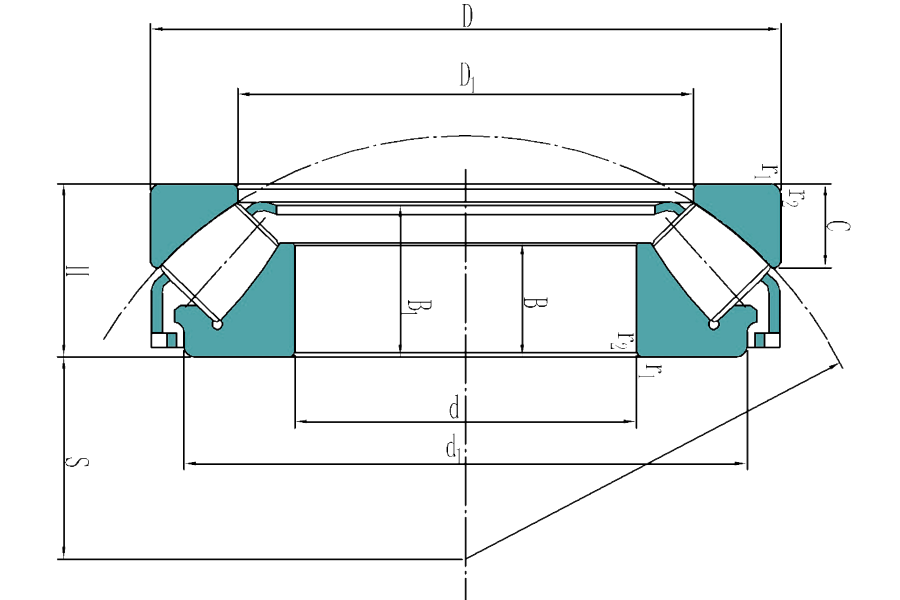

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Material

52100/100Cr6/SUJ2/Stainless Steel

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Inner diameter (d)

60-1100mm

Outer diameter (D)

130-1800mm

Applications

Mainly used in hydroelectric generators, vertical motors, propeller shafts for ships, tower cranes, extruders, etc

| NO. | Product | Product Number | Basic dynamic load rating | Basic static load rating | Bore | Height (H) | Mass | Outer diameter (D) |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

29412 E | 390 KN | 915 KN | 60 mm | 42 mm | 2.6 kg | 130 mm |

| 2 |

|

29413 E | 455 KN | 1080 KN | 65 mm | 45 mm | 3.2 kg | 140 mm |

| 3 |

|

29414 E | 520 KN | 1250 KN | 70 mm | 48 mm | 3.9 kg | 150 mm |

| 4 |

|

29415 E | 600 KN | 1430 KN | 75 mm | 51 mm | 4.7 kg | 160 mm |

| 5 |

|

29416 E | 670 KN | 1630 KN | 80 mm | 54 mm | 5.6 kg | 170 mm |

| 6 |

|

29317 E | 380 KN | 1060 KN | 85 mm | 39 mm | 2.75 kg | 150 mm |

| 7 |

|

29417 E | 735 KN | 1800 KN | 85 mm | 58 mm | 6.75 kg | 180 mm |

| 8 |

|

29318 E | 400 KN | 1080 KN | 90 mm | 39 mm | 2.85 kg | 155 mm |

| 9 |

|

29418 E | 815 KN | 2000 KN | 90 mm | 60 mm | 7.75 kg | 190 mm |

| 10 |

|

29320 E | 465 KN | 1290 KN | 100 mm | 42 mm | 3.65 kg | 170 mm |

| 11 |

|

29420 E | 980 KN | 2500 KN | 100 mm | 67 mm | 10.5 kg | 210 mm |

| 12 |

|

29322 E | 610 KN | 1730 KN | 110 mm | 48 mm | 5.3 kg | 190 mm |

| 13 |

|

29422 E | 1180 KN | 3000 KN | 110 mm | 73 mm | 13.5 kg | 230 mm |

| 14 |

|

29324 E | 765 KN | 2120 KN | 120 mm | 54 mm | 7.35 kg | 210 mm |

| 15 |

|

29424 E | 1370 KN | 3450 KN | 120 mm | 78 mm | 17.5 kg | 250 mm |

| 16 |

|

29326 E | 865 KN | 2500 KN | 130 mm | 58 mm | 9 kg | 225 mm |

| 17 |

|

29426 E | 1560 KN | 4050 KN | 130 mm | 85 mm | 22 kg | 270 mm |

| 18 |

|

29328 E | 980 KN | 2850 KN | 140 mm | 60 mm | 10.5 kg | 240 mm |

| 19 |

|

29428 E | 1630 KN | 4300 KN | 140 mm | 85 mm | 23 kg | 280 mm |

| 20 |

|

29230 E | 408 KN | 1600 KN | 150 mm | 39 mm | 4.3 kg | 215 mm |

| 21 |

|

29330 E | 1000 KN | 2850 KN | 150 mm | 60 mm | 11 kg | 250 mm |

| 22 |

|

29430 E | 1860 KN | 5100 KN | 150 mm | 90 mm | 28 kg | 300 mm |

| 23 |

|

29332 E | 1180 KN | 3450 KN | 160 mm | 67 mm | 14.5 kg | 270 mm |

| 24 |

|

29432 E | 2080 KN | 5600 KN | 160 mm | 95 mm | 32 kg | 320 mm |

| 25 |

|

29334 E | 1200 KN | 3550 KN | 170 mm | 67 mm | 15 kg | 280 mm |

| 26 |

|

29434 E | 2360 KN | 6550 KN | 170 mm | 103 mm | 44.5 kg | 340 mm |

| 27 |

|

29236 E | 495 KN | 2040 KN | 180 mm | 42 mm | 5.8 kg | 250 mm |

| 28 |

|

29336 E | 1430 KN | 4300 KN | 180 mm | 73 mm | 19.5 kg | 300 mm |

| 29 |

|

29436 E | 2600 KN | 7350 KN | 180 mm | 109 mm | 52.5 kg | 360 mm |

| 30 |

|

29338 E | 1630 KN | 4750 KN | 190 mm | 78 mm | 23.5 kg | 320 mm |

| 31 |

|

29438 E | 2850 KN | 8000 KN | 190 mm | 115 mm | 60.5 kg | 380 mm |

| 32 |

|

29240 E | 656 KN | 2650 KN | 200 mm | 48 mm | 9.3 kg | 280 mm |

| 33 |

|

29340 E | 1860 KN | 5500 KN | 200 mm | 85 mm | 28.5 kg | 340 mm |

| 34 |

|

29440 E | 3200 KN | 9000 KN | 200 mm | 122 mm | 72 kg | 400 mm |

| 35 |

|

29244 E | 690 KN | 3000 KN | 220 mm | 48 mm | 10 kg | 300 mm |

| 36 |

|

29344 E | 2000 KN | 6300 KN | 220 mm | 85 mm | 31 kg | 360 mm |

| 37 |

|

29444 E | 3350 KN | 9650 KN | 220 mm | 122 mm | 75 kg | 420 mm |

| 38 |

|

29248 | 799 KN | 3450 KN | 240 mm | 60 mm | 16.5 kg | 340 mm |

| 39 |

|

29348 E | 2040 KN | 6550 KN | 240 mm | 85 mm | 35.5 kg | 380 mm |

| 40 |

|

29448 E | 3400 KN | 10200 KN | 240 mm | 122 mm | 80 kg | 440 mm |

| 41 |

|

29252 | 817 KN | 3650 KN | 260 mm | 60 mm | 18.5 kg | 360 mm |

| 42 |

|

29352 E | 2550 KN | 8300 KN | 260 mm | 95 mm | 49 kg | 420 mm |

| 43 |

|

29452 E | 4050 KN | 12900 KN | 260 mm | 132 mm | 105 kg | 480 mm |

| 44 |

|

29256 | 863 KN | 4000 KN | 280 mm | 60 mm | 19.5 kg | 380 mm |

| 45 |

|

29356 E | 2550 KN | 8650 KN | 280 mm | 95 mm | 53 kg | 440 mm |

| 46 |

|

29456 E | 4900 KN | 15300 KN | 280 mm | 145 mm | 135 kg | 520 mm |

| 47 |

|

29260 | 1070 KN | 4800 KN | 300 mm | 73 mm | 30.5 kg | 420 mm |

| 48 |

|

29360 E | 3100 KN | 10600 KN | 300 mm | 109 mm | 75 kg | 480 mm |

| 49 |

|

29460 E | 5000 KN | 16600 KN | 300 mm | 145 mm | 140 kg | 540 mm |

| 50 |

|

29264 | 1110 KN | 5100 KN | 320 mm | 73 mm | 33 kg | 440 mm |

| 51 |

|

29364 E | 3350 KN | 11200 KN | 320 mm | 109 mm | 78 kg | 500 mm |

| 52 |

|

29464 E | 5700 KN | 19000 KN | 320 mm | 155 mm | 175 kg | 580 mm |

| 53 |

|

29268 | 1130 KN | 5400 KN | 340 mm | 73 mm | 33.5 kg | 460 mm |

| 54 |

|

29368 | 2710 KN | 11000 KN | 340 mm | 122 mm | 105 kg | 540 mm |

| 55 |

|

29468 E | 6700 KN | 22400 KN | 340 mm | 170 mm | 220 kg | 620 mm |

| 56 |

|

29272 | 1460 KN | 6800 KN | 360 mm | 85 mm | 52 kg | 500 mm |

| 57 |

|

29372 | 2760 KN | 11600 KN | 360 mm | 122 mm | 110 kg | 560 mm |

| 58 |

|

29472 EM | 6200 KN | 21200 KN | 360 mm | 170 mm | 230 kg | 640 mm |

| 59 |

|

29276 | 1580 KN | 7650 KN | 380 mm | 85 mm | 53 kg | 520 mm |

| 60 |

|

29376 | 3340 KN | 14000 KN | 380 mm | 132 mm | 140 kg | 600 mm |

| 61 |

|

29476 EM | 6800 KN | 24000 KN | 380 mm | 175 mm | 260 kg | 670 mm |

| 62 |

|

29280 | 1610 KN | 8000 KN | 400 mm | 85 mm | 55.5 kg | 540 mm |

| 63 |

|

29380 | 3450 KN | 14600 KN | 400 mm | 132 mm | 150 kg | 620 mm |

| 64 |

|

29480 EM | 7650 KN | 26500 KN | 400 mm | 185 mm | 310 kg | 710 mm |

| 65 |

|

29284 | 1990 KN | 9800 KN | 420 mm | 95 mm | 75.5 kg | 580 mm |

| 66 |

|

29384 | 3740 KN | 16000 KN | 420 mm | 140 mm | 170 kg | 650 mm |

| 67 |

|

29484 EM | 7800 KN | 27500 KN | 420 mm | 185 mm | 325 kg | 730 mm |

| 68 |

|

29288 | 2070 KN | 10400 KN | 440 mm | 95 mm | 78 kg | 600 mm |

| 69 |

|

29388 EM | 5200 KN | 19300 KN | 440 mm | 145 mm | 180 kg | 680 mm |

| 70 |

|

29488 EM | 9000 KN | 32000 KN | 440 mm | 206 mm | 410 kg | 780 mm |

| 71 |

|

29292 | 2070 KN | 10600 KN | 460 mm | 95 mm | 81 kg | 620 mm |

| 72 |

|

29392 | 4310 KN | 19000 KN | 460 mm | 150 mm | 215 kg | 710 mm |

| 73 |

|

29492 EM | 9300 KN | 33500 KN | 460 mm | 206 mm | 425 kg | 800 mm |

| 74 |

|

29296 | 2350 KN | 11800 KN | 480 mm | 103 mm | 98 kg | 650 mm |

| 75 |

|

29496 EM | 9550 KN | 39000 KN | 480 mm | 224 mm | 550 kg | 850 mm |

| 76 |

|

292/500 | 2390 KN | 12500 KN | 500 mm | 103 mm | 100 kg | 670 mm |

| 77 |

|

293/500 | 4490 KN | 20400 KN | 500 mm | 150 mm | 235 kg | 750 mm |

| 78 |

|

294/500 EM | 9370 KN | 40000 KN | 500 mm | 224 mm | 560 kg | 870 mm |

| 79 |

|

292/530 EM | 3110 KN | 15300 KN | 530 mm | 109 mm | 115 kg | 710 mm |

| 80 |

|

293/530 EM | 5870 KN | 26500 KN | 530 mm | 160 mm | 265 kg | 800 mm |

| 81 |

|

294/530 EM | 10500 KN | 44000 KN | 530 mm | 236 mm | 650 kg | 920 mm |

| 82 |

|

292/560 | 2990 KN | 16000 KN | 560 mm | 115 mm | 140 kg | 750 mm |

| 83 |

|

294/560 EM | 12000 KN | 51000 KN | 560 mm | 250 mm | 810 kg | 980 mm |

| 84 |

|

292/600 EM | 3740 KN | 18600 KN | 600 mm | 122 mm | 170 kg | 800 mm |

| 85 |

|

294/600 EM | 13100 KN | 56000 KN | 600 mm | 258 mm | 845 kg | 1030 mm |

| 86 |

|

292/630 EM | 4770 KN | 23600 KN | 630 mm | 132 mm | 210 kg | 850 mm |

| 87 |

|

293/630 EM | 8450 KN | 38000 KN | 630 mm | 190 mm | 485 kg | 950 mm |

| 88 |

|

294/630 EM | 14400 KN | 62000 KN | 630 mm | 280 mm | 1040 kg | 1090 mm |

| 89 |

|

294/670 EM | 15400 KN | 68000 KN | 670 mm | 290 mm | 1210 kg | 1150 mm |

| 90 |

|

293/710 EM | 9950 KN | 45500 KN | 710 mm | 212 mm | 610 kg | 1060 mm |

| 91 |

|

294/710 EF | 17600 KN | 76500 KN | 710 mm | 308 mm | 1500 kg | 1220 mm |

| 92 |

|

294/750 EF | 18700 KN | 85000 KN | 750 mm | 315 mm | 1650 kg | 1280 mm |

| 93 |

|

292/800 EM | 6560 KN | 34500 KN | 800 mm | 155 mm | 380 kg | 1060 mm |

| 94 |

|

293/800 EM | 11300 KN | 55000 KN | 800 mm | 230 mm | 810 kg | 1180 mm |

| 95 |

|

294/800 EF | 20200 KN | 93000 KN | 800 mm | 335 mm | 2030 kg | 1360 mm |

| 96 |

|

294/850 EF | 23900 KN | 108000 KN | 850 mm | 354 mm | 2390 kg | 1440 mm |

| 97 |

|

294/900 EF | 26700 KN | 122000 KN | 900 mm | 372 mm | 2650 kg | 1520 mm |

| 98 |

|

294/950 EF | 28200 KN | 132000 KN | 950 mm | 390 mm | 3070 kg | 1600 mm |

| 99 |

|

294/1000 EF | 31100 KN | 140000 KN | 1000 mm | 402 mm | 3390 kg | 1670 mm |

| 100 |

|

294/1060 EF | 33400 KN | 156000 KN | 1060 mm | 426 mm | 4280 kg | 1770 mm |

QIBR thrust spherical roller bearings solve several key problems in various fields, which are mainly reflected in the following aspects:

1. High load capacity

Thrust spherical roller bearings can withstand large axial loads. Due to the large contact area of the rollers, the bearings can share a larger axial force, especially suitable for high-load working environments.

2. High rigidity

Due to its structural characteristics and the design of cylindrical rollers, thrust spherical roller bearings have high rigidity. It can effectively reduce axial deformation, provide more stable movement and higher load capacity, suitable for high-precision and high-load applications.

3. Self-aligning roller structure

The bearing uses specially designed rollers inside, which can maintain a proper contact angle during operation, thereby improving the service life and performance of the bearing. Usually, these rollers are spherical rollers, and their contact surfaces form a self-aligning effect between the inner and outer rings of the bearing.

Wide range of applications: This bearing is widely used in mechanical equipment that needs to withstand axial loads and has shaft offset or misalignment.

QIBR thrust spherical roller bearing performance improvement and solutions

1. Improve material selection

High-performance materials: Use high-strength, high-wear-resistant materials to improve the durability of bearings.

High-temperature resistant materials: When working in a high-temperature environment, choosing high-temperature resistant materials can maintain the performance of the bearing and prevent material deformation or failure due to excessive temperature.

2. Optimize roller design

Optimize roller shape: By optimizing the geometry and size of the rollers, the bearing's load capacity and working performance can be improved.

Improve the uniformity of roller spacing: Improve the design of the cage to ensure that the rollers maintain a uniform spacing during operation, thereby improving the uniformity of the load distribution of the bearing and reducing local overload and wear.

Increase the number of rollers: Increasing the number of rollers inside the bearing can further improve the bearing's load capacity, especially for high-load bearing occasions.

3. Improve manufacturing accuracy

Higher bearing manufacturing accuracy: Improve the operating accuracy and stability of the bearing by improving processing accuracy, controlling tolerances and optimizing production processes.

4. Optimize lubrication management

Choose the right lubricant: Choose the right lubricant or grease according to the temperature, load and speed of the working environment to ensure that the bearing maintains proper lubrication during operation and reduces friction and wear.

Regular lubrication and maintenance: Check the lubrication status regularly, replace the lubricant or grease in time, avoid lubricant deterioration or contamination, and ensure long-term stable operation of the bearing.

Main application areas of QIBR thrust spherical roller bearings

1. Mining and metallurgical industries

Mining equipment: Various heavy machinery used in the mining process, such as crushers, screening machines, etc., usually require thrust spherical roller bearings to withstand the huge axial loads and impact loads generated during the operation of the equipment.

Metallurgical equipment: High-load parts of equipment such as steel smelting are often equipped with thrust spherical roller bearings to ensure the stable operation of the equipment.

2. Ship industry

Ship propulsion system: Thrust spherical roller bearings are used in ship propellers, steering gears and other parts. They can withstand the axial forces generated by the propulsion system and steering gear, and maintain stable operation.

Ship steering gear: Since the steering gear needs to withstand a large axial load, the thrust spherical roller bearing can ensure its normal operation and provide the necessary aligning function.

3. Hydroelectric generator sets

Thrust spherical roller bearings are widely used in the rotor components of hydroelectric generator sets to withstand the axial loads generated by the generator sets during operation.

4. Metallurgy, mining, oil field and other equipment

Thrust spherical roller bearings are often used in oil field drilling rigs, smelting equipment and other machinery to withstand heavy loads and stresses.