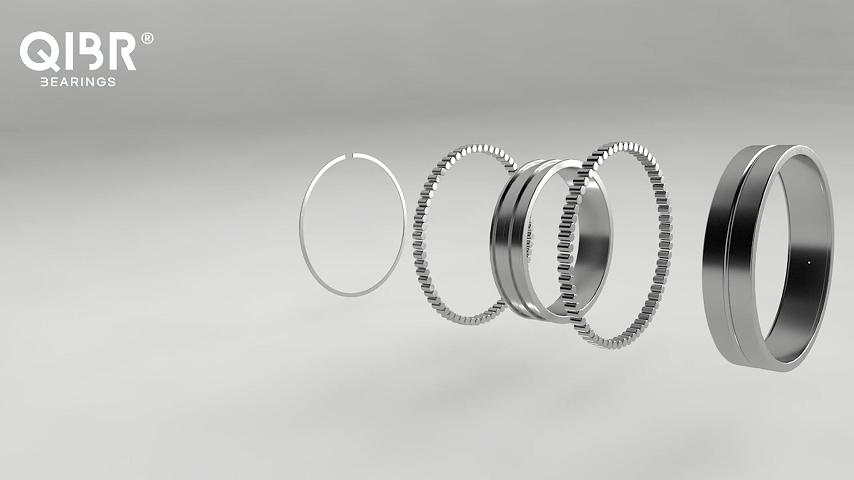

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh,DIN / VDEh

Material

GCr15/100Cr6/Bearing Steel

Inner ring diameter

25-190mm

Outer ring diameter

47-260mm

Weight

0.23-31.5kg

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

commonly used in heavy-duty applications where high radial loads are present, such as industrial gearboxes, rolling mills, and large electric motors.

| NO. | Product | Product Number | Inner diameter (d) | Mass | Outer diameter (D) | Width (B) |

|---|---|---|---|---|---|---|

| 1 |

|

NNCF 5005 CV | 25 mm | 0.23 kg | 47 mm | 30 mm |

| 2 |

|

NNCF 5005 CV/P5 | 25 mm | 0.23 kg | 47 mm | 30 mm |

| 3 |

|

NNCF 5006 CV | 30 mm | 0.35 kg | 55 mm | 34 mm |

| 4 |

|

NNCF 5006 CV/P5 | 30 mm | 0.35 kg | 55 mm | 34 mm |

| 5 |

|

NNCF 5007 CV | 35 mm | 0.46 kg | 62 mm | 36 mm |

| 6 |

|

NNCF 5007 CV/P5 | 35 mm | 0.46 kg | 62 mm | 36 mm |

| 7 |

|

NNCF 5008 CV | 40 mm | 0.56 kg | 68 mm | 38 mm |

| 8 |

|

NNCF 5008 CV/P5 | 40 mm | 0.56 kg | 68 mm | 38 mm |

| 9 |

|

NNCF 5009 CV | 45 mm | 0.71 kg | 75 mm | 40 mm |

| 10 |

|

NNCF 5009 CV/P5 | 45 mm | 0.71 kg | 75 mm | 40 mm |

| 11 |

|

NNCF 5010 CV | 50 mm | 0.76 kg | 80 mm | 40 mm |

| 12 |

|

NNCF 5010 CV/P5 | 50 mm | 0.76 kg | 80 mm | 40 mm |

| 13 |

|

NNCF 5011 CV | 55 mm | 1.15 kg | 90 mm | 46 mm |

| 14 |

|

NNCF 5011 CV/P5 | 55 mm | 1.15 kg | 90 mm | 46 mm |

| 15 |

|

NNCF 4912 CV | 60 mm | 0.48 kg | 85 mm | 25 mm |

| 16 |

|

NNCF 4912 CV/P5 | 60 mm | 0.48 kg | 85 mm | 25 mm |

| 17 |

|

NNCL 4912 CV | 60 mm | 0.47 kg | 85 mm | 25 mm |

| 18 |

|

NNCL 4912 CV/P5 | 60 mm | 0.47 kg | 85 mm | 25 mm |

| 19 |

|

NNC 4912 CV | 60 mm | 0.49 kg | 85 mm | 25 mm |

| 20 |

|

NNC 4912 CV/P5 | 60 mm | 0.49 kg | 85 mm | 25 mm |

| 21 |

|

NNCF 5012 CV | 60 mm | 1.25 kg | 95 mm | 46 mm |

| 22 |

|

NNCF 5012 CV/P5 | 60 mm | 1.25 kg | 95 mm | 46 mm |

| 23 |

|

NNCF 5013 CV | 65 mm | 1.3 kg | 100 mm | 46 mm |

| 24 |

|

NNCF 5013 CV/P5 | 65 mm | 1.3 kg | 100 mm | 46 mm |

| 25 |

|

NNCF 4914 CV | 70 mm | 0.77 kg | 100 mm | 30 mm |

| 26 |

|

NNCF 4914 CV/P5 | 70 mm | 0.77 kg | 100 mm | 30 mm |

| 27 |

|

NNCL 4914 CV | 70 mm | 0.75 kg | 100 mm | 30 mm |

| 28 |

|

NNCL 4914 CV/P5 | 70 mm | 0.75 kg | 100 mm | 30 mm |

| 29 |

|

NNC 4914 CV | 70 mm | 0.78 kg | 100 mm | 30 mm |

| 30 |

|

NNC 4914 CV/P5 | 70 mm | 0.78 kg | 100 mm | 30 mm |

| 31 |

|

NNCF 5014 CV | 70 mm | 1.85 kg | 110 mm | 54 mm |

| 32 |

|

NNCF 5014 CV/P5 | 70 mm | 1.85 kg | 110 mm | 54 mm |

| 33 |

|

NNCF 5015 CV | 75 mm | 1.95 kg | 115 mm | 54 mm |

| 34 |

|

NNCF 5015 CV/P5 | 75 mm | 1.95 kg | 115 mm | 54 mm |

| 35 |

|

NNCF 4916 CV | 80 mm | 0.87 kg | 110 mm | 30 mm |

| 36 |

|

NNCF 4916 CV/P5 | 80 mm | 0.87 kg | 110 mm | 30 mm |

| 37 |

|

NNCL 4916 CV | 80 mm | 0.85 kg | 110 mm | 30 mm |

| 38 |

|

NNCL 4916 CV/P5 | 80 mm | 0.85 kg | 110 mm | 30 mm |

| 39 |

|

NNC 4916 CV | 80 mm | 0.88 kg | 110 mm | 30 mm |

| 40 |

|

NNC 4916 CV/P5 | 80 mm | 0.88 kg | 110 mm | 30 mm |

| 41 |

|

NNCF 5016 CV | 80 mm | 2.6 kg | 125 mm | 60 mm |

| 42 |

|

NNCF 5016 CV/P5 | 80 mm | 2.6 kg | 125 mm | 60 mm |

| 43 |

|

NNCF 5017 CV | 85 mm | 2.7 kg | 130 mm | 60 mm |

| 44 |

|

NNCF 5017 CV/P5 | 85 mm | 2.7 kg | 130 mm | 60 mm |

| 45 |

|

NNCF 4918 CV | 90 mm | 1.35 kg | 125 mm | 35 mm |

| 46 |

|

NNCF 4918 CV/P5 | 90 mm | 1.35 kg | 125 mm | 35 mm |

| 47 |

|

NNCL 4918 CV | 90 mm | 1.3 kg | 125 mm | 35 mm |

| 48 |

|

NNCL 4918 CV/P5 | 90 mm | 1.3 kg | 125 mm | 35 mm |

| 49 |

|

NNC 4918 CV | 90 mm | 1.35 kg | 125 mm | 35 mm |

| 50 |

|

NNC 4918 CV/P5 | 90 mm | 1.35 kg | 125 mm | 35 mm |

| 51 |

|

NNCF 5018 CV | 90 mm | 3.6 kg | 140 mm | 67 mm |

| 52 |

|

NNCF 5018 CV/P5 | 90 mm | 3.6 kg | 140 mm | 67 mm |

| 53 |

|

NNCF 4920 CV | 100 mm | 1.95 kg | 140 mm | 40 mm |

| 54 |

|

NNCF 4920 CV/P5 | 100 mm | 1.95 kg | 140 mm | 40 mm |

| 55 |

|

NNCL 4920 CV | 100 mm | 1.9 kg | 140 mm | 40 mm |

| 56 |

|

NNCL 4920 CV/P5 | 100 mm | 1.9 kg | 140 mm | 40 mm |

| 57 |

|

NNC 4920 CV | 100 mm | 1.95 kg | 140 mm | 40 mm |

| 58 |

|

NNC 4920 CV/P5 | 100 mm | 1.95 kg | 140 mm | 40 mm |

| 59 |

|

NNCF 5020 CV | 100 mm | 3.95 kg | 150 mm | 67 mm |

| 60 |

|

NNCF 5020 CV/P5 | 100 mm | 3.95 kg | 150 mm | 67 mm |

| 61 |

|

NNCF 4922 CV | 110 mm | 2.1 kg | 150 mm | 40 mm |

| 62 |

|

NNCF 4922 CV/P5 | 110 mm | 2.1 kg | 150 mm | 40 mm |

| 63 |

|

NNCL 4922 CV | 110 mm | 2.1 kg | 150 mm | 40 mm |

| 64 |

|

NNCL 4922 CV/P5 | 110 mm | 2.1 kg | 150 mm | 40 mm |

| 65 |

|

NNC 4922 CV | 110 mm | 2.15 kg | 150 mm | 40 mm |

| 66 |

|

NNC 4922 CV/P5 | 110 mm | 2.15 kg | 150 mm | 40 mm |

| 67 |

|

NNCF 5022 CV | 110 mm | 6.3 kg | 170 mm | 80 mm |

| 68 |

|

NNCF 5022 CV/P5 | 110 mm | 6.3 kg | 170 mm | 80 mm |

| 69 |

|

NNCF 4924 CV | 120 mm | 2.9 kg | 165 mm | 45 mm |

| 70 |

|

NNCF 4924 CV/P5 | 120 mm | 2.9 kg | 165 mm | 45 mm |

| 71 |

|

NNCL 4924 CV | 120 mm | 2.85 kg | 165 mm | 45 mm |

| 72 |

|

NNCL 4924 CV/P5 | 120 mm | 2.85 kg | 165 mm | 45 mm |

| 73 |

|

NNC 4924 CV | 120 mm | 2.9 kg | 165 mm | 45 mm |

| 74 |

|

NNC 4924 CV/P5 | 120 mm | 2.9 kg | 165 mm | 45 mm |

| 75 |

|

NNCF 5024 CV | 120 mm | 6.75 kg | 180 mm | 80 mm |

| 76 |

|

NNCF 5024 CV/P5 | 120 mm | 6.75 kg | 180 mm | 80 mm |

| 77 |

|

NNCF 4926 CV | 130 mm | 3.9 kg | 180 mm | 50 mm |

| 78 |

|

NNCF 4926 CV/P5 | 130 mm | 3.9 kg | 180 mm | 50 mm |

| 79 |

|

NNCL 4926 CV | 130 mm | 3.8 kg | 180 mm | 50 mm |

| 80 |

|

NNCL 4926 CV/P5 | 130 mm | 3.8 kg | 180 mm | 50 mm |

| 81 |

|

NNC 4926 CV | 130 mm | 3.95 kg | 180 mm | 50 mm |

| 82 |

|

NNC 4926 CV/P5 | 130 mm | 3.95 kg | 180 mm | 50 mm |

| 83 |

|

NNCF 5026 CV | 130 mm | 10 kg | 200 mm | 95 mm |

| 84 |

|

NNCF 5026 CV/P5 | 130 mm | 10 kg | 200 mm | 95 mm |

| 85 |

|

NNCF 4928 CV | 140 mm | 4.15 kg | 190 mm | 50 mm |

| 86 |

|

NNCF 4928 CV/P5 | 140 mm | 4.15 kg | 190 mm | 50 mm |

| 87 |

|

NNCL 4928 CV | 140 mm | 4.1 kg | 190 mm | 50 mm |

| 88 |

|

NNCL 4928 CV/P5 | 140 mm | 4.1 kg | 190 mm | 50 mm |

| 89 |

|

NNC 4928 CV | 140 mm | 4.2 kg | 190 mm | 50 mm |

| 90 |

|

NNC 4928 CV/P5 | 140 mm | 4.2 kg | 190 mm | 50 mm |

| 91 |

|

NNCF 5028 CV | 140 mm | 11 kg | 210 mm | 95 mm |

| 92 |

|

NNCF 5028 CV/P5 | 140 mm | 11 kg | 210 mm | 95 mm |

| 93 |

|

NNCF 4830 CV | 150 mm | 2.8 kg | 190 mm | 40 mm |

| 94 |

|

NNCF 4830 CV/P5 | 150 mm | 2.8 kg | 190 mm | 40 mm |

| 95 |

|

NNCL 4830 CV | 150 mm | 2.7 kg | 190 mm | 40 mm |

| 96 |

|

NNCL 4830 CV/P5 | 150 mm | 2.7 kg | 190 mm | 40 mm |

| 97 |

|

NNC 4830 CV | 150 mm | 2.9 kg | 190 mm | 40 mm |

| 98 |

|

NNC 4830 CV/P5 | 150 mm | 2.9 kg | 190 mm | 40 mm |

| 99 |

|

NNCF 4930 CV | 150 mm | 6.55 kg | 210 mm | 60 mm |

| 100 |

|

NNCF 4930 CV/P5 | 150 mm | 6.55 kg | 210 mm | 60 mm |

Features and advantages of QIBR double row full complement cylindrical roller bearings

QIBR double row full complement cylindrical roller bearings solves several key problems in various fields, which are mainly reflected in the following aspects:

1. High load capacity of QIBR double row full complement cylindrical roller bearings

QIBR double row full complement cylindrical roller bearings have more rollers than ordinary cylindrical roller bearings, and the contact area between the rollers and the inner and outer rings is larger, which enables the bearings to withstand higher radial loads. The double-row design further enhances its load-bearing capacity, making it suitable for high-load applications.

2. QIBR double row full complement cylindrical roller bearings have excellent sealing performance

The sealing structure of QIBR double row full complement cylindrical roller bearings can effectively prevent lubricant leakage and external dust, moisture and other harmful substances from invading, thereby extending the service life

3. QIBR double row full complement cylindrical roller bearings have excellent rigidity and stability

QIBR double row full complement cylindrical roller bearings have small deformation when loaded and show high rigidity, which makes them particularly suitable for occasions such as machine tool spindles that require high precision and stability

4. QIBR double row full complement cylindrical roller bearings effectively control noise

The high-precision QIBR double row full complement cylindrical roller bearings can effectively reduce noise during operation and improve the overall performance of the equipment through precise installation, proper lubrication and advanced monitoring systems.

5. QIBR double row full complement cylindrical roller bearings are highly cost-effective

The design of QIBR double row full complement cylindrical roller bearings allows them to provide efficient load support in a relatively small space. Using QIBR double row full complement cylindrical roller bearings can reduce costs while improving rigidity and stability.

The performance improvement and solutions of QIBR double row full complement cylindrical roller bearings

1. Improve sealing performance

QIBR double row full complement cylindrical roller bearings use high temperature resistant, wear resistant and corrosion resistant sealing materials, which can better adapt to harsh working conditions and ensure long-term stable operation of bearings under extreme conditions.

2. Optimize rollers

QIBR double row full complement cylindrical roller bearings can reduce contact stress, improve load capacity and durability by optimizing roller shape. Roller surface treatment can reduce friction, improve rolling accuracy and load capacity, and extend the service life of bearings.

3. Improve manufacturing accuracy

QIBR double row full complement cylindrical roller bearings use advanced foreign processing equipment and processes, such as precision grinding, super-fine grinding, etc., to improve the geometric accuracy of inner and outer rings and rollers, reduce processing errors, and thus improve the rotation accuracy and roughness of bearings.

4. Improve material performance

QIBR double row full complement cylindrical roller bearings use surface coating technology (such as chrome plating, nitriding, etc.) to improve the wear resistance and corrosion resistance of bearings, effectively extend the service life of bearings, especially when working in harsh environments, the performance of bearings can be significantly improved.

Main application areas of QIBR double row full complement cylindrical roller bearings

1. Mining machinery

Such as ball mills, crushers, vibrating screens and other equipment. These equipment will generate large radial loads during operation and have a harsh working environment. QIBR double row full complement cylindrical roller bearings can effectively withstand this high load and have high impact resistance.

2. Heavy machine tools

In high-precision heavy machine tools, QIBR double row full complement cylindrical roller bearings are used to withstand heavy loads and ensure the processing accuracy and stability of the machine.

3. Drilling equipment

In oil drilling equipment, QIBR double row full complement cylindrical roller bearings are used to withstand the high load and complex working environment of the drilling rig. It can maintain good operation under extreme conditions.

4. Locomotive axle box

QIBR double row full complement cylindrical roller bearings are widely used in the axle boxes of railway locomotives. This bearing design can withstand high loads and effectively prevent the intrusion of dust and moisture, thereby improving the reliability and service life of the bearing.