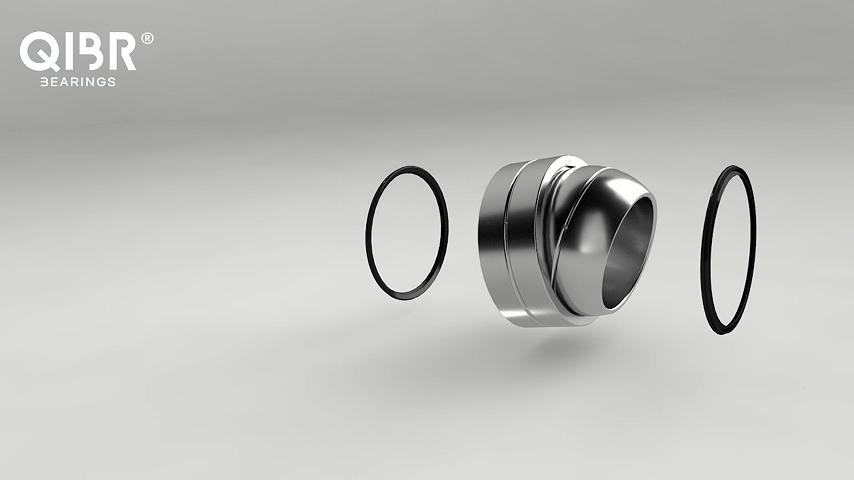

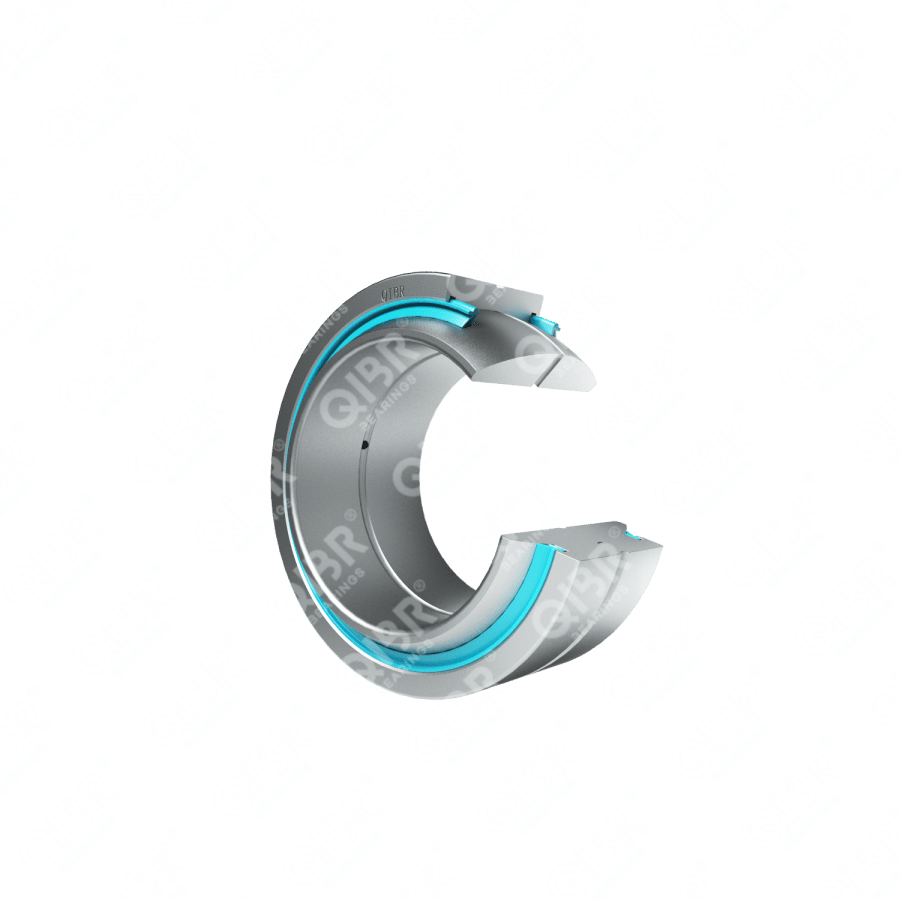

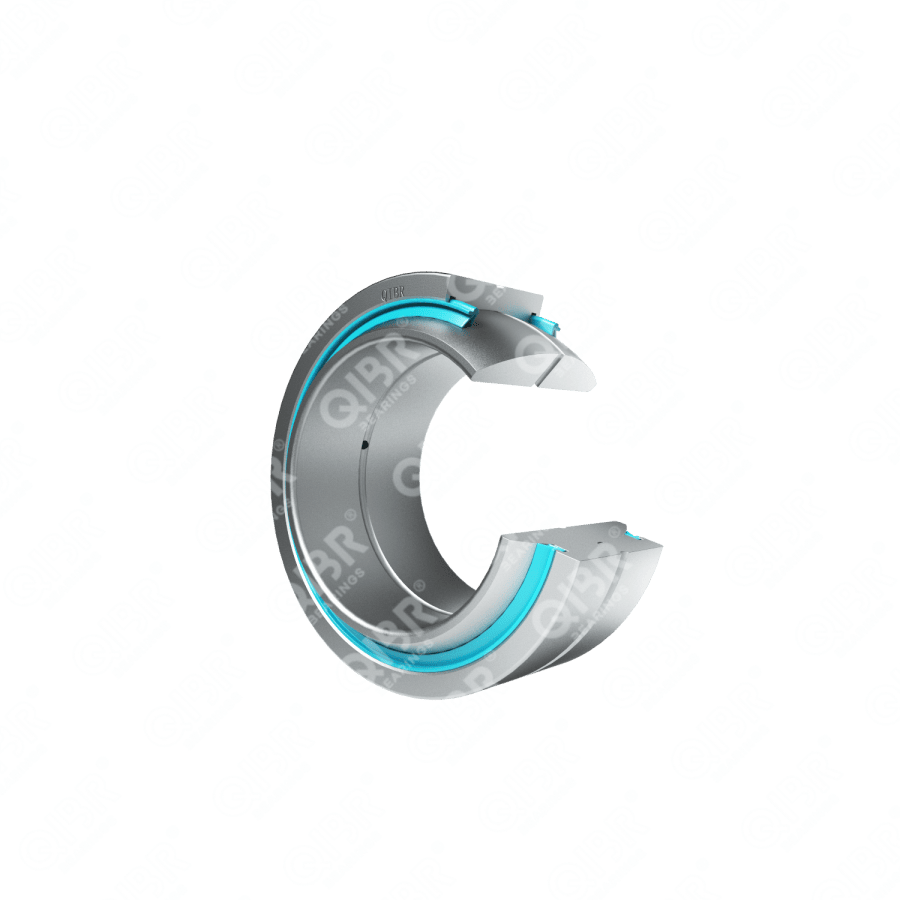

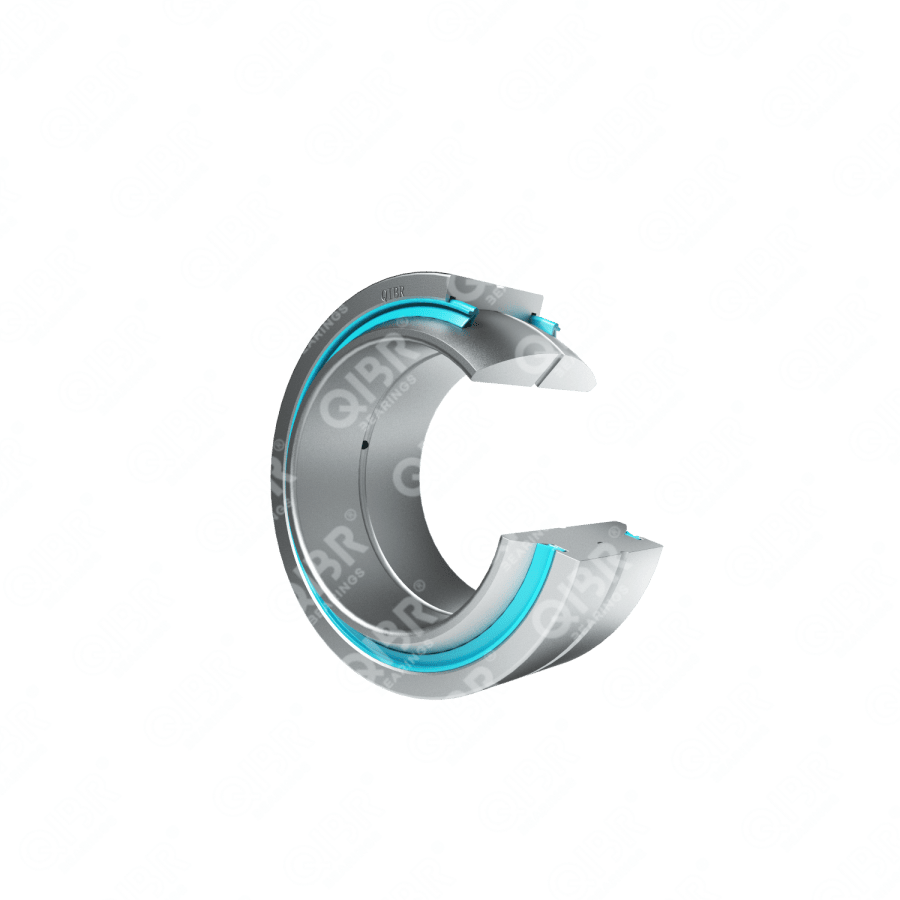

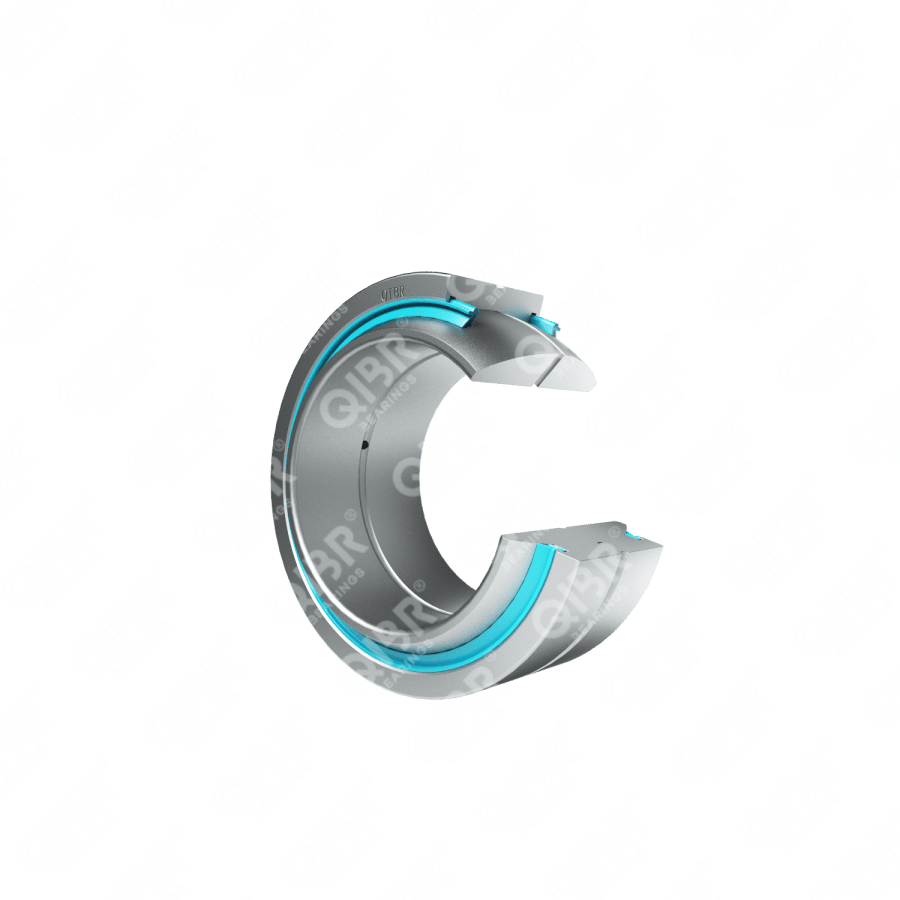

Image may differ from product. See technical specification for details.

Search for the bearing model you need

| NO. | Product | Product Number | Outer diameter (D) | Shaft (d) | Weight | Width (B) |

|---|---|---|---|---|---|---|

| 1 |

|

GE6DO | 0.551"/14 mm | 0.236"/6 mm | 0.009 lbs | 0.236"/6 mm |

| 2 |

|

GE8DO | 0.63"/16 mm | 0.315"/8 mm | 0.015 lbs | 0.315"/8 mm |

| 3 |

|

GE10DO | 0.748"/19 mm | 0.394"/10 mm | 0.024 lbs | 0.354"/9 mm |

| 4 |

|

GE12DO | 0.866"/22 mm | 0.472"/12 mm | 0.035 lbs | 0.394"/10 mm |

| 5 |

|

GE15DO | 1.024"/26 mm | 0.591"/15 mm | 0.055 lbs | 0.472"/12 mm |

| 6 |

|

GE16DO | 1.181"/30 mm | 0.63"/16 mm | 0.084 lbs | 0.551"/14 mm |

| 7 |

|

GE17DO | 1.181"/30 mm | 0.669"/17 mm | 0.090 lbs | 0.551"/14 mm |

| 8 |

|

GE17DO-2RS | 1.181"/30 mm | 0.669"/17 mm | 0.09 lbs | 0.551"/14 mm |

| 9 |

|

GE20DO | 1.378"/35 mm | 0.787"/20 mm | 0.135 lbs | 0.63"/16 mm |

| 10 |

|

GE20DO-2RS | 1.378"/35 mm | 0.787"/20 mm | 0.135 lbs | 0.63"/16 mm |

| 11 |

|

GE25DO | 1.654"/42 mm | 0.984"/25 mm | 0.243 lbs | 0.787"/20 mm |

| 12 |

|

GE25DO-2RS | 1.654"/42 mm | 0.984"/25 mm | 0.243 lbs | 0.787"/20 mm |

| 13 |

|

GE30DO | 1.85"/47 mm | 1.181"/30 mm | 0.309 lbs | 0.866"/22 mm |

| 14 |

|

GE30DO-2RS | 1.85"/47 mm | 1.181"/30 mm | 0.309 lbs | 0.866"/22 mm |

| 15 |

|

GE35DO | 2.165"/55 mm | 1.378"/35 mm | 0.485 lbs | 0.984"/25 mm |

| 16 |

|

GE35DO-2RS | 2.165"/55 mm | 1.378"/35 mm | 0.485 lbs | 0.984"/25 mm |

| 17 |

|

GE40DO | 2.441"/62 mm | 1.575"/40 mm | 0.662 lbs | 1.102"/28 mm |

| 18 |

|

GE40DO-2RS | 2.441"/62 mm | 1.575"/40 mm | 0.662 lbs | 1.102"/28 mm |

| 19 |

|

GE45DO | 2.677"/68 mm | 1.772"/45 mm | 0.882 lbs | 1.26"/32 mm |

| 20 |

|

GE45DO-2RS | 2.677"/68 mm | 1.772"/45 mm | 0.882 lbs | 1.26"/32 mm |

| 21 |

|

GE50DO | 2.953"/75 mm | 1.969"/50 mm | 1.191 lbs | 1.378"/35 mm |

| 22 |

|

GE50DO-2RS | 2.953"/75 mm | 1.969"/50 mm | 1.191 lbs | 1.378"/35 mm |

| 23 |

|

GE60DO | 3.543"/90 mm | 2.362"/60 mm | 2.205 lbs | 1.732"/44 mm |

| 24 |

|

GE60DO-2RS | 3.543"/90 mm | 2.362"/60 mm | 2.205 lbs | 1.732"/44 mm |

| 25 |

|

GE70DO | 4.134"/105mm | 2.756"/70 mm | 3.308 lbs | 1.929"/49 mm |

| 26 |

|

GE70DO-2RS | 4.134"/105 mm | 2.756"/70 mm | 3.308 lbs | 1.929"/49 mm |

| 27 |

|

GE80DO-2RS | 4.724"/120 mm | 3.15"/80 mm | 4.815 lbs | 2.165"/55 mm |

| 28 |

|

GE80DO | 4.724"/120 mm | 3.15"/80 mm | 4.815 lbs | 2.165"/55 mm |

| 29 |

|

GE90DO | 5.118"/130 mm | 3.543"/90 mm | 5.95lbs | 2.362"/60 mm |

| 30 |

|

GE90DO-2RS | 5.118"/130 mm | 3.543"/90 mm | 5.954 lbs | 2.362"/60 mm |

| 31 |

|

GE100DO | 5.906"/150 mm | 3.937"/100 mm | 9.48 lbs | 2.756"/70 mm |

| 32 |

|

GE100DO-2RS | 5.906"/150 mm | 3.937"/100 mm | 9.482 lbs | 2.756"/70 mm |

| 33 |

|

GE110DO | 6.299"/160 mm | 4.331"/110 mm | 10.36 lbs | 2.756"/70 mm |

| 34 |

|

GE110DO-2RS | 6.299"/160 mm | 4.331"/110 mm | 10.36lbs | 2.756"/70 mm |

| 35 |

|

GE120DO | 7.087"/180 mm | 4.724"/120 mm | 17.64 lbs | 3.346"/85 mm |

| 36 |

|

GE120DO-2RS | 7.087"/180 mm | 4.724"/120 mm | 17.64 lbs | 3.346"/85 mm |

| 37 |

|

GE140DO | 8.268"/210 mm | 5.512"/140 mm | 24.26 lbs | 3.543"/90 mm |

| 38 |

|

GE140DO-2RS | 8.268"/210 mm | 5.512"/140 mm | 24.26 lbs | 3.543"/90 mm |

| 39 |

|

GE160DO | 9.055"/230 mm | 6.299"/160 mm | 29.77 lbs | 4.134"/105 mm |

| 40 |

|

GE160DO-2RS | 9.055"/230 mm | 6.299"/160 mm | 29.77 lbs | 4.134"/105 mm |

| 41 |

|

GE180DO | 10.236"/260 mm | 7.087"/180 mm | 40.79 lbs | 4.134"/105 mm |

| 42 |

|

GE180DO-2RS | 10.236"/260 mm | 7.087"/180 mm | 40.79 lbs | 4.134"/105 mm |

| 43 |

|

GE200DO | 11.417"/290 mm | 7.874"/200 mm | 61.74 lbs | 5.118"/130 mm |

| 44 |

|

GE200DO-2RS | 11.417"/290 mm | 7.874"/200 mm | 61.74lbs | 5.118"/130 mm |

| 45 |

|

GE220DO-2RS | 12.598"/320 mm | 8.661"/220 mm | 78.28 lbs | 5.315"/135 mm |

| 46 |

|

GE240DO-2RS | 13.386"/340 mm | 9.449"/240 mm | 88.2 lbs | 5.512"/140 mm |

| 47 |

|

GE260DO-2RS | 14.567"/370 mm | 10.236"/260 mm | 110 lbs | 5.906"/150 mm |

| 48 |

|

GE280DO-2RS | 15.748"/400 mm | 11.024"/280 mm | 141 lbs | 6.102"/155 mm |

| 49 |

|

GE300DO-2RS | 16.929"/430 mm | 11.811"/300 mm | 165 lbs | 6.496"/165 mm |

| 50 |

|

GE320DO | 17.323"/440 mm | 12.598"/320 mm | 170 lbs | 6.299"/160 mm |

| 51 |

|

GE340DO | 18.11"/460 mm | 13.386"/340 mm | 181 lbs | 6.299"/160 mm |

| 52 |

|

GE360DO | 18.898"/480 mm | 14.173"/360 mm | 194 lbs | 6.299"/160 mm |

| 53 |

|

GE380DO | 20.472"/520 mm | 14.961"/380 mm | 280 lbs | 7.48"/190 mm |

| 54 |

|

GE400DO | 21.26"/540 mm | 15.748"/400 mm | 291 lbs | 7.48"/190 mm |

| 55 |

|

GE420DO | 22.047"/560 mm | 16.535"/420 mm | 320 lbs | 7.48"/190 mm |

| 56 |

|

GE440DO | 23.622"/600 mm | 17.323"/440 mm | 419 lbs | 8.583"/218 mm |

| 57 |

|

GE480DO | 25.591"/650 mm | 18.898"/480 mm | 525 lbs | 9.055"/230 mm |

| 58 |

|

GE500DO | 26.378"/670 mm | 19.685"/500 mm | 538 lbs | 9.055"/230 mm |

| 59 |

|

GE530DO | 27.953"/710 mm | 20.866"/530 mm | 639 lbs | 9.567"/243 mm |

| 60 |

|

GE560DO | 29.528"/750 mm | 22.047"/560 mm | 750 lbs | 10.157"/258 mm |

| 61 |

|

GE600DO | 31.496"/800 mm | 23.622"/600 mm | 902 lbs | 10.709"/272 mm |

| 62 |

|

GE630DO | 33.465"/850 mm | 24.803"/630 mm | 1160 lbs | 11.811"/300 mm |

| 63 |

|

GE670DO | 35.433"/900 mm | 26.378"/670 mm | 1314 lbs | 12.126"/308 mm |

| 64 |

|

GE710DO | 37.402"/950 mm | 27.953"/710 mm | 1528 lbs | 12.795"/325 mm |

| 65 |

|

GE750DO | 39.37"/1000 mm | 29.528"/750 mm | 1729 lbs | 13.189"/335 mm |

| 66 |

|

GE800DO | 41.732"/1060 mm | 31.496"/800 mm | 2040 lbs | 13.976"/355 mm |

| 67 |

|

GE850DO | 44.094"/1120 mm | 33.465"/850 mm | 2326 lbs | 14.37"/365 mm |

| 68 |

|

GE900DO | 46.457"/1180 mm | 35.433"/900 mm | 2624 lbs | 14.764"/375 mm |

| 69 |

|

GE950DO | 49.213"/1250 mm | 37.402"/950 mm | 3140 lbs | 15.748"/400 mm |

| 70 |

|

GE1000DO | 51.969"/1320 mm | 39.37"/1000 mm | 3870 lbs | 17.244"/438 mm |

Features and advantages of QIBR joint bearing GE..DO, GE..DO-2RS series

QIBR joint bearing GE..DO, GE..DO-2RS series addresses several critical issues in diverse fields, mainly in the following areas:

1. Multi-directional movement capability

The QIBR joint bearing GE..DO, GE..DO-2RS series is typically designed to rotate or swing in multiple directions, making them ideal for applications requiring angular motion. They allow a large relative angular movement between two connected parts.

2. High load capacity

The QIBR joint bearing GE..DO, GE..DO-2RS series can bear large radial and axial loads. Its spherical design effectively disperses and bears large forces, making it perform excellently in high-strength working environments.

3. Strong wear resistance

The QIBR joint bearing GE..DO, GE..DO-2RS series uses wear-resistant materials to effectively reduce the friction coefficient and improve the bearing's wear resistance. Some composite material joint bearings even do not require lubrication, making them suitable for harsh working environments.

4. Strong adaptability

The QIBR joint bearing GE..DO, GE..DO-2RS series can adapt to various working conditions and environments, including temperature variations, humidity, contaminants, and dust.

Performance improvements and solutions for QIBR joint bearing GE..DO, GE..DO-2RS series

1. Lubricant optimization

Selecting appropriate lubricants (oil or grease) and proper additive formulations to reduce friction and enhance wear resistance.

2. Raceway optimization

Optimizing the geometry of the inner and outer raceways, such as improving raceway accuracy and surface finish, to reduce friction, minimize energy loss, and enhance bearing efficiency.

3. Precision manufacturing and tolerance control

By using precision machining and strict tolerance control, the internal structure of the joint bearing can be made smoother and more accurate. Precise manufacturing helps reduce unnecessary friction, improves work efficiency, and mitigates the effects of unbalanced loads.

4. Increased load distribution area

By optimizing the contact surface design of the joint bearing to increase the load distribution area, local stress concentration can be reduced, improving load capacity and extending the service life.

Main application areas of QIBR joint bearing GE..DO, GE..DO-2RS series

1. Automotive industry

In automotive suspension systems, joint bearings are commonly used to connect moving parts between the wheels and the body, adapting to different dynamic loads and motions.

Steering systems: Used in steering ball joints and ball joint brackets, ensuring flexible directional adjustment.

Seat adjustment: The joint bearing is used in the adjustment mechanism of automotive seats, allowing for smooth and flexible movement of the seat.

2. Aerospace

Aircraft landing gear: Joint bearings are key components in the aircraft landing gear, helping the aircraft withstand heavy loads and providing flexibility during takeoff and landing.

3. Agricultural machinery

Agricultural tillage equipment: Joint bearings are used in tractors, combine harvesters, sprayers, and other agricultural machinery to withstand high loads, high temperatures, and corrosive environments, ensuring the stability of the equipment.

Transmission systems: Used in agricultural machinery to bear and transfer power in transmission components.

4. Construction machinery

Cranes and excavators: Joint bearings are widely used in the moving parts of cranes, excavators, and similar equipment to enable flexible movement of joints and rotating parts, bearing complex workloads.

Loaders and hoists: Joint bearings are used to connect or support rotating, lifting, and other moving components in these machines, enhancing work efficiency.