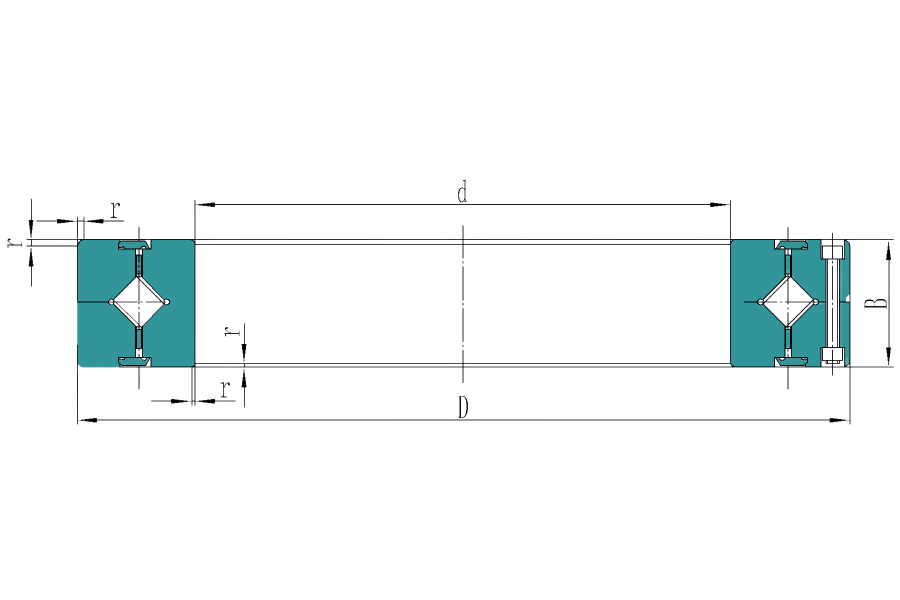

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Material

52100/100Cr6/SUJ2/Stainless Steel

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Inner diameter

30~300mm

Outer diameter

55~360mm

Applications

Aerospace Industry, Robotics, Medical Devices, Semiconductor Manufacturing Equipment, Optical Equipment, Industrial Machinery, Automotive, etc

| NO. | Product | Product Number | Chamfer dimension (r1) | Inner diameter (d) | Outer diameter (D) | Thickness | Type | Weight |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

CRBC 3010 UU | 0.3 mm | 30 mm | 55 mm | 10 mm | Two Sides Seals | 0.12 kg |

| 2 |

|

CRBC 4010 UU | 0.3 mm | 40 mm | 65 mm | 10 mm | Two Sides Seals | 0.15 kg |

| 3 |

|

CRBC 5013 UU | 0.6 mm | 50 mm | 80 mm | 13 mm | Two Sides Seals | 0.29 kg |

| 4 |

|

CRBC 6013 UU | 0.6 mm | 60 mm | 90 mm | 13 mm | Two Sides Seals | 0.33 kg |

| 5 |

|

CRBC 7013 UU | 0.6 mm | 70 mm | 100 mm | 13 mm | Two Sides Seals | 0.38 kg |

| 6 |

|

CRBC 8016 UU | 0.6 mm | 80 mm | 120 mm | 16 mm | Two Sides Seals | 0.74 kg |

| 7 |

|

CRBC 9016 UU | 1 mm | 90 mm | 130 mm | 16 mm | Two Sides Seals | 0.81 kg |

| 8 |

|

CRBC 10020 UU | 1 mm | 100 mm | 150 mm | 20 mm | Two Sides Seals | 1.45 kg |

| 9 |

|

CRBC 11020 UU | 1 mm | 110 mm | 160 mm | 20 mm | Two Sides Seals | 1.56 kg |

| 10 |

|

CRBC 12025 UU | 1.5 mm | 120 mm | 180 mm | 25 mm | Two Sides Seals | 2.62 kg |

| 11 |

|

CRBC 13025 UU | 1.5 mm | 130 mm | 190 mm | 25 mm | Two Sides Seals | 2.82 kg |

| 12 |

|

CRBC 14025 UU | 1.5 mm | 140 mm | 200 mm | 25 mm | Two Sides Seals | 2.96 kg |

| 13 |

|

CRBC 15025 UU | 1.5 mm | 150 mm | 210 mm | 25 mm | Two Sides Seals | 3.16 kg |

| 14 |

|

CRBC 15030 UU | 1.5 mm | 150 mm | 230 mm | 30 mm | Two Sides Seals | 5.3 kg |

| 15 |

|

CRBC 20025 UU | 2 mm | 200 mm | 260 mm | 25 mm | Two Sides Seals | 4.0 kg |

| 16 |

|

CRBC 25025 UU | 2.5 mm | 250 mm | 310 mm | 25 mm | Two Sides Seals | 4.97 kg |

| 17 |

|

CRBC 30025 UU | 2.5 mm | 300 mm | 360 mm | 25 mm | Two Sides Seals | 5.88 kg |

Features and advantages of QIBR Crossed Cylindrical Roller Bearings CRBC UU Series

QIBR Crossed Cylindrical Roller Bearings CRBC UU Series have many significant features and advantages, which can solve key problems in various fields, mainly in the following aspects:

1. QIBR crossed cylindrical roller bearings CRBC UU series have the characteristics of high rigidity and high load carrying capacity

QIBR Crossed Cylindrical Roller Bearings CRBC UU Series have good rigidity and load carrying capacity despite their compact design and are suitable for high load applications.

2. QIBR Crossed Cylindrical Roller Bearings CRBC UU Series Characteristics of optimized structural design

QIBR Crossed Cylindrical Roller Bearings CRBC UU Series have a split outer ring and a one-piece inner ring, so they are most suitable for applications that require rotational accuracy of the inner ring. Cage isolation blocks are used between rollers and rollers, the bearings rotate smoothly and are suitable for parts with high speeds.

3. QIBR Crossed Cylindrical Roller Bearings CRBC UU Series low friction and high efficiency

QIBR Crossed Cylindrical Roller Bearings CRBC UU Series reduce bearing friction torque and are suitable for use where low driving torque is required, improving the overall operating efficiency of the equipment.

4. QIBR Crossed Cylindrical Roller Bearings CRBC UU Series Customized Service

QIBR Crossed Cylindrical Roller Bearings CRBC UU Series usually provide customized service, which can design the bearings according to the specific needs and meet the special requirements and working conditions of different industries.

QIBR Crossed Cylindrical Roller Bearings CRBC UU Series Performance Improvement and Solutions

1. Effective improvement of material properties to enhance high load carrying capacity

QIBR Crossed Cylindrical Roller Bearings CRBC UU Series are manufactured with high quality steel for the inner and outer rings and balls, and vacuum heat treatment is used to improve the surface hardness and material properties, thus increasing the load carrying capacity and service life of the bearings.

2. Improvement of manufacturing precision and load capacity

QIBR Crossed Cylindrical Roller Bearings CRBC UU Series adopt foreign advanced processing equipment and technology, such as precision grinding, etc., to improve the geometric accuracy of the inner and outer rings and balls, reduce processing errors, thus improving the rotational accuracy and stability of the bearing.

3. Personalized design

For different occasions on the QIBR Crossed Cylindrical Roller Bearings CRBC UU Series application requirements, to provide personalized structure and size of the program to meet specific performance requirements. This approach not only enriches the standard of bearings, but also provides effective guidance for manufacturers to meet the individual needs of users.

In a word, through optimizing materials, manufacturing precision, personalized design and other measures, the performance of QIBR Crossed Cylindrical Roller Bearings CRBC UU Series can be significantly improved to meet the increasingly demanding application requirements.

QIBR Crossed Cylindrical Roller Bearings CRBC UU Series Main Application Areas

CNC Machine Tools

QIBR Crossed Cylindrical Roller Bearings CRBC UU series can improve the machining accuracy of machine tools and ensure the production of high quality parts. Crossed roller bearings are able to withstand large radial and axial loads at the same time. These bearings play a key role in the spindle and feed system of CNC machine tools, enhancing machining accuracy and productivity.

Rotary Table

QIBR Crossed Cylindrical Roller Bearings CRBC UU Series have high rigidity and can effectively withstand loads from all directions, which enables rotary tables to maintain higher stability and accuracy during operation.

Medical Equipment

The high rigidity and vibration resistance of QIBR Crossed Cylindrical Roller Bearings CRBC UU Series enable them to provide stable support in medical equipment. This is especially important for equipment that requires precise positioning and operation.