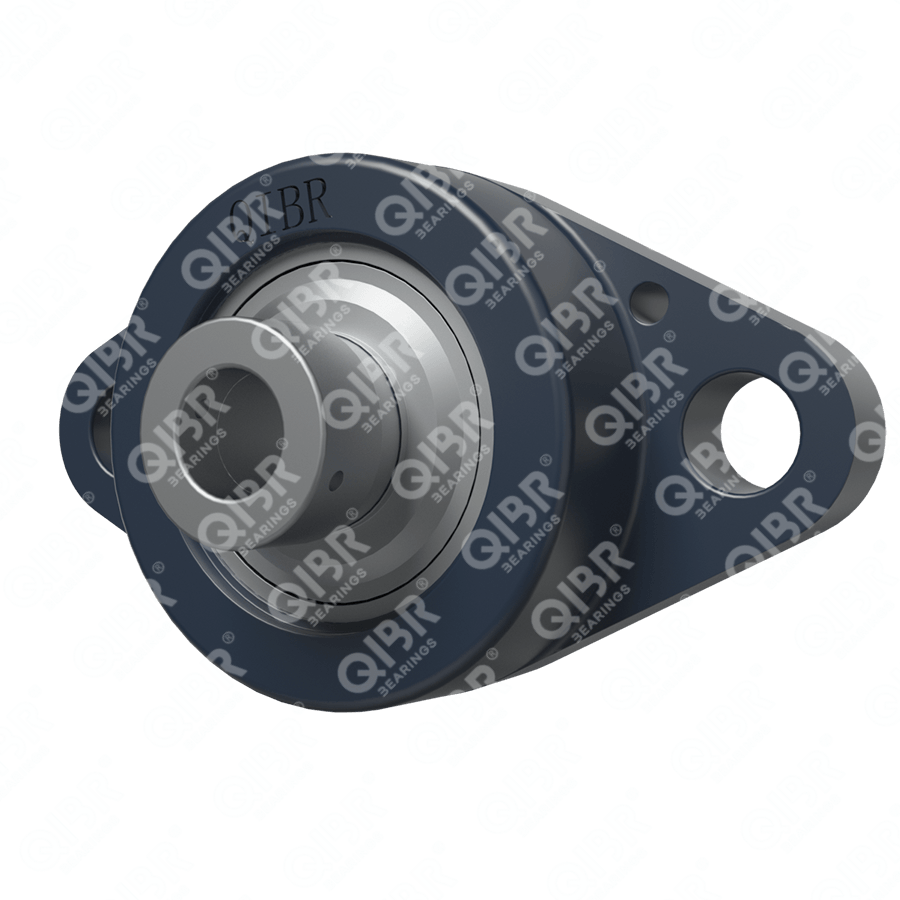

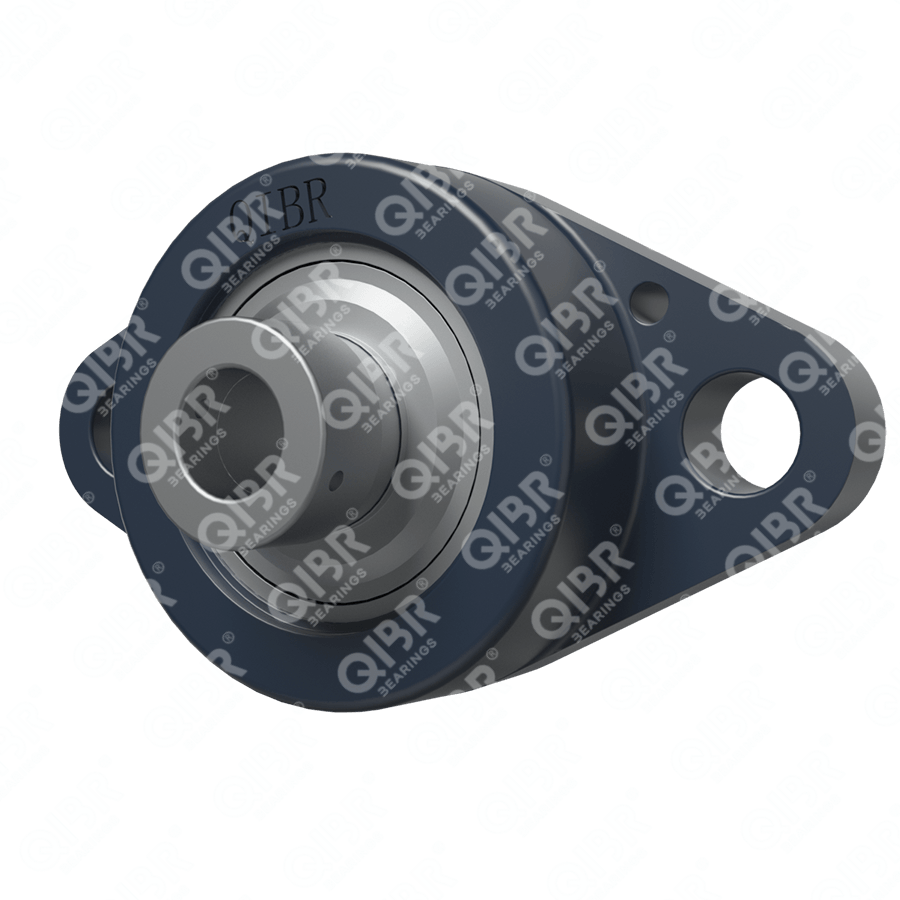

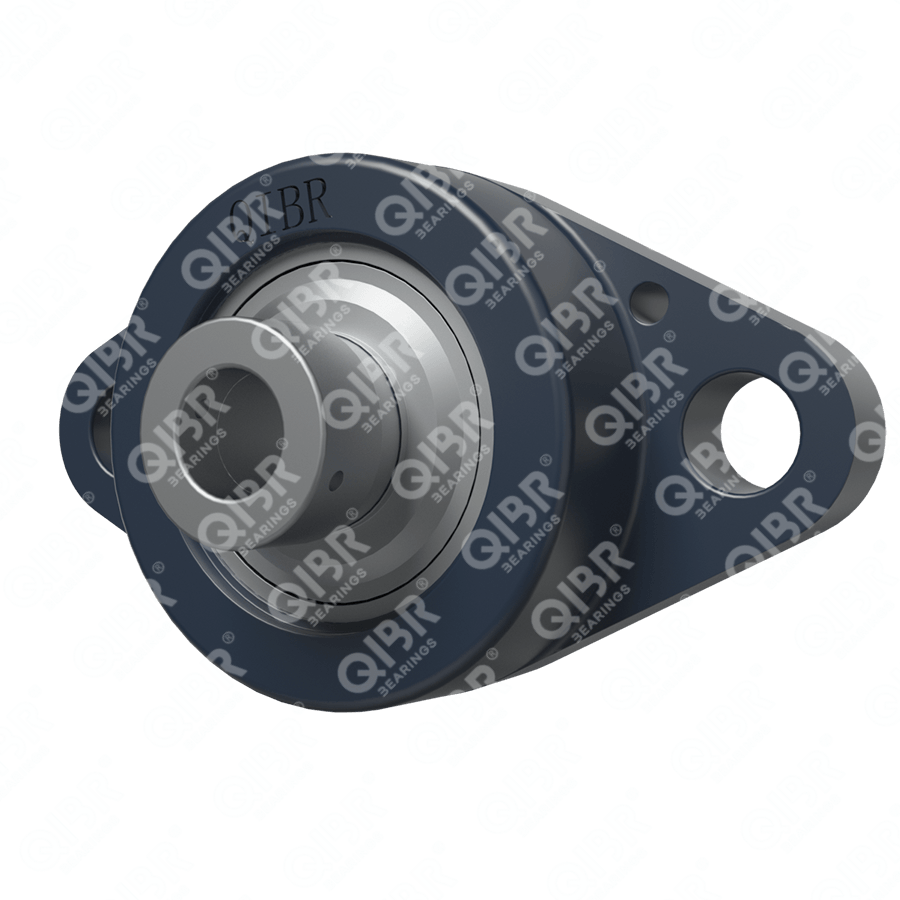

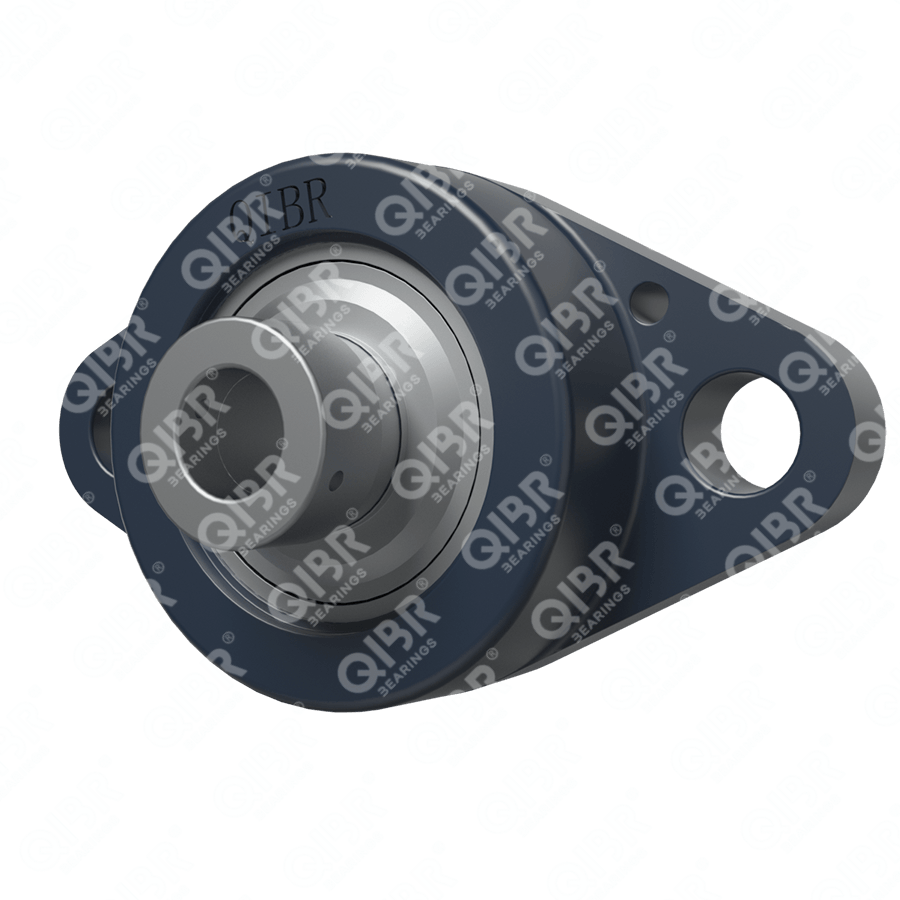

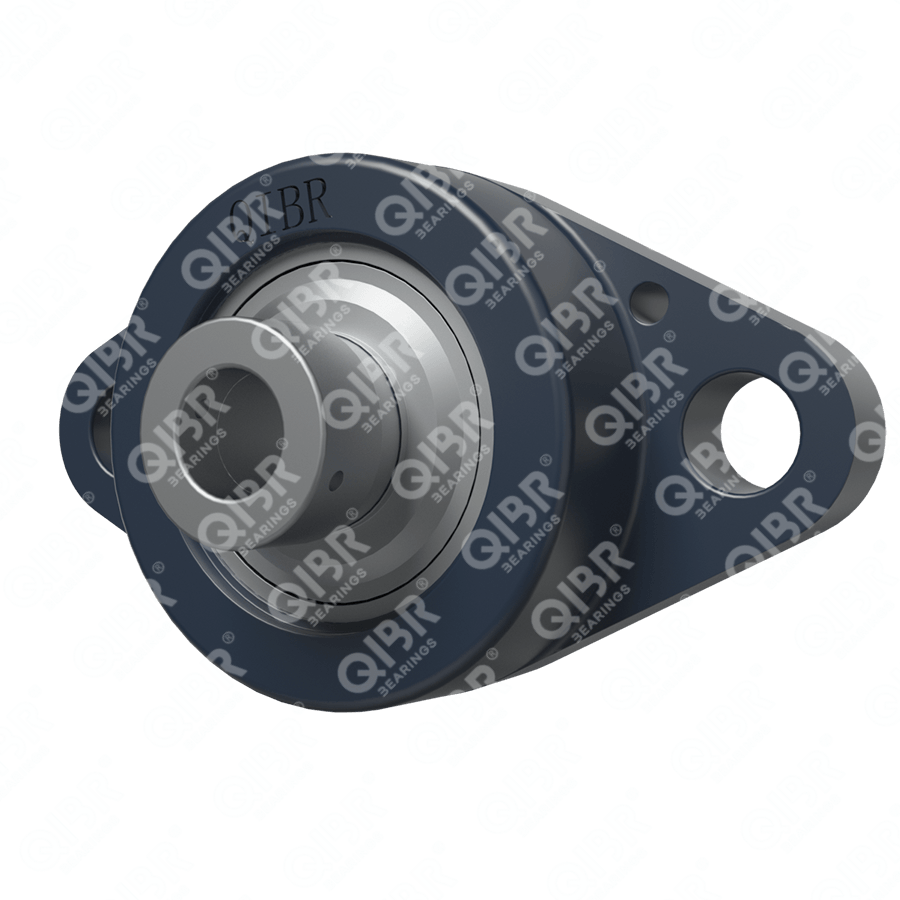

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh,DIN / VDEh

Material

Housing: cast iron or pressed steel Insert Bearing: 52100、100Cr6、SUJ2

Inner ring diameter

20-75mm

Weight

0.73-7.2kg

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

Industrial Machinery, Automotive, Agricultural Machinery, Material Handling Equipment, Mining and Construction, HVAC Systems, Marine Applications, Renewable Energy, Food and Beverage Industry, Medical Equipment, etc.

| NO. | Product | Product Number | Bearing model | Housing model | Weight |

|---|---|---|---|---|---|

| 1 |

|

HCFLU204 | HC204 | FLU204 | 0.73 kg |

| 2 |

|

HCFLU205 | HC205 | FLU205 | 0.8 kg |

| 3 |

|

HCFLU206 | HC206 | FLU206 | 1.2 kg |

| 4 |

|

HCFLU207 | HC207 | FLU207 | 1.6 kg |

| 5 |

|

HCFLU208 | HC208 | FLU208 | 1.9 kg |

| 6 |

|

HCFLU209 | HC209 | FLU209 | 2.3 kg |

| 7 |

|

HCFLU210 | HC210 | FLU210 | 2.6 kg |

| 8 |

|

HCFLU211 | HC211 | FLU211 | 3.8 kg |

| 9 |

|

HCFLU212 | HC212 | FLU212 | 4.8 kg |

| 10 |

|

HCFLU213 | HC213 | FLU213 | 6 kg |

| 11 |

|

HCFLU214 | HC214 | FLU214 | 6.3 kg |

| 12 |

|

HCFLU215 | HC215 | FLU215 | 7.2 kg |

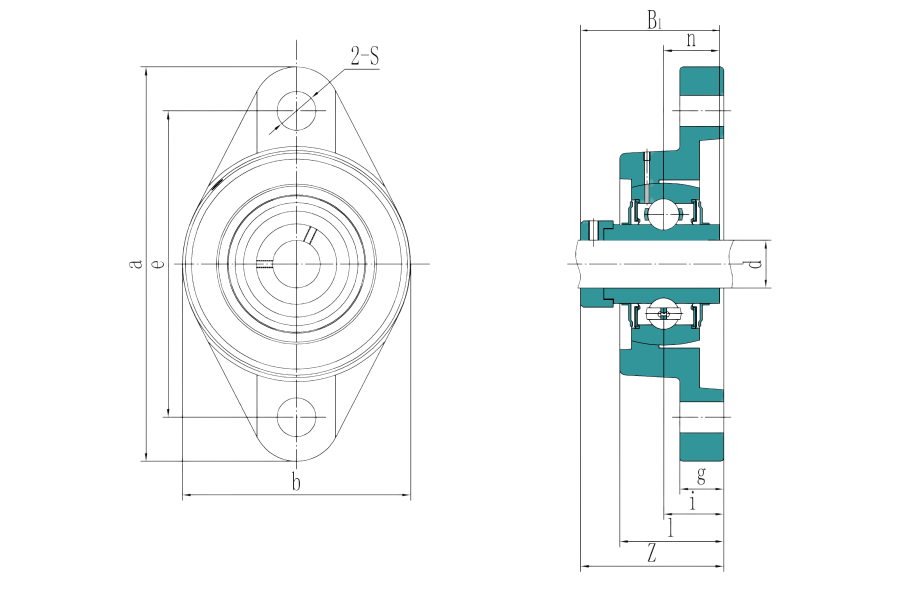

Features and advantages of HCFLU series bearing units

The HCFLU series bearing units have addressed several key issues across various fields, primarily reflected in the following aspects:

1. Eccentric locking mechanism

The eccentric locking collar is an installation and locking device that utilizes a circular eccentric design. During installation, the eccentric collar rotates and shifts position, generating a locking effect. This design eliminates the need for traditional fasteners like screws, offering higher installation efficiency and reliability.

2. Strong adaptability

The insert bearings are particularly suitable for working conditions with significant axial and radial displacement, imprecise installation locations, or high levels of vibration.

3. High load bearing capacity

The diamond flange bearing housing is typically made of robust materials, capable of withstanding significant axial and radial loads. Its unique structure provides stable support under high loads, making it ideal for applications requiring heavy-duty and precision operations.

4. Flexible installation

The diamond flange bearing housing offers versatile installation options, allowing for multi-angle mounting based on specific requirements. In space-constrained or precision-fit environments, it enables equipment designers to save space and improve overall assembly efficiency.

Performance enhancements and solutions for HCFLU series bearing units

1. Automatic lubrication system

In equipment requiring continuous operation, an automatic lubrication system ensures that the HCFLU series bearing units receive proper lubrication consistently. This reduces the need for manual intervention, enhances operational uptime, and improves the reliability of the equipment.

2. Damping materials

Adding damping materials (e.g., rubber pads, polyurethane pads) to the bearing housing can effectively reduce external vibration and impact, improving stability and durability, especially in high-vibration or heavy-load environments.

3. Increased machining precision

Precision machining equipment improves manufacturing accuracy, reduces surface roughness, ensures low friction coefficients during operation, and enhances load-bearing performance.

4. Improved bearing sealing

Enhanced sealing reduces lubricant leakage and prevents contamination, improving bearing efficiency, lowering maintenance frequency, and extending service life.

Main application fields of HCFLU series bearing units

Transmission System

The HCFLU series bearing units are widely used in various transmission devices, such as gearboxes, reducers, and drive shafts. They provide stable support and low friction performance, thereby improving mechanical equipment's efficiency and service life.

Mining equipment

Commonly used in devices like screens, crushers, and conveyor belts, the HCFLU series bearing units help sustain high-load operations and ensure long-term stability in ore processing.

Power and water facilities

In equipment such as pumps, fans, and generators, HCFLU series bearing units act as critical support components, ensuring long-term efficient operation, preventing excessive vibration, and avoiding shaft misalignment.

Agricultural machinery

Used in equipment like seeders, harvesters, and tractors, the HCFLU series bearing units provide support and stability for bearings, improving the durability and operational stability of agricultural machines, and reducing the need for frequent maintenance and repairs.