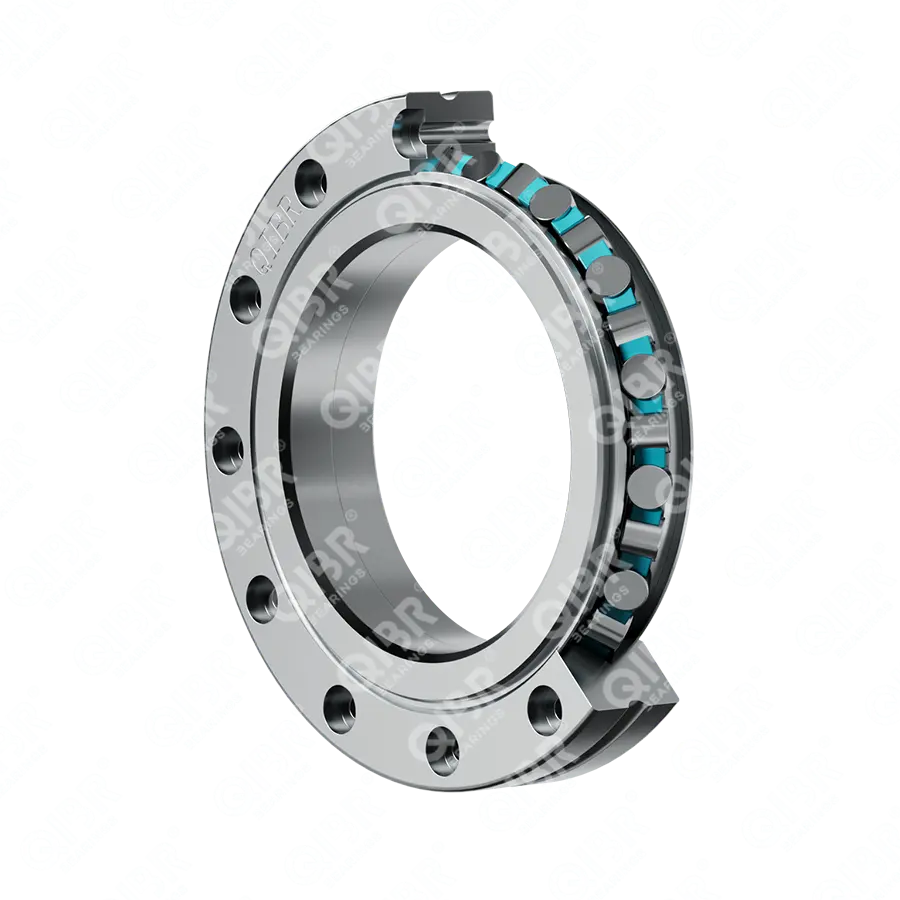

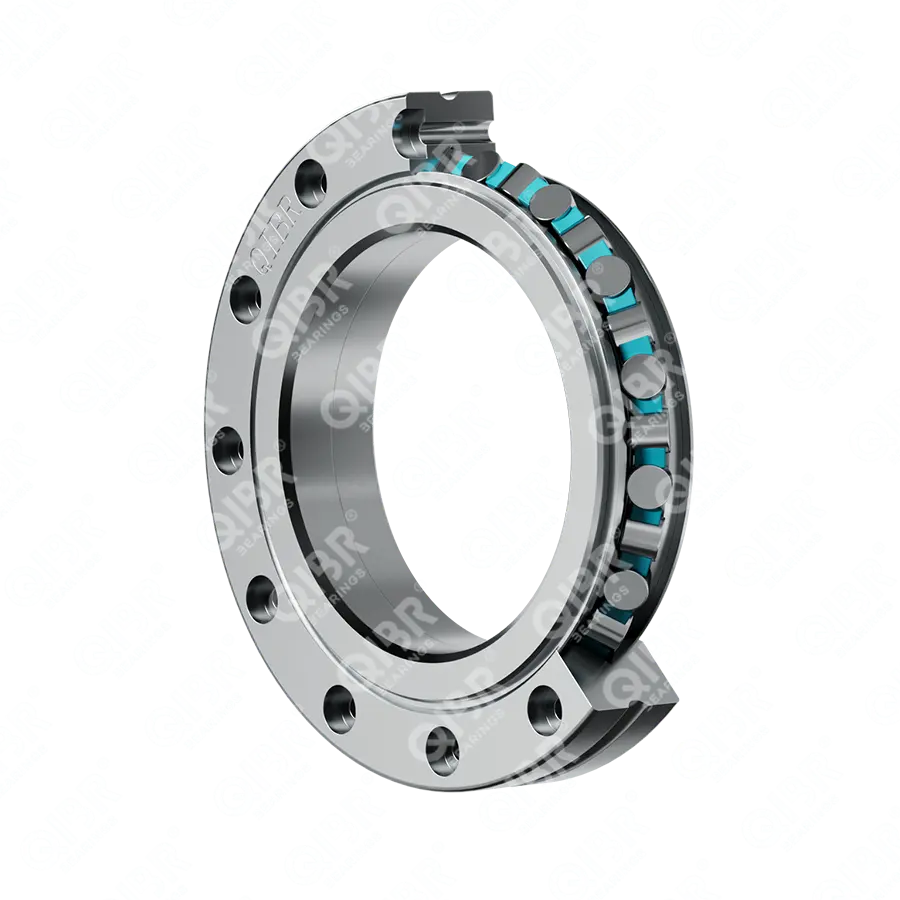

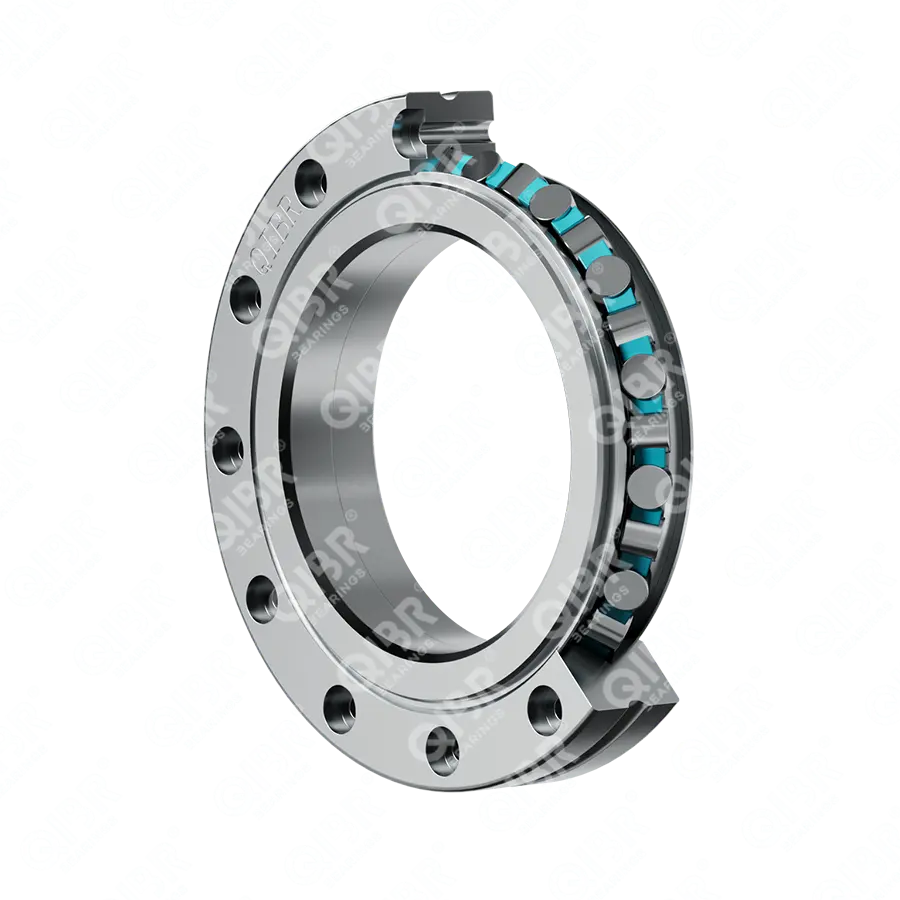

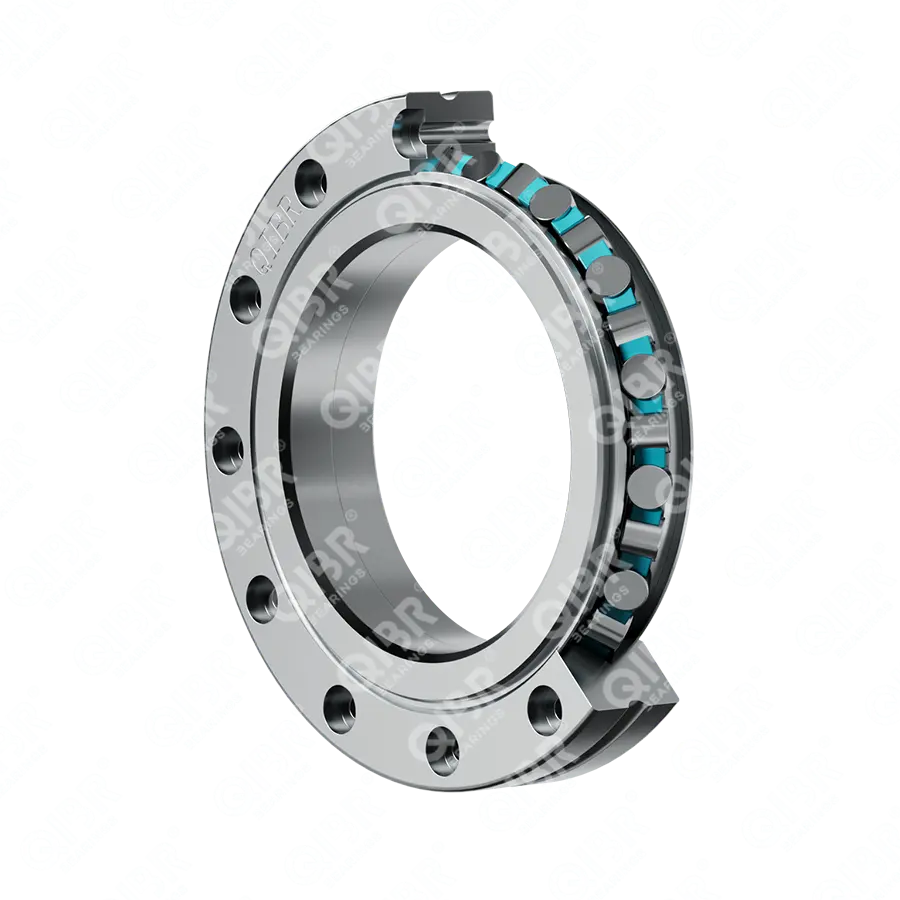

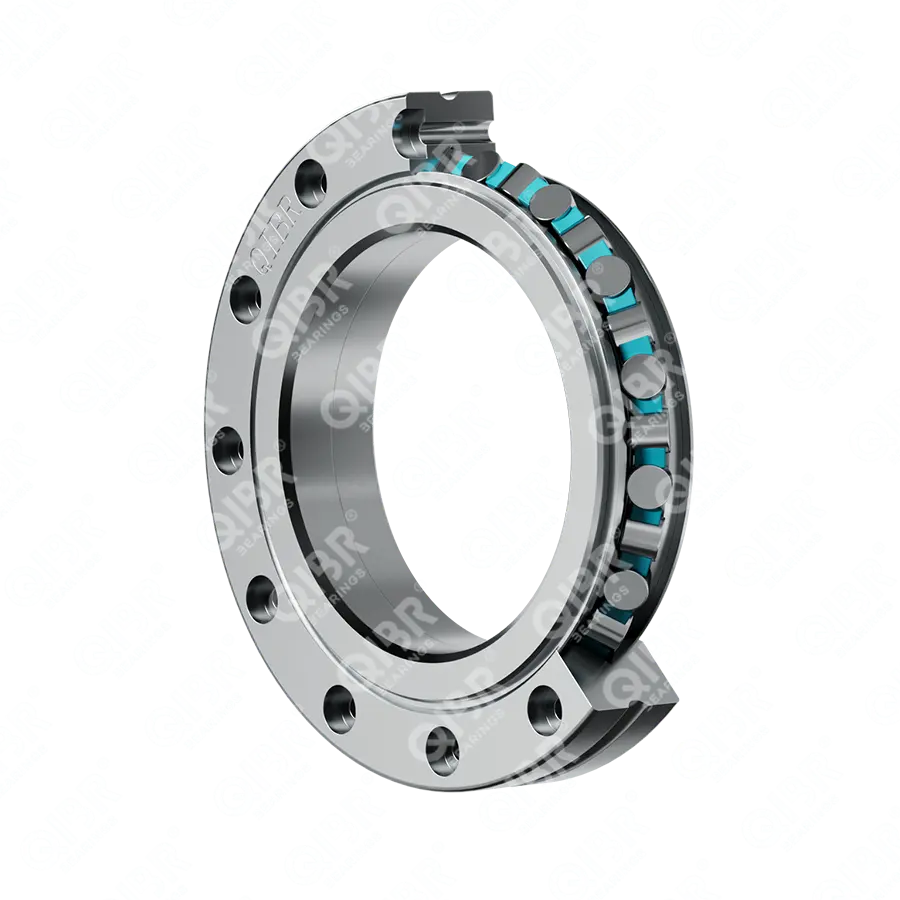

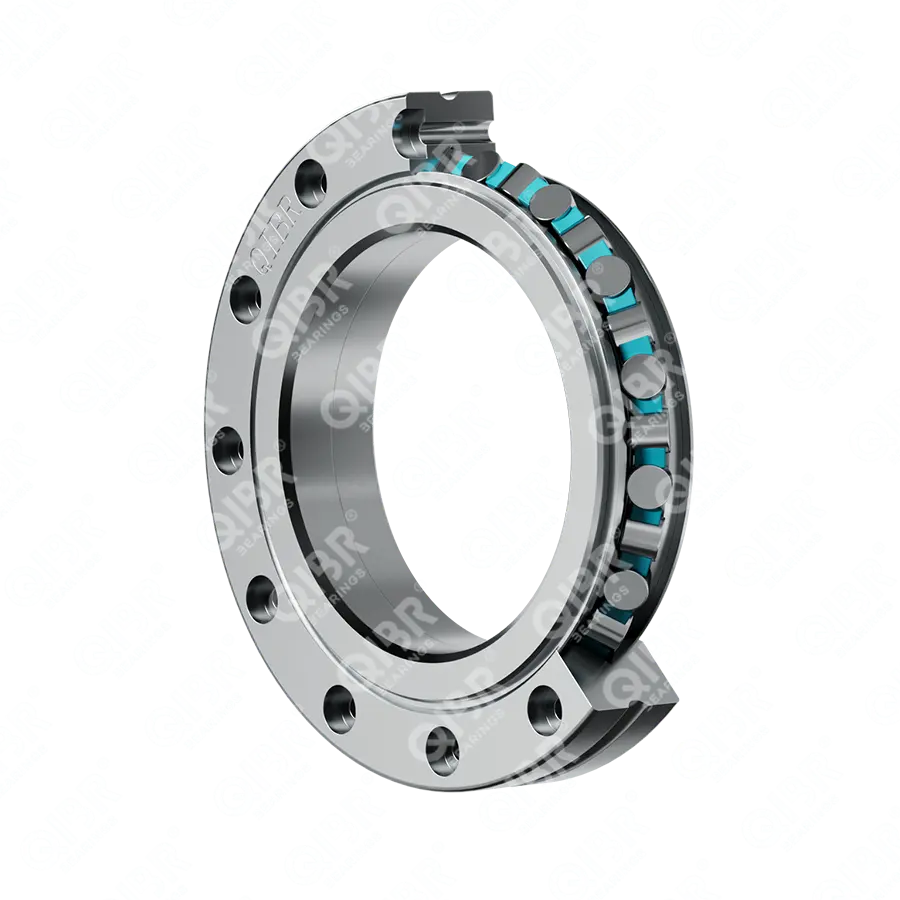

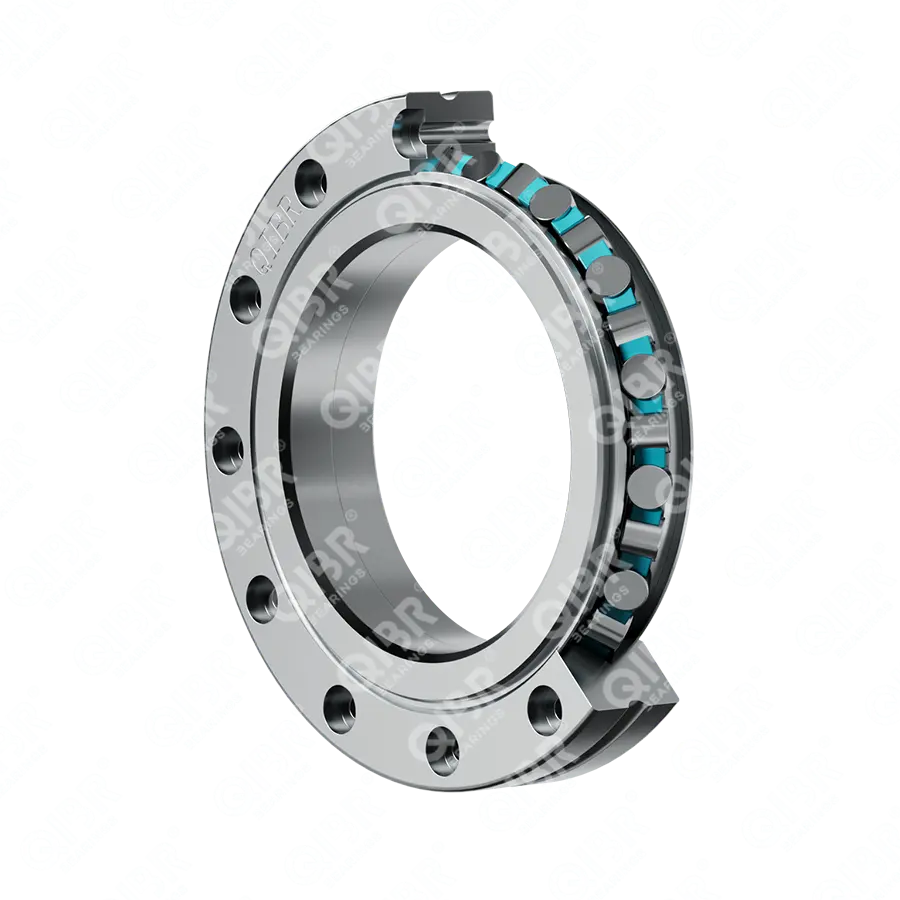

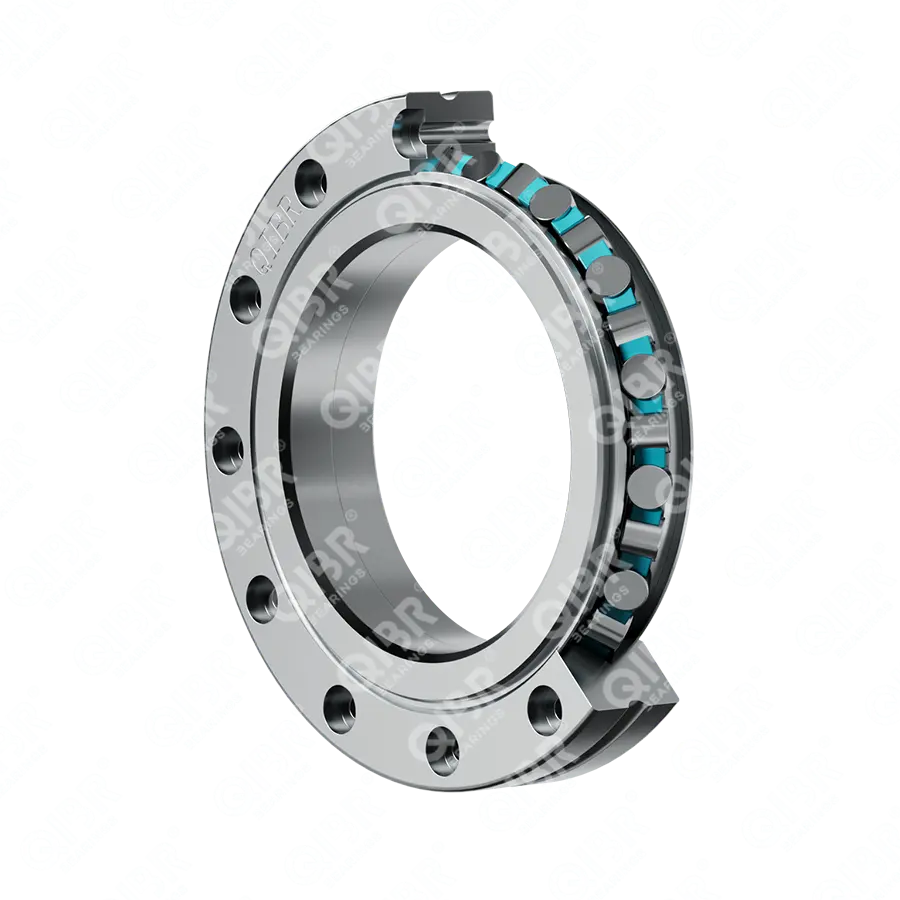

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Material

52100/100Cr6/SUJ2/Stainless Steel

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

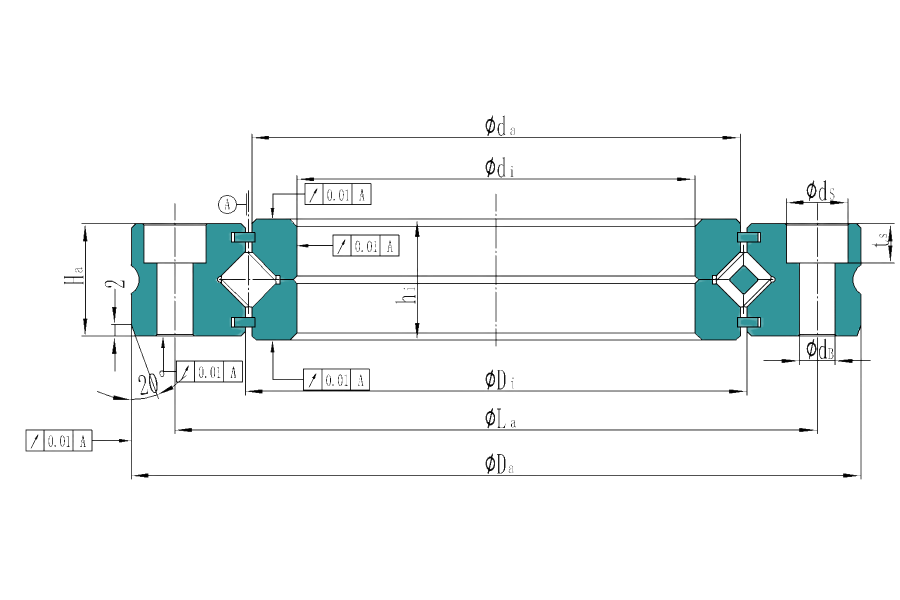

Da

75(+0~-0.019)~180(+0~-0.025)mm

di

30(+0008~-0005)~110(+0.06~-0.006)mm

Applications

Aerospace Industry, Robotics, Medical Devices, Semiconductor Manufacturing Equipment, Optical Equipment, Industrial Machinery, Automotive, etc

| NO. | Product | Product Number | Da | di | Fixing holes (ds) | Fixing holes (La) | Ha | Mass |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

XV 30 | 75(+0~-0.019) mm | 30(+0.008~–0.005) mm | 8 mm | 60 mm | 14 mm | 0.37 kg |

| 2 |

|

XV 40 | 85(+0~-0.022) mm | 40(+0.010~–0.006) mm | 8 mm | 70 mm | 14 mm | 0.44 kg |

| 3 |

|

XV 50 | 100(+0~-0.022) mm | 50(+0.010~–0.006) mm | 10 mm | 85 mm | 16 mm | 0.67 kg |

| 4 |

|

XV 60 | 110(+0~-0.022) mm | 60(+0.013~–0.006) mm | 10 mm | 95 mm | 16 mm | 0.75 kg |

| 5 |

|

XV 70 | 120(+0~-0.022) mm | 70(+0.013~–0.006) mm | 10 mm | 105 mm | 16 mm | 0.84 kg |

| 6 |

|

XV 80 | 135(+0~-0.025) mm | 80(+0.013~–0.006) mm | 11 mm | 120 mm | 18 mm | 1.18 kg |

| 7 |

|

XV 90 | 145(+0~-0.025) mm | 90(+0.016~–0.006) mm | 11 mm | 130 mm | 18 mm | 1.29 kg |

| 8 |

|

XV 100 | 170(+0~-0.025) mm | 100(+0.016~–0.006) mm | 15 mm | 150 mm | 22 mm | 2.31 kg |

| 9 |

|

XV 110 | 180(+0~-0.025) mm | 110(+0.016~–0.006) mm | 15 mm | 160 mm | 22 mm | 2.48 kg |

Features and Advantages of QIBR XV Series Crossed Cylindrical Roller Bearings

High Rigidity and Load Capacity

Despite its compact design, the QIBR XV Series Crossed Cylindrical Roller Bearings offer excellent rigidity and load-bearing capacity, making them suitable for high-load applications.

Optimized Structural Design

The integrated inner ring design of the QIBR XV Series makes it ideal for applications requiring high inner ring rotational precision. Both axial and radial sides have lubrication holes, allowing for convenient multi-directional oil injection.

Low Friction and High Efficiency

The QIBR XV Series Crossed Cylindrical Roller Bearings reduce friction torque, making them suitable for applications that require low driving torque, thereby improving the overall efficiency of the equipment.

Customized Services

QIBR XV Series Crossed Cylindrical Roller Bearings typically offer customization services, allowing for the design of bearings based on specific needs, meeting the unique demands of various industries and working conditions.

Performance Enhancements and Solutions for QIBR XV Series Crossed Cylindrical Roller Bearings

Enhanced Material Performance for Increased Load Capacity

The QIBR XV Series Crossed Cylindrical Roller Bearings are made from high-quality steel for the inner and outer rings and rollers. Vacuum heat treatment is used to improve surface hardness and material performance, thus enhancing the load capacity and extending the service life of the bearings.

Improved Manufacturing Precision and Load Capacity

Advanced foreign equipment and processes, such as precision grinding, are used in the production of the QIBR XV Series, improving the geometric accuracy of the inner and outer rings and rollers, reducing machining errors, and increasing rotational precision and operational stability.

Personalized Design

For different application needs, the QIBR XV Series offers personalized structural dimension solutions to meet specific performance requirements. This approach not only expands bearing standards but also provides manufacturers with effective guidance to meet customers' unique needs.