Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Material

GCr15、5200、100Cr6、SUJ2

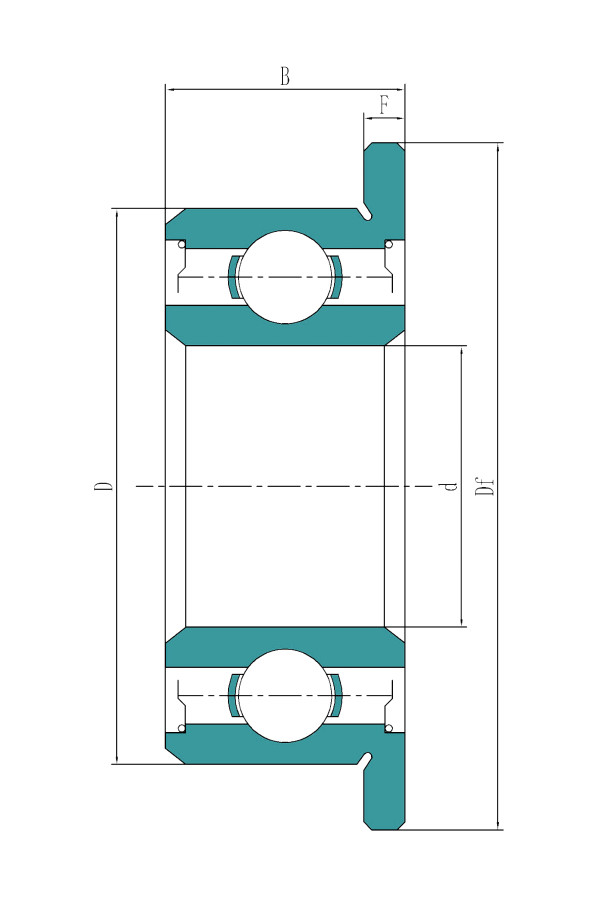

Inner ring diameter

1mm-3mm

Outer ring diameter

3mm-10mm

Weight

0.03g-1.65g

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

Machine tool spindle, centrifuge, booster pump, oil pump, blower, various gearboxes, laboratory equipment

| NO. | Product | Product Number | Inner diameter (d) | Outer diameter (D) | Width (B) |

|---|---|---|---|---|---|

| 1 |

|

B538DD | 0.625 inch | 1.0625 inch | 0.25 inch |

| 2 |

|

B539DD | 0.75 inch | 1.1875 inch | 0.25 inch |

| 3 |

|

B540DD | 0.8750 inch | 1.3125 inch | 0.25 inch |

| 4 |

|

B541DD | 1.0625 inch | 1.5 inch | 0.25 inch |

| 5 |

|

B542DD | 1.3125 inch | 1.75 inch | 0.25 inch |

| 6 |

|

B543DD | 1.5625 inch | 2 inch | 0.25 inch |

| 7 |

|

B544DD | 1.8125 inch | 2.25 inch | 0.25 inch |

| 8 |

|

B545DD | 2.0625 inch | 2.625 inch | 0.25 inch |

| 9 |

|

B546DD | 2.3125 inch | 2.875 inch | 0.25 inch |

| 10 |

|

SR09 | 0.0400 inch | 0.1250 inch | 0.0469 inch |

| 11 |

|

SR0 | 0.0469 inch | 0.1562 inch | 0.0625 inch |

| 12 |

|

SR1 | 0.0550 inch | 0.1875 inch | 0.0781 inch |

| 13 |

|

SR1-4 | 0.0781 inch | 0.2500 inch | 0.0937 inch |

| 14 |

|

SR133 | 0.0937 inch | 0.1875 inch | 0.0625 inch |

| 15 |

|

SR1-5 | 0.0937 inch | 0.3125 inch | 0.1094 inch |

| 16 |

|

SR144 | 0.1250 inch | 0.2500 inch | 0.0937 inch |

| 17 |

|

SR2-5 | 0.1250 inch | 0.3125 inch | 0.1094 inch |

| 18 |

|

SR2-6 | 0.1250 inch | 0.3750 inch | 0.1094 inch |

| 19 |

|

SR155 | 0.1562 inch | 0.3125 inch | 0.1094 inch |

| 20 |

|

SR156 | 0.1875 inch | 0.3125 inch | 0.1094 inch |

| 21 |

|

SR166 | 0.1875 inch | 0.3750 inch | 0.1250 inch |

| 22 |

|

SR168 | 0.2500 inch | 0.3750 inch | 0.1250 inch |

| 23 |

|

SR188 | 0.2500 inch | 0.5000 inch | 0.1250 inch |

| 24 |

|

SR1810 | 0.3125 inch | 0.5000 inch | 0.1562 inch |

| 25 |

|

SR2 | 0.1250 inch | 0.3750 inch | 0.1562 inch |

| 26 |

|

SR2A | 0.1250 inch | 0.5000 inch | 0.1719 inch |

| 27 |

|

SR3 | 0.1875 inch | 0.5000 inch | 0.1562 inch |

| 28 |

|

SR4 | 0.2500 inch | 0.6250 inch | 0.1960 inch |

| 29 |

|

SR4A | 0.2500 inch | 0.7500 inch | 0.2188 inch |

| 30 |

|

SR6 | 0.3750 inch | 0.8750 inch | 0.2188 inch |

| 31 |

|

SR6-5 | 0.5000 inch | 0.8750 inch | 0.2188 inch |

| 32 |

|

SR8 | 0.5000 inch | 1.1250 inch | 0.2500 inch |

| 33 |

|

SRW0 | 0.0469 inch | 0.1562 inch | 0.0625 inch |

| 34 |

|

SRW1 | 0.0550 inch | 0.1875 inch | 0.0781 inch |

| 35 |

|

SRW1-4 | 0.0781 inch | 0.2500 inch | 0.0937 inch |

| 36 |

|

SRW133 | 0.0937 inch | 0.1875 inch | 0.0625 inch |

| 37 |

|

SRW1-5 | 0.0937 inch | 0.3125 inch | 0.1094 inch |

| 38 |

|

SRW144 | 0.1250 inch | 0.2500 inch | 0.0937 inch |

| 39 |

|

SRW2-5 | 0.1250 inch | 0.3125 inch | 0.1094 inch |

| 40 |

|

SRW2-6 | 0.1250 inch | 0.3750 inch | 0.1094 inch |

| 41 |

|

SRW155 | 0.1562 inch | 0.3125 inch | 0.1094 inch |

| 42 |

|

SRW156 | 0.1875 inch | 0.3125 inch | 0.1094 inch |

| 43 |

|

SRW166 | 0.1875 inch | 0.3750 inch | 0.1250 inch |

| 44 |

|

SRW168 | 0.2500 inch | 0.3750 inch | 0.1250 inch |

| 45 |

|

SRW188 | 0.2500 inch | 0.5000 inch | 0.1250 inch |

| 46 |

|

SRW1810 | 0.3125 inch | 0.5000 inch | 0.1562 inch |

| 47 |

|

SRW2 | 0.1250 inch | 0.3750 inch | 0.1562 inch |

| 48 |

|

SRW3 | 0.1875 inch | 0.5000 inch | 0.1562 inch |

| 49 |

|

SRW4 | 0.2500 inch | 0.6250 inch | 0.1960 inch |

| 50 |

|

SR2AZZ | 0.1250 inch | 0.5000 inch | 0.1719 inch |

| 51 |

|

SR4AZZ | 0.2500 inch | 0.7500 inch | 0.2812 inch |

| 52 |

|

SR6ZZ | 0.3750 inch | 0.8750 inch | 0.2812 inch |

| 53 |

|

SR6-5ZZ | 0.5000 inch | 0.8750 inch | 0.2812 inch |

| 54 |

|

SR8ZZ | 0.5000 inch | 1.1250 inch | 0.3125 inch |

| 55 |

|

SR0ZZ | 0.0469 inch | 0.1562 inch | 0.0937 inch |

| 56 |

|

SR1ZZ | 0.0550 inch | 0.1875 inch | 0.1094 inch |

| 57 |

|

SR1-4ZZ | 0.0781 inch | 0.2500 inch | 0.1406 inch |

| 58 |

|

SR133ZZ | 0.0937 inch | 0.1875 inch | 0.0937 inch |

| 59 |

|

SR1-5ZZ | 0.0937 inch | 0.3125 inch | 0.1406 inch |

| 60 |

|

SR144ZZ | 0.1250 inch | 0.2500 inch | 0.1094 inch |

| 61 |

|

SR2-5ZZ | 0.1250 inch | 0.3125 inch | 0.1406 inch |

| 62 |

|

SR2-6ZZ | 0.1250 inch | 0.3750 inch | 0.1406 inch |

| 63 |

|

SR155ZZ | 0.1562 inch | 0.3125 inch | 0.1250 inch |

| 64 |

|

SR156ZZ | 0.1875 inch | 0.3125 inch | 0.1250 inch |

| 65 |

|

SR166ZZ | 0.1875 inch | 0.3750 inch | 0.1250 inch |

| 66 |

|

SR168ZZ | 0.2500 inch | 0.3750 inch | 0.1250 inch |

| 67 |

|

SR188ZZ | 0.2500 inch | 0.5000 inch | 0.1875 inch |

| 68 |

|

SR1810ZZ | 0.3125 inch | 0.5000 inch | 0.1562 inch |

| 69 |

|

SR2ZZ | 0.1250 inch | 0.3750 inch | 0.1562 inch |

| 70 |

|

SR3ZZ | 0.1875 inch | 0.5000 inch | 0.1960 inch |

| 71 |

|

SR4ZZ | 0.2500 inch | 0.6250 inch | 0.1960 inch |

| 72 |

|

SRW0ZZ | 0.0469 inch | 0.1562 inch | 0.0937 inch |

| 73 |

|

SRW1ZZ | 0.0550 inch | 0.1875 inch | 0.1094 inch |

| 74 |

|

SRW1-4ZZ | 0.0781 inch | 0.2500 inch | 0.1406 inch |

| 75 |

|

SRW133ZZ | 0.0937 inch | 0.1875 inch | 0.0937 inch |

| 76 |

|

SRW1-5ZZ | 0.0937 inch | 0.3125 inch | 0.1406 inch |

| 77 |

|

SRW144ZZ | 0.1250 inch | 0.2500 inch | 0.1094 inch |

| 78 |

|

SRW2-5ZZ | 0.1250 inch | 0.3125 inch | 0.1406 inch |

| 79 |

|

SRW2-6ZZ | 0.1250 inch | 0.3750 inch | 0.1406 inch |

| 80 |

|

SRW155ZZ | 0.1562 inch | 0.3125 inch | 0.1250 inch |

| 81 |

|

SRW156ZZ | 0.1875 inch | 0.3125 inch | 0.1250 inch |

| 82 |

|

SRW166ZZ | 0.1875 inch | 0.3750 inch | 0.1250 inch |

| 83 |

|

SRW168ZZ | 0.2500 inch | 0.3750 inch | 0.1250 inch |

| 84 |

|

SRW188ZZ | 0.2500 inch | 0.5000 inch | 0.1875 inch |

| 85 |

|

SRW1810ZZ | 0.3125 inch | 0.5000 inch | 0.1562 inch |

| 86 |

|

SRW2ZZ | 0.1250 inch | 0.3750 inch | 0.1562 inch |

| 87 |

|

SRW3ZZ | 0.1875 inch | 0.5000 inch | 0.1960 inch |

| 88 |

|

SRW4ZZ | 0.2500 inch | 0.6250 inch | 0.1960 inch |

| 89 |

|

SFR09 | 0.0400 inch | 0.1250 inch | 0.0469 inch |

| 90 |

|

SFR6 | 0.3750 inch | 0.8750 inch | 0.2188 inch |

| 91 |

|

SFR8 | 0.5000 inch | 1.1250 inch | 0.2500 inch |

| 92 |

|

SFR0 | 0.0469 inch | 0.1562 inch | 0.0625 inch |

| 93 |

|

SFR1 | 0.0550 inch | 0.1875 inch | 0.0781 inch |

| 94 |

|

SFR1-4 | 0.0781 inch | 0.2500 inch | 0.0937 inch |

| 95 |

|

SFR133 | 0.0937 inch | 0.1875 inch | 0.0625 inch |

| 96 |

|

SFR1-5 | 0.0937 inch | 0.3125 inch | 0.1094 inch |

| 97 |

|

SFR144 | 0.1250 inch | 0.2500 inch | 0.0937 inch |

| 98 |

|

SFR2-5 | 0.1250 inch | 0.3125 inch | 0.1094 inch |

| 99 |

|

SFR2-6 | 0.1250 inch | 0.3750 inch | 0.1094 inch |

| 100 |

|

SFR155 | 0.1562 inch | 0.3125 inch | 0.1094 inch |

Features and advantages of QIBR miniature deep groove ball bearings

QIBR miniature deep groove ball bearings are engineered to address critical operational demands in various industrial fields, offering the following key advantages:

1. Miniaturization

The outer dimensions of miniature deep groove ball bearings are extremely small, with inner and outer diameters ranging from a few millimeters to just over ten millimeters. They are widely used in compact, high-precision devices where space is limited.

2. Low noise and high speed

Manufactured with high-precision processes, these bearings exhibit low operational noise. Their design allows for stable operation at high speeds, making them ideal for devices requiring high rotational speeds.

3. Low friction and long service life

With a compact internal structure, these bearings minimize friction between the rolling elements and the inner and outer rings, reducing energy loss and extending service life.

4. Material versatility

QIBR miniature deep groove ball bearings are available in various materials, such as stainless steel, carbon steel, and ceramic, to meet the demands of different environments.

Performance enhancements for QIBR miniature deep groove ball bearings

1. Lubrication optimization

Advanced lubricants, such as synthetic or nano-lubricants, can reduce wear and friction, enhancing overall efficiency and durability. Proper application techniques further ensure optimal performance.

2. Raceway optimization

Precision machining of the raceway geometry, along with improved surface finish, minimizes frictional losses and enhances operational efficiency.

3. Enhanced rolling elements

Utilizing high-precision rolling elements, such as ceramic balls, improves surface hardness and reduces wear, resulting in superior performance under demanding conditions.

4. Corrosion resistance

For applications in aggressive environments, materials such as stainless steel, corrosion-resistant coatings, or surface treatment technologies can significantly improve durability.

5. Thin-walled design

To accommodate even smaller spaces, these bearings are designed with thin walls. Using thinner materials while maintaining strength and load capacity achieves an optimal balance of size and weight.

Primary application fields of QIBR miniature deep groove ball bearings

1. Mobile phones and computers

These bearings are commonly used in rotating components of electronic devices, such as motors, fans, ball rollers, and drive systems in smartphones, laptops, mice, and keyboards.

2. Cameras

Miniature bearings play a key role in auto-focus systems and image stabilization mechanisms within cameras.

3. Precision instruments and optical devices

QIBR miniature bearings are frequently used in microscopes, telescopes, scanners, and other optical instruments, ensuring smooth operation in rotating components, motor drives, and other precision mechanisms.

4. Medical equipment

These bearings are critical in high-precision medical devices such as surgical robots, imaging systems (e.g., CT and MRI), and dental tools, including drills, due to their accuracy and reliability.

5. Power tools

Miniature deep groove ball bearings are used in motors and motion systems of power tools, ensuring smooth operation and extended service life.

6. Dental tools

With their high precision, compact size, high-speed capability, and ability to handle significant radial loads, these bearings are ideal for use in dental drills.