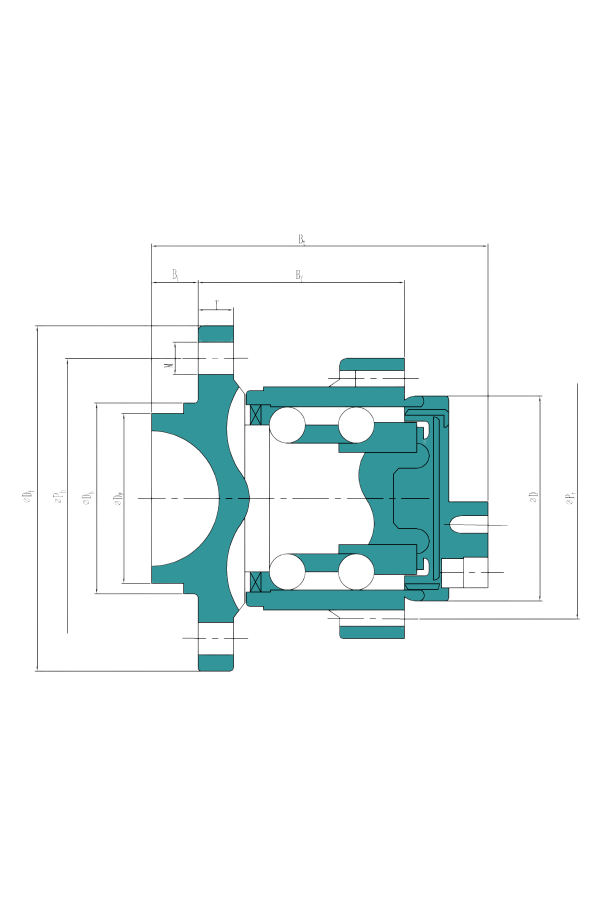

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh,DIN / VDEh

Inner diameter (d)

24.75mm-30mm

Outer diameter (Df)

121mm-152mm

Mass

1.45kg-5.9kg

Material

GCr15, 52100, 100Cr6, SUJ2

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

Automobile wheels

| NO. | Product | Product Number | Inner diameter (d) | Mass | Outer diameter (Df) | Width (Bt) |

|---|---|---|---|---|---|---|

| 1 |

|

ZA-56BWKH18B-Y--01 E | 24.75 mm | 2.207 kg | 121 mm | 82.2 mm |

| 2 |

|

ZA-57BWKH04D1-Y-01 E | 28.6 mm | 2.79 kg | 136.5 mm | 84 mm |

| 3 |

|

ZA-57BWKH04E2-Y-01 E | 28.6 mm | 2.799 kg | 136.5 mm | 84 mm |

| 4 |

|

ZA-60BWKH07R3-Y-01 E | 28.6 mm | 3.08 kg | 138.5 mm | 84 mm |

| 5 |

|

ZA-60BWKH15A-Y--01 E | 28.6 mm | 3.08 kg | 136.5 mm | 84 mm |

| 6 |

|

ZA-62BWKH01A1-Y-01 E | 26 mm | 2.75 kg | 137.5 mm | 70 mm |

| 7 |

|

ZA-62BWKH01E-Y--01 E | 26 mm | 2.77 kg | 137.5 mm | 70 mm |

| 8 |

|

ZA-55BWKH12U-Y-5CP01 | 25 mm | 3.37 kg | 124 mm | 95.3 mm |

| 9 |

|

ZA-58BWKH06E2-JB--01 | 25 mm | 2.94 kg | 143 mm | 88 mm |

| 10 |

|

ZA-58BWKH17B-Y-5CP01 | 26 mm | 2.8 kg | 152 mm | 82.5 mm |

| 11 |

|

ZA-62BWKH10D-Y-5CP01 | 26 mm | 1.45 kg | 139 mm | 76.5 mm |

| 12 |

|

ZA-/HO/62BWKH25B-Y01 | 25 mm | 2.83 kg | 122 mm | 74 mm |

| 13 |

|

ZA-/HO/62BWKH26D-Y01 | 25 mm | 3 kg | 122 mm | 74 mm |

| 14 |

|

ZA-/HO/62BWKH27-Y-01 | 25 mm | 3 kg | 136 mm | 74 mm |

| 15 |

|

ZA-/HO/63BWKH02A-Y01 | 30 mm | 2.72kg | 136 mm | 75.3 mm |

| 16 |

|

ZA-56BWKH05D-Y--01 E | - | 4.94 kg | 128 mm | 151.3 mm |

| 17 |

|

ZA-56BWKH06J-Y--01 E | - | 5.9 kg | 128 mm | 153.6 mm |

| 18 |

|

ZA-44BWKH14U3-Y-5C01 | - | 2.5 kg | 123 mm | 106.4 mm |

| 19 |

|

ZA-/HO/44BWKH41B-Y01 | - | 2.54 kg | 134 mm | 109.7 mm |

| 20 |

|

ZA-/HO/44BWKH42B-Y01 | - | 2.76 kg | 148 mm | 110.2 mm |

| 21 |

|

ZA-/HO/44BWKH43-Y-01 | - | 2.63 kg | 148 mm | 100.4 mm |

| 22 |

|

ZA-49BWKH22A-Y--01 E | - | 2.83 kg | 137.5 mm | 87.8 mm |

| 23 |

|

ZA-49BWKH22B-Y--01 E | - | 2.8 kg | 137.5 mm | 87.8 mm |

| 24 |

|

ZA-49BWKH23M-Y-5CP01 | - | 3.3 kg | 143 mm | 88 mm |

| 25 |

|

ZA-/HO/53BWKH20B-Y01 | - | 3.3 kg | 148 mm | 104.3 mm |

| 26 |

|

ZA-57BWKH02E-Y-5CP01 | - | 3.54 kg | 152 mm | 86.9 mm |

| 27 |

|

ZA-64BWKH15N-Y-5CP01 | - | 3.41 kg | 152 mm | 87.3 mm |

| 28 |

|

ZA-/HO/66BWKH26J-Y01 | - | 3.75 kg | 136 mm | 93.2 mm |

| 29 |

|

ZA-/HO/66BWKH27A-Y01 | - | 3.58 kg | 136 mm | 87.4 mm |

| 30 |

|

ZA-/HO/66BWKH28A-Y01 | - | 3.3 kg | 136 mm | 93.7 mm |

Features and advantages of third-generation hub bearings:

A higher degree of integration: The third-generation hub bearing adopts a more integrated design, featuring inner and outer flanges. The inner flange is bolted to the drive shaft, while the outer flange mounts the entire bearing assembly. This integrated design effectively simplifies the structure, reduces the number of components, lowers costs, and improves the overall stability and reliability of the system.

Enhanced durability and lifespan: The third-generation hub bearing has been further optimized regarding materials and design. It uses high-strength, wear-resistant materials such as high-performance steel and ceramic composites to enhance durability and fatigue resistance. These bearings generally have a much longer service life than the previous generations. They can handle more demanding driving environments (e.g., high temperatures, humidity, dust) and reduce the frequency of maintenance and replacement.

Reduced friction and noise:

The design of the third-generation hub bearing emphasizes reducing friction and suppressing noise. Third-generation hub bearings produce less friction and noise during operation by optimizing the lubrication system and improving the contact surfaces and precision of the bearings. This further enhances driving comfort, especially during high-speed or long-distance driving.

Environmental friendliness and energy efficiency: With increasingly stringent environmental regulations, third-generation hub bearings focus more on eco-friendliness in material selection and manufacturing processes. Many third-generation bearings use non-toxic and harmless lubricants, reducing environmental pollution. The optimized bearings design also helps minimize energy loss, improving fuel economy or battery range for vehicles (particularly in electric vehicles).

Versatility and modularity:

The design of third-generation hub bearings increasingly emphasizes versatility and modularity, enabling compatibility with various types of vehicles (such as gasoline, electric, and hybrid vehicles). Moreover, as vehicle technologies continue to evolve, third-generation hub bearings can adapt flexibly to different drive systems, suspension systems, and wheel size changes, showcasing strong adaptability.

Applications:

Electric vehicles:

With the rise of electric vehicles, third-generation hub bearings are particularly suitable for this segment due to their low friction and long lifespan, which help enhance range and driving performance.

High-performance vehicles:

In high-performance cars, supercars, or racing vehicles, where demands for hub bearings are more stringent, the high precision, low friction, and high-temperature resistance of third-generation hub bearings make them widely used in this field.

Development trends:

The third-generation hub bearing represents the forefront of modern automotive technology. Its main characteristics include higher integration, intelligence, low friction, low noise, long-term durability, and eco-friendliness. With technological advancements and the trend toward smart vehicles, third-generation hub bearings will play a vital role in the future automotive industry, enhancing driving experiences, reducing energy loss, and improving vehicle safety and comfort.