QIBR thin section ball bearings are used on the main bearings of medical CT machines

- Industry

- medical equipment industry

- Location

- Germany

- Goals

- maximum equipment accuracy and life

Products used

QIBR thin-section ball bearings are used on the main bearings of medical CT machines

Improved thin section ball bearings to increase the accuracy and life of main bearings for medical CT machines

Customer Introduction

Siemens Healthineers is a global leading medical technology company headquartered in Erlangen, Germany. Founded in 1847, the company is committed to improving the quality and efficiency of medical services and improving patients' health and quality of life through innovative technologies and solutions.

a) Challenges (existing problems and why they have not been solved)

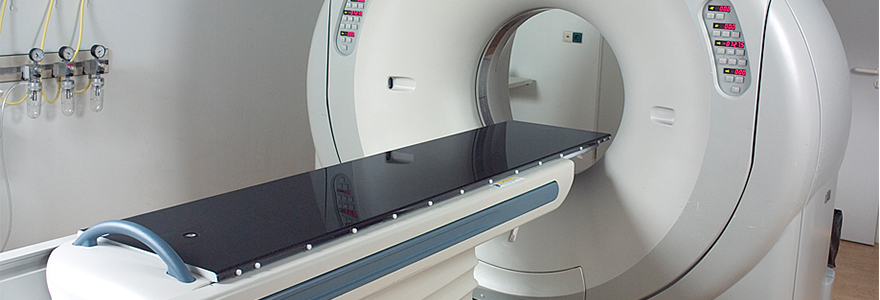

The main bearing of a medical CT machine is used to fix the connection between the CT frame and the rotating scanning part. It is a key component of the rotating scanning part of the CT machine. Its function is to transmit and withstand the axial load, radial load and overturning moment generated by devices such as X-ray tubes, collimators, detectors, and slip rings. It must meet the CT machine's requirements for high speed, low noise, high precision, low vibration and long life.

b) Solution (How does QIBR solve the problem)

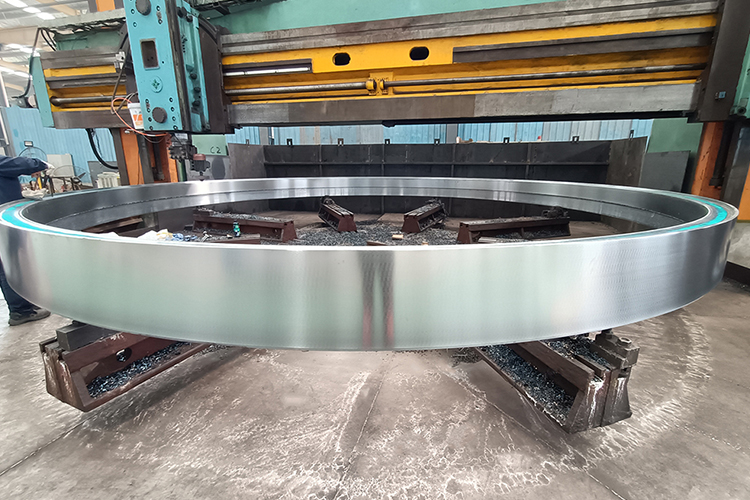

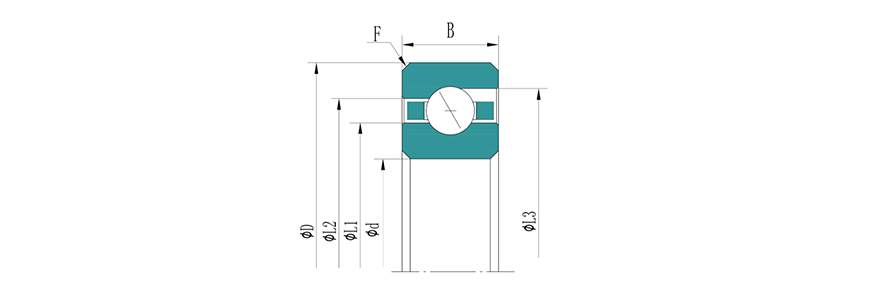

QIBR technicians designed thin section ball bearings according to actual conditions, and analyzed and improved them according to the use environment and required precision of the main bearings of medical CT machines. 52100 bearing steel was selected as the processing material for thin section ball bearings, and the surface was chrome-plated. A three-dimensional model of the QKAA10AG0 model was established, and the bearing was subjected to force design analysis using ABAQUS finite element analysis software to obtain experimental data. According to the experimental data obtained, the outer diameter ØD: 35mm, the inner diameter Ød: 25.4mm, the width B: 4.76mm, the bearing speed: 80-120r/min, the rotation accuracy: P5 level, the noise: less than 64dB, and the no-load starting friction torque: 40N.m. Based on the structural parameter optimization design technology, processing technology, precision assembly technology, cage structure and material research, sealing structure research, lubricant development, non-contact measurement technology of the ring and bearing comprehensive performance evaluation technology, a product that can reduce weight and space occupancy while ensuring the high precision and stability of medical scanning equipment was developed. It can replace well-known brands such as Kaydon, Franke, and Rothe Erde.

c) Results

1. Optimized the durability and stability of the bearing.。

2. Improved the running accuracy of the main bearing of the medical CT machine.

3. Reduced noise and vibration levels.

4. Improved bearing life and reliability

5. Reduced maintenance costs and downtime.

Customer Testimonials

QIBR's technical experts provided us with QIBR thin section ball bearings. Our company is engaged in medical equipment. The main bearings of medical CT machines could not meet our production requirements during the previous manufacturing and use process. After the technical department personnel conducted inspections, investigations and improvements, we finally encountered difficulties in bearings. We contacted and communicated with QIBR's technical department, raised our questions and expected results, and after the research and development of QIBR's technical personnel, we developed QIBR thin section ball bearings suitable for the installation and use of medical CT machine main bearings. After the first batch of installation tests, the data showed that the bearings provided by QIBR can ensure the high precision, high speed, long life and stability of the main bearings of medical CT machines.

The CEO spoke highly of QIBR, and we will continue to choose QIBR's professional products and services.

The CEO spoke highly of QIBR, and we will continue to choose QIBR's professional products and services.