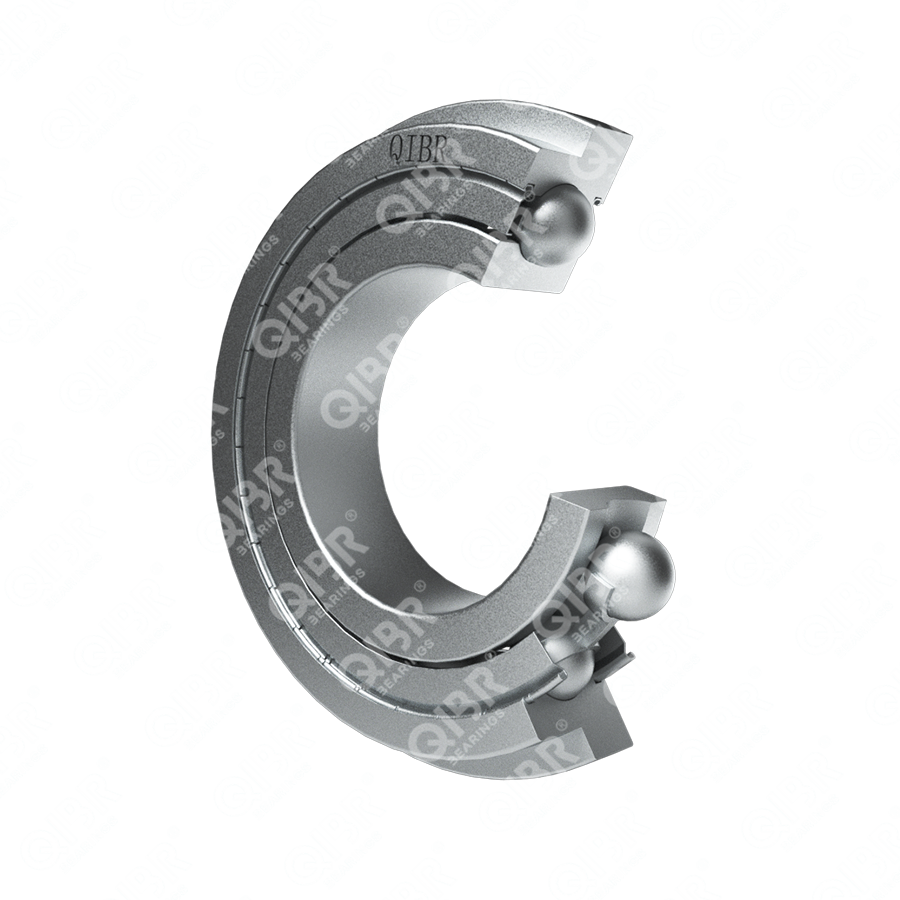

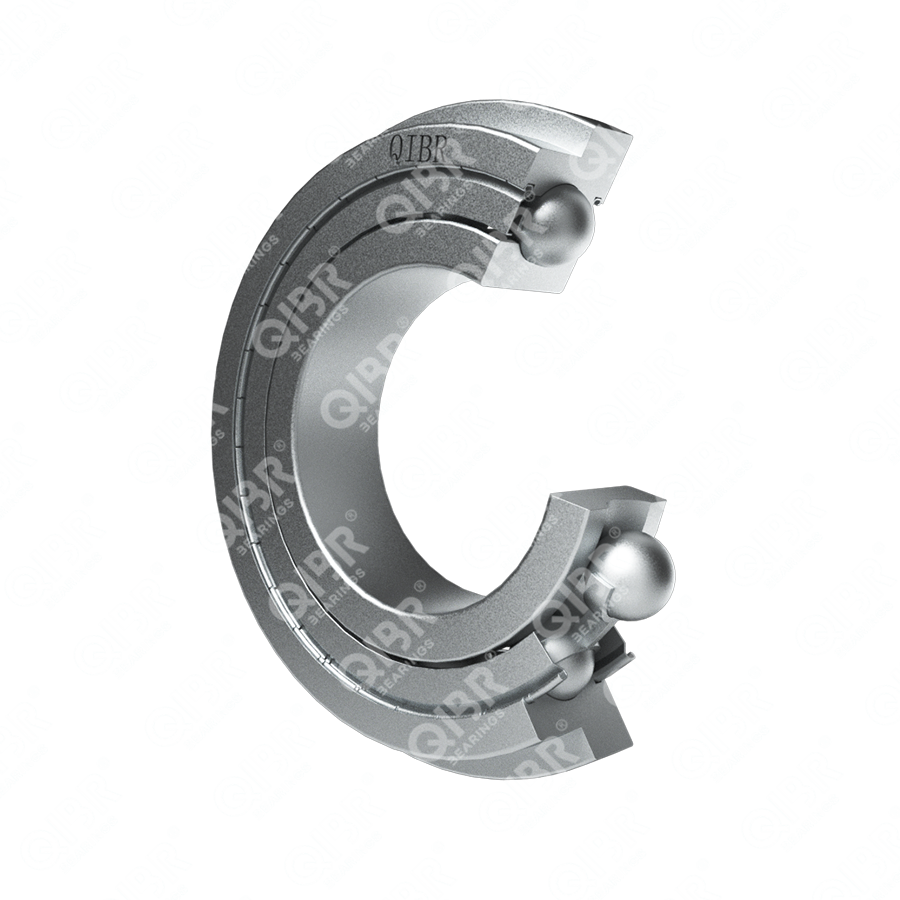

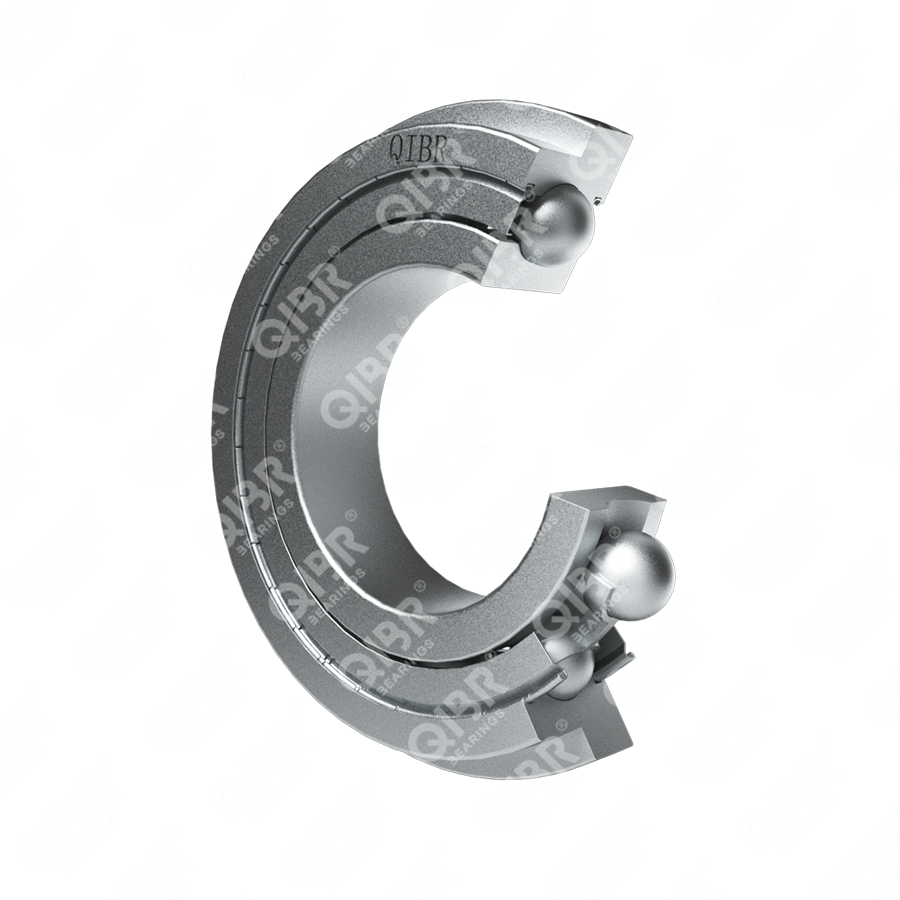

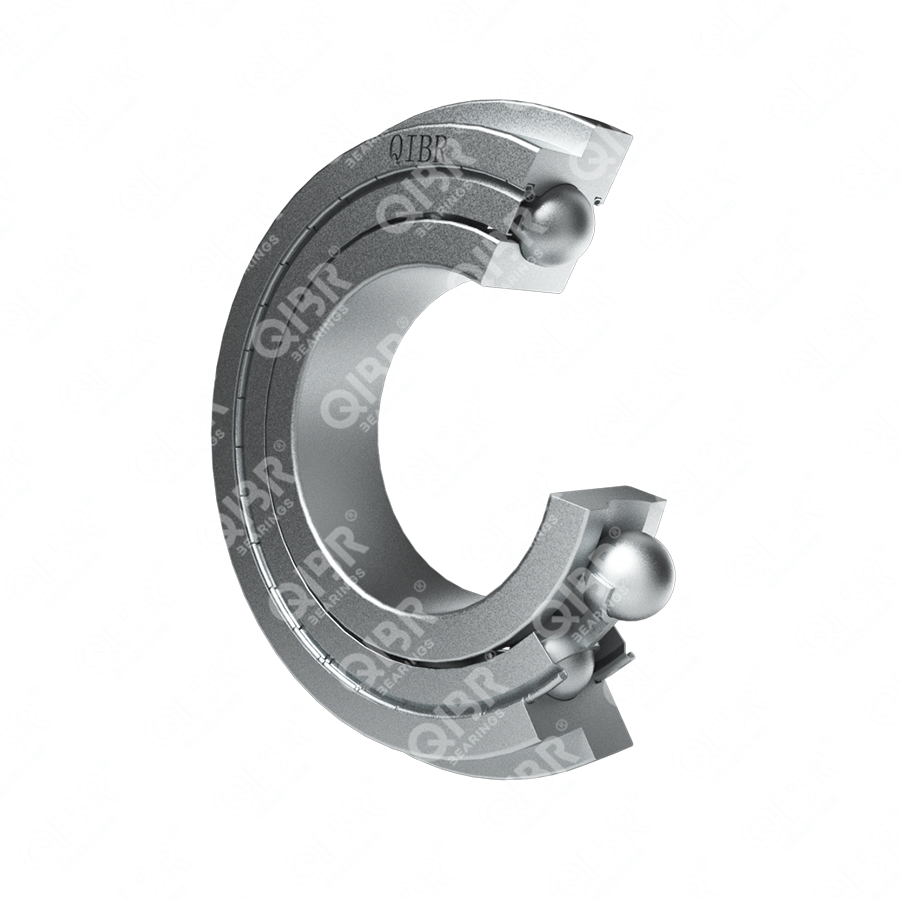

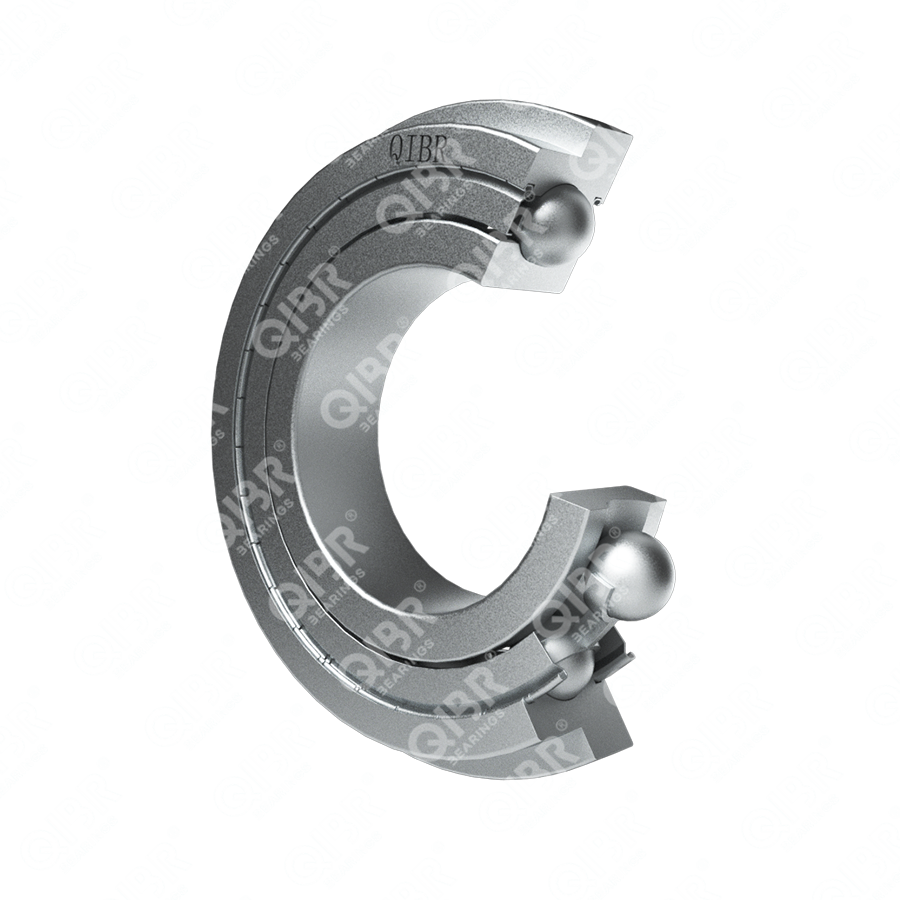

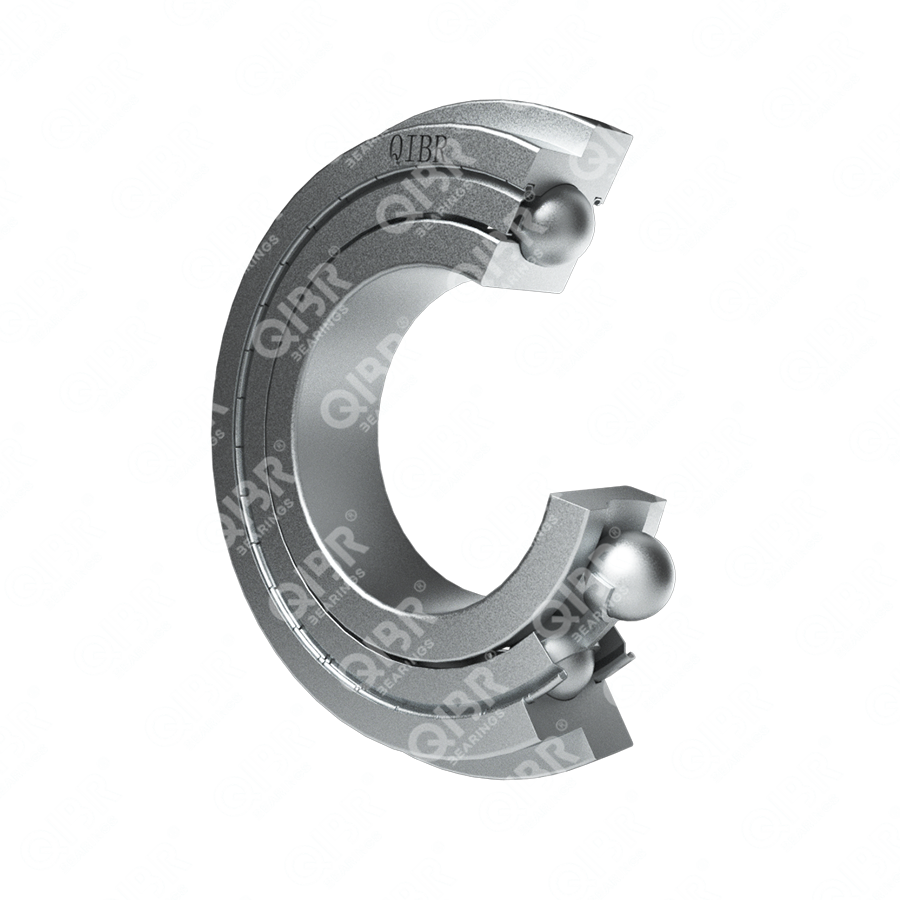

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Material

GCr15、5200、100Cr6、SUJ2

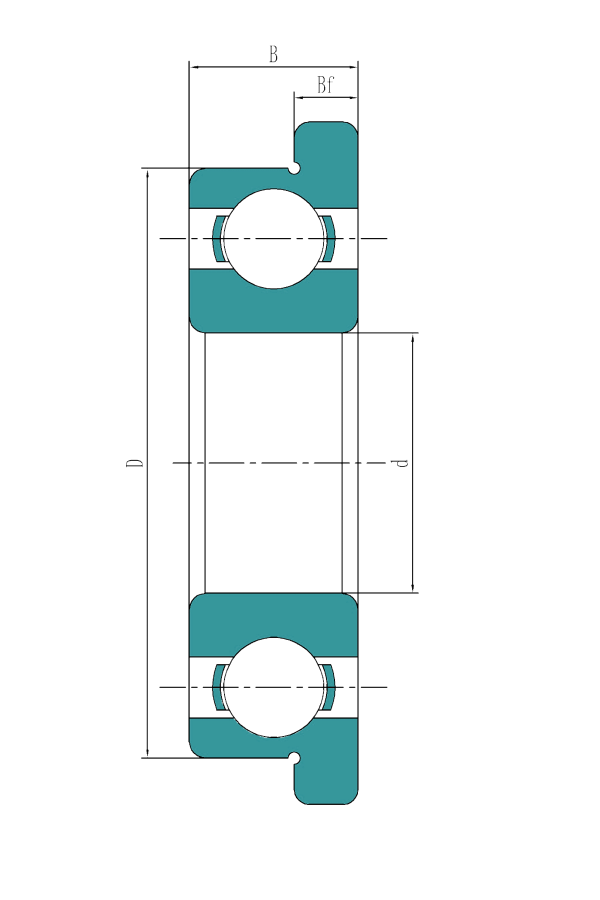

Inner ring diameter

1.191mm-9.525mm

Outer ring diameter

3.967mm-22.225mm

Weight

0.12g-12.39g

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

Machine tool spindle, centrifuge, booster pump, oil pump, blower, various gearboxes, laboratory equipment

| NO. | Product | Product Number | Outer diameter (D) | Inner diameter (d) | Width (B) | Mass | Basic dynamic load rating | Basic static load rating |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

FR0 | 3.967 mm | 1.191 mm | 1.588 mm | 0.12 g | 21 N | 6 N |

| 2 |

|

FR0 ZZ | 3.967 mm | 1.191 mm | 2.38 mm | 0.2 g | 21 N | 6 N |

| 3 |

|

FR1 | 4.763 mm | 1.397 mm | 1.984 mm | 0.19 g | 44 N | 12 N |

| 4 |

|

FR1 ZZ | 4.763 mm | 1.397 mm | 2.779 mm | 0.25 g | 44 N | 12 N |

| 5 |

|

FR1-4 | 6.35 mm | 1.984 mm | 2.38 mm | 0.46 g | 54 N | 17 N |

| 6 |

|

FR1-4 ZZ | 6.35 mm | 1.984 mm | 3.571 mm | 0.61 g | 54 N | 17 N |

| 7 |

|

FR1-5 | 7.938 mm | 2.38 mm | 2.779 mm | 0.67 g | 106 N | 32 N |

| 8 |

|

FR1-5-2RS | 7.938 mm | 2.38 mm | 3.571 mm | 1.25 g | 106 N | 32 N |

| 9 |

|

FR1-5 ZZ | 7.938 mm | 2.38 mm | 3.571 mm | 1.25 g | 106 N | 32 N |

| 10 |

|

FR133 | 4.763 mm | 2.38 mm | 1.588 mm | 0.13 g | 36 N | 11 N |

| 11 |

|

FR133-2RS | 4.763 mm | 2.38 mm | 2.38 mm | 0.13 g | 28 N | 10 N |

| 12 |

|

FR133 ZZ | 4.763 mm | 2.38 mm | 2.38 mm | 0.21 g | 36 N | 11 N |

| 13 |

|

FR144 | 6.35 mm | 3.175 mm | 2.38 mm | 0.33 g | 54 N | 17 N |

| 14 |

|

FR144-2RS | 6.35 mm | 3.175 mm | 2.779 mm | 0.48 g | 54 N | 17 N |

| 15 |

|

FR144 ZZ | 6.35 mm | 3.175 mm | 2.38 mm | 0.48 g | 54 N | 17 N |

| 16 |

|

FR2 | 9.525 mm | 3.175 mm | 3.967 mm | 1.2 g | 121 N | 39 N |

| 17 |

|

FR2-2RS | 9.525 mm | 3.175 mm | 3.967 mm | 1.53 g | 121 N | 39 N |

| 18 |

|

FR2 ZZ | 9.525 mm | 3.175 mm | 3.967 mm | 1.53 g | 121 N | 39 N |

| 19 |

|

FR2-5 | 7.938 mm | 3.175 mm | 2.779mm | 0.57 g | 107 N | 32 N |

| 20 |

|

FR2-5-2RS | 7.938 mm | 3.175 mm | 3.571 mm | 0.84 g | 107 N | 32 N |

| 21 |

|

FR2-5 ZZ | 7.938 mm | 3.175 mm | 3.571 mm | 0.84 g | 107 N | 32 N |

| 22 |

|

FR2-6 | 9.525 mm | 3.175 mm | 2.779 mm | 1.05 g | 122 N | 41 N |

| 23 |

|

FR2-6-2RS | 9.525 mm | 3.175 mm | 3.571 mm | 1.35 g | 122 N | 41 N |

| 24 |

|

FR2-6 ZZ | 9.525 mm | 3.175 mm | 2.779 mm | 1.35 g | 122 N | 41 N |

| 25 |

|

FR155 | 7.938 mm | 3.967 mm | 2.779 mm | 0.56 g | 69 N | 27 N |

| 26 |

|

FR155 ZZ | 7.938 mm | 3.967 mm | 3.175 mm | 0.72 g | 69 N | 27 N |

| 27 |

|

FR156 | 4.763 mm | 7.938 mm | 2.779 mm | 0.47 g | 69 N | 27 N |

| 28 |

|

FR156-2RS | 7.938 mm | 4.763 mm | 3.175 mm | 0.56 g | 69 N | 27 N |

| 29 |

|

FR156 ZZ | 4.763 mm | 7.938 mm | 3.175 mm | 0.56 g | 69 N | 27 N |

| 30 |

|

FR166 | 9.525 mm | 4.763 mm | 3.175 mm | 0.9 g | 136 N | 49 N |

| 31 |

|

FR166-2RS | 9.525 mm | 4.763 mm | 3.175 mm | 0.97 g | 136 N | 49 N |

| 32 |

|

FR3 | 12.7 mm | 4.763 mm | 3.967 mm | 2.5 g | 249 N | 88 N |

| 33 |

|

FR3-2RS | 12.7 mm | 4.763 mm | 4.978 mm | 3.24 g | 249 N | 88 N |

| 34 |

|

FR168 | 9.525 mm | 6.35 mm | 3.175 mm | 0.66 g | 71 N | 31 N |

| 35 |

|

FR168-2RS | 9.525 mm | 6.35 mm | 3.175 mm | 0.73 g | 71 N | 31 N |

| 36 |

|

FR168ZZ | 9.525 mm | 6.35 mm | 3.175 mm | 0.73 g | 71 N | 31 N |

| 37 |

|

FR3 ZZ | 12.7 mm | 4.763 mm | 3.967 mm | 3.24 g | 249 N | 88 N |

| 38 |

|

FR188 | 12.7 mm | 6.35 mm | 3.175 mm | 1.71 g | 207 N | 80 N |

| 39 |

|

FR188-2RS | 12.7 mm | 6.35 mm | 4.763 mm | 2.54 g | 207 N | 80 N |

| 40 |

|

FR188 ZZ | 12.7 mm | 6.35 mm | 4.763 mm | 2.54 g | 207 N | 80 N |

| 41 |

|

FR4 | 15.875 mm | 6.35 mm | 4.978 mm | 4.82 g | 283 N | 112 N |

| 42 |

|

FR4-2RS | 15.875 mm | 6.35 mm | 4.978 mm | 4.9 g | 283 N | 112 N |

| 43 |

|

FR1810 | 12.7 mm | 7.938 mm | 3.967 mm | 1.54 g | 104 N | 50 N |

| 44 |

|

FR1810-2RS | 12.7 mm | 7.938 mm | 3.967 mm | 1.72 g | 104 N | 50 N |

| 45 |

|

FR1810ZZ | 12.7 mm | 7.938 mm | 3.967 mm | 1.72 g | 104 N | 50 N |

| 46 |

|

FR4 ZZ | 15.875 mm | 6.35 mm | 4.978 mm | 4.9 g | 283 N | 112 N |

| 47 |

|

FR6 | 22.225 mm | 9.525 mm | 5.558 mm | 9.71 g | 637 N | 256 N |

| 48 |

|

FR6-2RS | 22.225 mm | 9.525 mm | 7.142 mm | 12.39 g | 637 N | 256 N |

| 49 |

|

FR6 ZZ | 22.225 mm | 9.525 mm | 5.558 mm | 12.39 g | 637 N | 256 N |

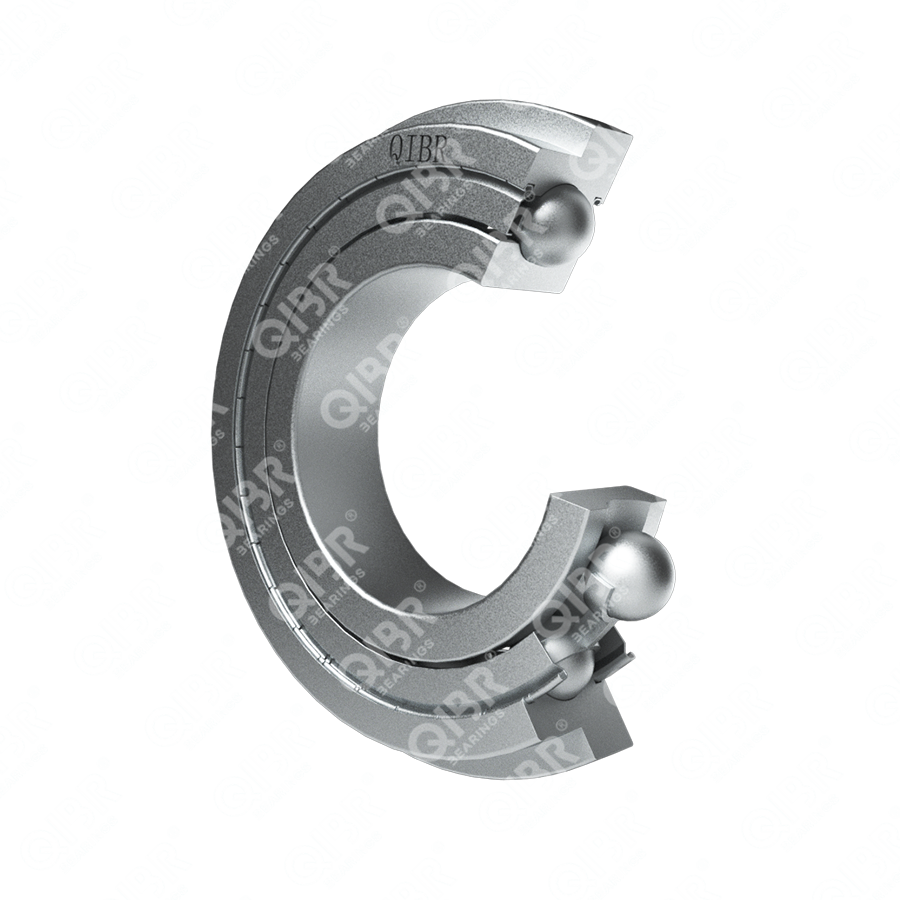

Features and advantages of QIBR flange deep groove ball bearings

QIBR flange deep groove ball bearings are engineered to address critical operational demands in various industrial fields, offering the following key advantages:

1. Flange design

The outer ring of the bearing has a flange (protruding edge) for direct positioning or fixation. This flange is typically designed to match the bearing housing, ensuring the bearing remains aligned during installation.

The flange simplifies installation, especially in situations where the bearing cannot be fixed on both sides.

It effectively helps secure the bearing's position.

2. Simple structure

As a type of deep groove ball bearing, flange deep groove ball bearings have a simple structure, are easy to manufacture, and are capable of handling both radial and axial loads effectively.

3. Wide applicability

These bearings are suitable for handling radial loads, and axial loads, and operating at high speeds.

Flange deep groove ball bearings are commonly used in machinery where the outer ring needs to be fixed or positioned.

4. Durability

Thanks to their robust and precise structure, these bearings are durable and suitable for long-term, high-speed operation.

5. No need for additional positioning devices

The presence of the flange eliminates the need for additional positioning devices during installation, reducing assembly complexity and improving production efficiency.

Performance enhancements for QIBR flange deep groove ball bearings

1. Lubrication optimization

Advanced lubricants, such as synthetic or nano-lubricants, can reduce wear and friction, enhancing overall efficiency and durability. Proper application techniques further ensure optimal performance.

2. Raceway optimization

Precision machining of the raceway geometry, along with improved surface finish, minimizes frictional losses and enhances operational efficiency.

3. Enhanced rolling elements

Utilizing high-precision rolling elements, such as ceramic balls, improves surface hardness and reduces wear, resulting in superior performance under demanding conditions.

4. Corrosion resistance

For applications in aggressive environments, materials such as stainless steel, corrosion-resistant coatings, or surface treatment technologies can significantly improve durability.

Primary application fields of QIBR flange deep groove ball bearings

1. Electric motors

QIBR flange deep groove ball bearings are widely used in electric motors, particularly in industrial motors with heavy load requirements. Their durability and efficiency make them essential for the rotor and stator components.

2. Automotive industry

These bearings are used in the automotive industry to handle large radial and axial loads. They play a crucial role in components like wheel bearings, drive shafts, and clutches. Their load-bearing capacity and wear resistance ensure stable performance in high-load environments.

3. Agricultural machinery

Agricultural machinery often operates under heavy and complex loads in harsh environments. These bearings, with their high load capacity and durability, are frequently used in such equipment.

4. Factory equipment

In automated production lines, conveyor belts, and packaging machinery, QIBR flange deep groove ball bearings serve as critical components, supporting heavy loads and high-speed rotation. Their load capacity and wear resistance make them suitable for continuous, high-efficiency operation in such equipment.