Successful Application of QIBR 6208 Deep Groove Ball Bearings in the Electric Main Shaft of a Famous French Brand of New Energy Aircraft

- Industry

- Aerospace

- Location

- France

- Goals

- Maximizing the ability of bearings in aircraft spindles to resist harsh environments, thereby enhancing aircraft service life

Products used

Successful Application of QIBR 6208 Deep Groove Ball Bearing in the Electric Spindle of New Energy Aircraft

Enhancing the Service Life of Aircraft by Optimizing the Ability of Bearings in the Aircraft's Spindle to Resist Harsh Environments

Customer Introduction

The client is a pioneering innovator in new energy aircraft technology, focusing on developing efficient, environmentally friendly, and high-performance aircraft products. Committed to driving the green transformation of the aviation industry through technological innovation, their new energy aircraft projects have garnered global recognition as benchmarks for future aviation travel.

a) Challenges (existing problems, why they have not been solved)

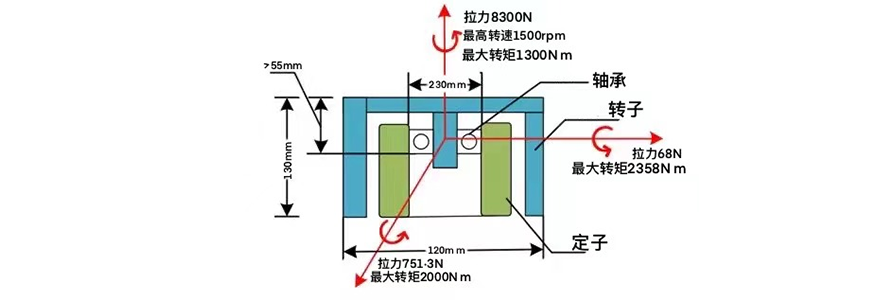

The client's new energy aircraft's electric spindle faced several formidable challenges, including extreme operating conditions such as a tilting moment of 2000N.m, an axial tension of 8300N, and a maximum rotational speed of approximately 1500rpm for 15 seconds, with a required service life of no less than 20,000 hours and a weight limit of 1Kg. Addressing these demands necessitated overcoming the following hurdles:

- Unspecified maintenance standards for bearings

- Inadequate bearing lightweighting

- Urgent need for breakthroughs in flight control, intelligent obstacle avoidance, and fault diagnosis technologies

- Lack of intelligent bearing development and application for real-time online monitoring and fault detection

- Room for improvement in domestically produced processors, components, and other core parts

- Deficiencies in product quality, lifespan, and consistency, along with a lack of mature technological systems

b) Solution (How QIBR solves the problem)

To tackle these challenges, QIBR took the following steps:

Engineering Analysis and Optimization:

QIBR's technical team created models and utilized ABAQUS finite element analysis software to simulate the bearing's stress conditions under various operating scenarios. This resulted in stress distribution maps, deformation diagrams, and fatigue analysis charts, which facilitated optimized bearing design and material selection, enhancing performance and durability.

Introduction of Intelligent Technology:

QIBR incorporated smart bearing technology into the electric spindle's bearings. The QIBR 6208 Deep Groove Ball Bearing is equipped with built-in sensors and advanced data analysis capabilities, enabling real-time monitoring of critical parameters such as temperature, vibration, load, and speed. This data is integrated and remotely monitored, empowering maintenance teams to promptly conduct fault analysis and decision-making without the need for physical presence, thereby providing comprehensive monitoring of equipment health.

Outcomes:

- Optimized bearing performance

- Enhanced aircraft safety and durability

- Reduced bearing damage caused by harsh environments

- Improved bearing lightweight and intelligence, boosting overall performance stability

- Increased aircraft service life

"Previously, the bearings we used could not meet the demands of our aircraft's spindle. Our procurement department collaborated with QIBR's technical team to address our requirements for resilience in extreme flight environments and extended lifespan. Their recommendations and optimizations significantly improved the reliability and durability of our aircraft's spindle, minimizing bearing damage caused by harsh conditions and enhancing the intelligence of our new energy aircraft's spindle.

After QIBR's technical experts developed the QIBR 6208 Deep Groove Ball Bearing, its incorporation into our production received overwhelmingly positive feedback from our customers. Not only did our order volume increase, but we also experienced repeat purchases. Our partnership with QIBR has boosted our production value, and we highly value their professional products and services. We will continue to choose QIBR for our future needs."

Enhancing the Service Life of Aircraft by Optimizing the Ability of Bearings in the Aircraft's Spindle to Resist Harsh Environments