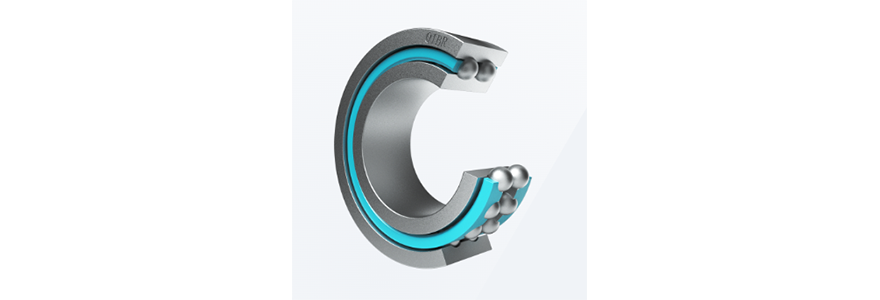

QIBR angular contact ball bearings are used in high-speed CNC machine tool spindles

- Industry

- High-speed CNC machine tool manufacturing

- Location

- USA

- Goals

- Improve bearing processing speed and accuracy

Products used

QIBR angular contact ball bearings are used in high-speed CNC machine tool spindles

-Maximize the bearing processing speed and accuracy by optimizing the bearing design drawings and processing technology

In August 2018, A customer from the United States, referred to us by a friend, informed us of serious technical issues they were facing in their daily production. These issues not only affected their production efficiency but also posed a threat to their business stability. Responding promptly to the client's concerns, our company swiftly mobilized engineers from all departments for an urgent meeting to brainstorm solutions.

After thorough analysis and discussion, we devised a comprehensive solution. From custom sample testing to finalization, followed by batch production and delivery, we meticulously followed the plan step by step. Throughout the process, engineers continuously optimized designs, overcame various technical challenges, and ensured that every detail met the client's requirements and standards.

After a three-month period, we successfully completed all stages and passed rigorous testing and acceptance by the client. This achievement is not merely the completion of a project but also the culmination of our team's collective wisdom and efforts. Through this collaboration, we not only resolved the client's technical issues but also established a strong partnership, laying a solid foundation for future cooperation.This case demonstrates our company's professional capabilities in facing challenges and our team's spirit of collaboration. We are committed to our mission of providing the highest quality solutions to clients.

Here are the details of this case,

1. Challenges

Compared with traditional machine tools, high-speed CNC machine tools have higher processing speed and precision, and can complete complex processing tasks in a short time. High-speed CNC machine tools are particularly important to enterprises. The spindles of machine tools generally use traditional angular contact ball bearings, which are difficult to meet the requirements of high-speed CNC machine tools.

For traditional angular contact ball bearings, when the spindle of the machine tool runs at high speed, it will generate a large centrifugal force and gyroscopic torque. The centrifugal force changes the contact stress and contact angle between the steel ball and the groove. The gyroscopic torque causes the steel ball to rotate around its own axis. When it is greater than the friction torque of the groove contact part, the steel ball slides. Under special working conditions such as high speed, emergency start and emergency stop, factors such as centrifugal force, gyroscopic torque, friction, thermal deformation, etc. seriously affect the motion stability of the bearing, making its internal motion form extremely complex.

2. Solutions

QIBR technicians designed and improved the bearings according to the requirements that high-speed CNC machine tool spindles need to meet. The technicians evaluated the improved bearing drawings and improved the stability and stability of high-speed CNC machine tool spindles, optimized product performance, reduced production costs, and increased bearing life while ensuring customer needs. From the forging of bearing materials to cutting and assembly, QIBR technicians supervised the measurement throughout the process to ensure that each process can achieve the expected results.

The improved angular contact ball bearings were sampled. The bearing diameter was 36mm, the ball diameter was 6.35mm, the contact angle was 25°, and the number of balls was 13. When the position angle was 180°, the maximum contact load was 3KN, the minimum gyroscopic torque was 90N.mm, and the maximum friction factor was 0.11. Considering the centrifugal expansion of the inner ring, when the speed was 9000r/min, the outer ring contact angle was 24°, the outer ring contact load was 1650N, the inner ring contact angle was 26.5°, and the inner ring contact load was 1550N.

The test data shows that angular contact ball bearings can well meet the requirements of high-speed CNC machine tool spindles for bearings.

Results

i. Optimized the motion stability and life of the bearing.

ii. Improved the working efficiency and processing accuracy of the machine tool.

iii. Reduced the downtime and maintenance cost of the equipment.

iv. Improved the stability and reliability of the customer's production line.

v. Reduced the production cost and energy consumption of the surface.

3. Customer Testimonials

“We are very satisfied with the performance of QIBR angular contact ball bearings and the company's services. Their technical team not only provides high-quality products, but also helps us solve key problems in equipment operation through professional consultation. Targeted improvements have been made to the operating speed and processing accuracy of high-speed CNC machine tools, which has reduced the cost of our CNC machine tools and increased the life of the bearings. After our company's high-speed CNC machine tool spindles were installed with QIBR angular contact ball bearings, customer feedback was very good and the repurchase rate increased.

Customers have given high praise to QIBR, and we will continue to choose QIBR's professional products.”

We are very satisfied with the performance of QIBR angular contact ball bearings and the company's services. Their technical team not only provides high-quality products, but also helps us solve key problems in equipment operation through professional consultation.