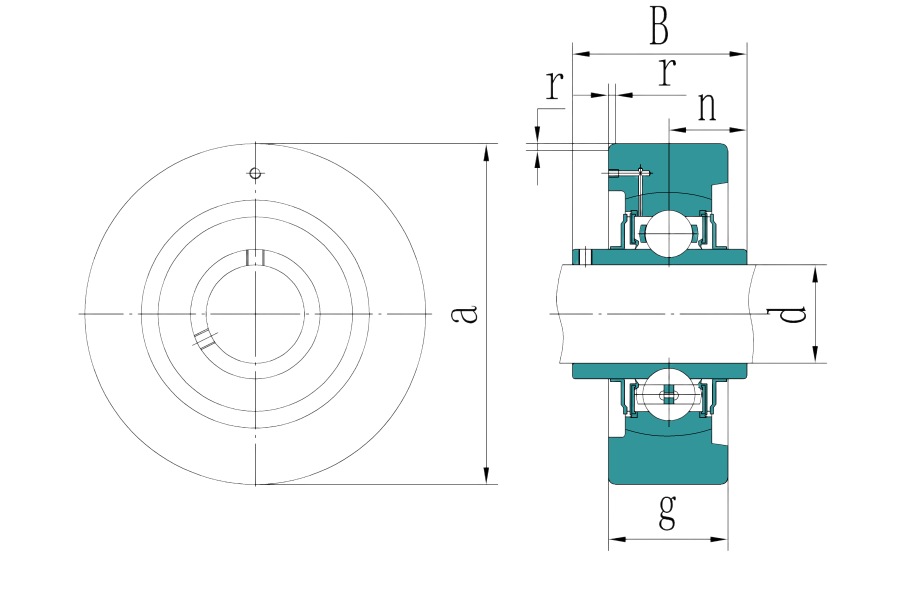

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh,DIN

Material

Housing: cast iron or pressed steel Insert Bearing: 52100、100Cr6、SUJ2

Inner ring diameter

12-65mm

Weight

0.52-2.79kg

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

Industrial Machinery, Automotive, Agricultural Machinery, Material Handling Equipment, Mining and Construction, HVAC Systems, Marine Applications, Renewable Energy, Food and Beverage Industry, Medical Equipment, etc.

| NO. | Product | Product Number | Bearing model | Housing model | Weight |

|---|---|---|---|---|---|

| 1 |

|

UCC201 | UC201 | C201 | 0.52 kg |

| 2 |

|

UCC202 | UC202 | C202 | 0.51 kg |

| 3 |

|

UCC203 | UC203 | C203 | 0.50 kg |

| 4 |

|

UCC204 | UC204 | C204 | 0.48 kg |

| 5 |

|

UCC205 | UC205 | C205 | 0.63 kg |

| 6 |

|

UCC206 | UC206 | C206 | 0.79 kg |

| 7 |

|

UCC207 | UC207 | C207 | 0.88 kg |

| 8 |

|

UCC208 | UC208 | C208 | 1.17 kg |

| 9 |

|

UCC209 | UC209 | C209 | 1.46 kg |

| 10 |

|

UCC210 | UC210 | C210 | 1.85 kg |

| 11 |

|

UCC211 | UC211 | C211 | 2.05 kg |

| 12 |

|

UCC212 | UC212 | C212 | 2.36 kg |

| 13 |

|

UCC213 | UC213 | C213 | 2.79 kg |

Features and advantages of the UCC series bearing units

1. Even load distribution

The round shape of the UCC series bearing housing helps distribute loads evenly, reducing stress concentrations.

2. High adaptability

The insert bearings are particularly suited for environments with significant axial and radial misalignment, inaccurate mounting positions, or high vibration levels.

3. Wide applications

UCC series bearing units are widely used in various mechanical equipment, especially in industrial devices requiring robust bearing support, such as electric motors, pumps, and conveyor belts.

4. Reduced vibration and noise

The UCC series is designed to minimize vibration and noise during high-speed operation, enhancing the smoothness and stability of equipment performance.

Performance enhancements and solutions for the UCC series

1. High-performance materials

Using materials with superior wear resistance and corrosion resistance (e.g., high-alloy steel, ceramics, or high-temperature alloys) significantly improves the durability and lifespan of bearing units.

2. Dust and water protection

For harsh working environments, designing more effective sealing structures (e.g., double-layer seals or automatic lubrication systems) prevents contaminants like dust and liquids from entering the bearing, maintaining optimal performance.

3. Precision fit

Enhancing the precision between the bearing housing and bearing reduces gaps and prevents issues like misalignment, vibration, or excessive friction, thereby extending the lifespan of the UCC series bearing units.

4. Optimized lubrication system

Selecting suitable lubricants and designing efficient oil grooves or lubrication paths ensure proper lubricant flow, reducing friction and prolonging the service life of the bearing units.

Main application fields of the UCC series bearing units

Mechanical equipment

Widely used in various mechanical devices, especially in transmission systems requiring high load capacity and stability.

Agricultural machinery

Frequently employed in agricultural equipment, particularly in machines requiring efficient power transmission and high-load support.

Concrete mixers

Used to support mixer shafts, ensuring stability during the mixing process.

Automatic packaging machines

Essential for supporting the rotating and transmission shafts in automated production lines.