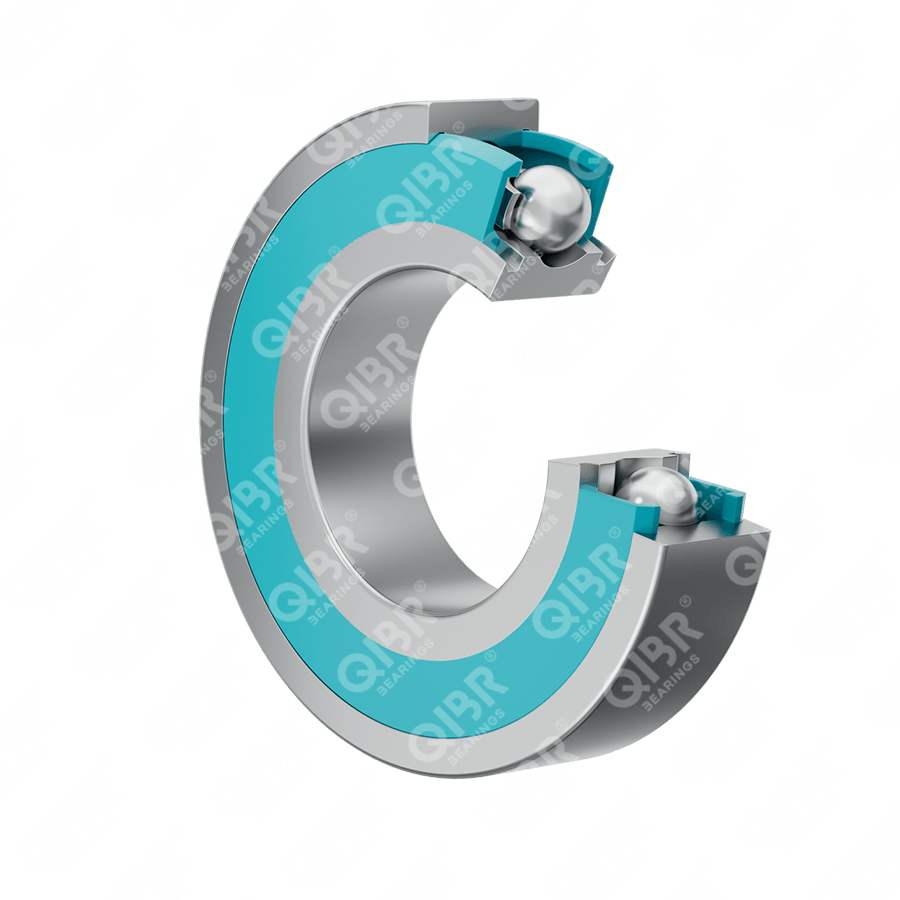

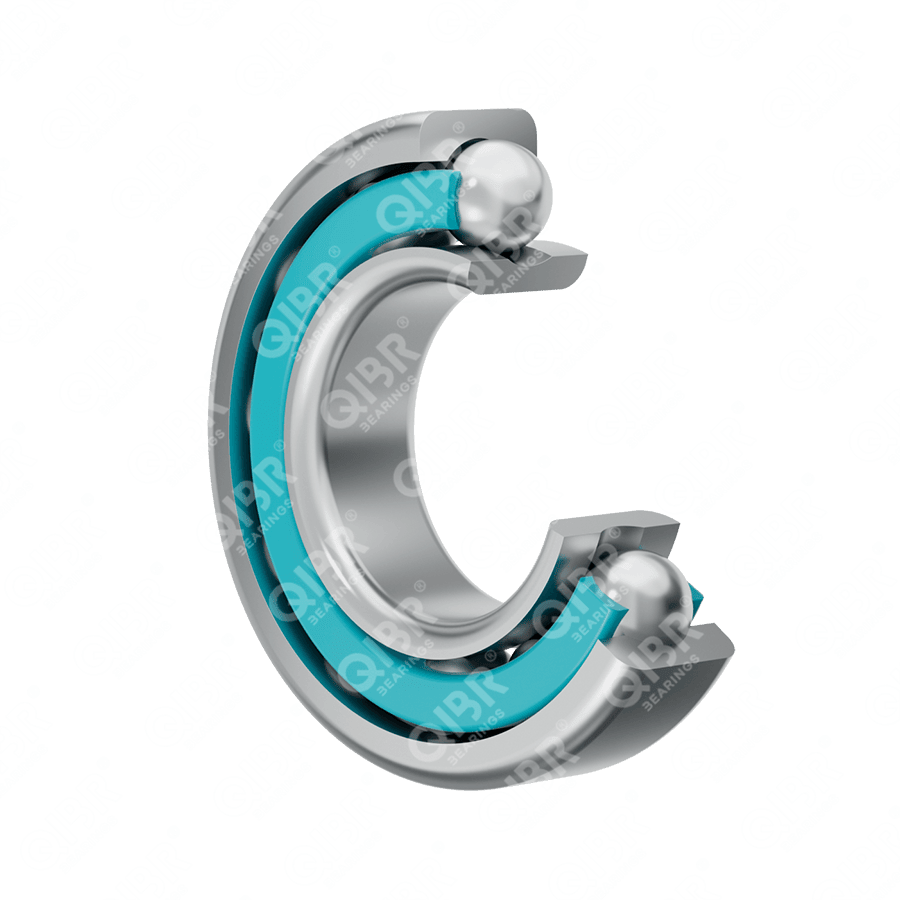

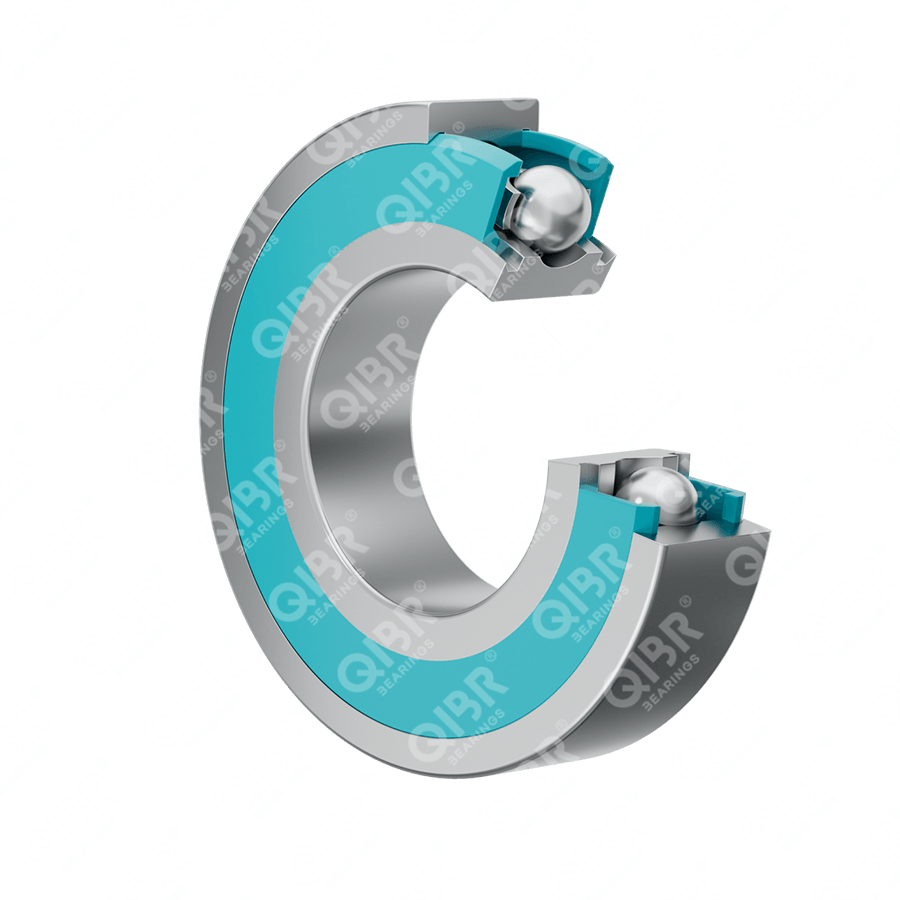

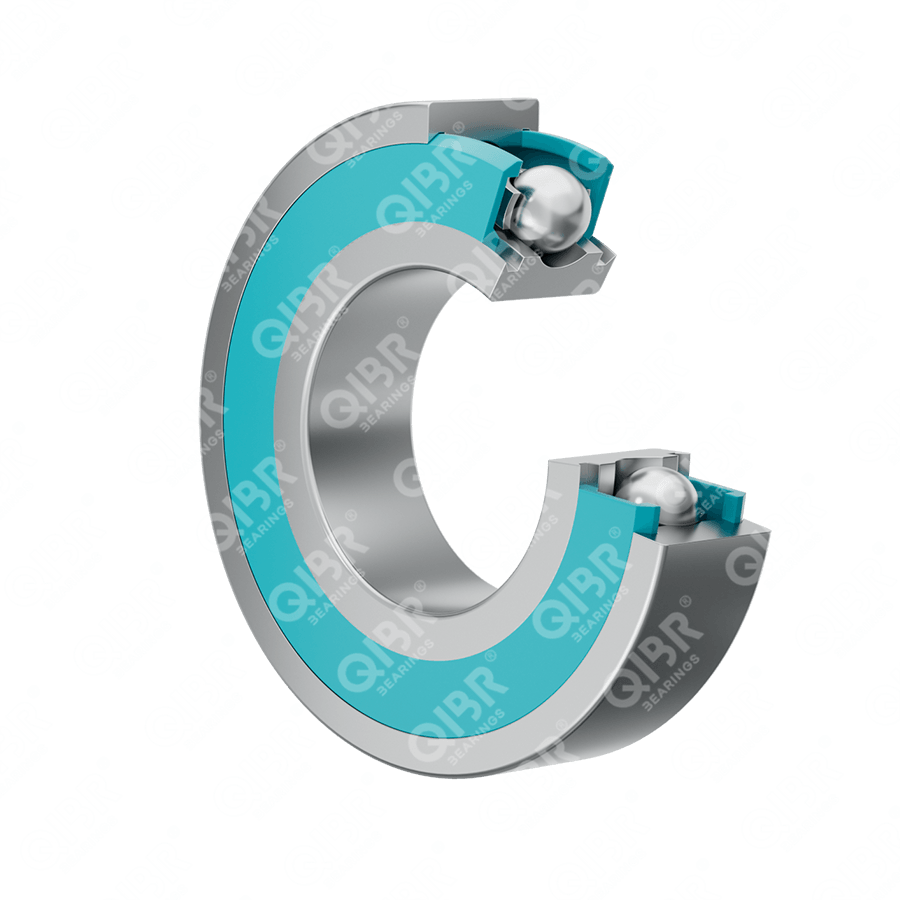

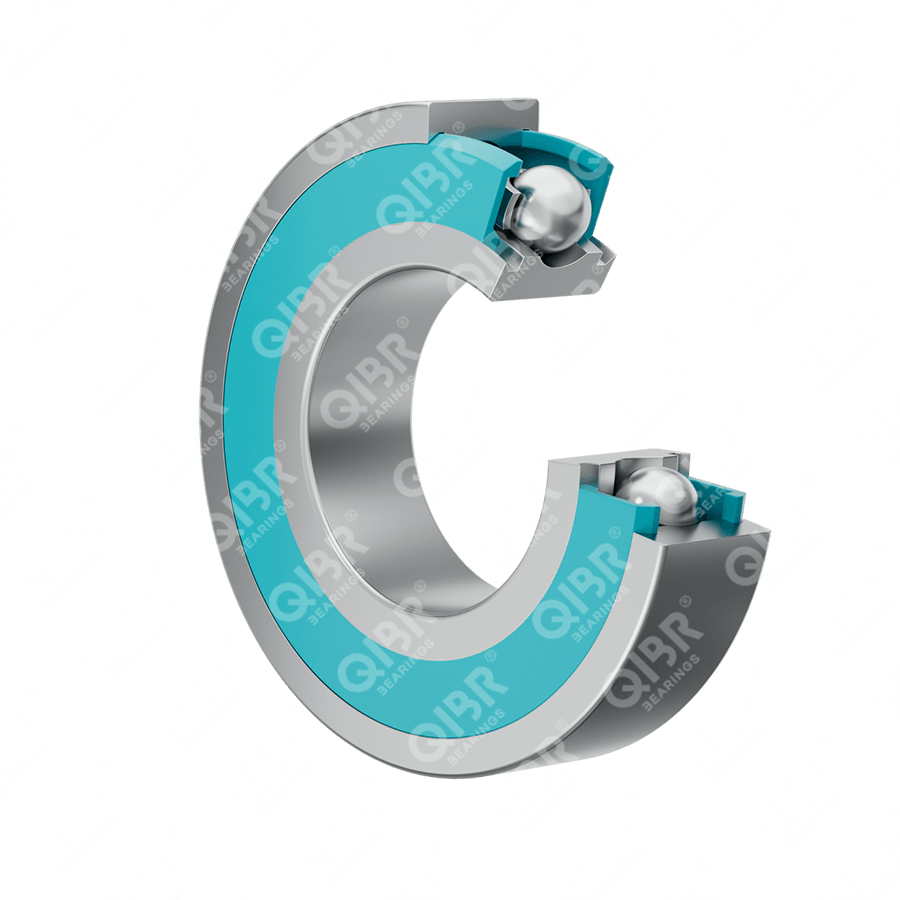

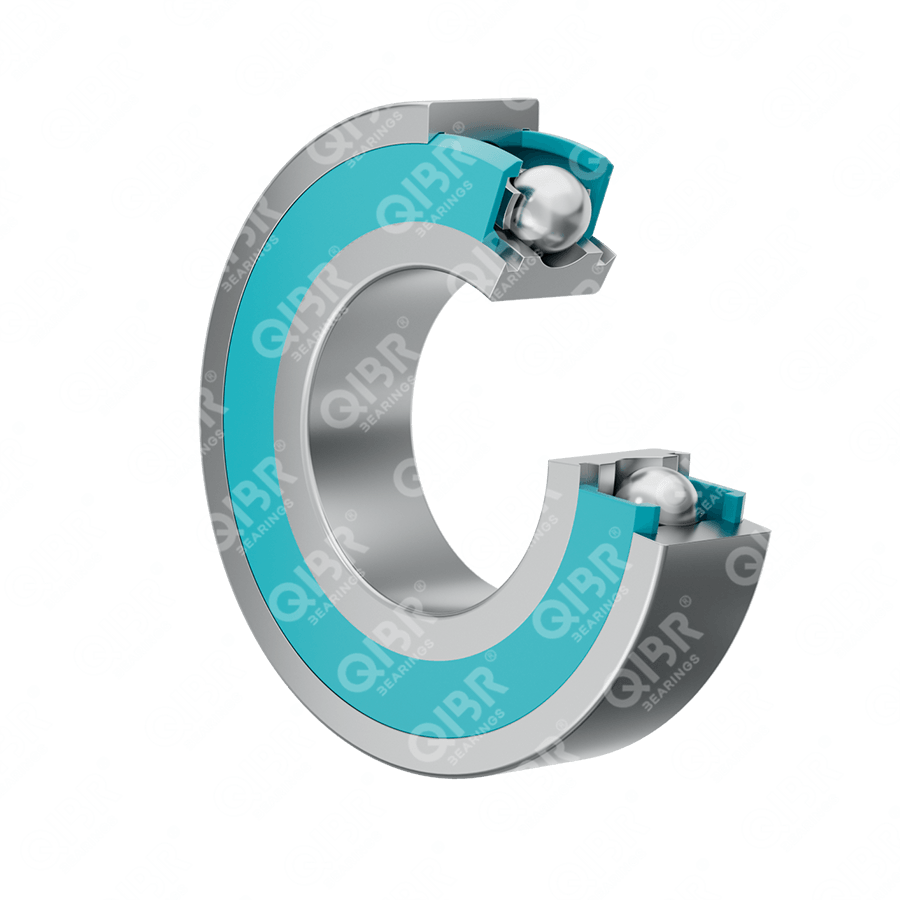

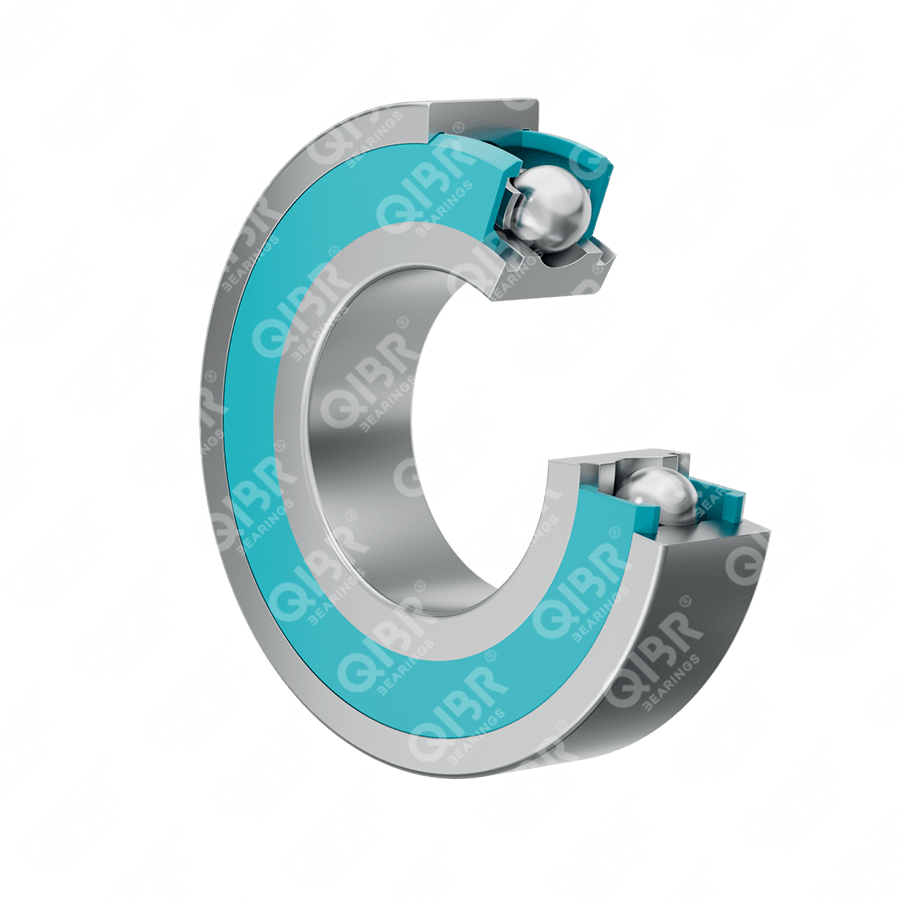

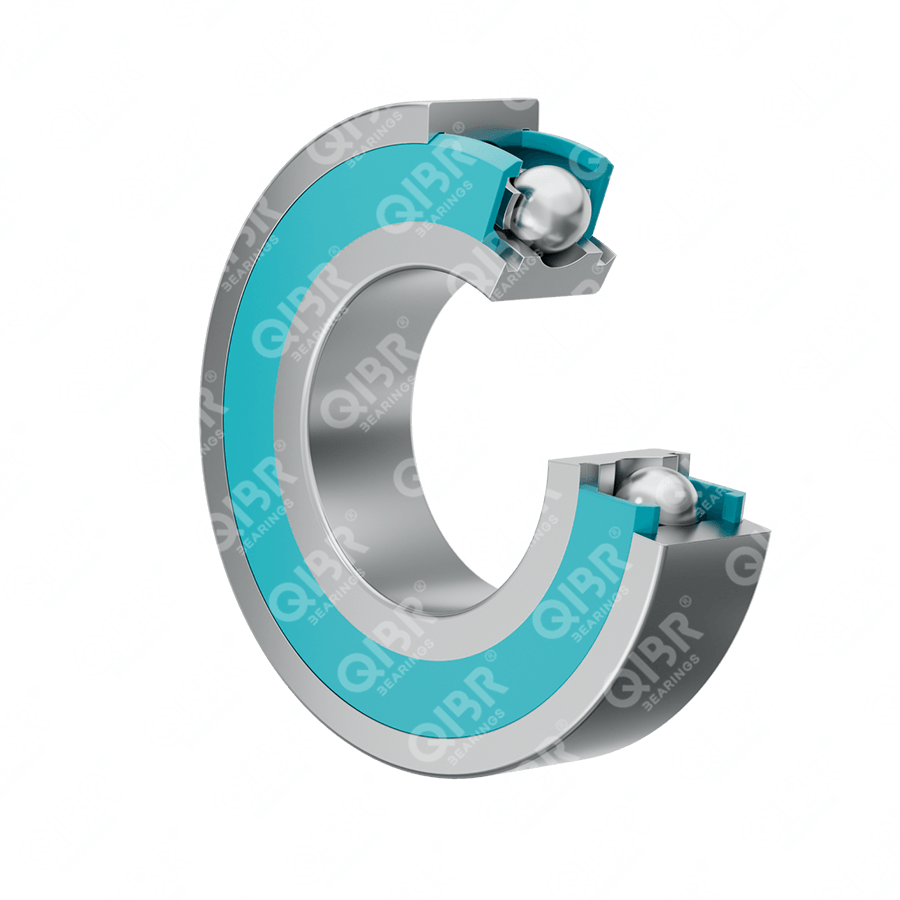

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Material

customized

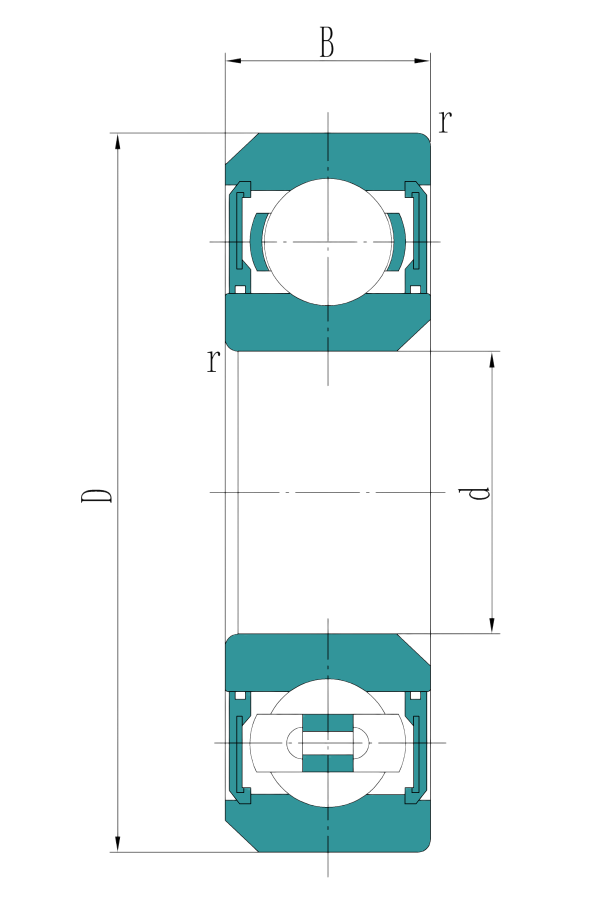

Inner ring diameter

27.15mm-50mm

Outer ring diameter

38mm-61.9mm

Width

6.3mm-8mm

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

Bicycle Parts

| NO. | Product | Product Number | Inner diameter (d) | Outer diameter (D) | Width (B) |

|---|---|---|---|---|---|

| 1 |

|

ACB305418H6.3-45/45 | 30.5 mm | 41.8 mm | 6.3 mm |

| 2 |

|

ACB4052H8 | 40 mm | 52 mm | 8 mm |

| 3 |

|

QIBR-ACB-3645-30-A-RS | 30mm | 41 mm | 6.5 mm |

| 4 |

|

S623-2Z-CB | 3 mm | 10 mm | 4 mm |

| 5 |

|

6900-2RS | 10 mm | 22 mm | 6 mm |

| 6 |

|

ACB307418H7.7-45/45 | 30.7 mm | 41.8 mm | 7.7 mm |

| 7 |

|

ACB4052H7 | 40 mm | 52 mm | 7 mm |

| 8 |

|

QIBR-ACB-4545-30-A-RS | 30mm | 41 mm | 6.5 mm |

| 9 |

|

S623-2RS | 3 mm | 10 mm | 4 mm |

| 10 |

|

6000-2RS | 10 mm | 26 mm | 8 mm |

| 11 |

|

ACB3144H6.3-45/45 | 31.4 mm | 44 mm | 6.3 mm |

| 12 |

|

QIBR-ACB-4545-30-B-RS | 30mm | 41.8 mm | 7 mm |

| 13 |

|

S624-2RS-CB | 4 mm | 13 mm | 5 mm |

| 14 |

|

6801-2RS | 12 mm | 21 mm | 5 mm |

| 15 |

|

ACB30.1541H6.5 | 30.15 mm | 41 mm | 6.5 mm |

| 16 |

|

ACB31448H6.3-45/45 | 31.4 mm | 44.8 mm | 6.3 mm |

| 17 |

|

QIBR-ACB-4545-30-C-RS | 30mm | 41.8 mm | 8 mm |

| 18 |

|

S624-2Z-CB | 4 mm | 13 mm | 5 mm |

| 19 |

|

6901-2RS | 12 mm | 24 mm | 6 mm |

| 20 |

|

ACB30.1541.8H6 | 30.15 mm | 41.8 mm | 6 mm |

| 21 |

|

ACB32438H7-45/45 | 32.4 mm | 43.8 mm | 7 mm |

| 22 |

|

QIBR-ACB-4545-30-F-C-RS | 30.5 mm | 41.8 mm | 8 mm |

| 23 |

|

S625-2Z-CB | 5 mm | 16 mm | 5 mm |

| 24 |

|

12267-2RS | 12 mm | 26 mm | 7 mm |

| 25 |

|

ACB30.1541.8H6.5 | 30.15 mm | 41.8 mm | 6.5 mm |

| 26 |

|

ACB32418H6-45/45 | 32.8 mm | 41.8 mm | 6 mm |

| 27 |

|

QIBR-ACB-4545-34-B-RS | 34 mm | 47 mm | 7 mm |

| 28 |

|

S625-2RS-CB | 5 mm | 16 mm | 5 mm |

| 29 |

|

6001-2RS | 12 mm | 28 mm | 8 mm |

| 30 |

|

ACB30.1541.8H7 | 30.15 mm | 41.8 mm | 7 mm |

| 31 |

|

ACB3344H6-36/45 | 33 mm | 44 mm | 6 mm |

| 32 |

|

QIBR-ACB-3645-40-A-RS | 40 mm | 52 mm | 6.5 mm |

| 33 |

|

S626-2RS-CB | 6 mm | 19 mm | 6 mm |

| 34 |

|

6802-2RS | 15 mm | 24 mm | 5 mm |

| 35 |

|

ACB30.541.8H8 | 30.5 mm | 41.8 mm | |

| 36 |

|

ACB33438H7-30/45 | 33.05 mm | 43.8 mm | 7 mm |

| 37 |

|

QIBR-ACB-3645-40-B-RS | 40 mm | 52 mm | 7 mm |

| 38 |

|

S626-2Z-CB | 6 mm | 19 mm | 6 mm |

| 39 |

|

15267-2RS | 15 mm | 26 mm | 7 mm |

| 40 |

|

ACB3345H7-45/45 | 33.5 mm | 45 mm | 7 mm |

| 41 |

|

ACB34.146.9H7 | 34.1 mm | 46.9 mm | |

| 42 |

|

S606-2RS-CB | 6 mm | 17 mm | 6 mm |

| 43 |

|

6902-2RS | 15 mm | 28 mm | 7 mm |

| 44 |

|

ACB3446H7-45/45 | 34.1 mm | 45 mm | 7 mm |

| 45 |

|

ACB3547H8 | 35 mm | 47 mm | |

| 46 |

|

K845H7 | 30.2 mm | 41.8 mm | 7 mm |

| 47 |

|

S606-2Z-CB | 6 mm | 17 mm | 6 mm |

| 48 |

|

6803-2RS | 17 mm | 26 mm | 5 mm |

| 49 |

|

ACB34468H7-45/45 | 34.1 mm | 46.8 mm | 7 mm |

| 50 |

|

ACB34469H7-45/45 | 34.1 mm | 46.9 mm | 7 mm |

| 51 |

|

S627-2Z-CB | 7 mm | 22 mm | 7 mm |

| 52 |

|

17287-2RS | 17 mm | 28 mm | 7 mm |

| 53 |

|

ACB4051H6.5 | 40 mm | 51 mm | |

| 54 |

|

S627-2RS-CB | 7 mm | 22 mm | 7 mm |

| 55 |

|

6903-2RS | 17 mm | 30 mm | 7 mm |

| 56 |

|

ACB3544H5-90/90 | 35 mm | 44 mm | 5 mm |

| 57 |

|

S608-2RSCB | 8 mm | 22 mm | 7 mm |

| 58 |

|

6804-2RS | 20 mm | 32 mm | 7 mm |

| 59 |

|

ACB3544H5.5-36/45 | 35 mm | 44 mm | 5.5 mm |

| 60 |

|

ACB5061.9H8 | 50 mm | 61.9 mm | |

| 61 |

|

S608-2Z-CB | 8 mm | 22 mm | 7 mm |

| 62 |

|

ACB27.1538H6.3 | 27.15 mm | 38 mm | |

| 63 |

|

ACB354535H7.3-45/45 | 35 mm | 45.35 mm | 7.3 mm |

| 64 |

|

S609-2RS-CB | 9 mm | 24 mm | 7 mm |

| 65 |

|

163110-2RS | 16 mm | 31 mm | 10 mm |

| 66 |

|

ACB30.1539H6.5 | 30.15 mm | 39 mm | |

| 67 |

|

ACB3547H8-45/45 | 35 mm | 47 mm | 8 mm |

| 68 |

|

S609-2Z-CB | 9 mm | 24 mm | 7 mm |

| 69 |

|

173110-2RS | 16 mm | 31 mm | 10 mm |

| 70 |

|

ACB36458H6.5-45/45 | 36.8 mm | 45.8 mm | 6.5 mm |

| 71 |

|

S629-2RS-CB | 9 mm | 26 mm | 8 mm |

| 72 |

|

19317-2RS | 17 mm | 31 mm | 7 mm |

| 73 |

|

ACB27.1538H6.5 | 40 mm | 51.8 mm | |

| 74 |

|

ACB3748H7-45/45 | 37 mm | 48 mm | 7 mm |

| 75 |

|

S629-2Z-CB | 9 mm | 26 mm | 8 mm |

| 76 |

|

19379-2RS | 19 mm | 37 mm | 9 mm |

| 77 |

|

ACB37489H6.5-36/45 | 37 mm | 48.9 mm | 6.5 mm |

| 78 |

|

ACB4051.8H8 | 40 mm | 51.8 mm | |

| 79 |

|

S6000-2RS-CB | 10 mm | 26 mm | 8 mm |

| 80 |

|

22379-2RS | 22 mm | 37 mm | 9 mm |

| 81 |

|

ACB3749H6.5-36/45 | 37 mm | 49 mm | 6.5 mm |

| 82 |

|

ACB4051.9H8 | 40 mm | 51.9 mm | |

| 83 |

|

S6000-2Z-CB | 10 mm | 26 mm | 8 mm |

| 84 |

|

ACB3749H7-36/45 | 37 mm | 49 mm | 7 mm |

| 85 |

|

ACB3749H7-45/45 | 37 mm | 49 mm | 6.5 mm |

| 86 |

|

ACB4051.9H7 | 40 mm | 51.9 mm | |

| 87 |

|

R12-2RS | 19.05 mm | 41.275 mm | 11.113 mm |

| 88 |

|

S61800-2RS-CB | 10 mm | 19 mm | 5 mm |

| 89 |

|

R12-2RS/22 | 22 mm | 41.275 mm | 11.113 mm |

| 90 |

|

S61800-2Z-CB | 10 mm | 19 mm | 5 mm |

| 91 |

|

215317-2RS | 21.5 mm | 31 mm | 7 mm |

| 92 |

|

ACB40508H7-45/90 | 40 mm | 50.8 mm | 6.5 mm |

| 93 |

|

ACB47.856.8H6.5 | 47.8 mm | 56.8 mm | |

| 94 |

|

S61900-2RS-CB | 10 mm | 22 mm | 6 mm |

| 95 |

|

24377-2RS | 24 mm | 37 mm | 7 mm |

| 96 |

|

ACB32.443.8H7 | 32.4 mm | 43.8 mm | |

| 97 |

|

ACB4051H6.5-36/36 | 40 mm | 51 mm | 6.5 mm |

| 98 |

|

24378-2RS | 24 mm | 37 mm | 8 mm |

| 99 |

|

ACB3749H7 | 37 mm | 49 mm | 7 mm |

| 100 |

|

ACB4051H8-36/45 | 40 mm | 51 mm | 8 mm |

Features and advantages of QIBR bicycle bearings

QIBR bicycle bearings solve several key problems in various fields, which are mainly reflected in the following aspects:

1. Reduce friction

The core function of bearings is to reduce friction. QIBR bicycle bearings achieve a low friction coefficient by using balls in bearings, thereby reducing energy loss.

2. Load-bearing capacity

Bicycle bearings can withstand the load of various components of the bicycle. Bearings are designed with different load capacities according to the load of the components.

3. High speed performance

Bicycle bearings are particularly suitable for high-speed operation and can withstand long-term high-speed operation without obvious wear. Especially in competitive bicycles, high-speed bearings can effectively reduce friction and ensure higher riding efficiency.

4. Durability and life

Bearings are often in high-speed rotation and load-bearing state in bicycles, so their durability is very important. The bearings are designed with sealing or dustproof functions, which can effectively prevent dust and moisture from entering and extend the service life of the bearings.

The performance improvement and solutions of QIBR bicycle bearing

1. Use high-quality materials

High wear-resistant alloys: Using high-strength steel alloys or ceramics as balls can greatly improve the wear resistance and service life of bearings. Ceramic bearings have a much lower friction coefficient than steel, so they can reduce friction and improve operating efficiency.

Stainless steel materials: Stainless steel bearings are more resistant to moisture and corrosion, and are particularly suitable for humid or rainy environments.

2. Optimize bearing design

Sealed design: Sealed bearings use rubber or other durable materials to seal the inside and outside of the bearing to prevent the intrusion of dirt, dust, moisture, etc., reduce friction and loss, and avoid corrosion. The two-way seal design can better protect the bearing.

Multi-row bearing structure: Compared with traditional single-row bearings, bearings with multi-row design can share more loads and enhance the bearing's load-bearing capacity and stability.

3. Efficient lubrication

Synthetic greases and lubricants: High-quality lubricating oils and greases can reduce friction, keep bearings running smoothly, and prevent moisture from penetrating. Using the right lubricant can greatly improve the operating efficiency and extend the service life of the bearing.

Lubrication frequency: Check and add lubricant regularly to avoid increased friction caused by excessive drying of the lubricant.

4. Precision manufacturing and processing

High-precision processing: During the manufacturing process, it is necessary to ensure the precise fit between the ball and the bearing seat, reduce the gap, and ensure accuracy. Bearings with small processing errors and smooth surfaces can significantly reduce friction.

Optimized clearance design: Appropriate bearing clearance can make the lubricant more evenly distributed and reduce friction. Too small a clearance will increase friction, and too large a clearance will affect the stability of the bearing.