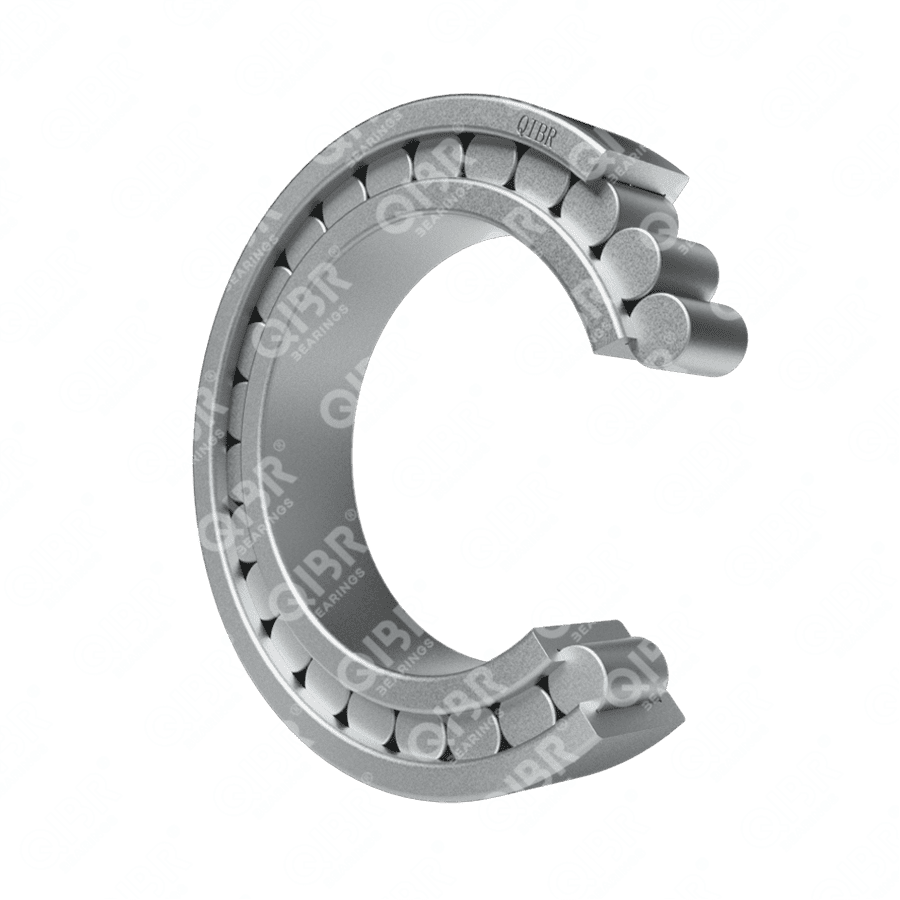

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh,DIN / VDEh

Material

GCr15/100Cr6/ Bearing Steel

Inner ring diameter

20-130mm

Outer ring diameter

42-280mm

Weight

0.11-28kg

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

Large and medium-sized electric motors, Locomotive vehicles, Machine tool spindles, Internal combustion engines, Generators, Gas turbines, Gearboxes, Rolling mills, Vibrating screens, lifting and transportation machinery, etc.

| NO. | Product | Product Number | Basic dynamic load rating | Basic static load rating | Inner diameter (d) | Outer diameter (D) | Width (B) |

|---|---|---|---|---|---|---|---|

| 1 |

|

NCF 3004 CV | 28.1 KN | 28.5 KN | 20 mm | 42 mm | 16 mm |

| 2 |

|

NCF 3004 CV/P5 | 28.1 KN | 28.5 KN | 20 mm | 42 mm | 16 mm |

| 3 |

|

NCF 3005 CV | 31.9 KN | 35.5 KN | 25 mm | 47 mm | 16 mm |

| 4 |

|

NCF 3005 CV/P5 | 31.9 KN | 35.5 KN | 25 mm | 47 mm | 16 mm |

| 5 |

|

NJG 2305 VH | 68.2 KN | 68 KN | 25 mm | 62 mm | 24 mm |

| 6 |

|

NJG 2305 VH/P5 | 68.2 KN | 68 KN | 25 mm | 62 mm | 24 mm |

| 7 |

|

NCF 3006 CV | 39.6 KN | 44 KN | 30 mm | 55 mm | 19 mm |

| 8 |

|

NCF 3006 CV/P5 | 39.6 KN | 44 KN | 30 mm | 55 mm | 19 mm |

| 9 |

|

NJG 2306 VH | 84.2 KN | 86.5 KN | 30 mm | 72 mm | 27 mm |

| 10 |

|

NJG 2306 VH/P5 | 84.2 KN | 86.5 KN | 30 mm | 72 mm | 27 mm |

| 11 |

|

NCF 3007 CV | 48.4 KN | 56 KN | 35 mm | 62 mm | 20 mm |

| 12 |

|

NCF 3007 CV/P5 | 48.4 KN | 56 KN | 35 mm | 62 mm | 20 mm |

| 13 |

|

NJG 2307 VH | 108 KN | 114 KN | 35 mm | 80 mm | 31 mm |

| 14 |

|

NJG 2307 VH/P5 | 108 KN | 114 KN | 35 mm | 80 mm | 31 mm |

| 15 |

|

NCF 3008 CV | 57.2 KN | 69.5 KN | 40 mm | 68 mm | 21 mm |

| 16 |

|

NCF 3008 CV/P5 | 57.2 KN | 69.5 KN | 40 mm | 68 mm | 21 mm |

| 17 |

|

NJG 2308 VH | 145 KN | 156 KN | 40 mm | 90 mm | 33 mm |

| 18 |

|

NJG 2308 VH/P5 | 145 KN | 156 KN | 40 mm | 90 mm | 33 mm |

| 19 |

|

NCF 3009 CV | 60.5 KN | 78 KN | 45 mm | 75 mm | 23 mm |

| 20 |

|

NCF 3009 CV/P5 | 60.5 KN | 78 KN | 45 mm | 75 mm | 23 mm |

| 21 |

|

NJG 309 VH | 110 KN | 112 KN | 45 mm | 100 mm | 25 mm |

| 22 |

|

NJG 309 VH/P5 | 110 KN | 112 KN | 45 mm | 100 mm | 25 mm |

| 23 |

|

NJG 2309 VH | 172 KN | 196 KN | 45 mm | 100 mm | 36 mm |

| 24 |

|

NJG 2309 VH/P5 | 172 KN | 196 KN | 45 mm | 100 mm | 36 mm |

| 25 |

|

NCF 3010 CV | 76.5 KN | 98 KN | 50 mm | 80 mm | 23 mm |

| 26 |

|

NCF 3010 CV/P5 | 76.5 KN | 98 KN | 50 mm | 80 mm | 23 mm |

| 27 |

|

NCF 3011 CV | 105 KN | 140 KN | 55 mm | 90 mm | 26 mm |

| 28 |

|

NCF 3011 CV/P5 | 105 KN | 140 KN | 55 mm | 90 mm | 26 mm |

| 29 |

|

NJG 2311 VH | 233 KN | 260 KN | 55 mm | 120 mm | 43 mm |

| 30 |

|

NJG 2311 VH/P5 | 233 KN | 260 KN | 55 mm | 120 mm | 43 mm |

| 31 |

|

NCF 2912 CV | 55 KN | 80 KN | 60 mm | 85 mm | 16 mm |

| 32 |

|

NCF 2912 CV/P5 | 55 KN | 80 KN | 60 mm | 85 mm | 16 mm |

| 33 |

|

NCF 3012 CV | 106 KN | 146 KN | 60 mm | 95 mm | 26 mm |

| 34 |

|

NCF 3012 CV/P5 | 106 KN | 146 KN | 60 mm | 95 mm | 26 mm |

| 35 |

|

NCF 2913 CV | 58.3 KN | 88 KN | 65 mm | 90 mm | 16 mm |

| 36 |

|

NCF 2913 CV/P5 | 58.3 KN | 88 KN | 65 mm | 90 mm | 16 mm |

| 37 |

|

NCF 3013 CV | 112 KN | 163 KN | 65 mm | 100 mm | 26 mm |

| 38 |

|

NCF 3013 CV/P5 | 112 KN | 163 KN | 65 mm | 100 mm | 26 mm |

| 39 |

|

NJG 2313 VH | 303 KN | 360 KN | 65 mm | 140 mm | 48 mm |

| 40 |

|

NJG 2313 VH/P5 | 303 KN | 360 KN | 65 mm | 140 mm | 48 mm |

| 41 |

|

NCF 2914 CV | 76.5 KN | 116 KN | 70 mm | 100 mm | 19 mm |

| 42 |

|

NCF 2914 CV/P5 | 76.5 KN | 116 KN | 70 mm | 100 mm | 19 mm |

| 43 |

|

NCF 3014 CV | 128 KN | 173 KN | 70 mm | 110 mm | 30 mm |

| 44 |

|

NCF 3014 CV/P5 | 128 KN | 173 KN | 70 mm | 110 mm | 30 mm |

| 45 |

|

NJG 2314 VH | 336 KN | 400 KN | 70 mm | 150 mm | 51 mm |

| 46 |

|

NJG 2314 VH/P5 | 336 KN | 400 KN | 70 mm | 150 mm | 51 mm |

| 47 |

|

NCF 2915 CV | 79.2 KN | 125 KN | 75 mm | 105 mm | 19 mm |

| 48 |

|

NCF 2915 CV/P5 | 79.2 KN | 125 KN | 75 mm | 105 mm | 19 mm |

| 49 |

|

NCF 3015 CV | 134 KN | 190 KN | 75 mm | 115 mm | 30 mm |

| 50 |

|

NCF 3015 CV/P5 | 134 KN | 190 KN | 75 mm | 115 mm | 30 mm |

| 51 |

|

NJG 2315 VH | 396 KN | 480 KN | 75 mm | 160 mm | 55 mm |

| 52 |

|

NJG 2315 VH/P5 | 396 KN | 480 KN | 75 mm | 160 mm | 55 mm |

| 53 |

|

NCF 2916 CV | 80.9 KN | 132 KN | 80 mm | 110 mm | 19 mm |

| 54 |

|

NCF 2916 CV/P5 | 80.9 KN | 132 KN | 80 mm | 110 mm | 19 mm |

| 55 |

|

NCF 3016 CV | 165 KN | 228 KN | 80 mm | 125 mm | 34 mm |

| 56 |

|

NCF 3016 CV/P5 | 165 KN | 228 KN | 80 mm | 125 mm | 34 mm |

| 57 |

|

NJG 2316 VH | 457 KN | 570 KN | 80 mm | 170 mm | 58 mm |

| 58 |

|

NJG 2316 VH/P5 | 457 KN | 570 KN | 80 mm | 170 mm | 58 mm |

| 59 |

|

NCF 2917 CV | 102 KN | 166 KN | 85 mm | 120 mm | 22 mm |

| 60 |

|

NCF 2917 CV/P5 | 102 KN | 166 KN | 85 mm | 120 mm | 22 mm |

| 61 |

|

NCF 3017 CV | 172 KN | 236 KN | 85 mm | 130 mm | 34 mm |

| 62 |

|

NCF 3017 CV/P5 | 172 KN | 236 KN | 85 mm | 130 mm | 34 mm |

| 63 |

|

NJG 2317 VH | 484 KN | 620 KN | 85 mm | 180 mm | 60 mm |

| 64 |

|

NJG 2317 VH/P5 | 484 KN | 620 KN | 85 mm | 180 mm | 60 mm |

| 65 |

|

NCF 2918 CV | 105 KN | 176 KN | 90 mm | 125 mm | 22 mm |

| 66 |

|

NCF 2918 CV/P5 | 105 KN | 176 KN | 90 mm | 125 mm | 22 mm |

| 67 |

|

NCF 3018 CV | 198 KN | 280 KN | 90 mm | 140 mm | 37 mm |

| 68 |

|

NCF 3018 CV/P5 | 198 KN | 280 KN | 90 mm | 140 mm | 37 mm |

| 69 |

|

NJG 2318 VH | 550 KN | 680 KN | 90 mm | 190 mm | 64 mm |

| 70 |

|

NJG 2318 VH/P5 | 550 KN | 680 KN | 90 mm | 190 mm | 64 mm |

| 71 |

|

NCF 2920 CV | 128 KN | 200 KN | 100 mm | 140 mm | 24 mm |

| 72 |

|

NCF 2920 CV/P5 | 128 KN | 200 KN | 100 mm | 140 mm | 24 mm |

| 73 |

|

NCF 3020 CV | 209 KN | 310 KN | 100 mm | 150 mm | 37 mm |

| 74 |

|

NCF 3020 CV/P5 | 209 KN | 310 KN | 100 mm | 150 mm | 37 mm |

| 75 |

|

NJG 2320 VH | 704 KN | 900 KN | 100 mm | 215 mm | 73 mm |

| 76 |

|

NJG 2320 VH/P5 | 704 KN | 900 KN | 100 mm | 215 mm | 73 mm |

| 77 |

|

NCF 2922 CV | 134 KN | 220 KN | 110 mm | 150 mm | 24 mm |

| 78 |

|

NCF 2922 CV/P5 | 134 KN | 220 KN | 110 mm | 150 mm | 24 mm |

| 79 |

|

NCF 3022 CV | 275 KN | 400 KN | 110 mm | 170 mm | 45 mm |

| 80 |

|

NCF 3022 CV/P5 | 275 KN | 400 KN | 110 mm | 170 mm | 45 mm |

| 81 |

|

NJG 2322 VH | 858 KN | 1060 KN | 110 mm | 240 mm | 80 mm |

| 82 |

|

NJG 2322 VH/P5 | 858 KN | 1060 KN | 110 mm | 240 mm | 80 mm |

| 83 |

|

NCF 2924 CV | 172 KN | 290 KN | 120 mm | 165 mm | 27 mm |

| 84 |

|

NCF 2924 CV/P5 | 172 KN | 290 KN | 120 mm | 165 mm | 27 mm |

| 85 |

|

NCF 3024 CV | 292 KN | 440 KN | 120 mm | 180 mm | 46 mm |

| 86 |

|

NCF 3024 CV/P5 | 292 KN | 440 KN | 120 mm | 180 mm | 46 mm |

| 87 |

|

NCF 2224 CV | 512 KN | 735 KN | 120 mm | 215 mm | 58 mm |

| 88 |

|

NCF 2224 CV/P5 | 512 KN | 735 KN | 120 mm | 215 mm | 58 mm |

| 89 |

|

NJG 2324 VH | 952 KN | 1250 KN | 120 mm | 260 mm | 86 mm |

| 90 |

|

NJG 2324 VH/P5 | 952 KN | 1250 KN | 120 mm | 260 mm | 86 mm |

| 91 |

|

NCF 2926 CV | 205 KN | 360 KN | 130 mm | 180 mm | 30 mm |

| 92 |

|

NCF 2926 CV/P5 | 205 KN | 360 KN | 130 mm | 180 mm | 30 mm |

| 93 |

|

NCF 3026 CV | 413 KN | 620 KN | 130 mm | 200 mm | 52 mm |

| 94 |

|

NCF 3026 CV/P5 | 413 KN | 620 KN | 130 mm | 200 mm | 52 mm |

| 95 |

|

NJG 2326 VH | 1080 KN | 1430 KN | 130 mm | 280 mm | 93 mm |

| 96 |

|

NJG 2326 VH/P5 | 1080 KN | 1430 KN | 130 mm | 280 mm | 93 mm |

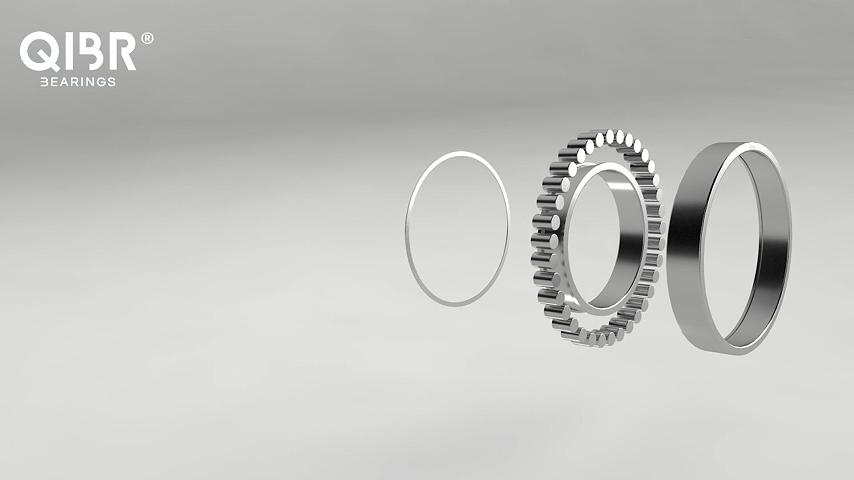

Features and advantages of QIBR single row full complement cylindrical roller bearings

QIBR single row full complement cylindrical roller bearings solves several key problems in various fields, which are mainly reflected in the following aspects:

1. High load capacity of QIBR single row full complement cylindrical roller bearings

QIBR single row full complement cylindrical roller bearings have more rollers than ordinary cylindrical roller bearings, and the contact area between the rollers and the inner and outer rings is larger, which enables the bearings to withstand higher radial loads.

2. Good wear resistance of QIBR single row full complement cylindrical roller bearings

QIBR single row full complement cylindrical roller bearings have a lower wear rate due to the large contact area of the rollers, which is suitable for equipment with high loads and long-term stable operation.

3. QIBR single row full complement cylindrical roller bearings have excellent rigidity and stability

QIBR single row full complement cylindrical roller bearings have small deformation when loaded and show high rigidity, which makes them particularly suitable for occasions such as machine tool spindles that require high precision and stability

4. QIBR single row full complement cylindrical roller bearings effectively control noise

High-precision QIBR single row full complement cylindrical roller bearings can effectively reduce noise during operation and improve the overall performance of the equipment through precise installation, proper lubrication and advanced monitoring systems.

5. QIBR single row full complement cylindrical roller bearings are highly cost-effective

The design of QIBR single row full complement cylindrical roller bearings allows them to provide efficient load support in a relatively small space. Using QIBR single row full complement cylindrical roller bearings can reduce costs while improving rigidity and stability.

The performance improvement and solutions of QIBR single row full complement cylindrical roller bearings

1. Dustproof and waterproof design

Especially in harsh environments, bearings need to have adequate protection measures to prevent dust, mud and water and other impurities from entering the bearings. This can be achieved by designing seals to avoid affecting the bearing's operating performance and life.

2. Improve the bearing's appearance structure

By optimizing the geometry of the outer and inner rings (such as rounded corners), reduce the friction between the inner and outer rings, and improve the smoothness and efficiency of operation.

3. Improve manufacturing accuracy

Adopt advanced foreign processing equipment and processes, such as precision grinding, super-fine grinding, etc., to improve the geometric accuracy of the inner and outer rings and rollers, reduce processing errors, and thus improve the rotation accuracy and roughness of the bearings.

4. Improve material performance

The use of surface coating technology (such as chrome plating, nitriding, etc.) can improve the wear resistance and corrosion resistance of the bearings, effectively extend the service life of the bearings, especially when working in harsh environments, the performance of the bearings can be significantly improved.

Main application areas of QIBR single row full complement cylindrical roller bearings

1. Mining machinery: such as ball mills, crushers, vibrating screens and other equipment, these equipment will generate large radial loads during operation, and the working environment is harsh. QIBR single row full complement cylindrical roller bearings can effectively withstand such high loads and have high impact resistance.

2. Heavy machine tools: In high-precision heavy machine tools, QIBR single row full complement cylindrical roller bearings are used to withstand heavy loads and ensure the processing accuracy and stability of the machine.

3. Power industry: In some large-scale power generation equipment, especially hydro-generators and wind turbines, QIBR single row full complement cylindrical roller bearings can withstand a large amount of radial loads to ensure the stability and efficient operation of the equipment.

4. Locomotive axle box: QIBR single row full complement cylindrical roller bearings are widely used in the axle box of railway locomotives. This bearing design can withstand high loads and effectively prevent the intrusion of dust and moisture, thereby improving the reliability and service life of the bearing.