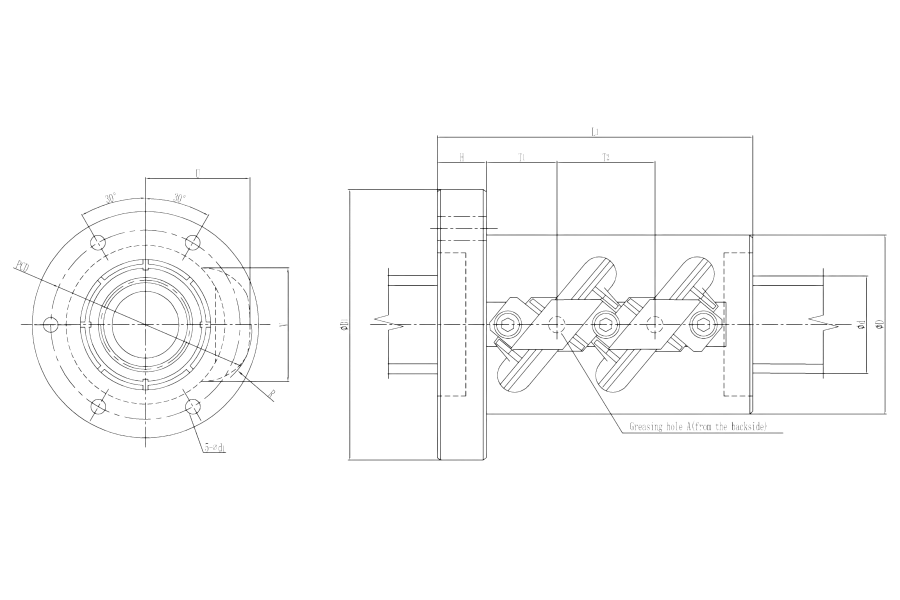

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh,DIN / VDEh

Screw shaft outer diameter (d)

32mm-63mm

Lead (Ph)

10mm-20mm

Ball center-to-center diameter (dp)

34mm-66.5mm

Material

Carbon Steel, Bearing Steel, Stainless Steel

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

Machine Tools, Precision Instruments, Semiconductor, Aerospace, Printing Machinery, Medical Devices

| NO. | Product | Product Number | Ball center-to-center diameter (dp) | Lead (Ph) | No. of loaded circuits rows X turns | Screw shaft outer diameter (d) | Thread minor diameter (dc) |

|---|---|---|---|---|---|---|---|

| 1 |

|

HBN 3210-5 | 34 mm | 10 mm | 2X2.5 | 32 mm | 26 mm |

| 2 |

|

HBN 3610-5 | 38 mm | 10 mm | 2X2.5 | 36 mm | 30 mm |

| 3 |

|

HBN 3612-5 | 38.4 mm | 12 mm | 2X2.5 | 36 mm | 29 mm |

| 4 |

|

HBN 4010-7.5 | 42 mm | 10 mm | 3X2.5 | 40 mm | 34 mm |

| 5 |

|

HBN 4012-7.5 | 42.4 mm | 12 mm | 3X2.5 | 40 mm | 33 mm |

| 6 |

|

HBN 5010-7.5 | 52 mm | 10 mm | 3X2.5 | 50 mm | 44 mm |

| 7 |

|

HBN 5012-7.5 | 52.4 mm | 12 mm | 3X2.5 | 50 mm | 43 mm |

| 8 |

|

HBN 5016-7.5 | 53 mm | 16 mm | 3X2.5 | 50 mm | 39.6 mm |

| 9 |

|

HBN 6316-7.5 | 66 mm | 16 mm | 3X2.5 | 63 mm | 52.6 mm |

| 10 |

|

HBN 6316-10.5 | 66 mm | 16 mm | 3X3.5 | 63 mm | 52.6 mm |

| 11 |

|

HBN 6320-7.5 | 66.5 mm | 20 mm | 3X2.5 | 63 mm | 49.6 mm |

Features and advantages of ball screw HBN series

The HBN series ball screw has many significant features and advantages, playing a key role in various fields, mainly reflected in the following aspects:

1. High efficiency

The working principle of the ball screw HBN series is that the steel ball rolls inside the screw thread and nut, reducing friction, so the transmission efficiency is higher.

2. Low friction and long life

The HBN series ball screw transmits power through rolling friction rather than sliding friction, so it has a lower friction coefficient, reduces energy loss, and has less wear and tear, extending its service life. The rolling friction when the ball contacts the thread generates much less heat than sliding friction and lowers the temperature rise, thus improving its durability and stability.

3. High precision

The HBN series ball screws can achieve high-precision motion control and are often used in applications that require precise positioning, such as CNC machine tools, precision instruments, etc.

4. Higher load capacity

Because the steel ball rolls between the screw and the nut, it can share a larger load. Compared with traditional linear bearings, the HBN series ball screw has a stronger load-bearing capacity. This makes it suitable for mechanical transmission applications requiring larger loads.

The performance improvement and solutions of ball screw HBN series

1. Improve accuracy

By using high-precision processing equipment (such as CNC machine tools, grinders, etc.), it is possible to ensure that the geometry, dimensional accuracy and surface roughness of the screw and ball track reach a higher level.

2. Reduce friction and improve transmission efficiency

The use of high-performance lubricants and greases can reduce friction, improve transmission efficiency, reduce temperature rise and extend service life.

Improve the lubrication design of the ball track: By rationally designing the contact angle and contact method between the ball and the track and adopting an appropriate lubrication system, it is possible to reduce wear while ensuring efficiency.

3. Torsion resistance and stability

The bending and torsion resistance of ball screws can be improved by improving the size ratio of the screw or using high-strength materials.

4. Self-locking design

The ball screw adopts a self-locking design, which can automatically lock when there is no load or a small load, reducing the free movement of the system when it stops and improving the stability of the system.

Main application areas of ball screw HBN series

1. CNC machine tools

Ball screws are used in feed systems in CNC machine tools to provide high-precision positioning and motion control.

2. Precision measuring equipment

Ball screws can provide stable linear drive and are widely used in equipment such as coordinate measuring machines.

3. Automation equipment

Ball screws are used in automation equipment to drive moving parts and control the positioning and delivery of materials.

4. Transportation

Ball screws are used in systems such as seat adjustment and steering wheel adjustment in electric vehicles, and are also used in power transmission systems in railways.