Image may differ from product. See technical specification for details.

Search for the bearing model you need

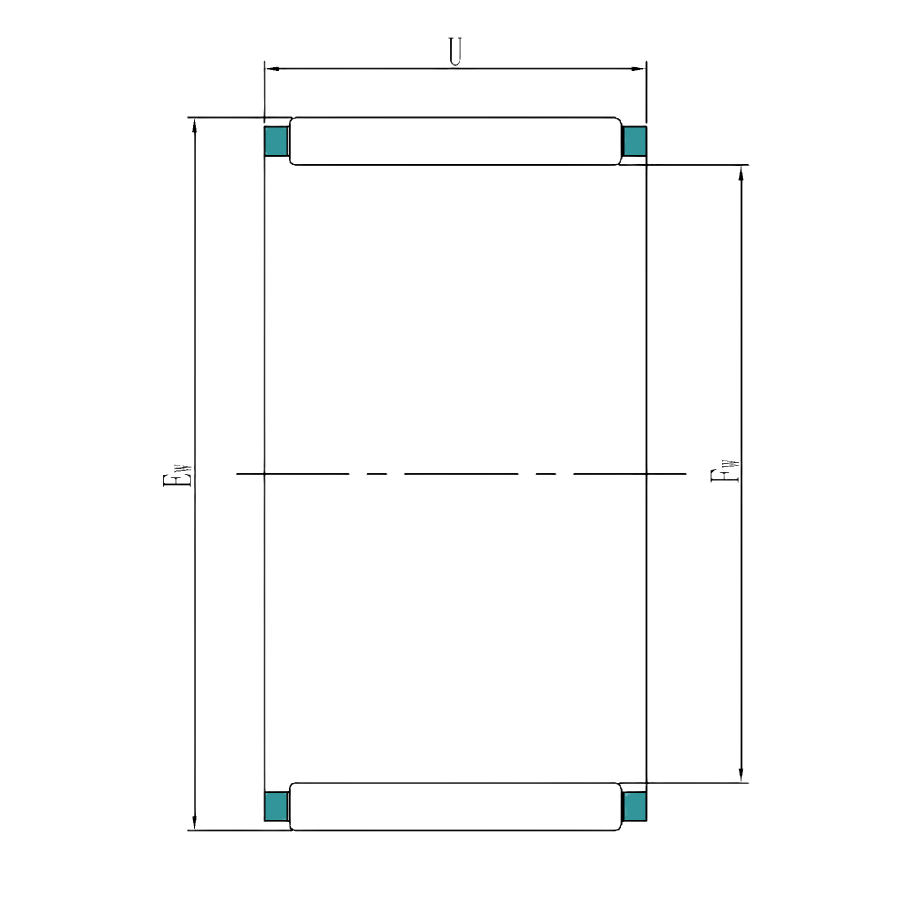

| NO. | Product | Product Number | Basic dynamic load rating | Basic static load rating | Diameter under rollers (Fw) | Fatigue load limit (Pu) | Mass | Outside diameter of needle roller complement (Ew) |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

K 3x5x7 TN | 1.51 KN | 1.34 KN | 3 mm | 0.134 KN | 0.0003 kg | 5 mm |

| 2 |

|

K 3x5x9 TN | 1.68 KN | 1.53 KN | 3 mm | 0.153 KN | 0.0004 kg | 5 mm |

| 3 |

|

K 4x7x7 TN | 1.72 KN | 1.32 KN | 4 mm | 0.137 KN | 0.0005 kg | 7 mm |

| 4 |

|

K 4x7x10 TN | 2.29 KN | 1.9 KN | 4 mm | 0.204 KN | 0.0007 kg | 7 mm |

| 5 |

|

K 5x8x8 TN | 2.29 KN | 2 KN | 5 mm | 0.212 KN | 0.0007 kg | 8 mm |

| 6 |

|

K 5x8x10 TN | 2.92 KN | 2.7 KN | 5 mm | 0.29 KN | 0.0009 kg | 8 mm |

| 7 |

|

K 6x9x8 TN | 2.55 KN | 2.36 KN | 6 mm | 0.25 KN | 0.0008 kg | 9 mm |

| 8 |

|

K 6x9x10 TN | 3.3 KN | 3.2 KN | 6 mm | 0.345 KN | 0.0011 kg | 9 mm |

| 9 |

|

K 7x10x8 TN | 2.81 KN | 2.75 KN | 7 mm | 0.29 KN | 0.0009 kg | 10 mm |

| 10 |

|

K 7x10x10 TN | 3.58 KN | 3.75 KN | 7 mm | 0.415 KN | 0.001 kg | 10 mm |

| 11 |

|

K 8x11x10 TN | 3.8 KN | 4.25 KN | 8 mm | 0.465 KN | 0.0012 kg | 11 mm |

| 12 |

|

K 8x11x13 TN | 5.01 KN | 5.85 KN | 8 mm | 0.67 KN | 0.0017 kg | 11 mm |

| 13 |

|

K 8x12x10 TN | 4.84 KN | 4.75 KN | 8 mm | 0.54 KN | 0.002 kg | 12 mm |

| 14 |

|

K 9x12x10 TN | 4.4 KN | 5.2 KN | 9 mm | 0.57 KN | 0.0015 kg | 12 mm |

| 15 |

|

K 10x13x10 TN | 4.57 KN | 5.7 KN | 10 mm | 0.63 KN | 0.0016 kg | 13 mm |

| 16 |

|

K 10x13x13 TN | 5.94 KN | 8 KN | 10 mm | 0.9 KN | 0.0023 kg | 13 mm |

| 17 |

|

K 10x14x10 TN | 5.61 KN | 6.1 KN | 10 mm | 0.695 KN | 0.0025 kg | 14 mm |

| 18 |

|

K 10x14x13 TN | 7.21 KN | 8.5 KN | 10 mm | 0.98 KN | 0.0046 kg | 14 mm |

| 19 |

|

K 10x16x12 TN | 7.65 KN | 7.2 KN | 10 mm | 0.85 KN | 0.0055 kg | 16 mm |

| 20 |

|

K 12x15x10 TN | 4.73 KN | 6.2 KN | 12 mm | 0.695 KN | 0.0029 kg | 15 mm |

| 21 |

|

K 12x15x13 TN | 6.16 KN | 8.65 KN | 12 mm | 0.98 KN | 0.0023 kg | 15 mm |

| 22 |

|

K 12x16x13 TN | 7.65 KN | 9.5 KN | 12 mm | 1.1 KN | 0.0036 kg | 16 mm |

| 23 |

|

K 12x17x13 TN | 9.13 KN | 10.4 KN | 12 mm | 1.22 KN | 0.0049 kg | 17 mm |

| 24 |

|

K 12x18x12 TN | 9.52 KN | 10 KN | 12 mm | 1.18 KN | 0.006 kg | 18 mm |

| 25 |

|

K 14x18x10 | 6.93 KN | 8.65 KN | 14 mm | 1 KN | 0.004 kg | 18 mm |

| 26 |

|

K 14x18x13 | 7.92 KN | 10.2 KN | 14 mm | 1.18 KN | 0.0065 kg | 18 mm |

| 27 |

|

K 14x18x15 TN | 9.13 KN | 12.5 KN | 14 mm | 1.46 KN | 0.005 kg | 18 mm |

| 28 |

|

K 14x18x17 | 10.5 KN | 14.6 KN | 14 mm | 1.7 KN | 0.008 kg | 18 mm |

| 29 |

|

K 15x19x13 | 8.25 KN | 11.2 KN | 15 mm | 1.29 KN | 0.007 kg | 19 mm |

| 30 |

|

K 15x19x17 | 10.8 KN | 15.6 KN | 15 mm | 1.86 KN | 0.0095 kg | 19 mm |

| 31 |

|

K 15x21x15 | 13.8 KN | 16.3 KN | 15 mm | 2 KN | 0.011 kg | 21 mm |

| 32 |

|

K 15x21x21 | 18.7 KN | 24.5 KN | 15 mm | 3 KN | 0.017 kg | 21 mm |

| 33 |

|

K 16x20x10 | 7.48 KN | 10 KN | 16 mm | 1.16 KN | 0.0055 kg | 20 mm |

| 34 |

|

K 16x20x13 | 8.58 KN | 12 KN | 16 mm | 1.37 KN | 0.0075 kg | 20 mm |

| 35 |

|

K 16x20x17 | 11.2 KN | 17 KN | 16 mm | 2 KN | 0.010 kg | 20 mm |

| 36 |

|

K 16x22x12 | 11 KN | 12.5 KN | 16 mm | 1.5 KN | 0.010 kg | 22 mm |

| 37 |

|

K 16x22x16 | 14.2 KN | 17.6 KN | 16 mm | 2.12 KN | 0.012 kg | 22 mm |

| 38 |

|

K 16x22x20 | 17.6 KN | 22.8 KN | 16 mm | 2.8 KN | 0.017 kg | 22 mm |

| 39 |

|

K 16x24x20 | 20.5 KN | 23.6 KN | 16 mm | 2.9 KN | 0.022 kg | 24 mm |

| 40 |

|

K 17x21x10 | 7.81 KN | 10.8 KN | 17 mm | 1.22 KN | 0.0055 kg | 21 mm |

| 41 |

|

K 18x24x12 | 12.1 KN | 15 KN | 18 mm | 1.8 KN | 0.012 kg | 24 mm |

| 42 |

|

K 19x23x13 | 9.13 KN | 13.7 KN | 19 mm | 1.6 KN | 0.008 kg | 23 mm |

| 43 |

|

K 20x24x10 | 8.58 KN | 12.9 KN | 20 mm | 1.46 KN | 0.0065 kg | 24 mm |

| 44 |

|

K 20x24x13 | 9.52 KN | 14.6 KN | 20 mm | 1.66 KN | 0.009 kg | 24 mm |

| 45 |

|

K 20x24x17 | 12.5 KN | 20.8 KN | 20 mm | 2.4 KN | 0.012 kg | 24 mm |

| 46 |

|

K 20x26x17 | 18.3 KN | 26 KN | 20 mm | 3.2 KN | 0.016 kg | 26 mm |

| 47 |

|

K 20x26x20 | 20.1 KN | 29 KN | 20 mm | 3.6 KN | 0.019 kg | 26 mm |

| 48 |

|

K 20x28x20 | 22.9 KN | 28.5 KN | 20 mm | 3.45 KN | 0.027 kg | 28 mm |

| 49 |

|

K 20x28x25 | 29.2 KN | 39 KN | 20 mm | 4.9 KN | 0.032 kg | 28 mm |

| 50 |

|

K 20x30x30 | 34.1 KN | 41.5 KN | 20 mm | 5.2 KN | 0.049 kg | 30 mm |

| 51 |

|

K 21x25x13 | 9.68 KN | 15.3 KN | 21 mm | 1.76 KN | 0.009 kg | 25 mm |

| 52 |

|

K 22x26x10 | 8.8 KN | 13.7 KN | 22 mm | 1.56 KN | 0.0075 kg | 26 mm |

| 53 |

|

K 22x26x13 | 10.1 KN | 16.3 KN | 22 mm | 1.86 KN | 0.0095 kg | 26 mm |

| 54 |

|

K 22x26x17 | 13.2 KN | 22.8 KN | 22 mm | 2.7 KN | 0.012 kg | 26 mm |

| 55 |

|

K 22x28x17 | 18.3 KN | 27 KN | 22 mm | 3.25 KN | 0.018 kg | 28 mm |

| 56 |

|

K 22x29x16 | 19.4 KN | 25.5 KN | 22 mm | 3.05 KN | 0.016 kg | 29 mm |

| 57 |

|

K 22x30x15 TN | 19 KN | 23.6 KN | 22 mm | 2.8 KN | 0.018 kg | 30 mm |

| 58 |

|

K 23x35x16 TN | 24.2 KN | 23.2 KN | 23 mm | 2.9 KN | 0.029 kg | 35 mm |

| 59 |

|

K 24x28x10 | 9.35 KN | 15 KN | 24 mm | 1.73 KN | 0.0085 kg | 28 mm |

| 60 |

|

K 24x28x13 | 10.6 KN | 18 KN | 24 mm | 2.08 KN | 0.010 kg | 28 mm |

| 61 |

|

K 24x30x17 | 18.7 KN | 27.5 KN | 24 mm | 3.4 KN | 0.019 kg | 30 mm |

| 62 |

|

K 25x29x10 | 9.52 KN | 15.6 KN | 25 mm | 1.8 KN | 0.0085 kg | 29 mm |

| 63 |

|

K 25x29x13 | 10.8 KN | 18.6 KN | 25 mm | 2.16 KN | 0.011 kg | 29 mm |

| 64 |

|

K 25x30x17 | 17.9 KN | 30.5 KN | 25 mm | 3.6 KN | 0.016 kg | 30 mm |

| 65 |

|

K 25x30x20 | 20.9 KN | 36.5 KN | 25 mm | 4.4 KN | 0.018 kg | 30 mm |

| 66 |

|

K 25x32x16 | 19.8 KN | 27.5 KN | 25 mm | 3.35 KN | 0.021 kg | 32 mm |

| 67 |

|

K 25x33x20 | 27.5 KN | 38 KN | 25 mm | 4.65 KN | 0.033 kg | 33 mm |

| 68 |

|

K 25x35x30 | 44.6 KN | 62 KN | 25 mm | 7.8 KN | 0.065 kg | 35 mm |

| 69 |

|

K 26x30x13 | 11.2 KN | 19.6 KN | 26 mm | 2.28 KN | 0.011 kg | 30 mm |

| 70 |

|

K 28x33x13 | 14.7 KN | 24.5 KN | 28 mm | 2.85 KN | 0.013 kg | 33 mm |

| 71 |

|

K 28x33x17 | 19 KN | 33.5 KN | 28 mm | 4.05 KN | 0.017 kg | 33 mm |

| 72 |

|

K 30x35x13 | 15.1 KN | 25.5 KN | 30 mm | 3 KN | 0.014 kg | 35 mm |

| 73 |

|

K 30x35x17 | 18.7 KN | 34 KN | 30 mm | 4.05 KN | 0.019 kg | 35 mm |

| 74 |

|

K 30x35x27 | 29.2 KN | 60 KN | 30 mm | 7.35 KN | 0.030 kg | 35 mm |

| 75 |

|

K 30x37x18 | 25.1 KN | 39 KN | 30 mm | 4.65 KN | 0.030 kg | 37 mm |

| 76 |

|

K 30x40x30 | 46.8 KN | 69.5 KN | 30 mm | 8.65 KN | 0.073 kg | 40 mm |

| 77 |

|

K 32x37x13 | 14.7 KN | 25.5 KN | 32 mm | 3 KN | 0.018 kg | 37 mm |

| 78 |

|

K 32x37x17 | 19 KN | 35.5 KN | 32 mm | 4.25 KN | 0.019 kg | 37 mm |

| 79 |

|

K 32x38x20 | 25.1 KN | 45 KN | 32 mm | 5.6 KN | 0.030 kg | 38 mm |

| 80 |

|

K 32x40x25 | 35.8 KN | 58.5 KN | 32 mm | 7.2 KN | 0.049 kg | 40 mm |

| 81 |

|

K 35x40x13 | 15.4 KN | 28 KN | 35 mm | 3.25 KN | 0.019 kg | 40 mm |

| 82 |

|

K 35x40x17 | 19.8 KN | 39 KN | 35 mm | 4.65 KN | 0.021 kg | 40 mm |

| 83 |

|

K 35x40x27 TN | 23.8 KN | 49 KN | 35 mm | 6 KN | 0.039 kg | 40 mm |

| 84 |

|

K 35x42x16 | 23.3 KN | 37.5 KN | 35 mm | 4.5 KN | 0.034 kg | 42 mm |

| 85 |

|

K 35x42x18 | 26.4 KN | 44 KN | 35 mm | 5.3 KN | 0.034 kg | 42 mm |

| 86 |

|

K 35x45x20 | 35.2 KN | 50 KN | 35 mm | 6.2 KN | 0.056 kg | 45 mm |

| 87 |

|

K 37x42x17 | 21.6 KN | 43 KN | 37 mm | 5.2 KN | 0.022 kg | 42 mm |

| 88 |

|

K 38x43x17 | 19.8 KN | 39 KN | 38 mm | 4.65 KN | 0.029 kg | 43 mm |

| 89 |

|

K 38x46x32 | 52.3 KN | 100 KN | 38 mm | 12.5 KN | 0.076 kg | 46 mm |

| 90 |

|

K 40x45x17 | 20.5 KN | 41.5 KN | 40 mm | 5 KN | 0.031 kg | 45 mm |

| 91 |

|

K 40x45x27 | 31.4 KN | 73.5 KN | 40 mm | 9 KN | 0.046 kg | 45 mm |

| 92 |

|

K 40x48x20 | 37.4 KN | 58.5 KN | 40 mm | 7.35 KN | 0.049 kg | 48 mm |

| 93 |

|

K 42x47x17 | 20.9 KN | 43 KN | 42 mm | 5.2 KN | 0.032 kg | 47 mm |

| 94 |

|

K 42x50x20 | 33.6 KN | 57 KN | 42 mm | 7.1 KN | 0.053 kg | 50 mm |

| 95 |

|

K 43x48x17 | 20.9 KN | 43 KN | 43 mm | 5.2 KN | 0.030 kg | 48 mm |

| 96 |

|

K 45x50x17 | 21.6 KN | 46.5 KN | 45 mm | 5.6 KN | 0.034 kg | 50 mm |

| 97 |

|

K 45x50x27 | 33 KN | 81.5 KN | 45 mm | 10 KN | 0.052 kg | 50 mm |

| 98 |

|

K 45x53x28 | 49.5 KN | 98 KN | 45 mm | 12.2 KN | 0.081 kg | 53 mm |

| 99 |

|

K 47x52x17 | 22.4 KN | 49 KN | 47mm | 6 KN | 0.035 kg | 52 mm |

| 100 |

|

K 50x55x20 | 25.5 KN | 60 KN | 50 mm | 7.2 KN | 0.043 kg | 55 mm |

Features and advantages of QIBR needle roller and cage assemblies

QIBR needle roller and cage assemblies address several critical issues in diverse fields, mainly in the following areas:

1. Compact structure

Using needle rollers as rolling elements allows these bearings to handle large radial loads while being relatively small in size, making them suitable for installation in limited spaces, particularly in compact mechanical designs.

2. Low friction and high efficiency

Thanks to the precise design between the needle rollers and the cage, these bearings exhibit low friction losses, reducing heat generation and improving operational efficiency. This makes them suitable for high-speed and high-efficiency environments.

3. High durability

The cage stabilizes the position of the needle rollers, reducing contact and wear among them, thereby extending the bearing's lifespan. Proper clearance and precision design ensure stability and reliability during operation.

4. Low noise and vibration

The rational structure between the needle rollers and the cage minimizes contact among the rollers, reducing noise and vibration, and making them ideal for environments requiring low noise levels.

5. Adaptability to high-speed applications

With small needle roller shapes and reduced contact area, these bearings are well-suited for high-speed applications, effectively preventing excessive friction and overheating at high speeds.

Performance improvements and solutions for QIBR needle roller and cage assemblies

1. Improved materials

High-performance material selection: Using materials with greater hardness, wear resistance, and corrosion resistance can significantly enhance bearing durability and stability.

2. Optimized cage design

Structural optimization: Enhancing the cage structure to achieve better needle roller arrangement and uniform load distribution. Optimizing the cage reduces needle roller collisions, improving operational stability and efficiency.

Reduced contact area: By refining the cage geometry and needle roller arrangement, contact areas among rollers are minimized, reducing friction and wear.

3. Enhanced lubrication performance

Efficient lubricants: Employing greases or oils suited for high-temperature and high-pressure environments ensures consistent lubricant performance during extended operations, reducing friction and improving durability.

4. Increased precision

Precision machining: Enhancing manufacturing accuracy minimizes errors between bearing components, ensuring more uniform and stable contact between needle rollers and the cage. This improves performance, extends lifespan, and reduces noise and vibration.

Main application areas of QIBR needle roller and cage assemblies

1. Transmissions

Needle roller and cage assemblies are commonly used between the gears and shafts inside transmissions to enhance transmission efficiency and reduce overall size.

2. Industrial machinery

Gearboxes and Transmission Systems: Widely used in gearboxes and gear-driven systems, these bearings can handle large radial loads, reduce space usage, and improve transmission efficiency.

Automation Equipment: In automated production lines, QIBR needle roller and cage assemblies support rotating components, ensuring the precision and stability of the equipment.

3. Aviation engines

Turbo Shafts and Rotating Components: In aviation engines, QIBR needle roller and cage assemblies are used in turboshafts, turbines, and other rotating components to ensure smooth operation at high speeds while handling radial loads generated by high-speed rotation.

4. Household appliances

Home Appliances: QIBR needle roller and cage assemblies are widely used in products such as washing machines, electric fans, power tools, and motors, providing high efficiency and stability while reducing space requirements.