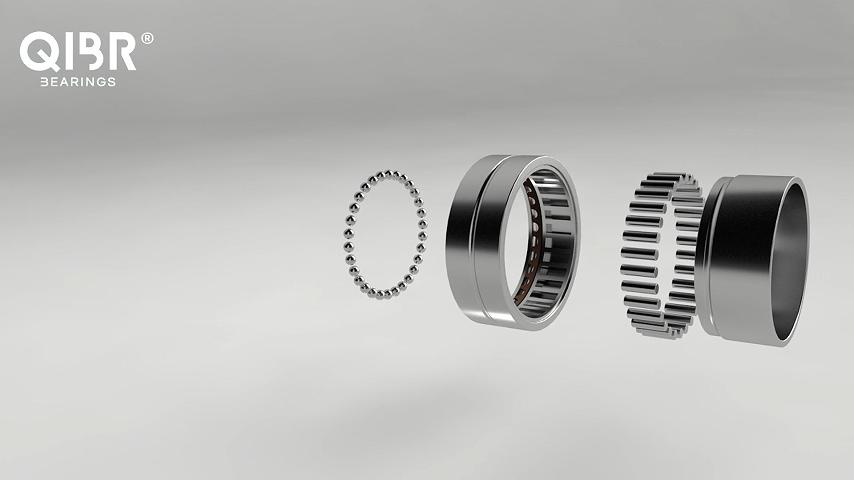

Image may differ from product. See technical specification for details.

Search for the bearing model you need

| NO. | Product | Product Number | Bore | Outer diameter (D) | Width (B) | Mass | Limiting speed | Basic dynamic load rating |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

NKIA 5901 | 12 mm | 24 mm | 16 mm | 0.04 kg | 26000 rpm | 8.09 KN |

| 2 |

|

NKIA 5902 | 15 mm | 28 mm | 18 mm | 0.05 kg | 22000 rpm | 11.2 KN |

| 3 |

|

NKIA 5903 | 17 mm | 30 mm | 18 mm | 0.056 kg | 20000 rpm | 11.4 KN |

| 4 |

|

NKIA 5904 | 20 mm | 37 mm | 23 mm | 0.1 kg | 17000 rpm | 21.6 KN |

| 5 |

|

NKIA 59/22 | 22 mm | 39 mm | 23 mm | 0.12 kg | 15000 rpm | 23.3 KN |

| 6 |

|

NKIA 5905 | 25 mm | 42 mm | 23 mm | 0.13 kg | 15000 rpm | 24.2 KN |

| 7 |

|

NKIA 5906 | 30 mm | 47 mm | 23 mm | 0.15 kg | 13000 rpm | 25.5 KN |

| 8 |

|

NKIA 5907 | 35 mm | 55 mm | 27 mm | 0.24 kg | 11000 rpm | 31.9 KN |

| 9 |

|

NKIA 5908 | 40 mm | 62 mm | 30 mm | 0.32 kg | 9500 rpm | 42.9 KN |

| 10 |

|

NKIA 5909 | 45 mm | 68 mm | 30 mm | 0.38 kg | 8500 rpm | 45.7 KN |

| 11 |

|

NKIA 5910 | 50 mm | 72 mm | 30 mm | 0.38 kg | 8000 rpm | 47.3 KN |

| 12 |

|

NKIA 5911 | 55 mm | 80 mm | 34 mm | 0.55 kg | 7000 rpm | 57.2 KN |

| 13 |

|

NKIA 5912 | 60 mm | 85 mm | 34 mm | 0.59 kg | 6700 rpm | 60.5 KN |

| 14 |

|

NKIA 5913 | 65 mm | 90 mm | 34 mm | 0.64 kg | 6300 rpm | 61.6 KN |

| 15 |

|

NKIA 5914 | 70 mm | 100 mm | 40 mm | 0.98 kg | 5600 rpm | 84.2 KN |

| 16 |

|

NKIB 5901 | 12 mm | 24 mm | 17.5 mm | 0.043 kg | 26000 rpm | 8.09 KN |

| 17 |

|

NKIB 5902 | 15 mm | 28 mm | 20 mm | 0.052 kg | 22000 rpm | 11.2 KN |

| 18 |

|

NKIB 5903 | 17 mm | 30 mm | 20 mm | 0.058 kg | 20000 rpm | 11.4 KN |

| 19 |

|

NKIB 5904 | 20 mm | 37 mm | 25 mm | 0.11 kg | 17000 rpm | 21.6 KN |

| 20 |

|

NKIB 59/22 | 22 mm | 39 mm | 25 mm | 0.12 kg | 15000 rpm | 23.3 KN |

| 21 |

|

NKIB 5905 | 25 mm | 42 mm | 25 mm | 0.13 kg | 15000 rpm | 24.2 KN |

| 22 |

|

NKIB 5906 | 30 mm | 47 mm | 25 mm | 0.15 kg | 13000 rpm | 25.5 KN |

| 23 |

|

NKIB 5907 | 35 mm | 55 mm | 30 mm | 0.25 kg | 11000 rpm | 31.9 KN |

| 24 |

|

NKIB 5908 | 40 mm | 62 mm | 34 mm | 0.32 kg | 9500 rpm | 42.9 KN |

| 25 |

|

NKIB 5909 | 45 mm | 68 mm | 34 mm | 0.38 kg | 9500 rpm | 45.7 KN |

| 26 |

|

NKIB 5910 | 50 mm | 72 mm | 34 mm | 0.39 kg | 8000 rpm | 47.3 KN |

| 27 |

|

NKIB 5911 | 55 mm | 80 mm | 38 mm | 0.56 kg | 7000 r/min | 57.2 KN |

| 28 |

|

NKIB 5912 | 60 mm | 85 mm | 38 mm | 0.6 kg | 6700 rpm | 60.5 KN |

| 29 |

|

NKIB 5913 | 65 mm | 90 mm | 38 mm | 0.64 kg | 6300 rpm | 61.6 KN |

| 30 |

|

NKIB 5914 | 70 mm | 100 mm | 45 mm | 0.99 kg | 5600 rpm | 84.2 KN |

Features and advantages of QIBR needle roller / angular contact ball bearings

QIBR needle roller / angular contact ball bearings address several critical issues in diverse fields, mainly in the following areas:

1. Capability to handle composite loads

This type of bearing can simultaneously handle radial and axial loads, making it suitable for complex environments where both types of forces act together, especially in applications requiring torque and radial force handling.

2. Space-saving and simplified design

Because these bearings manage both radial and axial loads, there is no need for multiple bearings to handle different load types, saving installation space.

In compact designs, using this combination bearing can significantly simplify the assembly process, reduce the number of components, and lower manufacturing and maintenance costs.

3. High precision and stability

Angular contact ball bearings offer high precision and stability, maintaining low friction and high operational accuracy at high speeds. When combined with needle roller bearings, this type of bearing ensures efficient operation under high load conditions, making it suitable for applications requiring precision.

4. Strong adaptability

These bearings can adapt to complex working environments, functioning effectively under high loads, vibrations, impacts, and changing load directions.

Performance improvements and solutions for QIBR needle roller / angular contact ball bearings

1. Improved materials

High-performance material selection: Utilizing materials with greater hardness, wear resistance, and corrosion resistance to significantly enhance durability and stability.

2. Optimized cage design

Cage structure optimization: Redesigning the cage structure for better needle roller arrangement and uniform load distribution. Improving the cage structure reduces roller collisions, enhancing operational stability and efficiency.

3. Enhanced lubrication performance

Efficient lubricants: Using greases or oils designed for high-temperature and high-pressure environments ensures consistent lubricant performance during extended operations, reducing friction and improving durability.

4. Increased precision

Precision machining techniques: Enhancing manufacturing accuracy reduces errors between bearing components, ensuring more uniform and stable contact between the rollers and the cage. This improves performance, extends service life, and reduces noise and vibration.

Main application areas of QIBR needle roller / angular contact ball bearings

1. Automatic transmissions

These bearings are used in automatic transmissions to handle significant axial and radial loads, ensuring smooth operation of the transmission system.

2. High-precision machine tools

In precision CNC machine tools, particularly in high-speed spindles, these bearings provide high rigidity and precision, ensuring the machining accuracy and stability of the machine tool.

3. Robotic arms

In industrial robots, especially in joints that require high load capacity, these bearings provide higher torque capacity, ensuring the flexibility and stability of robotic arms.

4. High-speed rotating equipment

In high-performance sports equipment such as skiing, racing, and marine equipment, these bearings provide precise rotational control and stability, ensuring performance and safety.