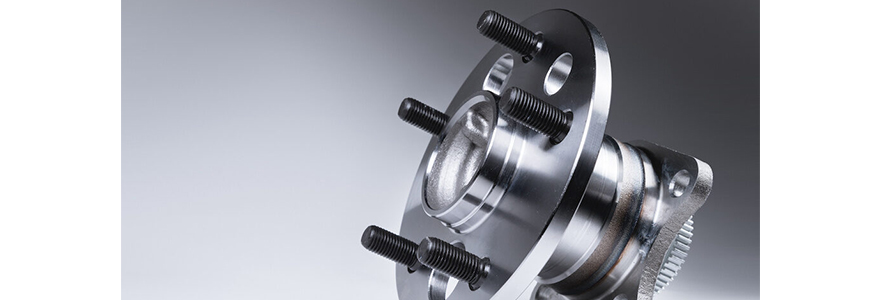

QIBR QJ206 angular contact ball bearings are used on the automobile wheel hub unit

- Industry

- Automobile industry

- Location

- Netherlands

- Goals

- Improved the turbocharger bearings to maximize their adaptability to various environments

Products used

QIBR QJ206 angular contact ball bearings are used on the automobile wheel hub unit

- Improve the radial and axial load support of the automotive hub unit by improving the bearing design

Customer introduction:

The client is a leading automobile wheel manufacturer in the Netherlands, specializing in the production of high-performance aluminum alloy and carbon fiber wheels, and is committed to providing high-quality products to global automobile manufacturers and motorsports. The company enjoys a good reputation in the industry for its excellent product quality and innovative design capabilities. The company has always adhered to the concept of technological progress and environmental protection, and has won the trust and cooperation of many internationally renowned automobile manufacturers.

a) Challenges(Problems that exist and why they are not solved)

In the modern automobile industry, wheel hub units are subject to complex axial and radial loads, which come from the weight of the vehicle, the inertial force during driving, and the impact and vibration caused by uneven road surfaces. Traditional wheel hub unit bearings are prone to problems such as short life and unstable operation under long-term high-load operation.

Ordinary bearings cannot meet the modern automobile industry's demand for high strength and high durability of wheel hub units. It is necessary to design suitable bearings based on the needs of modern automobiles.

b) Solution (How QIBR Solves the Problem)

QIBR improves the bearing design to improve the radial and axial load support of the hub unit while ensuring the stability of the car during driving. QIBR QJ206 angular contact ball bearings use advanced materials and manufacturing processes. The driving environment of cars varies greatly, and the selection of materials is particularly important to adapt to different environments. Using 3D software to build models and perform force analysis, we continuously improve the design plan and design a product that meets customer needs, QIBR QJ206 angular contact ball bearings, and conduct actual tests on the designed QIBR QJ206 angular contact ball bearings.

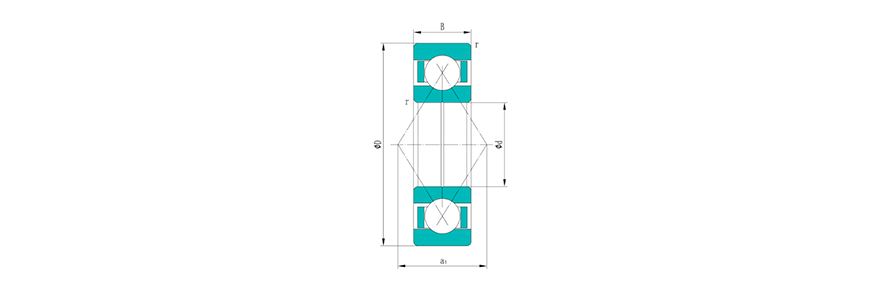

QIBR QJ206 angular contact ball bearings are two-point contact bearings with inner diameter Ød: 62mm, outer diameter ØD: 30mm, width B: 16mm, and can withstand a basic rated dynamic load of 31000N, a basic rated static load of 45000N, and a reference speed of 8500r/min. The weight of QIBR QJ206 angular contact ball bearings is 0.24kg, and the tolerance grade can reach P6.

Combined with the optimized internal structure and contact angle, QIBR QJ206 angular contact ball bearings can effectively carry axial and radial dual loads under high-speed operation and complex working conditions, while maintaining stability and long life.

c) Results

- Optimized axial and radial load carrying capacity of the hub unit

- Improved the overall vehicle performance and driving safety

- Reduces the vibration and noise of the vehicle when driving at high speed and on uneven roads

- Improved vehicle repair frequency and downtime due to wheel hub unit issues

- Reduces maintenance requirements and costs of hub units

Testimonials

QIBR's technical experts analyzed and improved the problems of the previous bearings. After communication, they provided us with QIBR QJ206 angular contact ball bearings, and made suggestions and optimizations for the problems of our automotive hub units when running under high loads. Compared with previous bearings, it can not only improve the radial and axial load support, but also achieve P6 level of precision. After our car was installed with QIBR QJ206 angular contact ball bearings, the company's technical department tested the car's performance. The data showed that it met the requirements we had previously communicated with QIBR, and the stability was greatly improved, which improved the comfort of the car.

The end customers gave high praise to QIBR, and we will continue to choose QIBR's professional products/services.

The end customers gave high praise to QIBR, and we will continue to choose QIBR's professional products/services.