Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN/VDEh,DIN/VDEh

Inner diameter

128-2830mm

Outer diameter

300-2540kg

Weight

11.7-1460kg

Structures

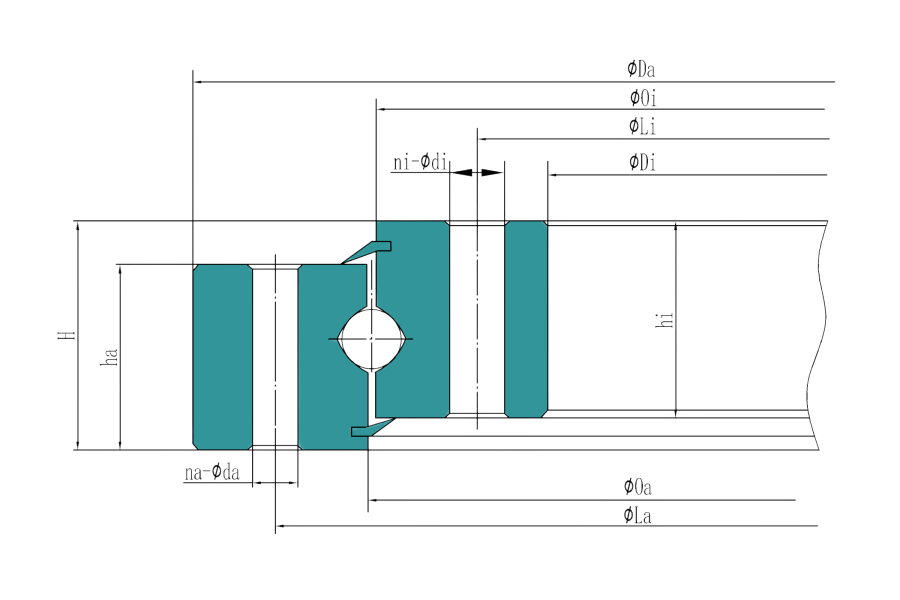

Outer Ring, Inner Ring, Spacer, Rolling element, Seal

Brand

QIBR/OEM/Neutral

Package

Standard Export Package

Material

42CrMo, 50Mn, or Stainless Steel

Effective center location (a)

Hoisting machinery, construction machinery, material handling machinery, mining machinery, metallurgical machinery, medical instruments,ships and warships, radar,wind turbine

| NO. | Product | Product Number | Inner diameter (Di) | Mass | Outer diameter (Da) | Overall height (H) |

|---|---|---|---|---|---|---|

| 1 |

|

TH128A | 128 mm | 11.7 kg | 300 mm | 35 mm |

| 2 |

|

TH182A | 182 mm | 17.8 kg | 338 mm | 45 mm |

| 3 |

|

TH208B | 208 mm | 11.8 kg | 335.6 mm | 35 mm |

| 4 |

|

TH270A | 270 mm | 31.9 kg | 430 mm | 60 mm |

| 5 |

|

TH280C | 280 mm | 46.5 kg | 463 mm | 70 mm |

| 6 |

|

TH295 | 295 mm | 63.0 kg | 515 mm | 85 mm |

| 7 |

|

TH310G-1 | 310 mm | 63.0 kg | 516 mm | 80 mm |

| 8 |

|

TH320G-5 | 319.5 mm | 18.3 kg | 463 mm | 35 mm |

| 9 |

|

TH330B-1 | 330 mm | 41.4 kg | 510 mm | 60 mm |

| 10 |

|

TH330F | 330 mm | 39.5 kg | 510 mm | 57 mm |

| 11 |

|

TH390A | 390 mm | 38.4 kg | 544 mm | 58 mm |

| 12 |

|

TH402 | 402 mm | 45.0 kg | 558 mm | 65 mm |

| 13 |

|

TH426-1 | 426 mm | 35.0 kg | 574 mm | 45 mm |

| 14 |

|

TH460D | 460 mm | 117 kg | 685 mm | 95 mm |

| 15 |

|

TH570D-1 | 570 mm | 66.0 kg | 750 mm | 58 mm |

| 16 |

|

TH584A | 584 mm | 127 kg | 808 mm | 83 mm |

| 17 |

|

TH620D | 620 mm | 79.5 kg | 800 mm | 69 mm |

| 18 |

|

TH650B | 650 mm | 114 kg | 852 mm | 81 mm |

| 19 |

|

TH715R | 715 mm | 180 kg | 950 mm | 98 mm |

| 20 |

|

TH895G | 895 mm | 218 kg | 1125 mm | 100 mm |

| 21 |

|

TH1260A | 1260.2 mm | 285 kg | 1509.8 mm | 90 mm |

| 22 |

|

TH1295A | 1295 mm | 290 kg | 1525 mm | 100 mm |

| 23 |

|

TH1350H | 1350 mm | 565 kg | 1645 mm | 135 mm |

| 24 |

|

TH1910D | 1910 mm | 719 kg | 2180 mm | 120 mm |

| 25 |

|

TH2200J | 2200 mm | 1090 kg | 2540 mm | 135 mm |

| 26 |

|

TH2830A | 2830 mm | 1460 kg | 3185 mm | 145 mm |

Features and advantages of QIBR four-point contact ball slewing bearing TH toothless type

QIBR four-point contact ball slewing bearing TH toothless type has many significant features and advantages, and plays a key role in various fields, mainly reflected in the following aspects:

1. QIBR four-point contact ball slewing bearing TH toothless type has small friction

QIBR four-point contact ball slewing bearing TH toothless type has four contact points between the raceway and the steel ball, with small contact area and small friction, which helps to improve mechanical efficiency and reduce energy consumption.

2.QIBR four-point contact ball slewing bearing TH toothless type has good stability and long life

QIBR four-point contact ball slewing bearing TH toothless type has high working stability due to uniform load distribution, reduces system vibration and noise, and improves the smoothness and reliability of operation. Optimized contact angle and load distribution can reduce internal wear of the bearing, thereby extending the service life of the bearing.

3. Customized service for QIBR four-point contact ball slewing bearing TH toothless type

QIBR four-point contact ball slewing bearing TH toothless type can provide customized service, and can design bearings according to specific needs to meet the special requirements and operating conditions of different industries.

Performance improvement and solution of QIBR four-point contact ball slewing bearing TH toothless type

1. Improve bearing material performance

QIBR four-point contact ball slewing bearing TH toothless type can use materials such as polytetrafluoroethylene cage to improve the speed and service life of the bearing.

2. Improve bearing rotation accuracy

QIBR four-point contact ball slewing bearing TH toothless type production adopts advanced processing equipment and processes, such as machining center and precision heat treatment, to improve the geometric accuracy of inner and outer rings, reduce machining errors, and thus improve the rotation accuracy and stability of the bearing.

3. Reduce the need for bearing maintenance and replacement

QIBR four-point contact ball slewing bearing TH toothless type is designed with seals and lubricating oil holes. The seal can prevent contaminants from entering the bearing and reduce grease leakage; the lubricating hole is convenient for grease filling, the service life is extended, and the cost of maintenance and replacement is reduced.

4. Personalized design

For different occasions, QIBR four-point contact ball slewing bearing TH toothless type can provide personalized size solutions to meet special applications. This not only enriches the standards of bearings, but also provides effective guidance for manufacturers to meet the personalized needs of users.

In short, by optimizing materials, manufacturing precision, personalized design and other measures, the performance of QIBR four-point contact ball slewing bearing TH toothless type can be significantly improved to meet the increasingly demanding application requirements.

Main application areas of QIBR four-point contact ball slewing bearing TH without gear

Machine tools

QIBR four-point contact ball slewing bearing TH without gear can simultaneously withstand large radial loads and axial loads as well as overturning moments, providing stable support and high-speed performance in the spindle and turntable of CNC machine tools.

Wind power generation

QIBR four-point contact ball slewing bearing TH without gear is used for the slewing connection between the tower and the nacelle of the wind turbine, helping to achieve smooth rotation of the nacelle to align with the wind direction.

Amusement facilities

QIBR four-point contact ball slewing bearing TH without gear is used on carousels to ensure its safe and stable operation.

Radar system

QIBR four-point contact ball slewing bearing TH without gear is used in the rotating part of the radar antenna to ensure accurate monitoring and tracking.