Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Material

52100、100Cr6、SUJ2、Stainless Steel

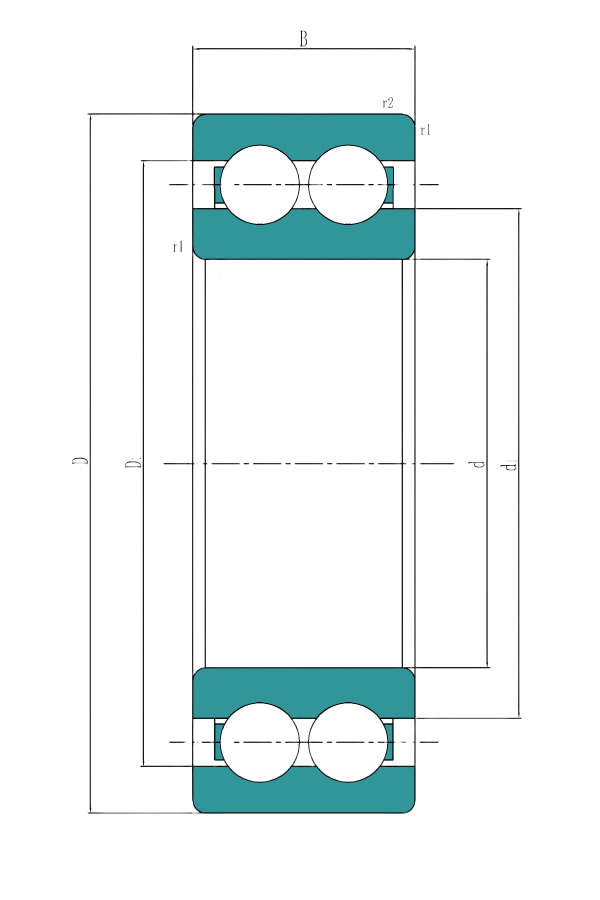

Inner ring diameter

10mm-90mm

Outer ring diameter

30mm-160mm

Weight

0.049kg-302kg

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

Machine tool spindle, centrifuge, booster pump, oil pump, blower, various gearboxes, laboratory equipment

| NO. | Product | Product Number | Basic dynamic load rating | Basic static load rating | Inner diameter (d) | Mass | Outer diameter (D) | Width (B) |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

4200 ATN9 | 9.23 KN | 5.2 KN | 10 mm | 0.049 kg | 30 mm | 14 mm |

| 2 |

|

4201 ATN9 | 10.6 KN | 6.2 KN | 12 mm | 0.052 kg | 32 mm | 14 mm |

| 3 |

|

4301 ATN9 | 13 KN | 7.8 KN | 12 mm | 0.092 kg | 37 mm | 17 mm |

| 4 |

|

4202 ATN9 | 11.9 K | 7.5 KN | 15 mm | 0.059 kg | 35 mm | 14 mm |

| 5 |

|

4302 ATN9 | 14.8 KN | 9.5 KN | 15 mm | 0.12 kg | 42 mm | 17 mm |

| 6 |

|

4203 ATN9 | 14.8 KN | 9.5 KN | 17 mm | 0.09 kg | 40 mm | 16 mm |

| 7 |

|

4303 ATN9 | 19.5 KN | 13.2 KN | 17 mm | 0.16 kg | 47 mm | 19 mm |

| 8 |

|

4204 ATN9 | 17.8 KN | 12.5 KN | 20 mm | 0.14 kg | 47 mm | 18 mm |

| 9 |

|

4304 ATN9 | 23.4 KN | 16 KN | 20 mm | 0.21 kg | 52 mm | 21 mm |

| 10 |

|

4205 ATN9 | 19 KN | 14.6 KN | 25 mm | 0.17 kg | 52 mm | 18 mm |

| 11 |

|

4305 ATN9 | 31.9 KN | 22.4 KN | 25 mm | 0.34 kg | 62 mm | 24 mm |

| 12 |

|

4206 ATN9 | 26 KN | 20.8 KN | 30 mm | 0.29 kg | 62 mm | 20 mm |

| 13 |

|

4306 ATN9 | 41 KN | 30 KN | 30 mm | 0.5 kg | 72 mm | 27 mm |

| 14 |

|

4207 ATN9 | 35.1 KN | 28.5 KN | 35 mm | 0.4 kg | 72 mm | 23 mm |

| 15 |

|

4307 ATN9 | 50.7 KN | 38 KN | 35 mm | 0.68 kg | 80 mm | 31 mm |

| 16 |

|

4208 ATN9 | 37.1 KN | 32.5 KN | 40 mm | 0.5 kg | 80 mm | 23 mm |

| 17 |

|

4308 ATN9 | 55.9 KN | 45 KN | 40 mm | 0.95 kg | 90 mm | 33 mm |

| 18 |

|

4209 ATN9 | 29 KN | 36 KN | 45 mm | 0.54 kg | 85 mm | 23 mm |

| 19 |

|

4309 ATN9 | 68.9 KN | 56 KN | 45 mm | 1.25 kg | 100 mm | 36 mm |

| 20 |

|

4210 ATN9 | 41 KN | 40 KN | 50 mm | 0.58 kg | 90 mm | 23 mm |

| 21 |

|

4211 ATN9 | 44.9 KN | 44 KN | 55 mm | 0.8 kg | 100 mm | 25 mm |

| 22 |

|

4310 ATN9 | 81.9 KN | 69.5 KN | 50 mm | 1.7 kg | 110 mm | 40 mm |

| 23 |

|

4311 ATN9 | 97.5 KN | 83 KN | 55 mm | 2.15 kg | 120 mm | 43 mm |

| 24 |

|

4212 ATN9 | 57.2 KN | 55 KN | 60 mm | 1.1 kg | 110 mm | 28 mm |

| 25 |

|

4312 ATN9 | 112 KN | 98 KN | 60 mm | 2.65 kg | 130 mm | 46 mm |

| 26 |

|

4213 ATN9 | 67.6 KN | 67 KN | 65 mm | 1.45 kg | 120 mm | 31 mm |

| 27 |

|

4313 ATN9 | 121 KN | 106 KN | 65 mm | 3.25 kg | 140 mm | 48 mm |

| 28 |

|

4214 ATN9 | 70.2 KN | 73.5 KN | 70 mm | 1.5 kg | 125 mm | 31 mm |

| 29 |

|

4215 ATN9 | 72.8 KN | 80 KN | 75 mm | 1.6 kg | 130 mm | 31 mm |

| 30 |

|

4315 ATN9 | 156 KN | 143 KN | 75 mm | 4.8 kg | 160 mm | 55 mm |

| 31 |

|

4216 ATN9 | 80.6 KN | 90 KN | 80 mm | 2 kg | 140 mm | 33 mm |

| 32 |

|

4217 ATN9 | 93.6 KN | 102 KN | 85 mm | 2.55 kg | 150 mm | 36 mm |

| 33 |

|

4218 ATN9 | 112 KN | 122 KN | 90 mm | 3.2 kg | 160 mm | 40 mm |

Features and advantages of QIBR double row deep groove ball bearings

QIBR double row deep groove ball bearings are engineered to address critical operational demands in various industrial fields, offering the following key advantages:

1. Enhanced radial load capacity

QIBR double row deep groove ball bearings can support higher radial loads compared to single row bearings. This increased capacity makes them suitable for applications requiring greater durability.

2. High axial load capacity

With two rows of rolling elements, these bearings can also handle significant axial loads. This makes them ideal for working environments where large axial forces are present.

3. Long service life

QIBR double row deep groove ball bearings have a low coefficient of friction, resulting in reduced energy loss and wear. This allows them to maintain stable performance over extended periods.

4. Compact and efficient design

Although similar in size to single row deep groove ball bearings, the double row design provides greater load-carrying capacity. By incorporating two rows of rolling elements within the same outer diameter, the bearings achieve improved durability and performance. This compact structure makes them suitable for applications where space is limited but high load capacity is required.

Performance enhancements for QIBR double row deep groove ball bearings

1. Lubrication optimization

Advanced lubricants, such as synthetic or nano-lubricants, can reduce wear and friction, enhancing overall efficiency and durability. Proper application techniques further ensure optimal performance.

2. Raceway optimization

Precision machining of the raceway geometry, along with improved surface finish, minimizes frictional losses and enhances operational efficiency.

3. Enhanced rolling elements

Utilizing high-precision rolling elements, such as ceramic balls, improves surface hardness and reduces wear, resulting in superior performance under demanding conditions.

4. Corrosion resistance

For applications in aggressive environments, materials such as stainless steel, corrosion-resistant coatings, or surface treatment technologies can significantly improve durability.

Primary application fields of QIBR double row deep groove ball bearings

1. Electric motors

These bearings are widely used in electric motors, particularly in industrial motors that must withstand heavy loads. Their durability and efficiency make them essential for rotor and stator components.

2. Automotive industry

In the automotive sector, QIBR double row deep groove ball bearings handle substantial radial and axial loads. They play vital roles in components such as wheel bearings, drive shafts, and clutches. Their load capacity and wear resistance ensure stable performance in high-stress automotive environments.

3. Agricultural machinery

Agricultural equipment often operates under heavy and complex loads, especially in harsh conditions. QIBR double row deep groove ball bearings, with their high load capacity and durability, are frequently used in such machinery.

4. Factory equipment

These bearings are key components in automated production lines, conveyor systems, and packaging machinery. Their high load capacity and wear resistance make them ideal for high-efficiency, continuous-operation environments.