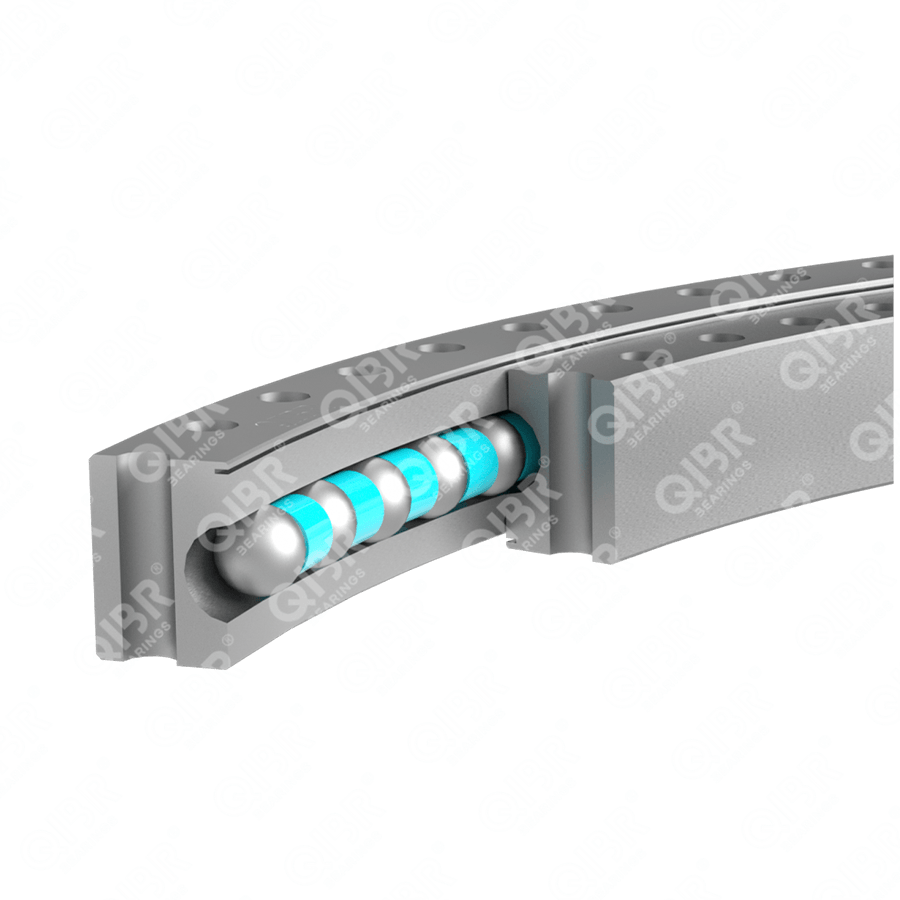

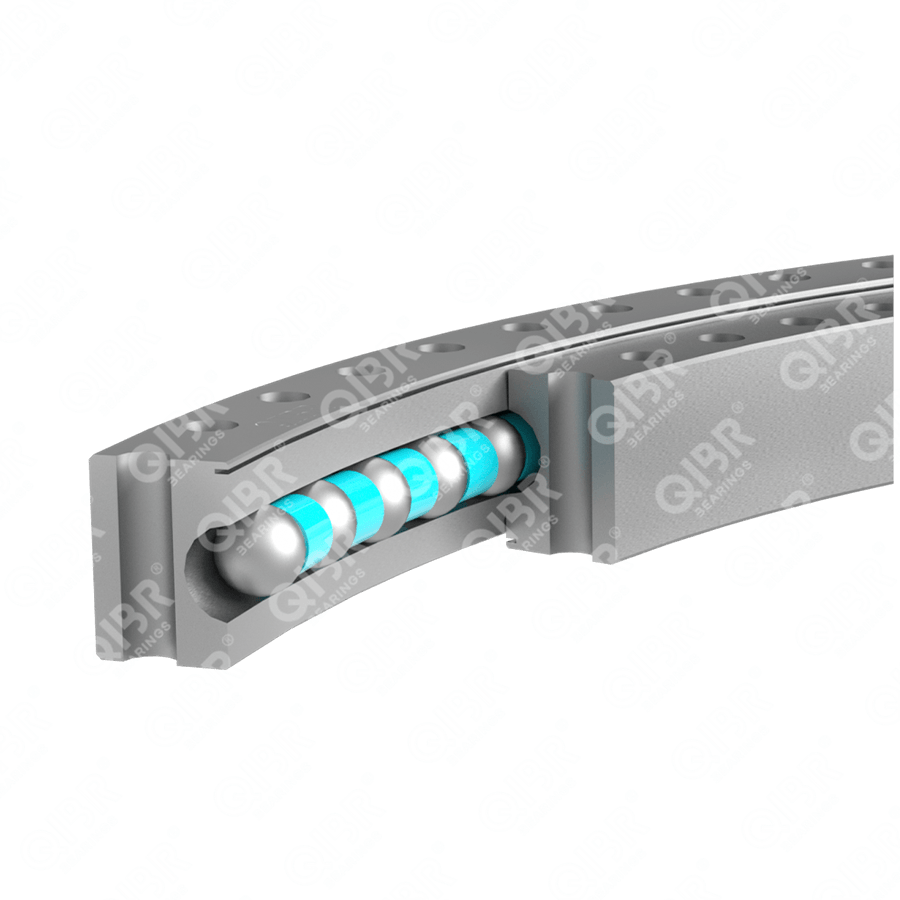

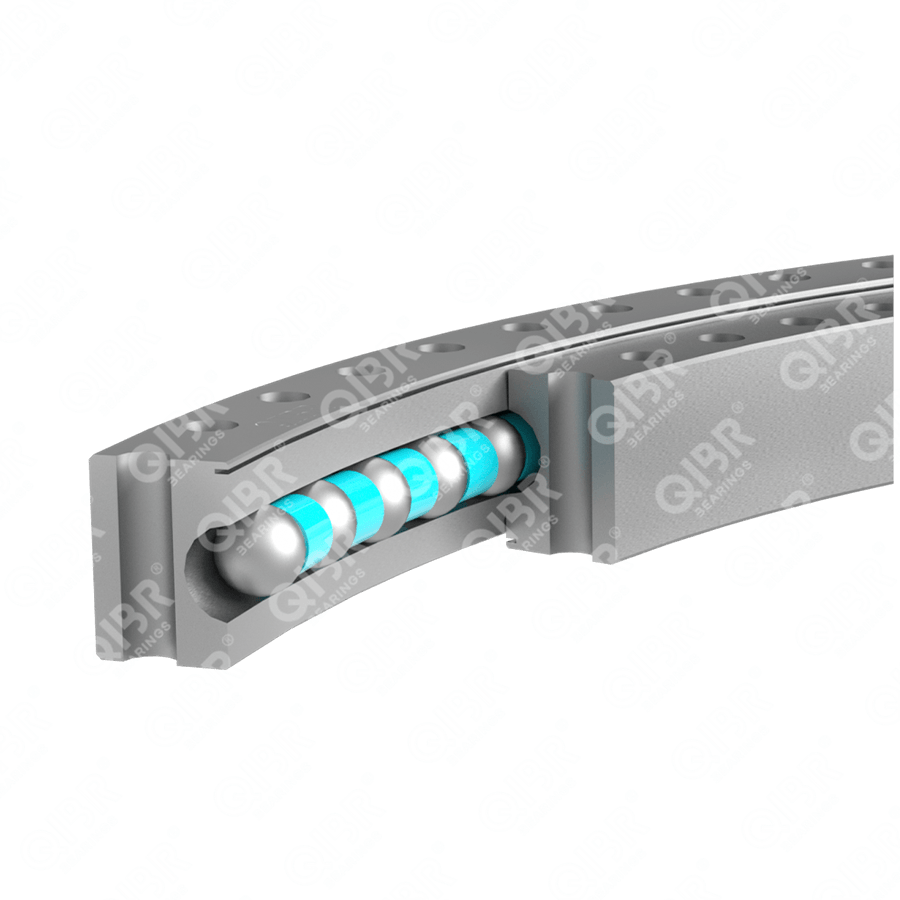

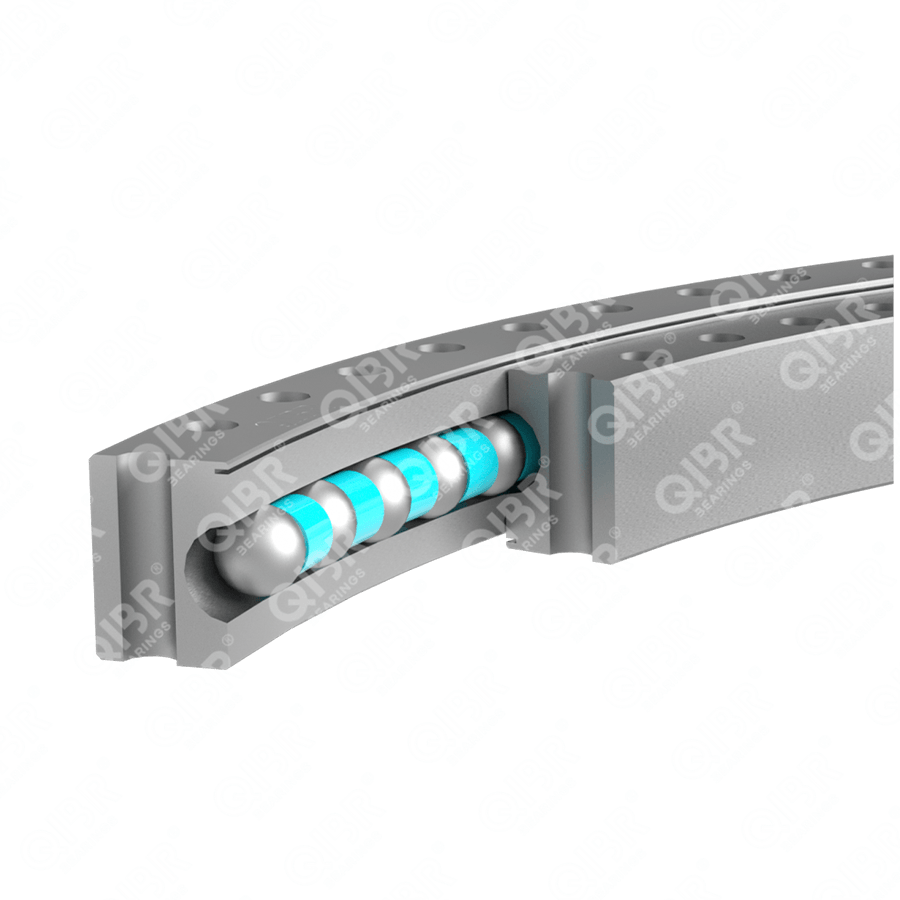

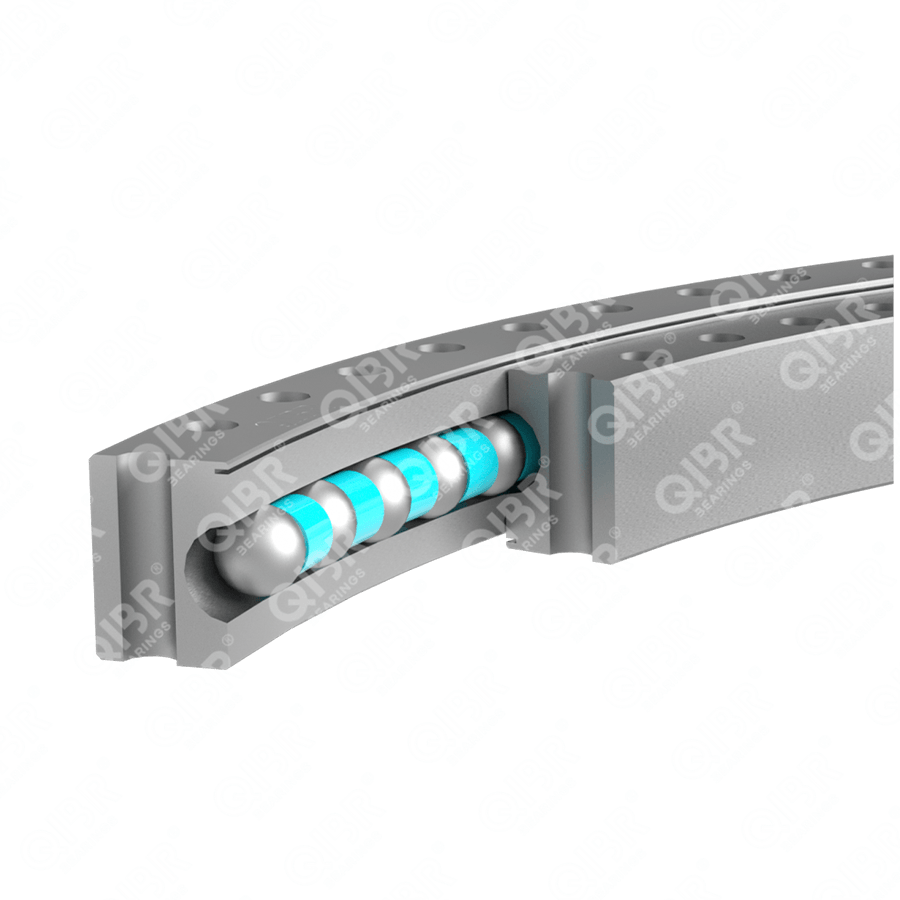

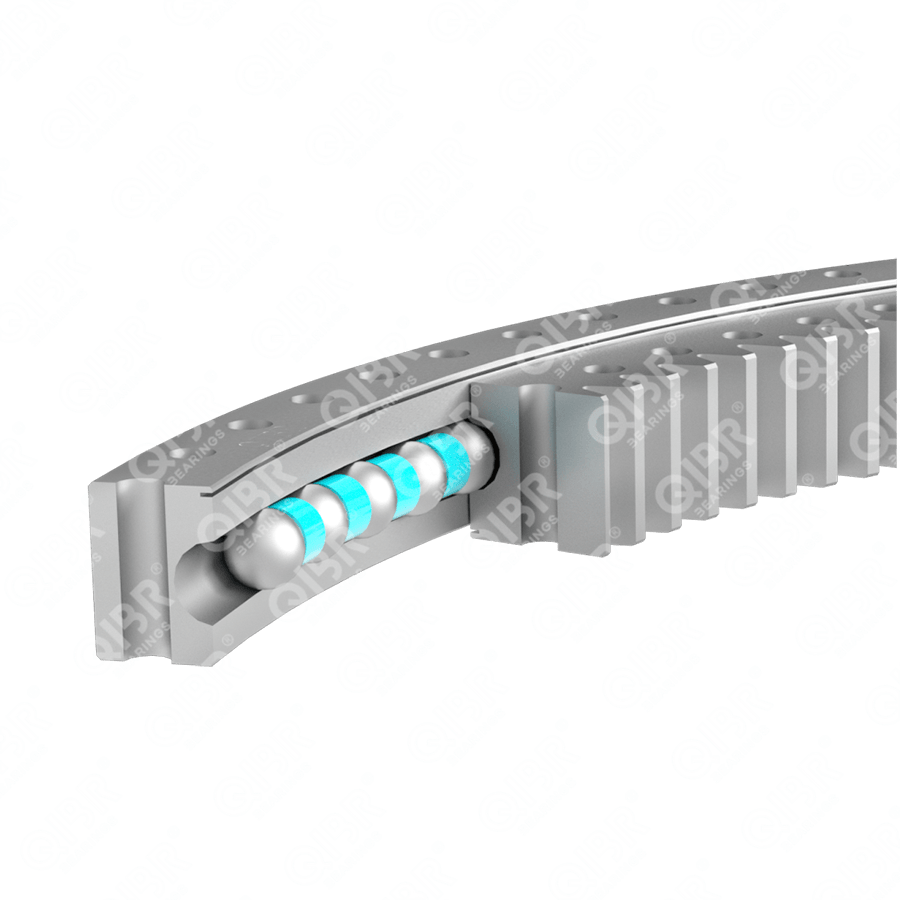

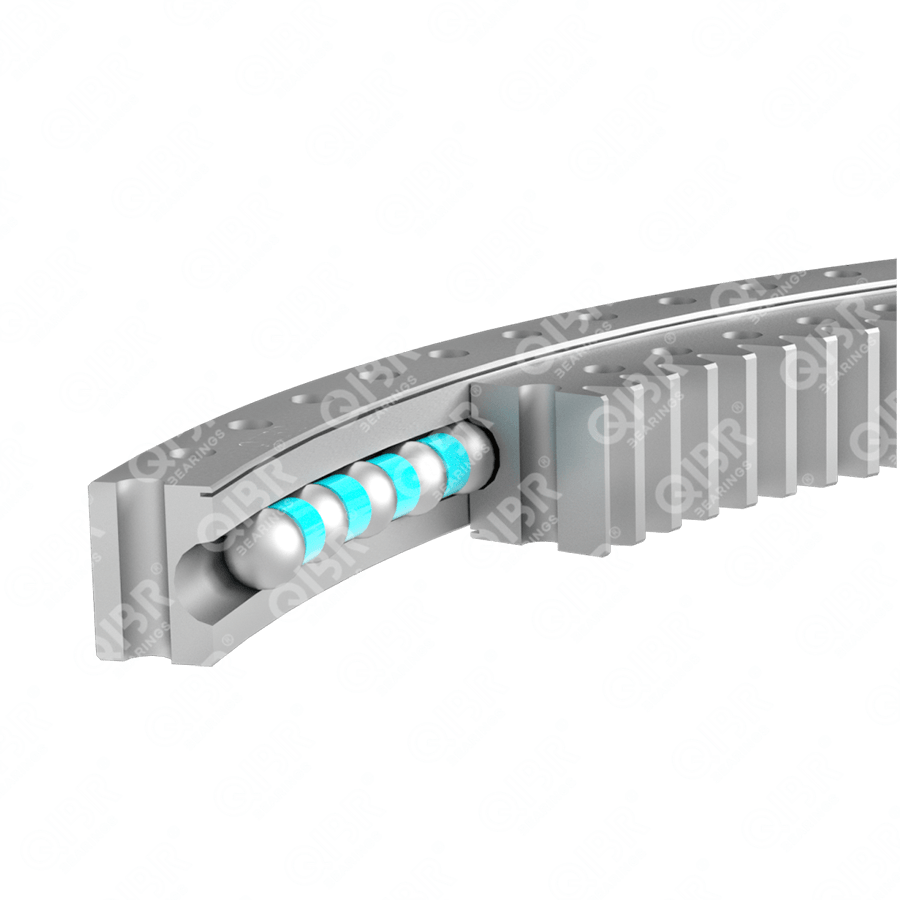

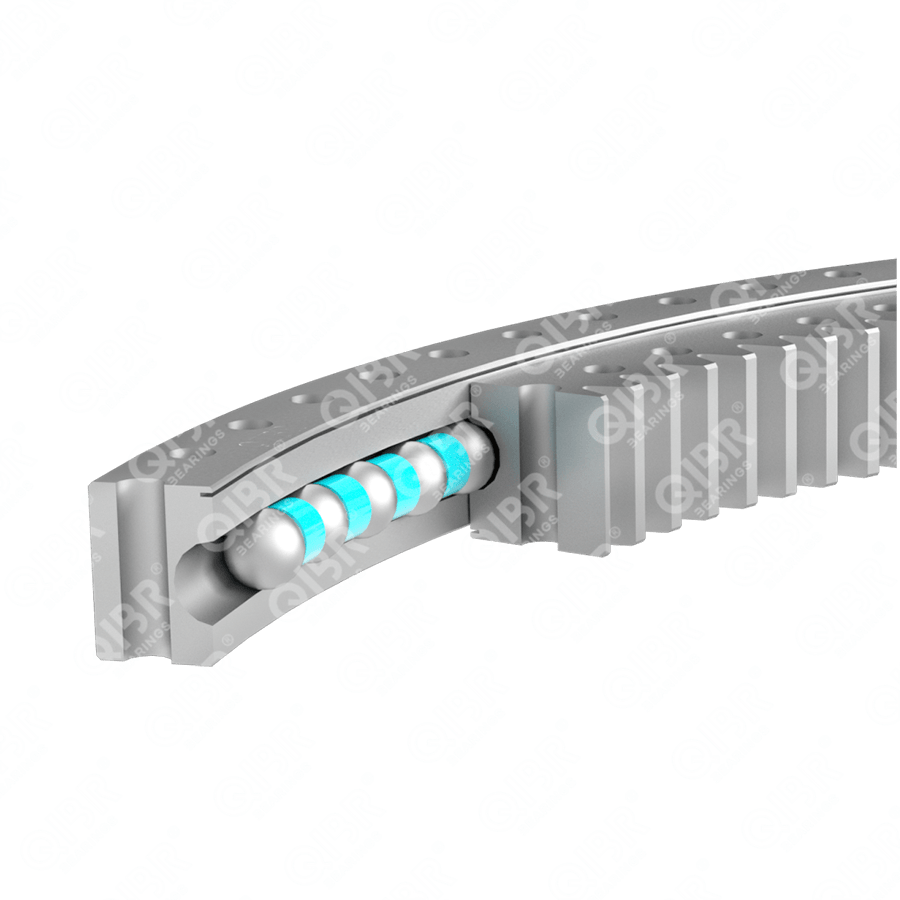

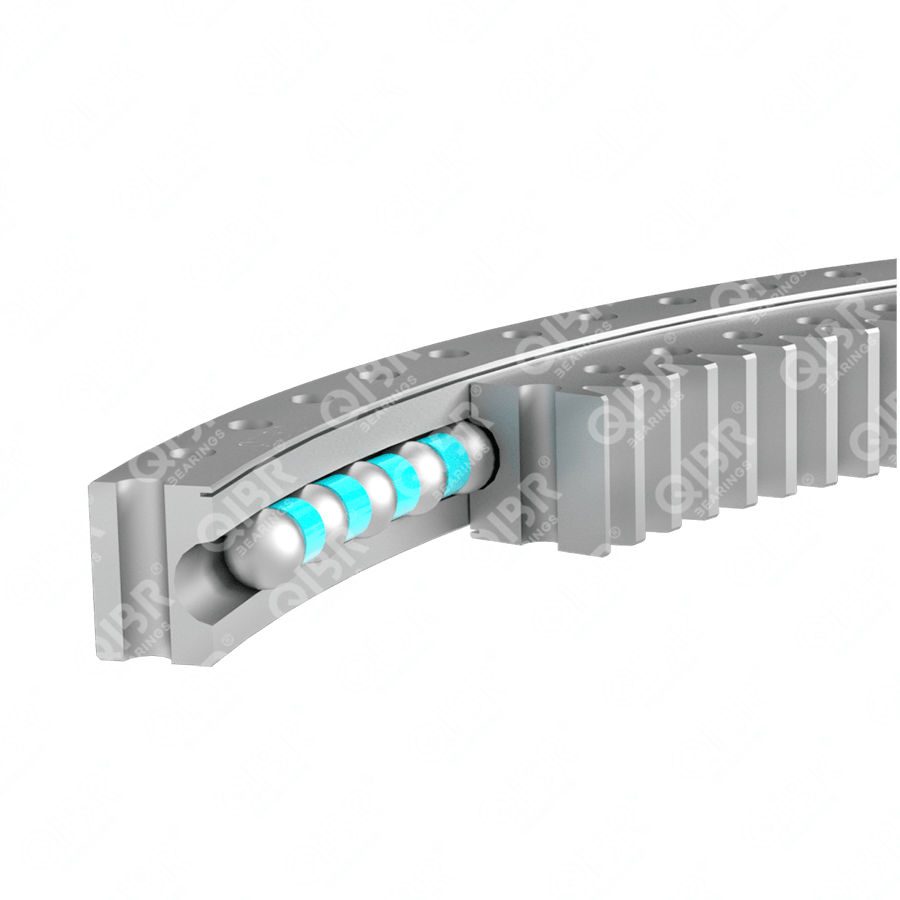

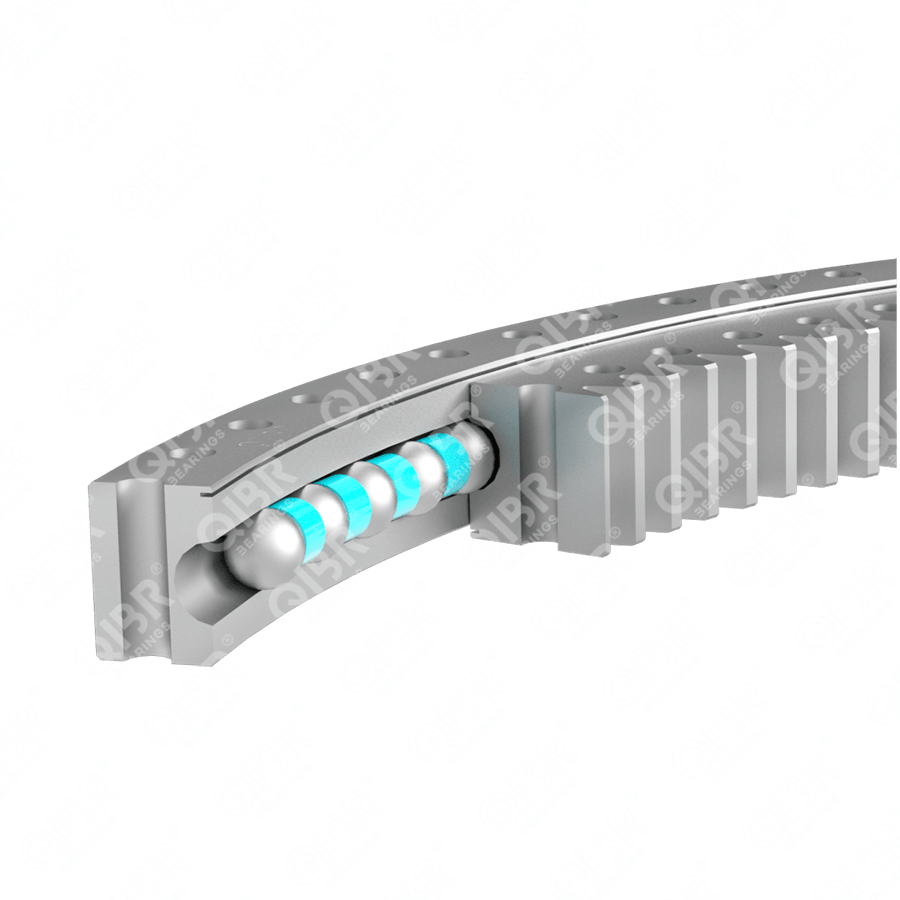

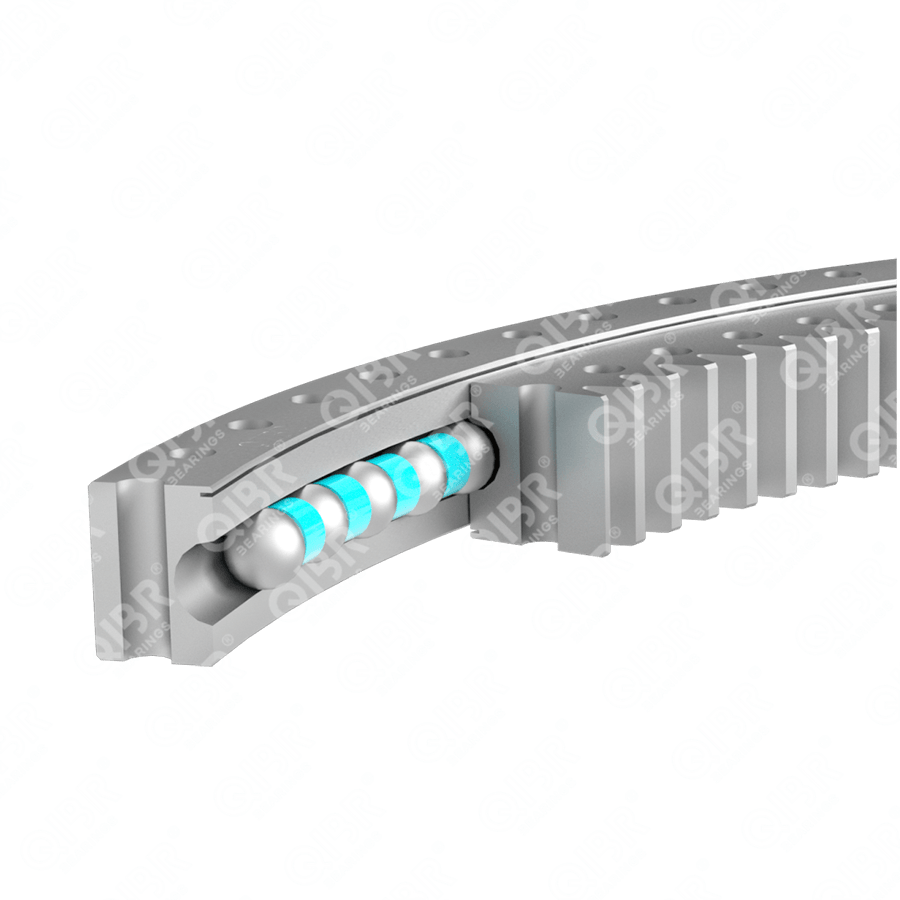

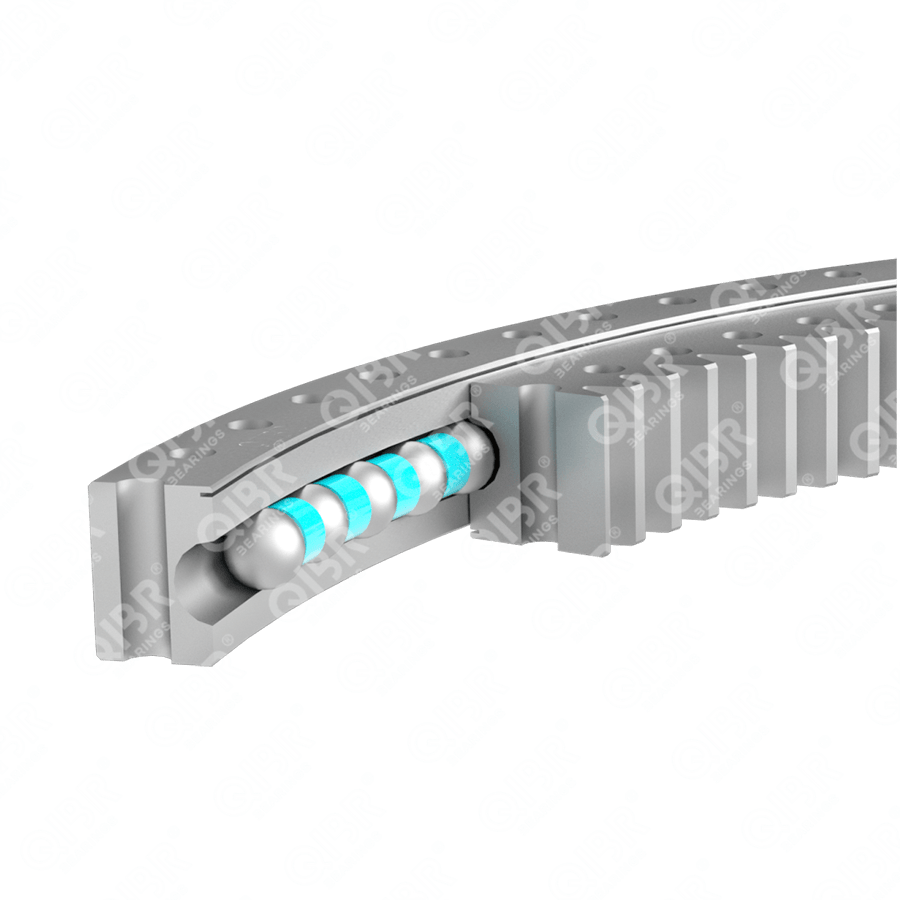

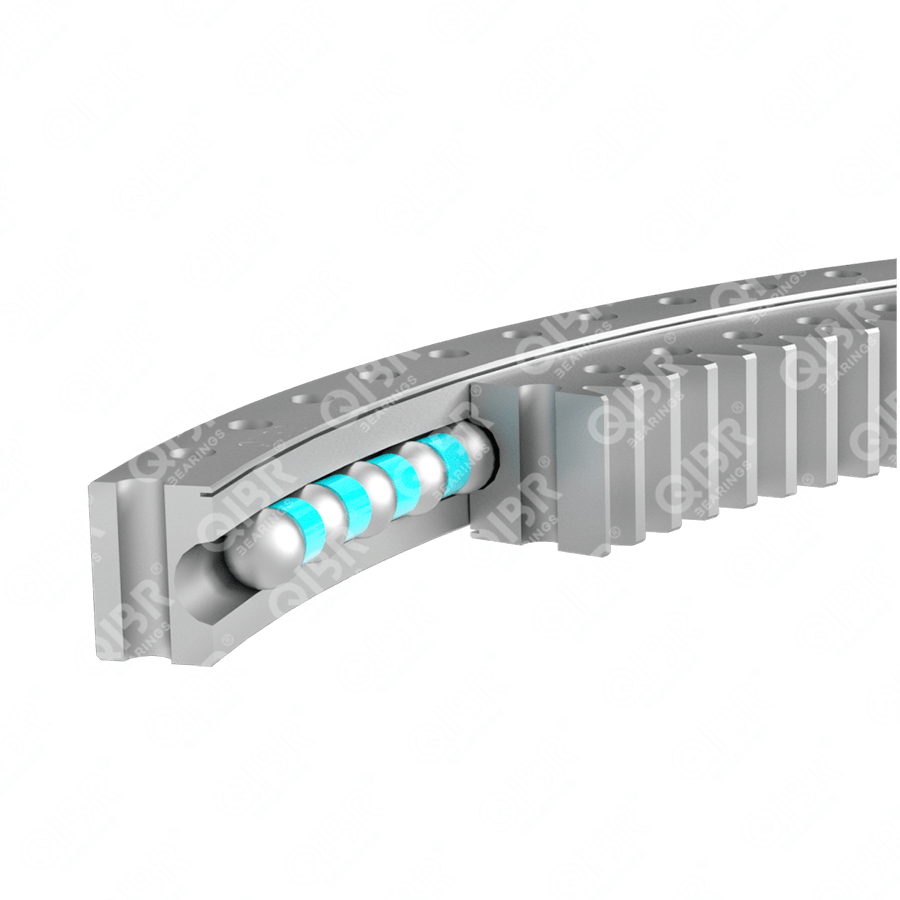

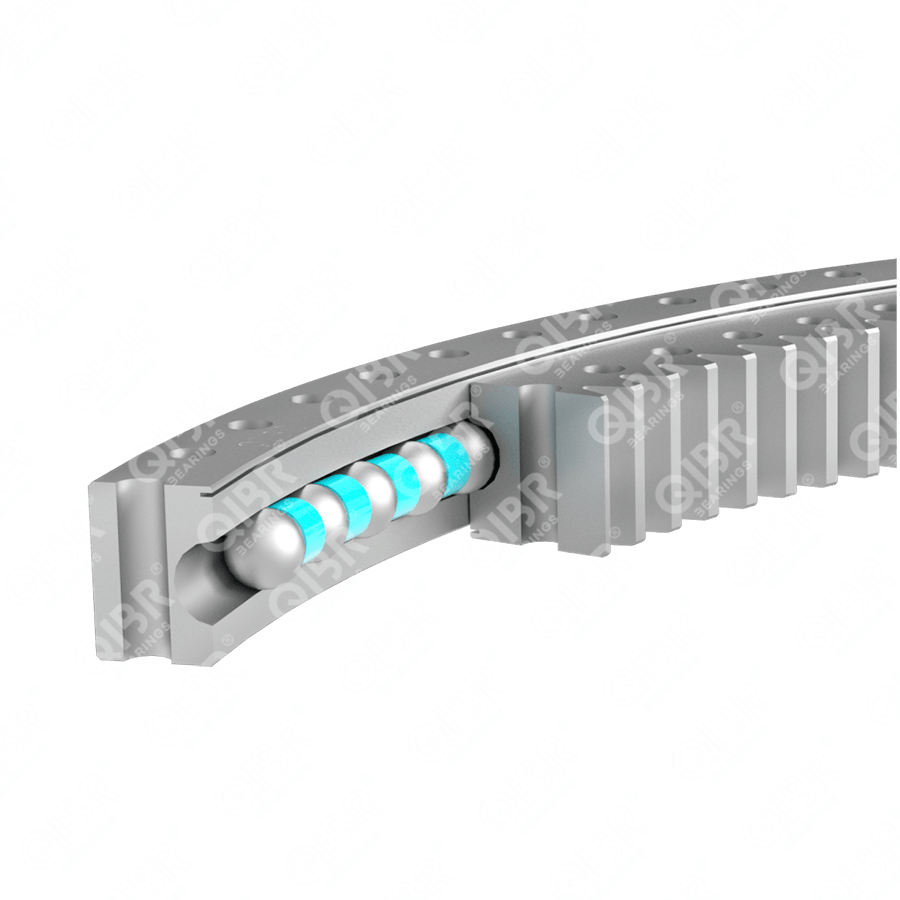

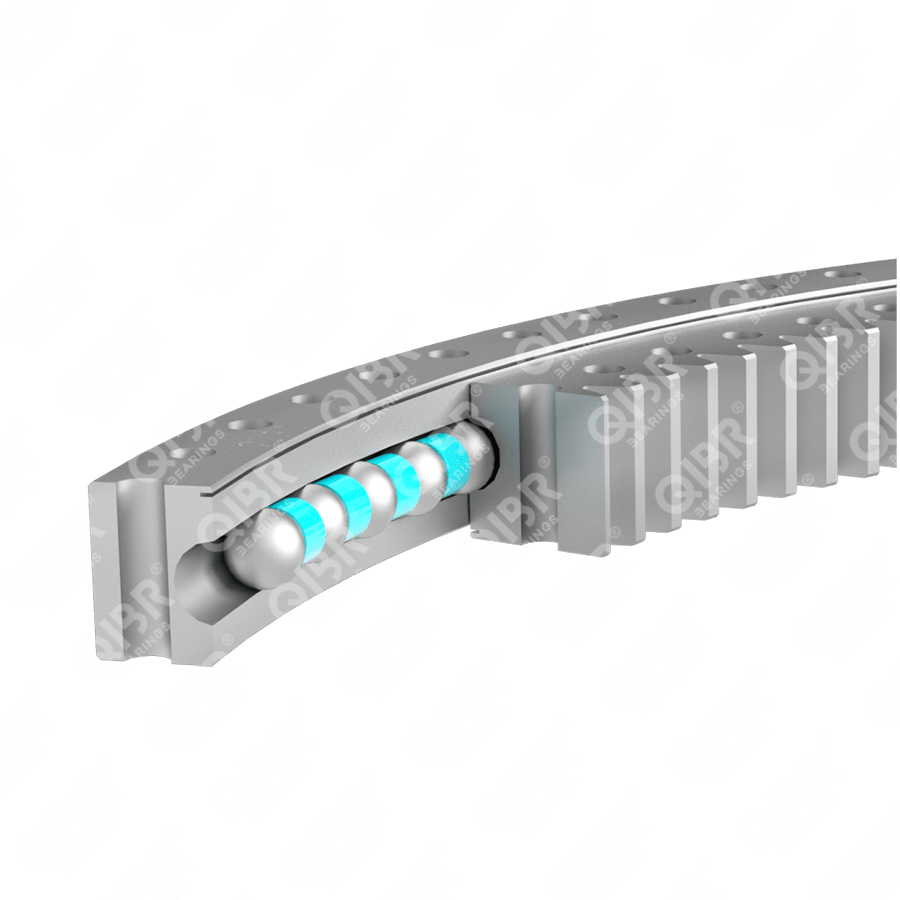

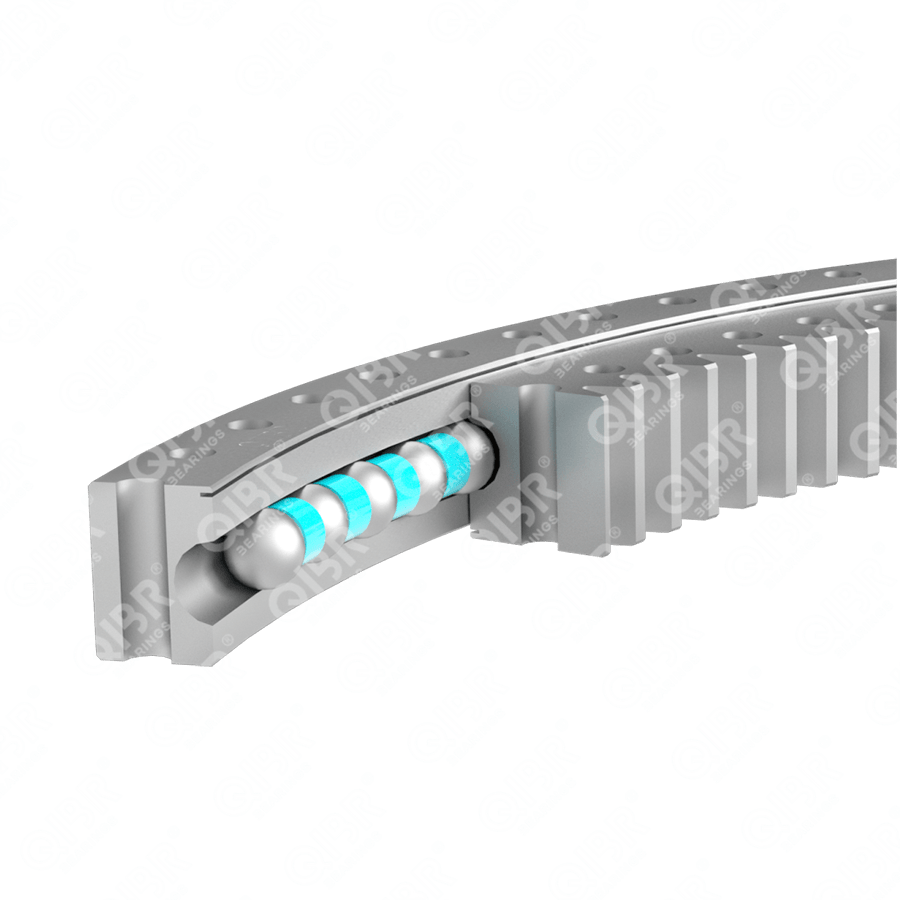

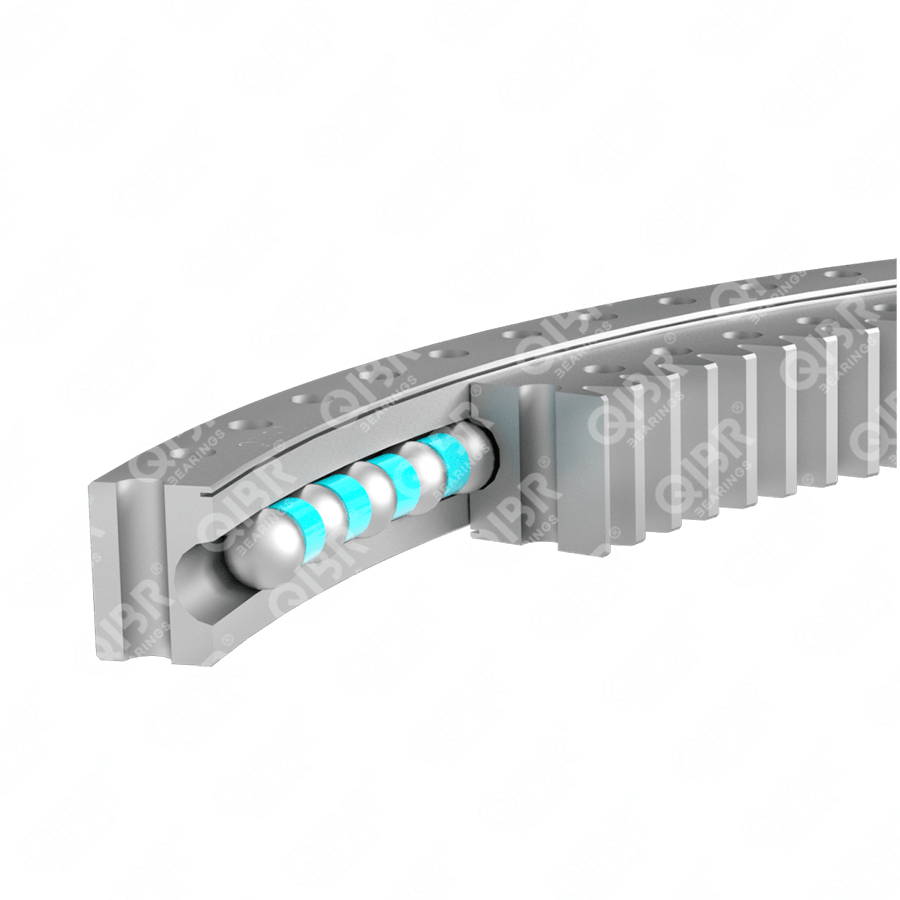

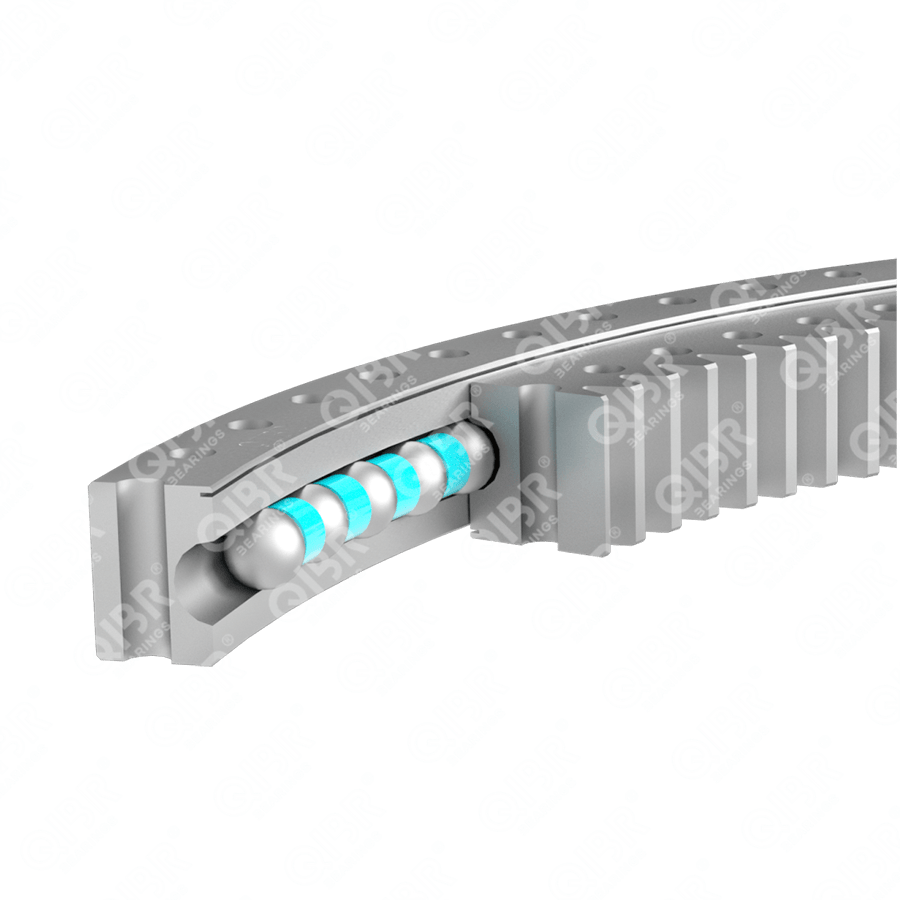

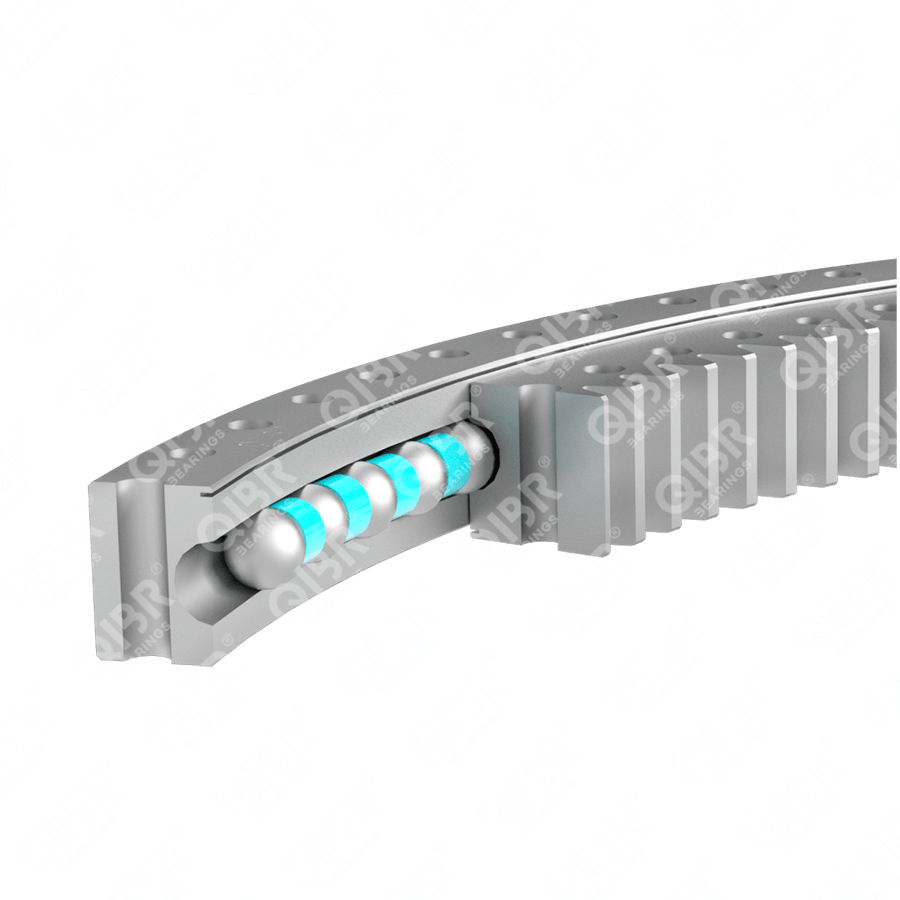

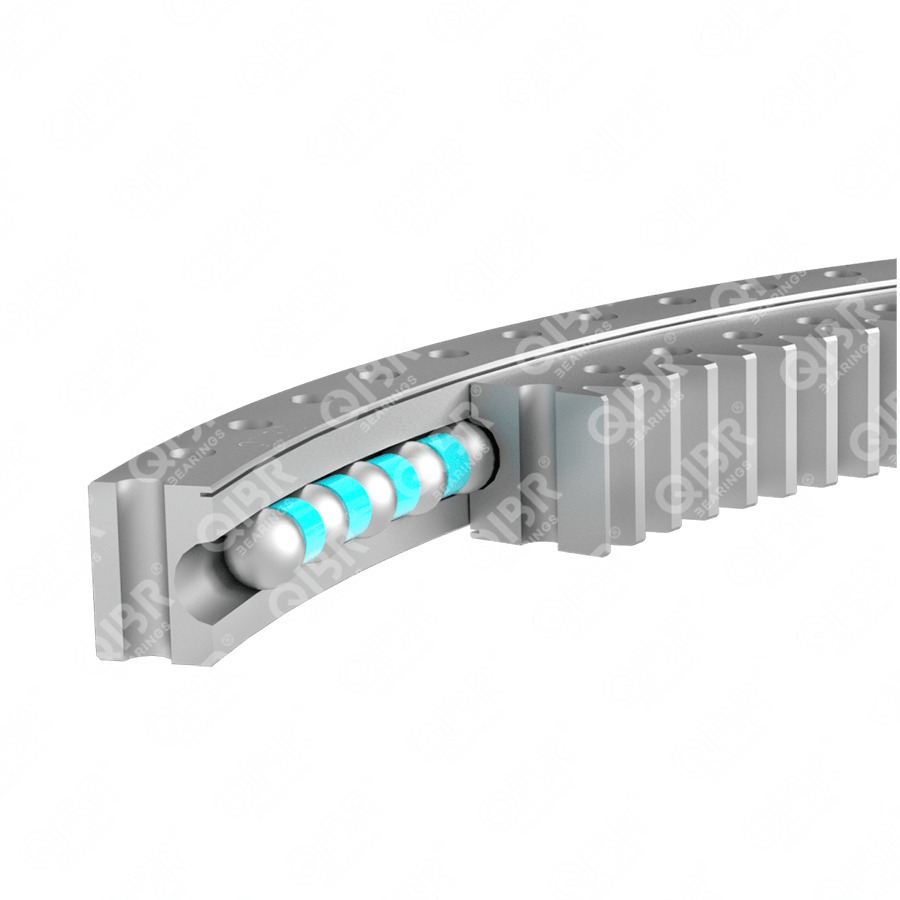

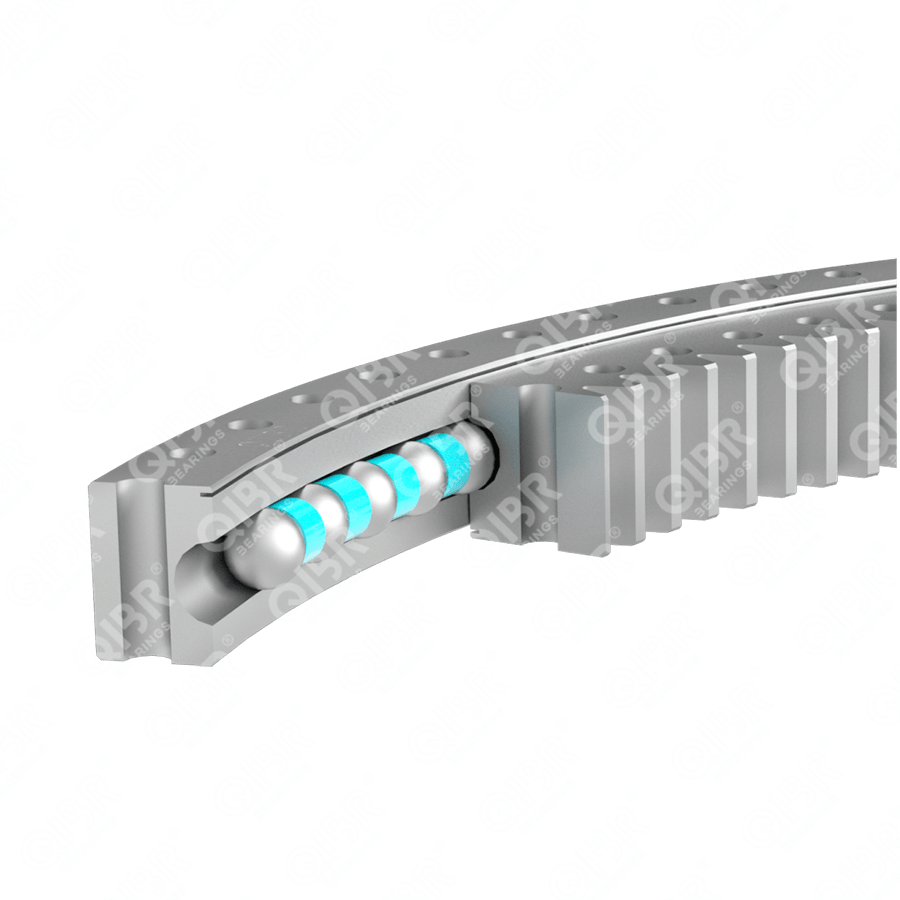

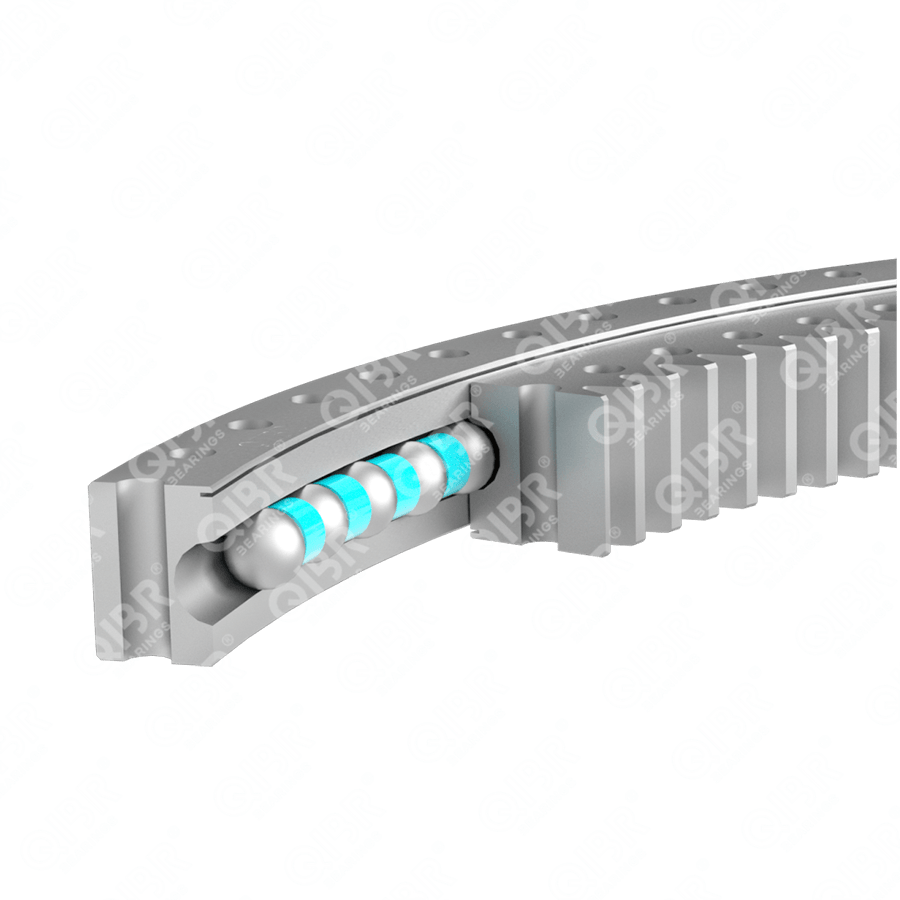

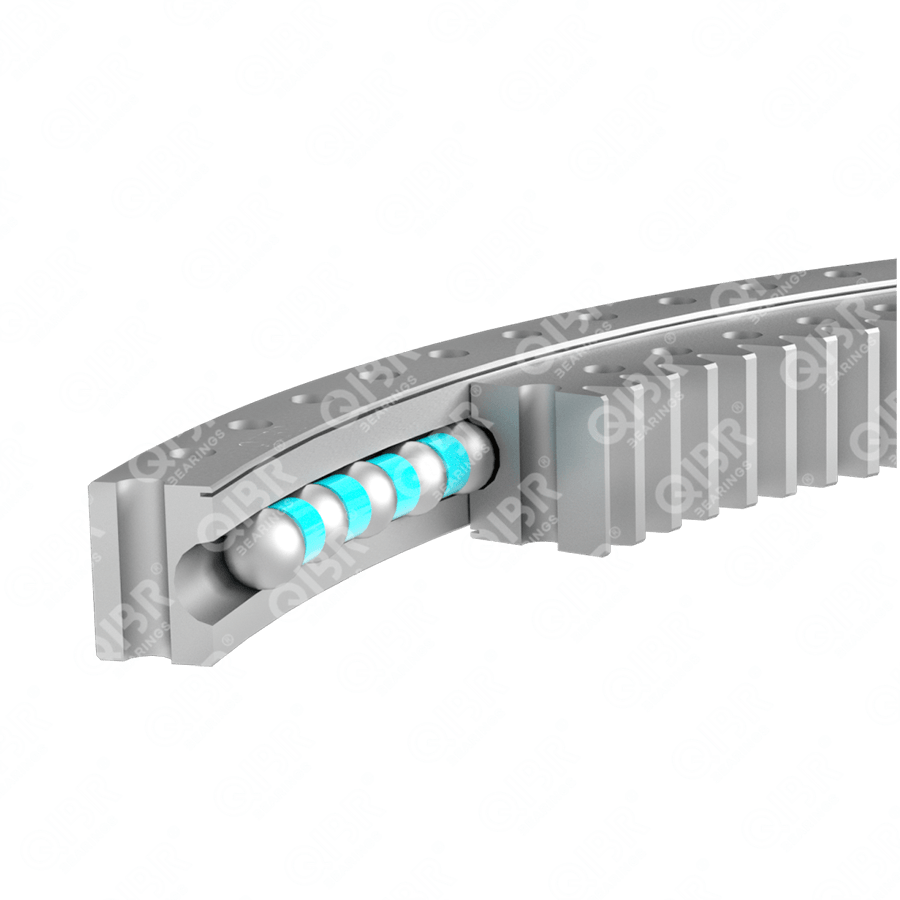

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN/VDEh,DIN/VDEh

Inner diameter

120mm-8000mm

Outer diameter

280mm-8000mm

Weight

20kg-8000kg

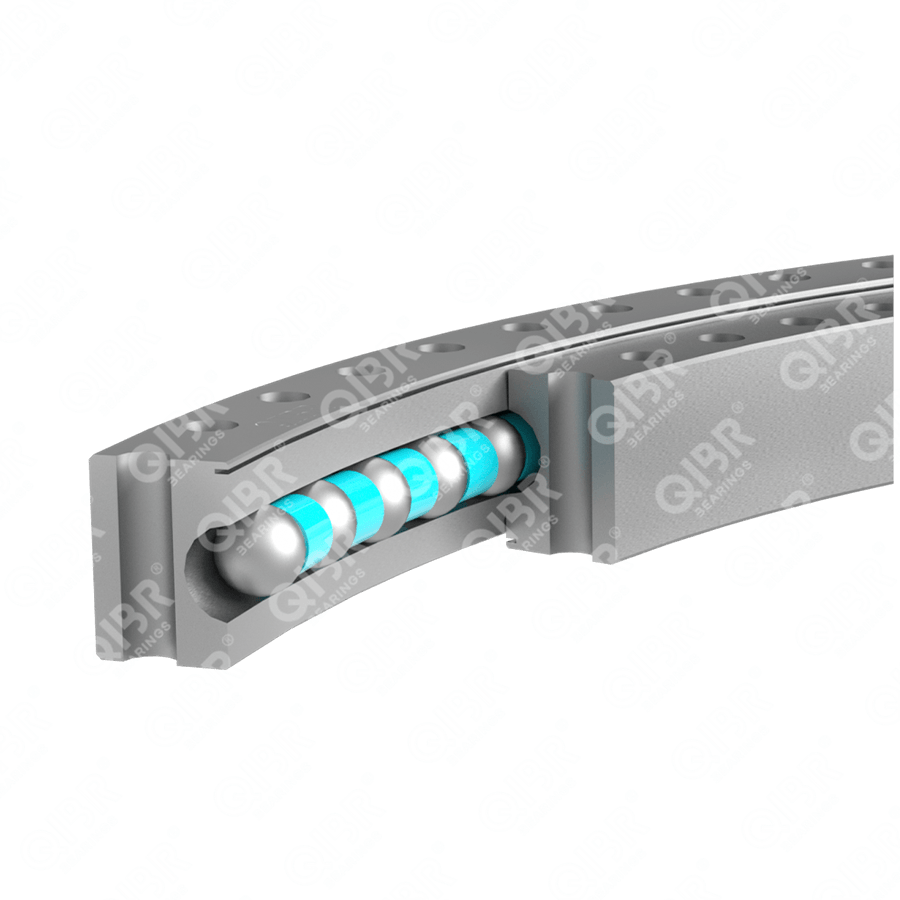

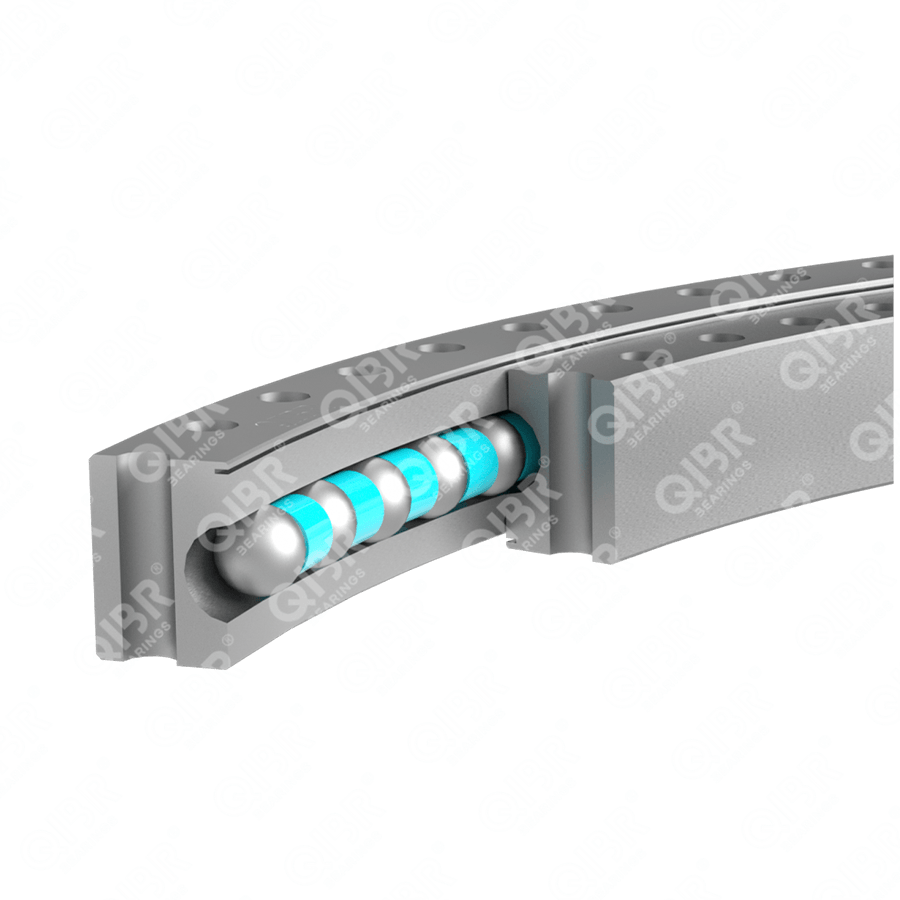

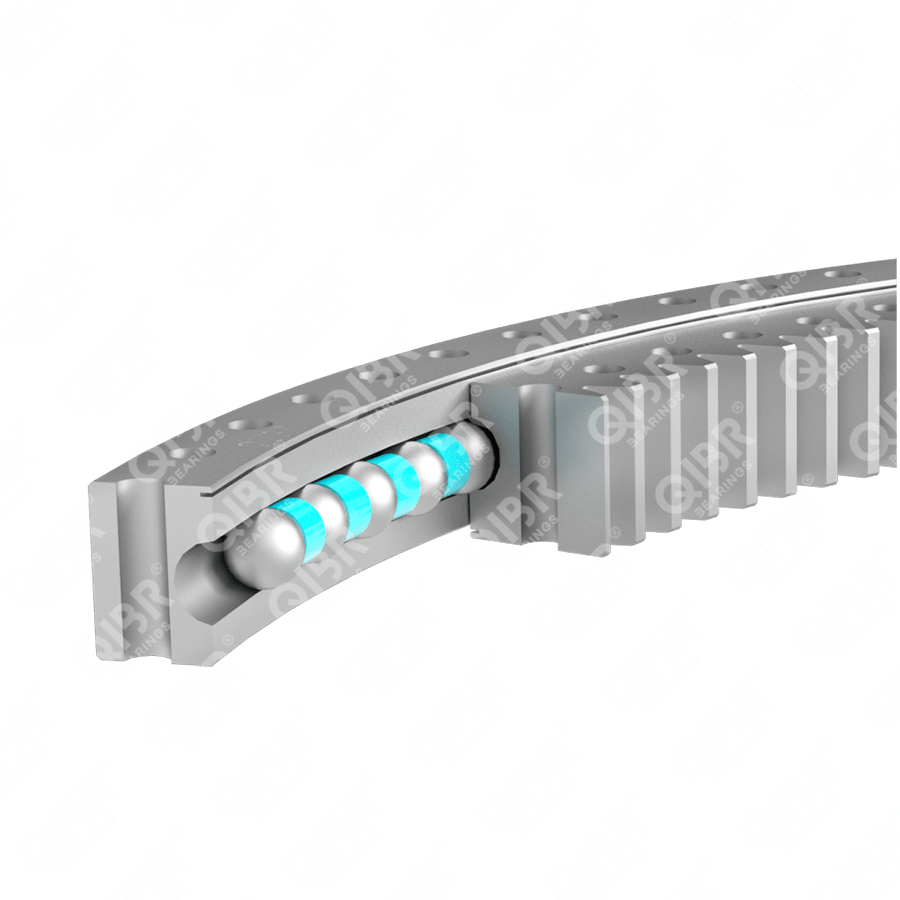

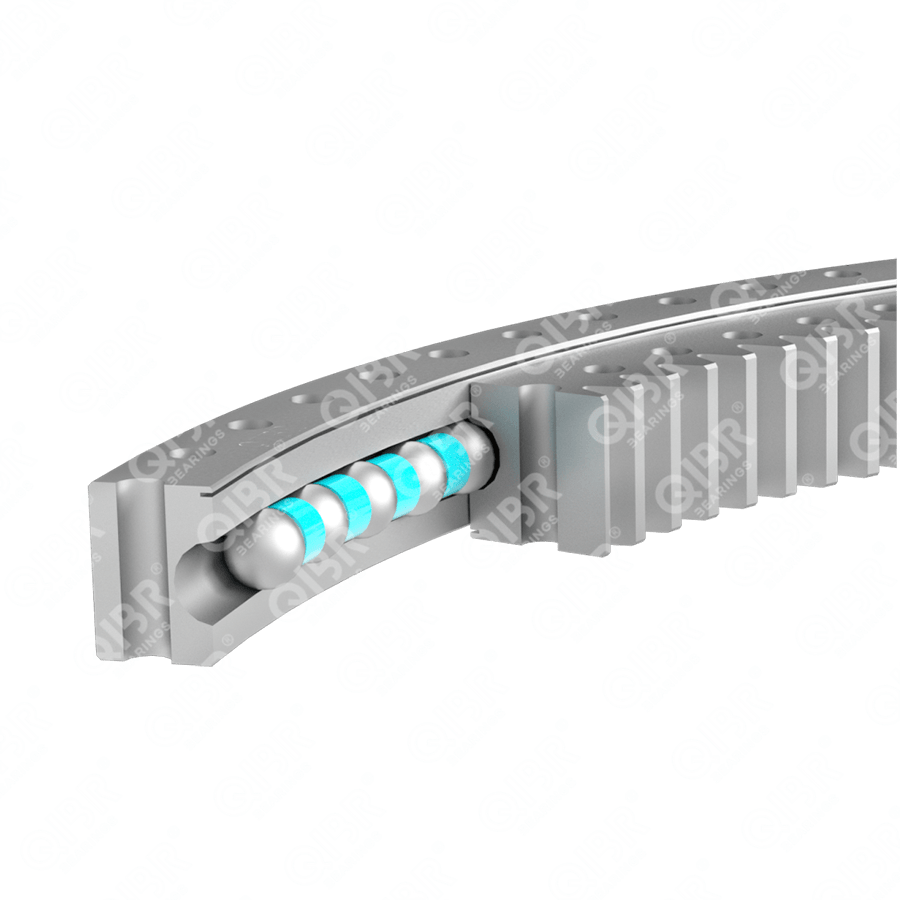

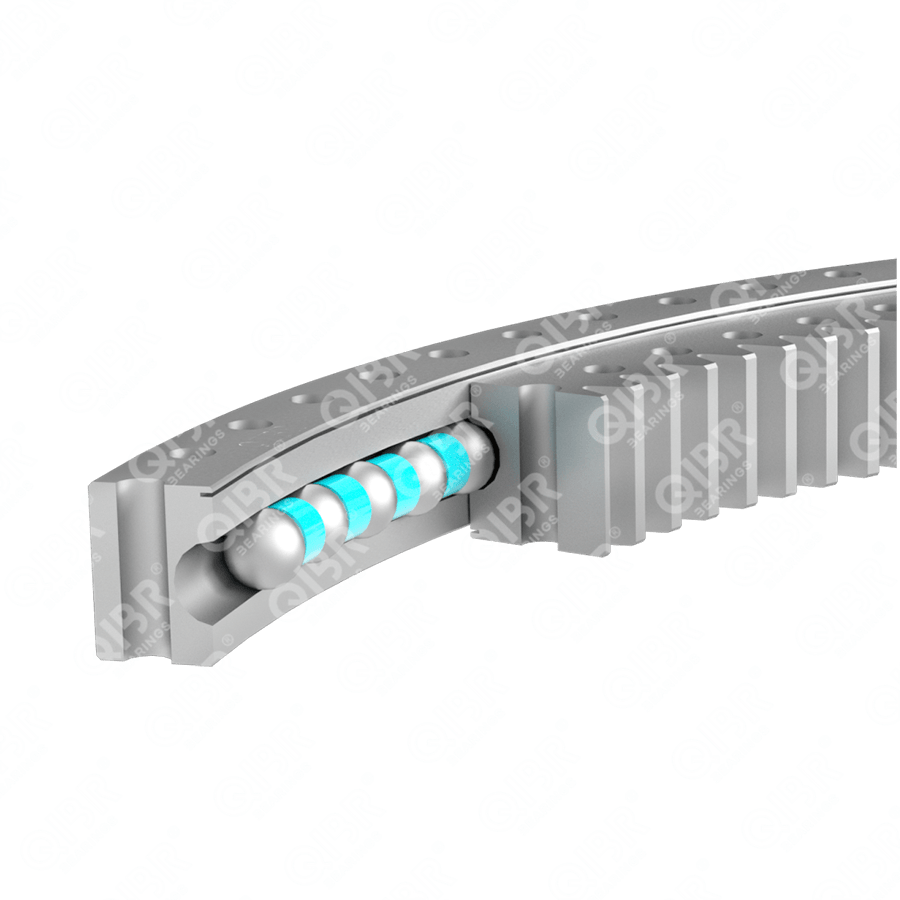

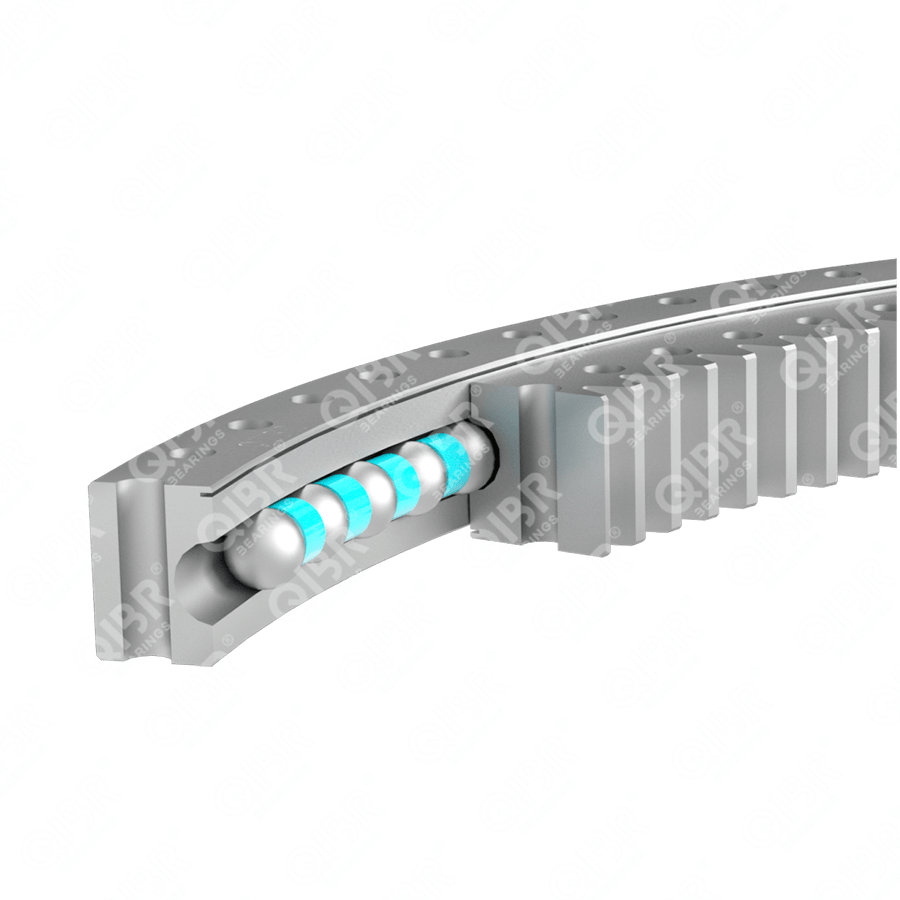

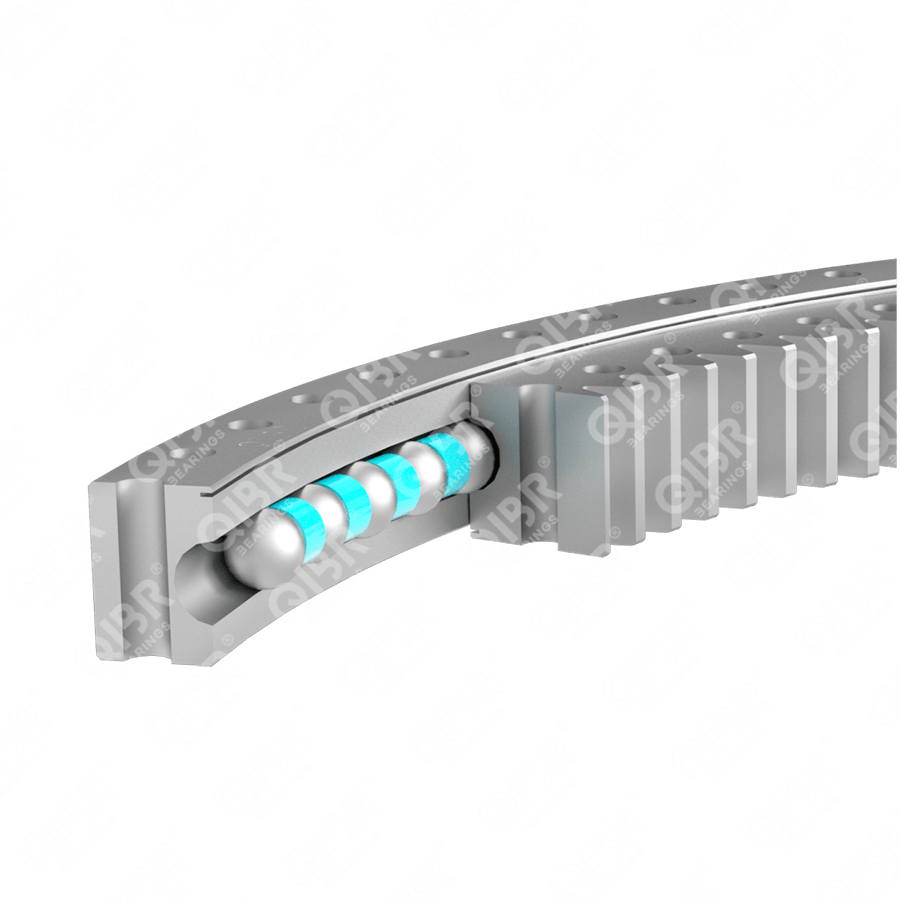

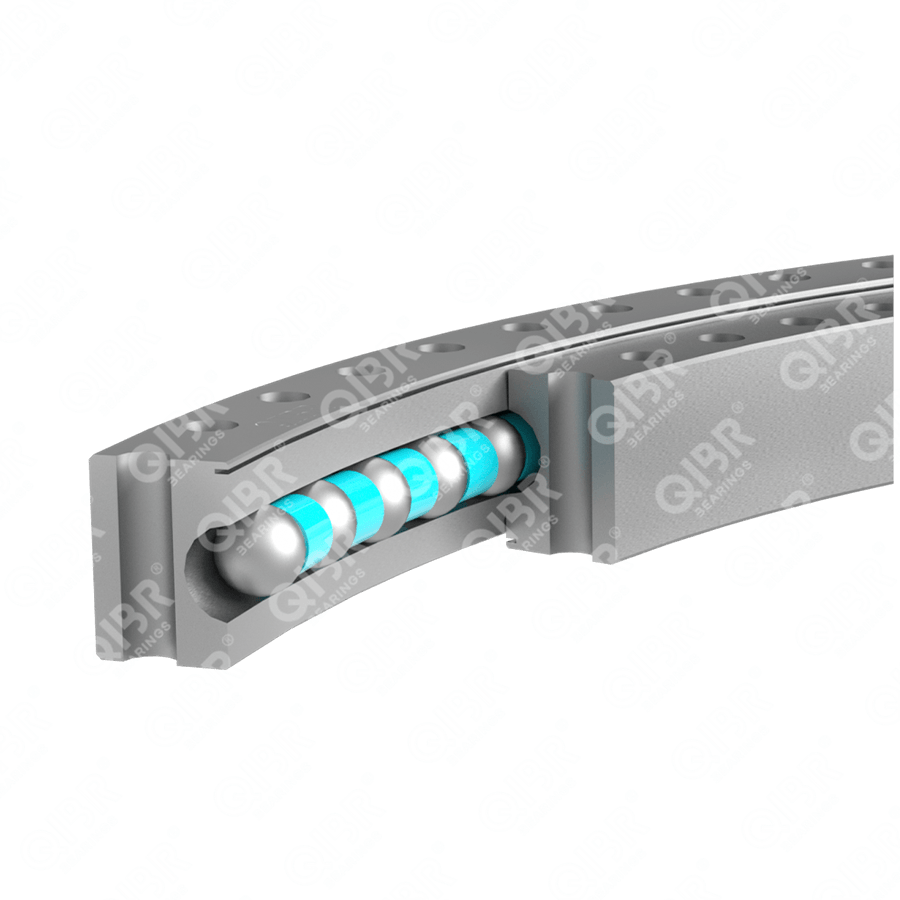

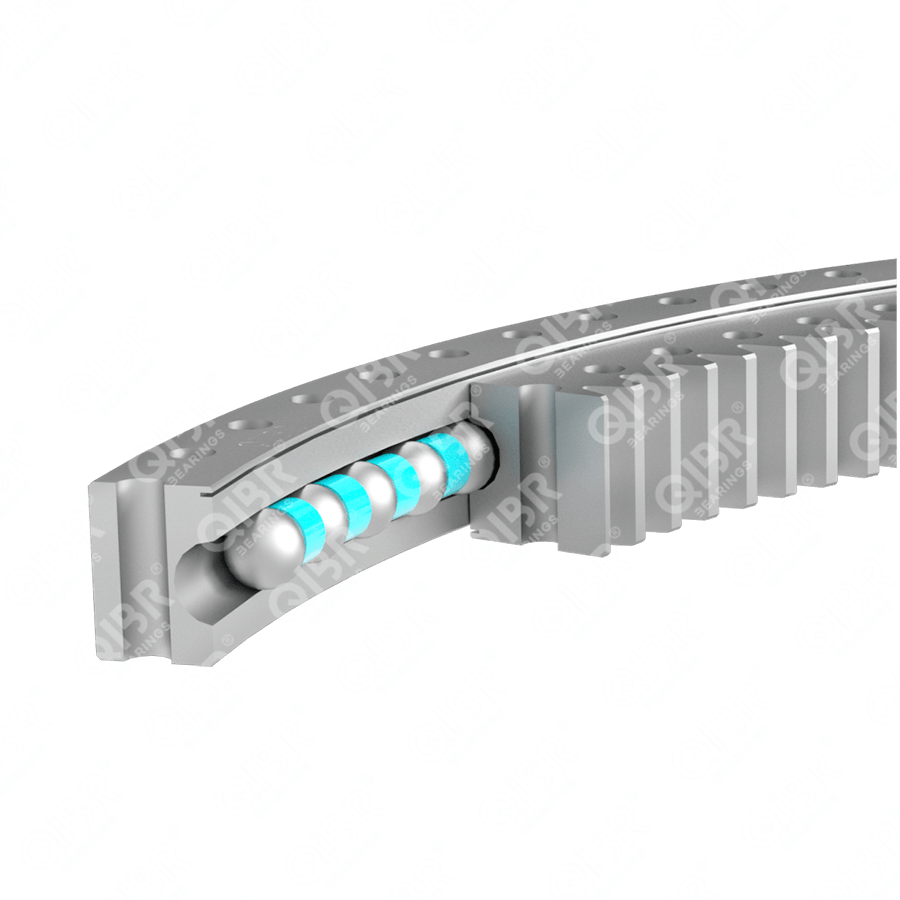

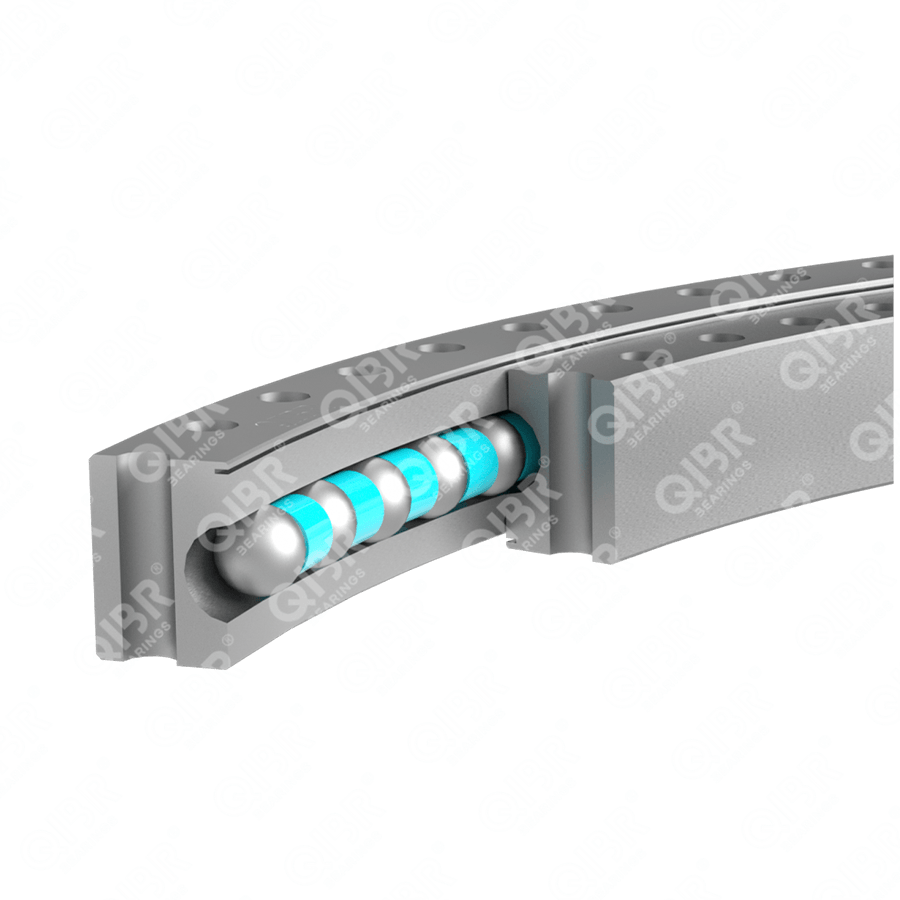

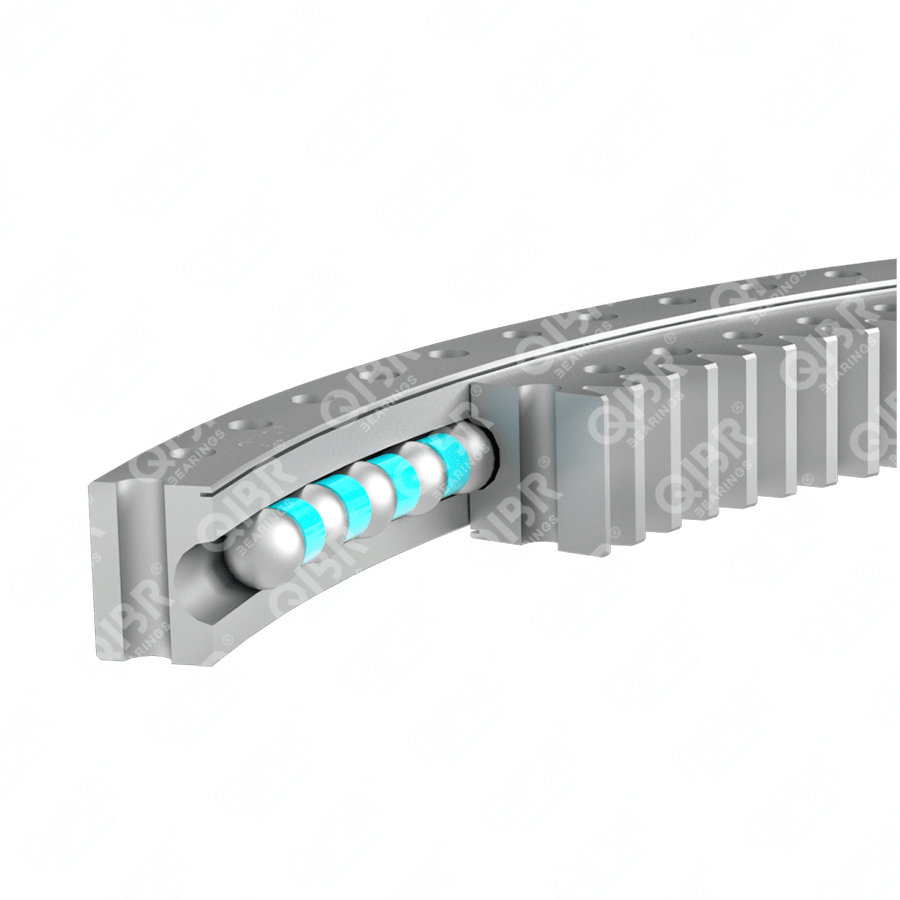

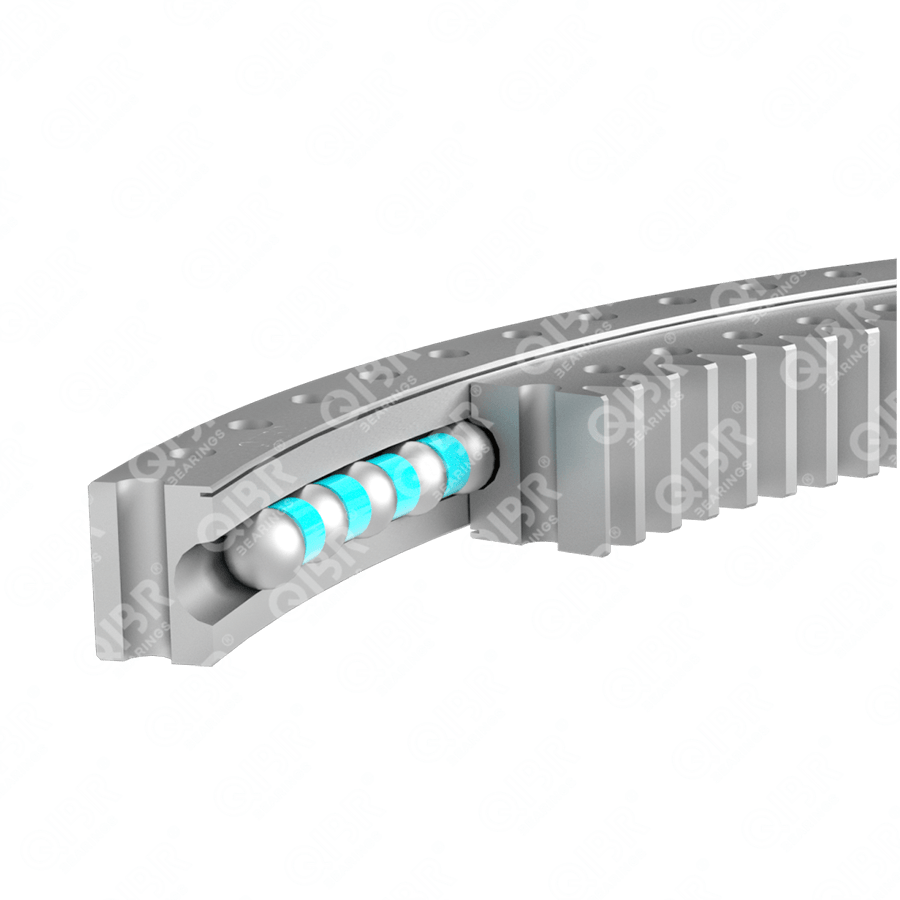

Structures

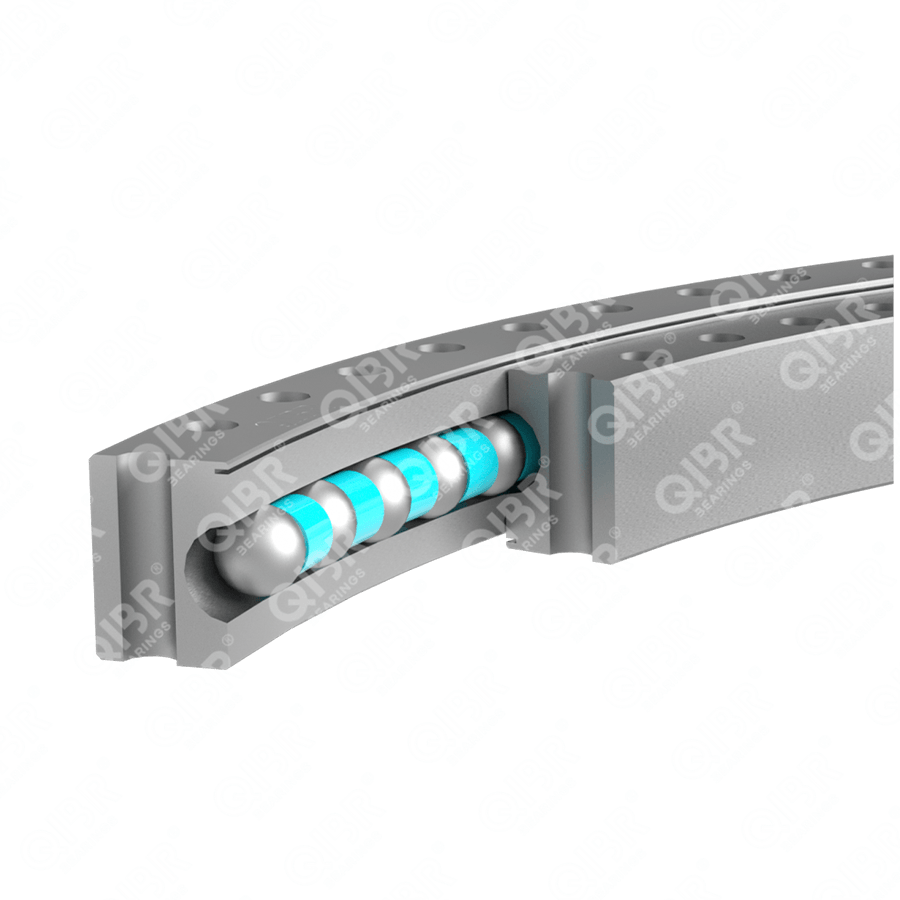

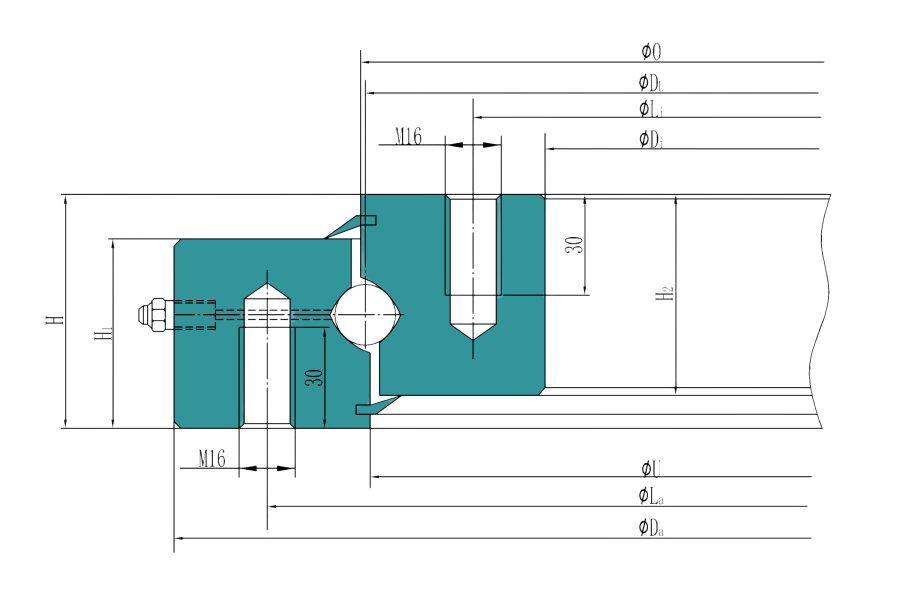

Outer Ring, Inner Ring, Spacer, Rolling element, Seal

Brand

QIBR/OEM/Neutral

Package

Standard Export Package

Material

42CrMo, 50Mn, or Stainless Steel

Applications

Hoisting machinery, construction machinery, material handling machinery, mining machinery, metallurgical machinery, medical instruments,ships and warships, radar,wind turbine

| NO. | Product | Product Number | Gear type | Inner diameter (Di) | Outer diameter (Da) | Overall height (H) | Weight |

|---|---|---|---|---|---|---|---|

| 1 |

|

060.22.0370.301.11.1504 | No Gear | 289 mm | 456 mm | 59 mm | 35 kg |

| 2 |

|

060.22.0505.000.11.1503 | No Gear | 425 mm | 585 mm | 58 mm | 44 kg |

| 3 |

|

060.22.0660.001.11.1503 | No Gear | 580 mm | 740 mm | 58 mm | 59 kg |

| 4 |

|

060.25.0475.000.11.1504 | No Gear | 385 mm | 565 mm | 64 mm | 50 kg |

| 5 |

|

060.25.0555.000.11.1504 | No Gear | 460 mm | 650 mm | 63 mm | 61 kg |

| 6 |

|

060.30.0550.100.11.1504 | No Gear | 450 mm | 650 mm | 75 mm | 73 kg |

| 7 |

|

060.35.0680.000.11.1503 | No Gear | 560 mm | 800 mm | 82 mm | 131 kg |

| 8 |

|

060.45.0805.001.11.1504 | No Gear | 662 mm | 948 mm | 99 mm | 215 kg |

| 9 |

|

061.25.0764.103.11.1504 | External Gear | 670 mm | 862.8 mm | 82 mm | 98 kg |

| 10 |

|

061.25.0764.106.21.1504 | External Gear | 670 mm | 862.8 mm | 82 mm | 98 kg |

| 11 |

|

061.25.0980.107.11.1504 | External Gear | 886 mm | 1078.4 mm | 79 mm | 123 kg |

| 12 |

|

061.25.0980.108.21.1504 | External Gear | 886 mm | 1078.4 mm | 79 mm | 123 kg |

| 13 |

|

061.20.0400.100.11.1503 | External Gear | 325 mm | 499.8 mm | 55 mm | 35 kg |

| 14 |

|

061.20.0400.101.21.1503 | External Gear | 325 mm | 499.8 mm | 55 mm | 35 kg |

| 15 |

|

061.20.0450.100.11.1503 | External Gear | 369 mm | 554.8 mm | 55 mm | 39 kg |

| 16 |

|

061.20.0450.101.21.1503 | External Gear | 369 mm | 554.8 mm | 55 mm | 39 kg |

| 17 |

|

061.20.0560.100.11.1503 | External Gear | 479 mm | 670.8 mm | 55 mm | 53 kg |

| 18 |

|

061.20.0560.101.21.1503 | External Gear | 479 mm | 670.8 mm | 55 mm | 53 kg |

| 19 |

|

061.20.0630.100.11.1503 | External Gear | 543 mm | 742.8 mm | 55 mm | 61 kg |

| 20 |

|

061.20.0630.101.21.1503 | External Gear | 543 mm | 742.8 mm | 55 mm | 61 kg |

| 21 |

|

061.20.0710.100.11.1503 | External Gear | 623 mm | 820.8 mm | 55 mm | 67 kg |

| 22 |

|

061.20.0710.101.21.1503 | External Gear | 623 mm | 820.8 mm | 55 mm | 67 kg |

| 23 |

|

061.25.0764.600.11.1503 | External Gear | 671 mm | 886.8 mm | 63 mm | 95 kg |

| 24 |

|

061.25.0764.601.21.1503 | External Gear | 671 mm | 886.8 mm | 63 mm | 95 kg |

| 25 |

|

061.25.0980.890.11.1503 | External Gear | 887 mm | 1110.4 mm | 63 mm | 124 kg |

| 26 |

|

061.25.0980.891.21.1503 | External Gear | 887 mm | 1110.4 mm | 63 mm | 124 kg |

| 27 |

|

061.25.1120.000.11.1504 | External Gear | 1013 mm | 1278.4 mm | 79 mm | 182 kg |

| 28 |

|

061.25.1120.001.21.1504 | External Gear | 1013 mm | 1278.4 mm | 79 mm | 182 kg |

| 29 |

|

061.25.1250.100.11.1504 | External Gear | 1143 mm | 1408.4 mm | 79 mm | 221 kg |

| 30 |

|

061.25.1250.101.21.1504 | External Gear | 1143 mm | 1408.4 mm | 79 mm | 221 kg |

| 31 |

|

061.30.1180.000.11.1504 | External Gear | 1068 mm | 1338 mm | 79 mm | 227 kg |

| 32 |

|

061.30.1180.001.21.1504 | External Gear | 1068 mm | 1338 mm | 79 mm | 227 kg |

| 33 |

|

061.30.1320.000.11.1504 | External Gear | 1208 mm | 1497.6 mm | 89 mm | 298 kg |

| 34 |

|

061.30.1320.001.21.1504 | External Gear | 1208 mm | 1497.6 mm | 89 mm | 298 kg |

| 35 |

|

061.30.1500.200.11.1504 | External Gear | 1388 mm | 1677.6 mm | 89 mm | 338 kg |

| 36 |

|

061.30.1500.201.21.1523 | External Gear | 1388 mm | 1677.6 mm | 89 mm | 338 kg |

| 37 |

|

061.40.1400.000.19.1504 | External Gear | 1266 mm | 1593.6 mm | 94 mm | 404 kg |

| 38 |

|

061.40.1400.001.29.1504 | External Gear | 1266 mm | 1593.6 mm | 94 mm | 404 kg |

| 39 |

|

061.40.1600.008.19.1503 | External Gear | 1466 mm | 1803.2 mm | 94 mm | 479 kg |

| 40 |

|

061.40.1600.009.29.1503 | External Gear | 1466 mm | 1803.2 mm | 94 mm | 479 kg |

| 41 |

|

061.40.1800.013.19.1503 | External Gear | 1666 mm | 1999.2 mm | 94 mm | 531 kg |

| 42 |

|

061.40.1800.014.29.1503 | External Gear | 1666 mm | 1999.2 mm | 94 mm | 531 kg |

| 43 |

|

061.50.1900.001.49.1504 | External Gear | 1729 mm | 2139.2 mm | 109 mm | 820 kg |

| 44 |

|

061.50.2130.001.49.1504 | External Gear | 1959 mm | 2380.8 mm | 109 mm | 931 kg |

| 45 |

|

061.50.2355.001.49.1504 | External Gear | 2184 mm | 2604.8 mm | 109 mm | 1024 kg |

| 46 |

|

061.50.2645.001.49.1504 | External Gear | 2474 mm | 2892.8 mm | 109 mm | 1142 kg |

| 47 |

|

062.25.0886.106.11.1504 | Internal Gear | 784 mm | 980 mm | 77 mm | 109 kg |

| 48 |

|

062.25.0886.109.21.1504 | Internal Gear | 784 mm | 980 mm | 77 mm | 109 kg |

| 49 |

|

062.25.1077.308.11.1504 | Internal Gear | 960 mm | 1170 mm | 84 mm | 148 kg |

| 50 |

|

062.25.1077.304.21.1504 | Internal Gear | 960 mm | 1170 mm | 84 mm | 148 kg |

| 51 |

|

062.20.0400.000.11.1503 | External Gear | 300 mm | 475 mm | 55 mm | 33 kg |

| 52 |

|

062.20.0400.001.21.1503 | Internal Gear | 300 mm | 475 mm | 55 mm | 33 kg |

| 53 |

|

062.20.0450.000.11.1503 | Internal Gear | 345 mm | 531 mm | 55 mm | 38 kg |

| 54 |

|

062.20.0450.001.21.1503 | Internal Gear | 345 mm | 531 mm | 55 mm | 38 kg |

| 55 |

|

062.20.0560.000.11.1503 | Internal Gear | 450 mm | 641 mm | 55 mm | 51 kg |

| 56 |

|

062.20.0560.001.21.1503 | Internal Gear | 450 mm | 641 mm | 55 mm | 51 kg |

| 57 |

|

062.20.0630.000.11.1503 | Internal Gear | 516 mm | 717 mm | 55 mm | 59 kg |

| 58 |

|

062.20.0630.001.21.1503 | Internal Gear | 516 mm | 717 mm | 55 mm | 59 kg |

| 59 |

|

062.20.0710.000.11.1503 | Internal Gear | 594 mm | 797 mm | 55 mm | 68 kg |

| 60 |

|

062.20.0710.001.21.1503 | Internal Gear | 594 mm | 797 mm | 55 mm | 68 kg |

| 61 |

|

062.25.0886.800.11.1504 | Internal Gear | 752 mm | 980 mm | 63 mm | 111 kg |

| 62 |

|

062.25.0886.801.21.1504 | Internal Gear | 752mm | 980 mm | 63 mm | 111 kg |

| 63 |

|

062.25.1077.890.11.1503 | Internal Gear | 930 mm | 1169 mm | 63 mm | 140 kg |

| 64 |

|

062.25.1077.891.21.1503 | Internal Gear | 930 mm | 1169 mm | 63 mm | 140 kg |

| 65 |

|

062.25.1180.000.11.1504 | Internal Gear | 1020 mm | 1287 mm | 69 mm | 185 kg |

| 66 |

|

062.25.1180.001.21.1504 | Internal Gear | 1020 mm | 1287 mm | 69 mm | 185 kg |

| 67 |

|

062.30.1120.000.11.1504 | Internal Gear | 960 mm | 1232 mm | 79 mm | 206 kg |

| 68 |

|

062.30.1120.001.21.1504 | Internal Gear | 960 mm | 1232 mm | 79 mm | 206 kg |

| 69 |

|

062.30.1250.000.11.1504 | Internal Gear | 1090 mm | 1362 mm | 79 mm | 231 kg |

| 70 |

|

062.30.1250.001.21.1504 | Internal Gear | 1090 mm | 1362 mm | 79 mm | 231 kg |

| 71 |

|

062.30.1400.000.11.1504 | Internal Gear | 1224 mm | 1512 mm | 89 mm | 296 kg |

| 72 |

|

062.30.1400.001.21.1504 | Internal Gear | 1224 mm | 1512 mm | 89 mm | 296 kg |

| 73 |

|

062.30.1600.000.11.1504 | Internal Gear | 1428 mm | 1712 mm | 89 mm | 334 kg |

| 74 |

|

062.30.1600.001.21.1504 | Internal Gear | 1428 mm | 1712 mm | 89 mm | 334 kg |

| 75 |

|

062.40.1500.000.19.1504 | Internal Gear | 1308 mm | 1634 mm | 94 mm | 410 kg |

| 76 |

|

062.40.1500.001.29.1504 | Internal Gear | 1308 mm | 1634 mm | 94 mm | 410 kg |

| 77 |

|

062.40.1700.007.19.1503 | Internal Gear | 1498 mm | 1834 mm | 94 mm | 475 kg |

| 78 |

|

062.40.1700.008.29.1503 | Internal Gear | 1498 mm | 1834 mm | 94 mm | 475 kg |

| 79 |

|

062.50.1800.001.49.1504 | Internal Gear | 1554 mm | 1971 mm | 109 mm | 762 kg |

| 80 |

|

062.50.2000.001.49.1504 | Internal Gear | 1764 mm | 2171 mm | 109 mm | 843 kg |

| 81 |

|

062.50.2240.001.49.1504 | Internal Gear | 1984 mm | 2411 mm | 109 mm | 961 kg |

| 82 |

|

062.50.2490.001.49.1504 | Internal Gear | 2240 mm | 2661 mm | 109 mm | 1053 kg |

| 83 |

|

062.50.2800.001.49.1504 | Internal Gear | 2544 mm | 2971 mm | 109 mm | 1205 kg |

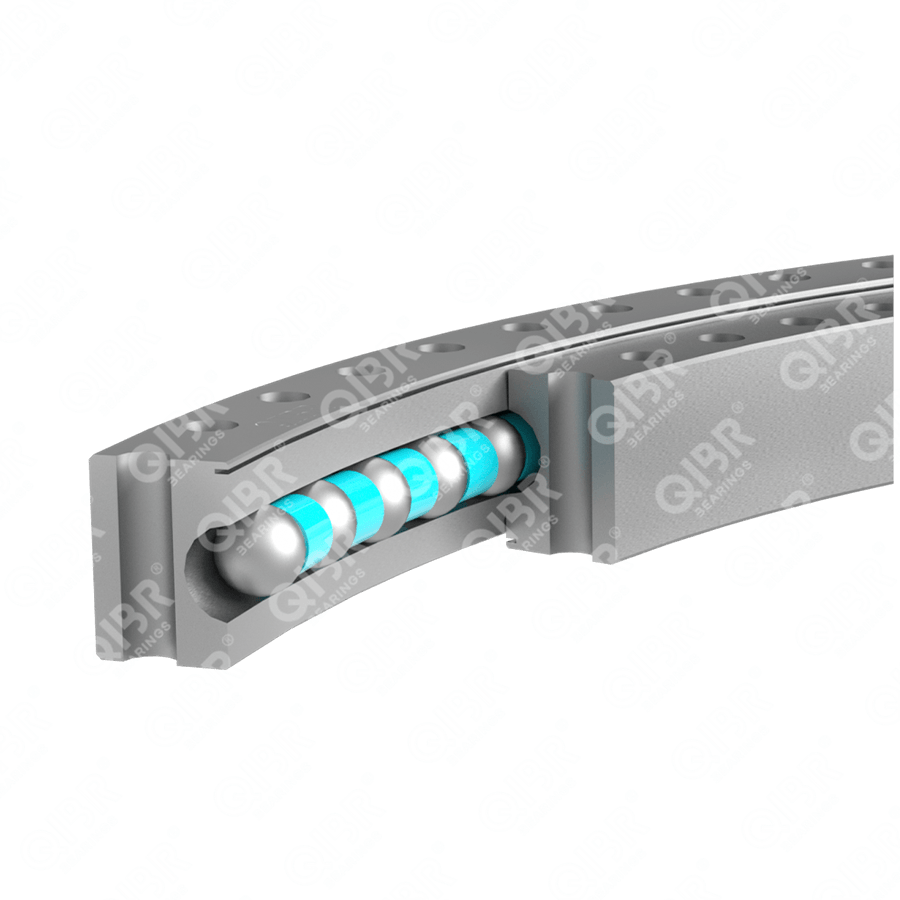

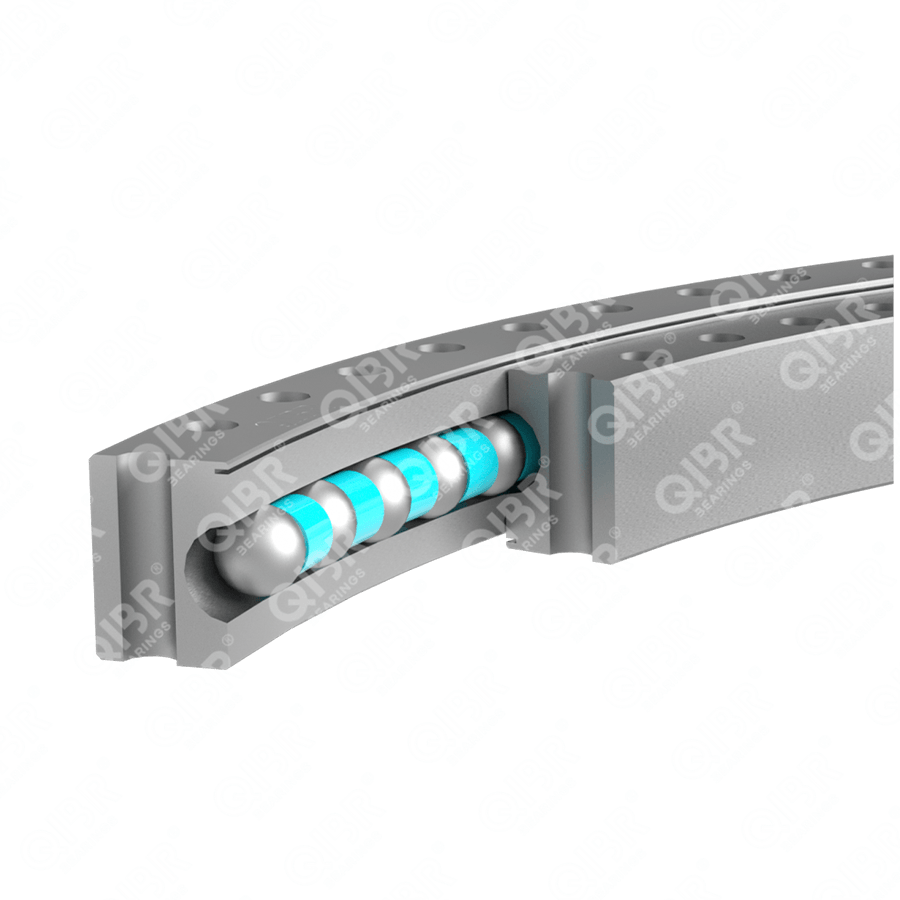

Features and advantages of QIBR four-point contact ball slewing bearing KD 600 series:

The QIBR four-point contact ball rotary bearing KD 600 series has several notable features and advantages, playing a crucial role in various fields, mainly reflected in the following aspects:

1.Compact Design:

The KD 600 series has a compact structure, capable of achieving high load-bearing capacity and rotational capability within limited space, suitable for equipment with space constraints.

2.Multi-directional Load Capacity:

The KD 600 series can withstand loads from multiple directions, performing excellently under complex and dynamic loading conditions. It is suitable for applications requiring frequent rotation and swinging.

3.Customization Services:

The KD 600 series offers customization services, allowing bearings to be designed according to specific needs, meeting the special requirements and operating conditions of different industries.

Performance improvement and solutions for QIBR four-point contact ball slewing bearing KD 600 series:

1.Enhancing Material Performance:

The KD-600 series can adapt to various working conditions through special processes or the use of special materials.

2.Improving Rotational Precision:

The production of the KD-600 series employs advanced processing equipment and techniques, such as machining centers and precise heat treatment, to improve the geometric accuracy of the inner and outer rings, reduce processing errors, and thereby enhance the rotational precision and stability of the bearing.

3.Reducing Noise and Vibration:

By optimizing the mass balance and dynamic/static balance of the bearing, the KD-600 series reduces vibrations and noise generated during rotation, ensuring smooth and comfortable operation of the equipment.

In summary, by optimizing materials, manufacturing precision, and other measures, the performance of the QIBR four-point contact ball rotary bearing KD 600 series can be significantly improved to meet increasingly stringent application requirements.

Main application fields of QIBR four-point contact ball slewing bearing KD 600 series:

Laser cutting machine

Laser cutting machines usually have a rotating table or rotating axis for processing complex workpieces or cutting at different angles. QIBR four-point contact ball slewing bearing KD 600 series provides precise rotation support, and each contact point in its structure evenly distributes the load, ensuring the stability and smooth operation of the rotating axis.

Conveying system

QIBR four-point contact ball slewing bearing KD 600 series is used for rotating conveying equipment in automated production lines and logistics centers to improve material handling efficiency.

Wind turbine

QIBR four-point contact ball slewing bearing KD 600 series is used to connect the blades and tower of the wind turbine to ensure the stable rotation of the wind turbine driven by wind. The working environment of the wind turbine requires the bearing to have strong load-bearing capacity and durability to cope with the instability of wind force and complex working conditions.

Amusement facilities

QIBR four-point contact ball slewing bearing KD 600 series is used on carousels to ensure its safe and stable operation.