Newsroom

How Are Slewing Bearings Fixed to Shafts?

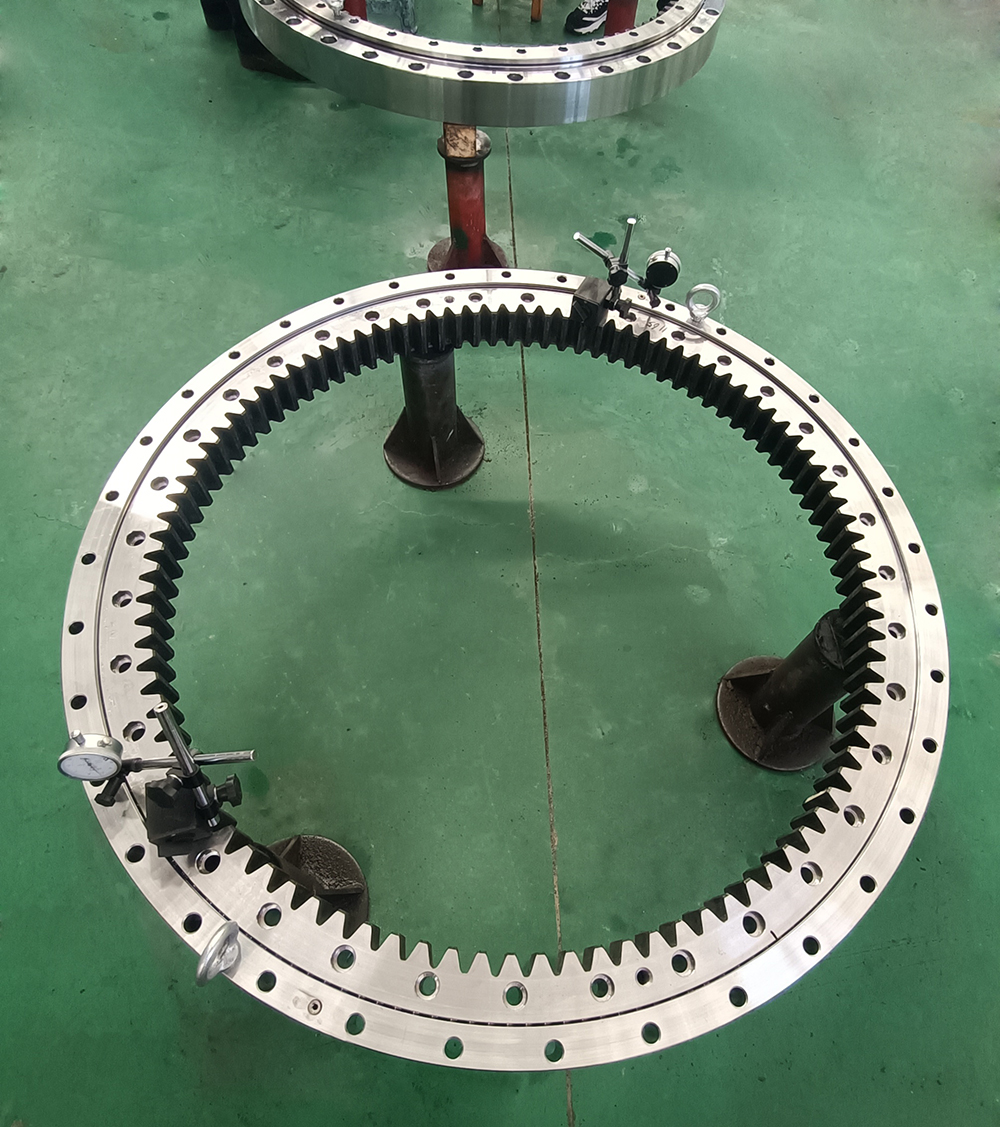

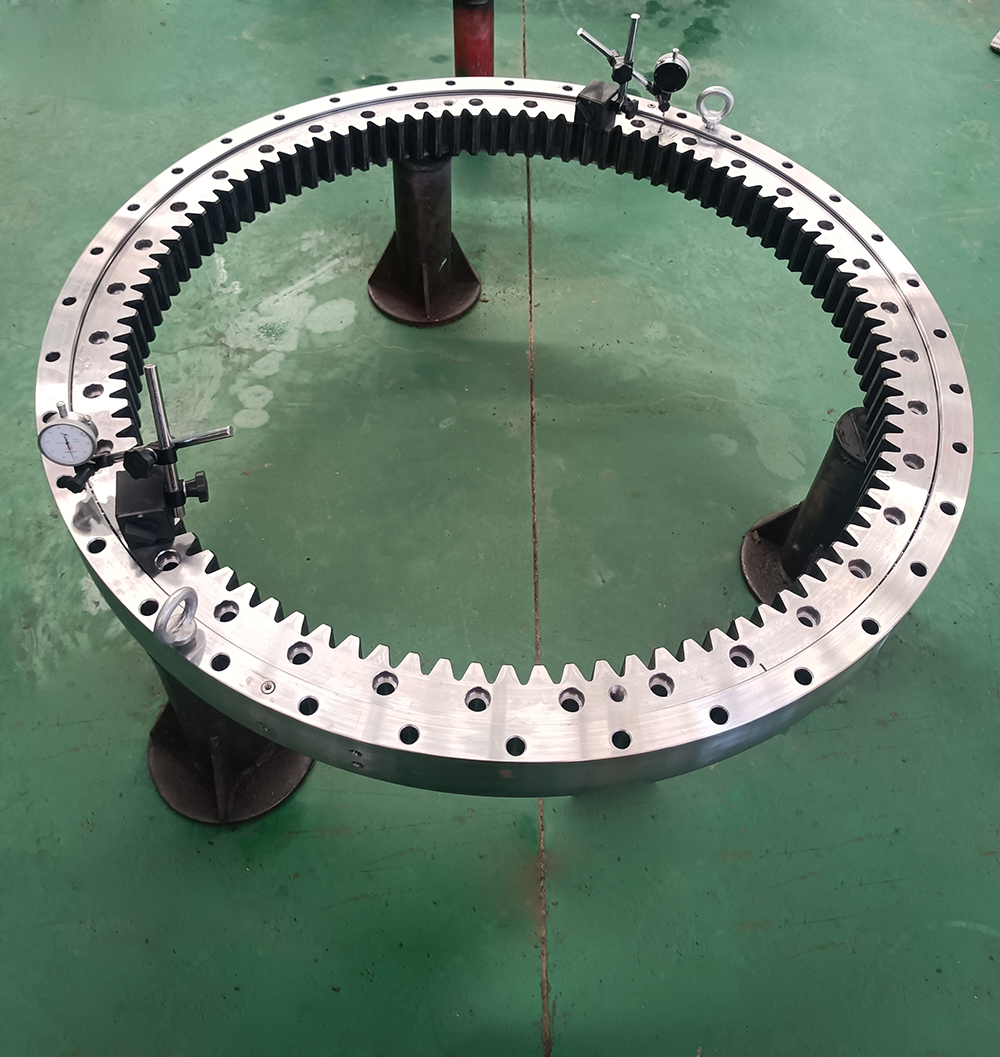

Slewing bearings are widely used large bearings found in various industries, including machinery, construction, coal, and shipping. These components come with built-in mounting holes, lubrication systems, and sealing devices, making them suitable for different working conditions across various machines. This article will discuss how slewing bearings are fixed to shafts.

Overview of Fixing Methods

1. Interference Fit

Interference fit is one of the most common methods for connecting slewing bearings to shafts. Specifically, the outer diameter of the shaft is typically machined to be about two thousandths of a millimeter larger than the inner diameter of the bearing. This design prevents the shaft from being inserted into the bearing bore at room temperature. To install, the bearing is usually heated to about 90 degrees Celsius, causing its inner bore to expand due to thermal expansion. At this point, it can be easily mounted onto the shaft. Once the bearing cools down, it contracts and tightly grips the shaft, ensuring a secure connection. This method is not only simple and effective but also ensures that there is no loosening due to vibration or load changes during operation.

2. Set Screws

In some cases, the inner ring of the slewing bearing may be designed with set screws. This design allows for positioning the bearing on the shaft using screws. In this situation, the machining size of the shaft is slightly smaller than that of the inner diameter of the bearing, allowing for adjustments and positioning. This method is suitable for applications where frequent adjustments or replacements are needed, providing greater flexibility.

3. Locking Sleeves

Locking sleeves represent a special fixing method where the inner diameter is tapered and contains an outer tapered locking sleeve. By tightening a nut, both the bearing and locking sleeve can be secured together. This design not only effectively transmits loads but also simplifies the installation process, making it suitable for various types of machinery.

Installation and Positioning Techniques

In practical applications, correct installation and positioning techniques are crucial for ensuring the performance of slewing bearings.

1. Hot and Cold Installation

Hot Installation: For bearings with significant interference fits, thermal expansion can be utilized by heating the bearing before installation. This process typically keeps temperatures below 100°C to avoid damaging materials.

Cold Installation: For smaller components, cooling agents like liquid nitrogen can be used to shrink them before rapid installation.

2. Hydraulic Press Method

Using a hydraulic press for insertion should apply pressure directly on the end face of the interference-fitted bearing ring to avoid damaging working surfaces. This method is suitable for mass production or high-precision installations.

3. Copper Rod and Sleeve Method

For medium and small-sized bearings, a copper rod can be used with manual hammering for installation. By using a copper rod to transmit force evenly while tapping, this method effectively prevents damage from uneven stress distribution. Additionally, using a dedicated sleeve can enhance installation efficiency by ensuring even force distribution.

Axial Positioning

In slewing bearings, besides circumferential fixing, axial positioning must also be considered. Common axial positioning methods include:

1. Shoulder Fixing

Using a shoulder on the shaft along with interference fit achieves fixation of the inner ring. This method is suitable for structures that require fixation at both ends.

2. Elastic Retaining Rings

Elastic retaining rings combined with locking nuts can secure the inner ring in place. This method can withstand a certain level of bidirectional load and is suitable for applications with lower loads.

3. Lock Nuts

In high-speed and heavy-load working environments, securing the inner ring with lock nuts is common practice. This method ensures stability even under high load conditions.

4. Thrust Washers

Thrust washers are typically used in constrained spaces or where threading is difficult; they work in conjunction with end rings to secure the inner ring.

Importance of Fixation

The secure connection between slewing bearings and shafts not only affects the operational efficiency of machinery but also directly relates to equipment safety and service life. Improper connections may lead to unstable operation, increased wear, or even failure of equipment. Therefore, during design and installation processes, it is essential to choose the most appropriate fixing method based on specific working conditions to ensure long-term stable operation of equipment.

In summary, there are various ways to fix slewing bearings to shafts, each with its own characteristics. In practical applications, selecting an appropriate method based on specific circumstances can achieve optimal performance. Through reasonable design and precise installation, mechanical equipment's overall efficiency and reliability can be significantly enhanced.

If you need any further assistance or modifications, feel free to CONTACT US!