N1016BMR1

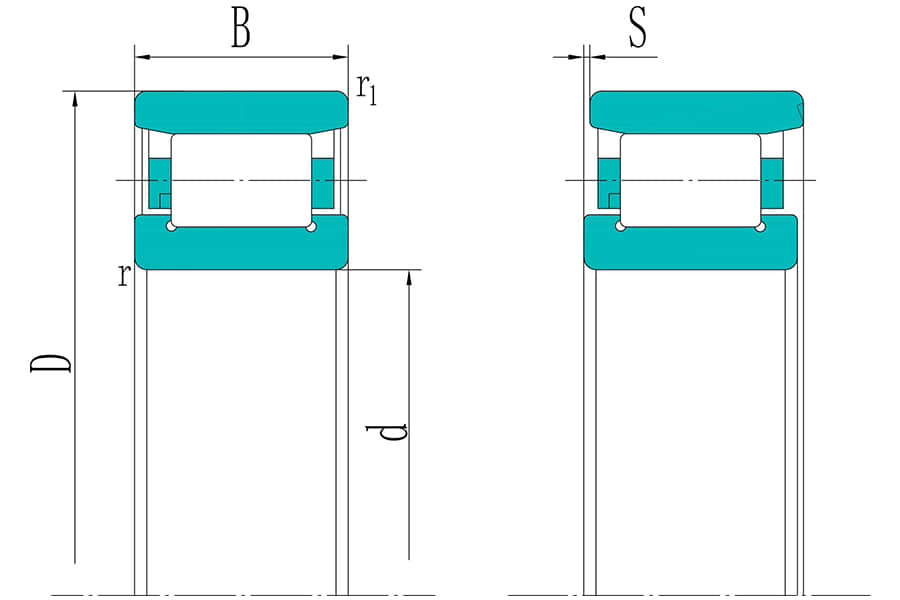

- Inner diameter:

- 80mm

- Outer diameter:

- 125mm

- Width:

- 22mm

- Mass:

- 0.957kg

We will provide you with the most suitable solution.

Image may differ from product. See technical specification for details.

Specifications

Seris - N1016BMR1

Description

QIBR - N1016BMR1 Precision Cylindrical Roller Bearings Advantages and Applications

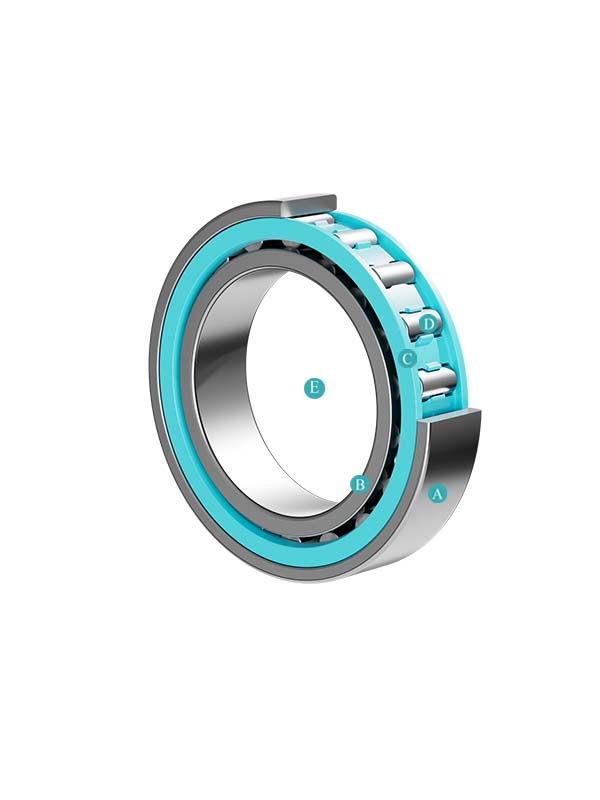

N1016BMR1 Precision Cylindrical Roller Bearings, high load capacity, low friction, Inner diameter (d) is 80 mm, Outer diameter (D) is 125 mm, Width (B) is 22 mm, Weight is 0.957 kg, suitable for compressors, crushers, paper machines and generators, etc., and is the most widely used bearing in working conditions with high load capacity requirements.

QIBR - N1016BMR1 Precision Cylindrical Roller Bearings Characteristics

N1016BMR1 Precision Cylindrical Roller Bearings, long life, high cost performance. N1016BMR1 Precision Cylindrical Roller Bearings, can bear radial load and small axial load, suitable for mechanical equipment with high life requirements.

N1016BMR1 Precision Cylindrical Roller Bearings Features and Advantages

High Precision: These bearings offer extremely high precision, with a precision grade of P4, making them suitable for applications requiring high rotational accuracy.

High Load Capacity: The line contact between the cylindrical rollers and raceways allows them to bear large radial loads.

Low Friction: The line contact between the rollers and raceways results in low friction, enhancing mechanical efficiency.

Floating Characteristics: There is no constraint force between the rollers and the raceways without flanges, allowing compensation for length changes during rotational motion, making them suitable as floating bearings.

Application: Widely used in machine tool manufacturing, precision machining equipment, heavy-duty and high-speed machinery, aerospace, research and experimental equipment, and other fields.

QIBR - N1016BMR1 Precision Cylindrical Roller Bearings Optimization

High-Performance Materials: Different materials, such as 100Cr6, GCr15, 20CrMo, AISI 52100, etc., can be provided according to customer requirements.

Cage Material: The cage material can be selected based on customer needs, including steel, brass, nylon, polyamide, PEEK, and PPS, among others.

Lubricants: Suitable lubricants, such as SKF LGHP 2, RENOLIT LX EP 2, Shell Gadus S2 V100 2, etc., can be chosen based on operating conditions and specific parts of the bearing.

More customization: QIBR can design and optimize bearings according to the customer's operating conditions and requirements.

QIBR - N1016BMR1 Precision Cylindrical Roller Bearings Quality Control

Dimension measurement: Various high-precision instruments are used to measure multiple dimensions of the bearing, with an accuracy of up to 0.001mm.

Rotation accuracy: A dial gauge measures minor surface flaws or deviations, with measurement accuracy reaching 0.001mm.

Hardness measurement: Surface hardness is measured using a hardness tester, with an accuracy of ±0.5HRC.

Metallographic analysis: The internal metallographic structure of the metal is analyzed using a professional metallographic microscope.

Geometric tolerance: A contour measuring instrument is used to measure the geometric shape and relative position of the bearing.

Noise monitoring: Vibration data is obtained by monitoring the vibrations during operation with a vibration meter.

Raw material control: Steel and parts are sourced from ISO 14001-certified suppliers, ensuring product stability while promoting sustainable development.

Features & Benefits

Cylindrical roller bearings are widely used in large motor, machine tool spindle, axle box, diesel engine crankshaft, automobile and so on. The common features of these application scenarios are high speed, high load, and high precision. cylindrical roller bearing for its high load capacity, low noise, high speed characteristics, and the rolling element and the ring flange friction is small, is especially suitable for the need to bear heavy loads and high-speed rotation occasions. In addition, cylindrical roller bearing also has the structural characteristics of the inner ring and outer ring can be separated, makes installation and disassembly is relatively simple, further broadens its application range.

Downloads