Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh,DIN / VDEh

Inner ring diameter

8mm-100mm

Outer ring diameter

22mm-150mm

Weight

0.011kg-1.24kg

Material

Silicon Nitride (Si3N4), Zirconia (ZrO2), Silicon Carbide (Sic), Alumina

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

Machine tool spindle, Turbocharger, Robot, Aerospace, Medical equipment

Pairing method

DB, DF, DT, DBD, DBB, SU

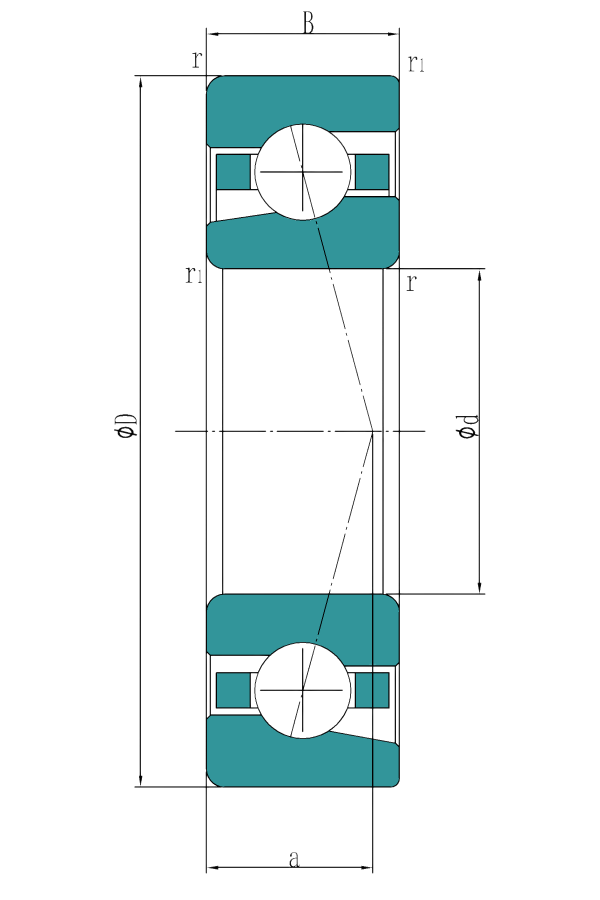

| NO. | Product | Product Number | Chamfer dimension (r1) | Inner diameter (d) | Mass | Outer diameter (D) | Chamfer dimension (r) | Width (B) |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

40 BNC 10 SN24 | 0.6 mm | 40 mm | 0.198 kg | 68 mm | 1 mm | 15 mm |

| 2 |

|

45 BNC 10 SN24 | 0.6 mm | 45 mm | 0.242 kg | 75 mm | 1 mm | 16 mm |

| 3 |

|

50 BNC 10 SN24 | 0.6 mm | 50 mm | 0.262 kg | 80 mm | 1 mm | 16 mm |

| 4 |

|

55 BNC 10 SN24 | 0.6 mm | 55 mm | 0.368 kg | 90 mm | 1.1 mm | 18 mm |

| 5 |

|

60 BNC 10 SN24 | 0.6 mm | 60 mm | 0.419 kg | 95 mm | 1.1 mm | 18 mm |

| 6 |

|

65 BNC 10 SN24 | 0.6 mm | 65 mm | 0.451 kg | 100 mm | 1.1 mm | 18 mm |

| 7 |

|

70 BNC 10 SN24 | 0.6 mm | 70 mm | 0.597 kg | 110 mm | 1.1 mm | 20 mm |

| 8 |

|

75 BNC 10 SN24 | 0.6 mm | 75 mm | 0.63 kg | 115 mm | 1.1 mm | 20 mm |

| 9 |

|

80 BNC 10 SN24 | 0.6 mm | 80 mm | 0.861 kg | 125 mm | 1.1 mm | 22 mm |

| 10 |

|

85 BNC 10 SN24 | 0.6 mm | 85 mm | 0.901 kg | 130 mm | 1.1 mm | 22 mm |

| 11 |

|

90 BNC 10 SN24 | 1 mm | 90 mm | 1.14 kg | 140 mm | 1.5 mm | 24 mm |

| 12 |

|

95 BNC 10 SN24 | 1 mm | 95 mm | 1.19 kg | 145 mm | 1.5 mm | 24 mm |

| 13 |

|

100 BNC 10 SN24 | 1 mm | 100 mm | 1.24 kg | 150 mm | 1.5 mm | 24 mm |

| 14 |

|

35 BNC 19 SN24 | 0.3 mm | 35 mm | 0.066 kg | 55 mm | 0.6 mm | 10 mm |

| 15 |

|

40 BNC 19 SN24 | 0.3 mm | 40 mm | 0.105 kg | 62 mm | 0.6 mm | 12 mm |

| 16 |

|

45 BNC 19 SN24 | 0.3 mm | 45 mm | 0.125 kg | 68 mm | 0.6 mm | 12 mm |

| 17 |

|

50 BNC 19 SN24 | 0.3 mm | 50 mm | 0.126 kg | 72 mm | 0.6 mm | 12 mm |

| 18 |

|

55 BNC 19 SN24 | 0.6 mm | 55 mm | 0.179 kg | 80 mm | 1 mm | 13 mm |

| 19 |

|

60 BNC 19 SN24 | 0.6 mm | 60 mm | 0.19 kg | 85 mm | 1 mm | 13 mm |

| 20 |

|

65 BNC 19 SN24 | 0.6 mm | 65 mm | 0.206 kg | 90 mm | 1 mm | 13 mm |

| 21 |

|

70 BNC 19 SN24 | 0.6 mm | 70 mm | 0.345 kg | 100 mm | 1 mm | 16 mm |

| 22 |

|

80 BNC 19 SN24 | 0.6 mm | 80 mm | 0.385 kg | 110 mm | 1 mm | 16 mm |

| 23 |

|

85 BNC 19 SN24 | 0.6 mm | 85 mm | 0.564 kg | 120 mm | 1.1 mm | 18 mm |

| 24 |

|

90 BNC 19 SN24 | 0.6 mm | 90 mm | 0.576 kg | 125 mm | 1.1 mm | 18 mm |

| 25 |

|

95 BNC 19 SN24 | 0.6 mm | 95 mm | 0.604 kg | 130 mm | 1.1 mm | 18 mm |

| 26 |

|

100 BNC 19 SN24 | 0.6 mm | 100 mm | 0.796 kg | 140 mm | 1.1 mm | 20 mm |

| 27 |

|

8 BNT 10F SN24 | 0.15 mm | 8 mm | 0.011 kg | 22 mm | 0.3 mm | 7 mm |

| 28 |

|

10 BNT 10F SN24 | 0.15 mm | 10 mm | 0.016 kg | 26 mm | 0.3 mm | 8 mm |

| 29 |

|

12 BNT 10F SN24 | 0.15 mm | 12 mm | 0.018 kg | 28 mm | 0.3 mm | 8 mm |

| 30 |

|

15 BNT 10F SN24 | 0.15 mm | 15 mm | 0.026 kg | 32 mm | 0.3 mm | 9 mm |

| 31 |

|

17 BNT 10F SN24 | 0.15 mm | 17 mm | 0.033 kg | 35 mm | 0.3 mm | 10 mm |

| 32 |

|

20 BNT 10F SN24 | 0.3 mm | 20 mm | 0.058 kg | 42 mm | 0.6 mm | 12 mm |

| 33 |

|

25 BNT 10F SN24 | 0.3 mm | 25 mm | 0.067 kg | 47 mm | 0.6 mm | 12 mm |

| 34 |

|

30 BNT 10F SN24 | 0.6 mm | 30 mm | 0.097 kg | 55 mm | 1 mm | 13 mm |

Characteristics and advantages of QIBR ceramic angular contact ball bearings

- QIBR ceramic angular contact ball bearings have high temperature and cold resistance, and ceramic materials can maintain their performance in high and low temperature environments, making them suitable for applications under extreme temperature conditions.

- QIBR ceramic angular contact ball bearings have corrosion resistance, and ceramic bearings have good chemical inertness, which can resist the erosion of corrosive media and extend their service life.

- QIBR ceramic angular contact ball bearings have a low coefficient of friction. Ceramic bearings have a lower coefficient of friction, which helps improve operating efficiency, reduce energy loss, and lower wear.

- QIBR ceramic angular contact ball bearings have low density, with ceramic materials having a lower density than steel, reducing the overall weight of the bearing. This is particularly important in high-speed applications and helps to reduce energy consumption.

- QIBR ceramic angular contact ball bearings have excellent mechanical properties. The ceramic has a high elastic modulus and is not easily deformed under stress, which helps to improve working speed and accuracy.

- QIBR ceramic angular contact ball bearings have electrical insulation properties, and ceramic materials are non-conductive, making them suitable for use in applications that require electrical insulation.

Performance improvement and solution of QIBR ceramic angular contact ball bearings

- QIBR ceramic angular contact ball bearings can greatly reduce friction and heat generation. The combination of ceramic rolling elements and steel inner and outer rings in hybrid ceramic bearings can significantly reduce the friction coefficient. This low friction characteristic reduces energy loss, improving overall efficiency and reducing heat generation.

- QIBR ceramic angular contact ball bearings extend the life of lubricants, and the superior performance of ceramic materials enables hybrid ceramic bearings to perform better under lubrication conditions, which can extend the service life of lubricants. This means that bearings can maintain efficient operation for a longer period of time, reducing maintenance frequency and costs.

- QIBR ceramic angular contact ball bearings improve load-bearing capacity and service life. The high hardness and lightweight characteristics of ceramic rolling elements enable hybrid ceramic bearings to withstand higher loads while reducing the impact of centrifugal force on the bearings, extending their service life.

- QIBR ceramic angular contact ball bearings are more adaptable to extreme working conditions, while hybrid ceramic bearings can still operate normally even under poor lubrication.

- QIBR ceramic angular contact ball bearings are more suitable for high wear resistance working conditions. The hardness of ceramic materials is twice that of bearing steel, and the wear amount is only 50% of that of steel bearings.

- QIBR ceramic angular contact ball bearings have excellent thermal stability, and ceramic bearings perform well at high temperatures. The maximum temperature limit for the use of silicon nitride can reach 800 ℃, far exceeding traditional bearing materials.

- QIBR ceramic angular contact ball bearings have excellent chemical stability, and silicon nitride ceramics have good corrosion resistance to various acids and bases, making them suitable for use in harsh chemical environments.

The main application areas of QIBR ceramic angular contact ball bearings

- Machinery manufacturing fields: used for high-precision and high-rigidity moving parts such as machine tool spindles and industrial robots.

- Aerospace fields: Ceramic bearings are widely used in key components of aircraft due to their high-temperature resistance and low friction characteristics.

- Transportation fields: Used in automotive differential, wheel hub and transmission shaft and other components to improve vehicle performance and safety.

- Energy and power fields: In generators and motors, ceramic hybrid bearings provide effective electrical insulation and are suitable for environments with high acceleration and vibration.

- Chemical and metallurgical fields: In corrosive environments, the chemical stability of ceramic materials makes them ideal.