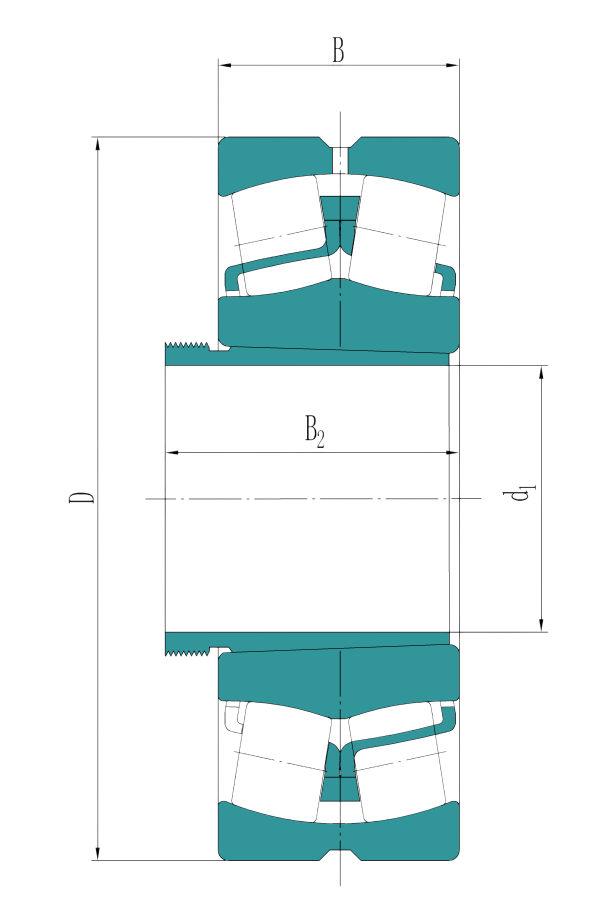

Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh,DIN / VDEh

Inner ring diameter

35mm-1000mm

Outer ring diameter

80mm-1580mm

Weight

0.6kg-4800kg

Material

52100/100Cr6/SUJ2/20Cr2Ni4A

Brand

QIBR/OEM/Neutral

Package

QIBR/Standard Industrial Package/OEM

Applications

Conveyor, crushers, screens, cranes, forklifts, tractors, locomotives, railcars, freight trains, wind turbine, rolling mills, continuous casting machines

| NO. | Product | Product Number | Basic dynamic load rating | Inner diameter (d1) | Outer diameter (D) | Overall width (B) | Weight | Withdrawal sleeve |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

22208 EK+AH 308 | 98.5 KN | 35 mm | 80 mm | 23 mm | 0.6 kg | AH 308 |

| 2 |

|

21308 EK+AH 308 | 107 KN | 35 mm | 90 mm | 23 mm | 0.84 kg | AH 308 |

| 3 |

|

22308 EK+AH 2308 | 155 KN | 35 mm | 90 mm | 33 mm | 1.2 kg | AH 2308 |

| 4 |

|

22209 EK+AH 309 | 104 KN | 40 mm | 85 mm | 23 mm | 0.7 kg | AH 309 |

| 5 |

|

21309 EK+AH 309 | 129 KN | 40 mm | 100 mm | 25 mm | 1.1 kg | AH 309 |

| 6 |

|

22309 EK+AH 2309 | 190 KN | 40 mm | 100 mm | 36 mm | 1.55 kg | AH 2309 |

| 7 |

|

22210 EK+AHX 310 | 107 KN | 45 mm | 90 mm | 23 mm | 0.75 kg | AHX 310 |

| 8 |

|

21310 EK+AHX 310 | 159 KN | 45 mm | 110 mm | 27 mm | 1.45 kg | AHX 310 |

| 9 |

|

22310 EK+AHX 2310 | 228 KN | 45 mm | 110 mm | 40 mm | 2.1 kg | AHX 2310 |

| 10 |

|

22211 EK+AHX 311 | 129 KN | 50 mm | 100 mm | 25 mm | 0.95 kg | AHX 311 |

| 11 |

|

21311 EK+AHX 311 | 159 KN | 50 mm | 120 mm | 29 mm | 1.8 kg | AHX 311 |

| 12 |

|

22311 EK+AHX 2311 | 280 KN | 50 mm | 120 mm | 43 mm | 2.7 kg | AHX 2311 |

| 13 |

|

22212 EK+AHX 312 | 159 KN | 55 mm | 110 mm | 28 mm | 1.3 kg | AHX 312 |

| 14 |

|

21312 EK+AHX 312 | 217 KN | 55 mm | 130 mm | 31 mm | 2.2 kg | AHX 312 |

| 15 |

|

22312 EK+AHX 2312 | 325 KN | 55 mm | 130 mm | 46 mm | 3.3 kg | AHX 2312 |

| 16 |

|

22213 EK+AH 313 G | 198 KN | 60 mm | 120 mm | 31 mm | 1.7 kg | AH 313 G |

| 17 |

|

21313 EK+AH 313 G | 243 KN | 60 mm | 140 mm | 33 mm | 2.75 kg | AH 313 G |

| 18 |

|

22313 EK+AH 2313 G | 357 KN | 60 mm | 140 mm | 48 mm | 4.1 kg | AH 2313 G |

| 19 |

|

22214 EK+AH 314 G | 213 KN | 65 mm | 125 mm | 31 mm | 1.8 kg | AH 314 G |

| 20 |

|

21314 EK+AH 314 G | 291 KN | 65 mm | 150 mm | 35 mm | 3.35 kg | AH 314 G |

| 21 |

|

22314 EK+AHX 2314 G | 413 KN | 65 mm | 150 mm | 51 mm | 4.9 kg | AHX 2314 G |

| 22 |

|

22215 EK+AH 315 G | 217 KN | 70 mm | 130 mm | 31 mm | 1.95 kg | AH 315 G |

| 23 |

|

21315 EK+AH 315 G | 291 KN | 70 mm | 160 mm | 37 mm | 4.15 kg | AH 315 G |

| 24 |

|

22315 EK+AHX 2315 G | 462 KN | 70 mm | 160 mm | 55 mm | 6 kg | AHX 2315 G |

| 25 |

|

22216 EK+AH 316 | 243 KN | 75 mm | 140 mm | 33 mm | 2.4 kg | AH 316 |

| 26 |

|

21316 EK+AH 316 | 331 KN | 75 mm | 170 mm | 39 mm | 4.75 kg | AH 316 |

| 27 |

|

22316 EK+AHX 2316 | 516 KN | 75 mm | 170 mm | 58 mm | 7 kg | AHX 2316 |

| 28 |

|

22217 EK+AHX 317 | 291 KN | 80 mm | 150 mm | 36 mm | 3.05 kg | AHX 317 |

| 29 |

|

21317 EK+AHX 317 | 331 KN | 80 mm | 180 mm | 41 mm | 5.55 kg | AHX 317 |

| 30 |

|

22317 EK+AHX 2317 | 577 KN | 80 mm | 180 mm | 60 mm | 8.15 kg | AHX 2317 |

| 31 |

|

22218 EK+AHX 318 | 331 KN | 85 mm | 160 mm | 40 mm | 3.7 kg | AHX 318 |

| 32 |

|

23218 CCK/W33+AHX 3218 | 372 KN | 85 mm | 160 mm | 52.4 mm | 5 kg | AHX 3218 |

| 33 |

|

21318 EK+AHX 318 | 393 KN | 85 mm | 190 mm | 43 mm | 6.4 kg | AHX 318 |

| 34 |

|

22318 EK+AHX 2318 | 637 KN | 85 mm | 190 mm | 64 mm | 9.5 kg | AHX 2318 |

| 35 |

|

22219 EK+AHX 319 | 393 KN | 90 mm | 170 mm | 43 mm | 4.6 kg | AHX 319 |

| 36 |

|

21319 EK+AHX 319 | 433 KN | 90 mm | 200 mm | 45 mm | 7.4 kg | AHX 319 |

| 37 |

|

22319 EK+AHX 2319 | 699 KN | 90 mm | 200 mm | 67 mm | 11 kg | AHX 2319 |

| 38 |

|

23120 CCK/W33+AHX 3120 | 385 KN | 95 mm | 165 mm | 52 mm | 5 kg | AHX 3120 |

| 39 |

|

22220 EK+AHX 320 | 433 KN | 90 mm | 180 mm | 46 mm | 5.4 kg | AHX 320 |

| 40 |

|

23220 CCK/W33+AHX 3220 | 498 KN | 95 mm | 180 mm | 60.3 mm | 7.3 kg | AHX 3220 |

| 41 |

|

21320 EK+AHX 320 | 433 KN | 95 mm | 215 mm | 47 mm | 9.1 kg | AHX 320 |

| 42 |

|

22320 EK+AHX 2320 | 847 KN | 95 mm | 215 mm | 73 mm | 14 kg | AHX 2320 |

| 43 |

|

23022 CCK/W33+AHX 322 | 326 KN | 105 mm | 170 mm | 45 mm | 4.45 kg | AHX 322 |

| 44 |

|

23122 CCK/W33+AHX 3122 | 450 KN | 105 mm | 180 mm | 56 mm | 6.35 kg | AHX 3122 |

| 45 |

|

24122 CCK30/W33+AH 24122 | 539 KN | 105 mm | 180 mm | 69 mm | 7.7 kg | AH 24122 |

| 46 |

|

22222 EK+AHX 3122 | 572 KN | 105 mm | 200 mm | 53 mm | 7.5 kg | AHX 3122 |

| 47 |

|

23222 CCK/W33+AHX 3222 G | 626 KN | 105 mm | 200 mm | 69.8 mm | 10.5 kg | AHX 3222 G |

| 48 |

|

22322 EK+AHX 2322 G | 989 KN | 105 mm | 240 mm | 80 mm | 19.5 kg | AHX 2322 G |

| 49 |

|

23024 CCK/W33+AHX 3024 | 366 KN | 115 mm | 180 mm | 46 mm | 4.8 kg | AHX 3024 |

| 50 |

|

24024 CCK30/W33+AH 24024 | 456 KN | 115 mm | 180 mm | 60 mm | 5.95 kg | AH 24024 |

| 51 |

|

23124 CCK/W33+AHX 3124 | 534 KN | 115 mm | 200 mm | 62 mm | 8.7 kg | AHX 3124 |

| 52 |

|

24124 CCK30/W33+AH 24124 | 679 KN | 115 mm | 200 mm | 80 mm | 11 kg | AH 24124 |

| 53 |

|

22224 EK+AHX 3124 | 652 KN | 115 mm | 215 mm | 58 mm | 9.55 kg | AHX 3124 |

| 54 |

|

23224 CCK/W33+AHX 3224 G | 732 KN | 115 mm | 215 mm | 76 mm | 13 kg | AHX 3224 G |

| 55 |

|

22324 CCK/W33+AHX 2324 G | 1019 KN | 115 mm | 260 mm | 86 mm | 24 kg | AHX 2324 G |

| 56 |

|

23026 CCK/W33+AHX 3026 | 452 KN | 125 mm | 200 mm | 52 mm | 6.75 kg | AHX 3026 |

| 57 |

|

24026 CCK30/W33+AH 24026 | 569 KN | 125 mm | 200 mm | 69 mm | 8.65 kg | AH 24026 |

| 58 |

|

23126 CCK/W33+AHX 3126 | 586 KN | 125 mm | 210 mm | 64 mm | 9.6 kg | AHX 3126 |

| 59 |

|

24126 CCK30/W33+AH 24126 | 699 KN | 125 mm | 210 mm | 80 mm | 11.5 kg | AH 24126 |

| 60 |

|

22226 EK+AHX 3126 | 758 KN | 125 mm | 230mm | 64 mm | 11.5 kg | AHX 3126 |

| 61 |

|

23226 CCK/W33+AHX 3226 G | 826 KN | 125 mm | 230 mm | 80 mm | 15.5 kg | AHX 3226 G |

| 62 |

|

22326 CCK/W33+AHX 2326 G | 1176 KN | 125 mm | 280 mm | 93 mm | 30.5 kg | AHX 2326 G |

| 63 |

|

23028 CCK/W33+AHX 3028 | 485 KN | 135 mm | 210 mm | 53 mm | 7.35 kg | AHX 3028 |

| 64 |

|

24028 CCK30/W33+AH 24028 | 600 KN | 135 mm | 210 mm | 69 mm | 9.2 kg | AH 24028 |

| 65 |

|

23128 CCK/W33+AHX 3128 | 659 KN | 135 mm | 225 mm | 68 mm | 11.5 kg | AHX 3128 |

| 66 |

|

24128 CCK30/W33+AH 24128 | 796 KN | 135 mm | 225 mm | 85 mm | 14.5 kg | AH 24128 |

| 67 |

|

22228 CCK/W33+AHX 3128 | 743 KN | 135 mm | 250 mm | 68 mm | 15 kg | AHX 3128 |

| 68 |

|

23228 CCK/W33+AHX 3228 G | 962 KN | 135 mm | 250 mm | 88 mm | 20.5 kg | AHX 3228 G |

| 69 |

|

22328 CCK/W33+AHX 2328 G | 1357 KN | 135 mm | 300 mm | 102 mm | 38 kg | AHX 2328 G |

| 70 |

|

23030 CCK/W33+AHX 3030 | 531 KN | 145 mm | 225 mm | 56 mm | 8.85 kg | AHX 3030 |

| 71 |

|

24030 CCK30/W33+AH 24030 | 680 KN | 145 mm | 225 mm | 75 mm | 11.5 kg | AH 24030 |

| 72 |

|

23130 CCK/W33+AHX 3130 G | 883 KN | 145 mm | 250 mm | 80 mm | 17 kg | AHX 3130 G |

| 73 |

|

24130 CCK30/W33+AH 24130 | 1054 KN | 145 mm | 250 mm | 100 mm | 21 kg | AH 24130 |

| 74 |

|

22230 CCK/W33+AHX 3130 G | 898 KN | 145 mm | 270 mm | 73 mm | 19 kg | AHX 3130 G |

| 75 |

|

23230 CCK/W33+AHX 3230 G | 1129 KN | 145 mm | 270 mm | 96 mm | 26 kg | AHX 3230 G |

| 76 |

|

22330 CCK/W33+AHX 2330 G | 1539 KN | 145 mm | 320 mm | 108 mm | 45.5 kg | AHX 2330 G |

| 77 |

|

23032 CCK/W33+AH 3032 | 614 KN | 150 mm | 240 mm | 60 mm | 11.5 kg | AH 3032 |

| 78 |

|

24032 CCK30/W33+AH 24032 | 783 KN | 150 mm | 240 mm | 80 mm | 15 kg | AH 24032 |

| 79 |

|

23132 CCK/W33+AH 3132 G | 1029 KN | 150 mm | 270 mm | 86 mm | 23 kg | AH 3132 G |

| 80 |

|

24132 CCK30/W33+AH 24132 | 1227 KN | 150 mm | 270 mm | 109 mm | 28.5 kg | AH 24132 |

| 81 |

|

22232 CCK/W33+AH 3132 G | 1043 KN | 150 mm | 290 mm | 80 mm | 25 kg | AH 3132 G |

| 82 |

|

23232 CCK/W33+AH 3232 G | 1281 KN | 150 mm | 290 mm | 104 mm | 34.5 kg | AH 3232 G |

| 83 |

|

22332 CCK/W33+AH 2332 G | 1680 KN | 150 mm | 340 mm | 114 mm | 56 kg | AH 2332 G |

| 84 |

|

23034 CCK/W33+AH 3034 | 745 KN | 160 mm | 260 mm | 67 mm | 15 kg | AH 3034 |

| 85 |

|

24034 CCK30/W33+AH 24034 | 963 KN | 160 mm | 260 mm | 90 mm | 20 kg | AH 24034 |

| 86 |

|

23134 CCK/W33+AH 3134 G | 1086 KN | 160 mm | 280 mm | 88 mm | 25 kg | AH 3134 G |

| 87 |

|

24134 CCK30/W33+AH 24134 | 1270 KN | 160 mm | 280 mm | 109 mm | 30 kg | AH 24134 |

| 88 |

|

22234 CCK/W33+AH 3134 G | 1183 KN | 160 mm | 310 mm | 86 mm | 31 kg | AH 3134 G |

| 89 |

|

23234 CCK/W33+AH 3234 G | 1472 KN | 160 mm | 310 mm | 110 mm | 41 kg | AH 3234 G |

| 90 |

|

22334 CCK/W33+AH 2334 G | 1863 KN | 160 mm | 360 mm | 120 mm | 65 kg | AH 2334 G |

| 91 |

|

23036 CCK/W33+AH 3036 | 883 KN | 170 mm | 280 mm | 74 mm | 19.5 kg | AH 3036 |

| 92 |

|

24036 CCK30/W33+AH 24036 | 1134 KN | 170 mm | 280 mm | 100 mm | 25.5 kg | AH 24036 |

| 93 |

|

23136 CCK/W33+AH 3136 G | 1263 KN | 170 mm | 300 mm | 96 mm | 32 kg | AH 3136 G |

| 94 |

|

24136 CCK30/W33+AH 24136 | 1449 KN | 170 mm | 300 mm | 118 mm | 37 kg | AH 24136 |

| 95 |

|

22236 CCK/W33+AH 2236 G | 1237 KN | 170 mm | 320 mm | 86 mm | 32.5 kg | AH 2236 G |

| 96 |

|

23236 CCK/W33+AH 3236 G | 1557 KN | 170 mm | 320 mm | 112 mm | 43.5 kg | AH 3236 G |

| 97 |

|

22336 CCK/W33+AH 2336 G | 2077 KN | 170 mm | 380 mm | 126 mm | 76 kg | AH 2336 G |

| 98 |

|

23038 CCK/W33+AH 3038 G | 916 KN | 180 mm | 290 mm | 75 mm | 21 kg | AH 3038 G |

| 99 |

|

24038 CCK30/W33+AH 24038 | 1164 KN | 180 mm | 290 mm | 100 mm | 27.5 kg | AH 24038 |

| 100 |

|

23138 CCK/W33+AH 3138 G | 1456 KN | 180 mm | 320 mm | 104 mm | 38.5 kg | AH 3138 G |

Features and advantages of QIBR double-row spherical roller bearings with withdrawal sleeves

QIBR double-row spherical roller bearings with withdrawal sleeves have solved many key problems in various fields, which are mainly reflected in the following aspects:

1. Self-aligning ability

The raceways of the inner and outer rings of double-row spherical roller bearings with withdrawal sleeves are curved, and the bearings have the function of self-aligning, that is, they can automatically compensate for the angular deviation caused by the bending of the shaft or the installation error. Therefore, it can withstand a certain axial load while bearing radial loads, and is particularly suitable for applications with low requirements for installation accuracy.

2. Strong load-bearing capacity

The rollers of double-row spherical roller bearings with withdrawal sleeves are cylindrical or slightly inclined, with a large contact surface, and can withstand large radial loads and bidirectional axial loads. Due to the large number of rollers, it has a higher load-bearing capacity, especially in high-load and high-impact application scenarios, and performs outstandingly.

3. Suitable for harsh working conditions

This type of bearing is often used in harsh environments such as high temperature, high speed, and heavy load, and can operate reliably under relatively harsh working conditions. Double-row spherical roller bearings with withdrawal sleeves are highly adaptable and can accommodate large axial offsets and radial load changes.

4. Easy to install and remove

The design of the withdrawal sleeve makes it easier to install and remove the bearing from the shaft. During installation, the outer surface of the withdrawal sleeve fits tightly with the inner ring of the bearing, and when disassembly is required, the withdrawal sleeve can be moved outward by bolts, so that the bearing can be removed from the shaft smoothly.

The performance improvement and solution of QIBR double-row spherical roller bearing with withdrawal sleeve

1. Lubricant optimization

Select appropriate lubricating oil or grease, and make appropriate additions and blends to reduce friction and improve wear resistance. The use of synthetic lubricants or nano-lubricants can significantly improve the efficiency and life of bearings.

2. Heat treatment process

Optimize the heat treatment process to ensure that the hardness and toughness of the bearing material are in the best state, and enhance its fatigue resistance and wear resistance.

3. Improve the quality of rolling elements

Reduce friction and wear by improving the surface finish and hardness of the rolling elements. The use of high-precision rolling elements (such as ceramics) can significantly improve the operating performance of the bearing.

4. Cage design optimization

Use a more optimized cage structure, such as using high-temperature and corrosion-resistant materials and designs to improve the durability of the cage and the stability of the bearing.

Main application areas of QIBR double-row spherical roller bearings with withdrawal sleeves

1.Mining machinery

Such as crushers, conveyors, ball mills and other equipment, due to their harsh working environment and heavy loads, spherical roller bearings can provide high load bearing capacity and avoid failures caused by installation errors.

2.Metallurgical equipment

Such as rolling mill equipment and roller tables in steel plants, spherical roller bearings can effectively withstand heavy loads and impacts generated in metallurgical production.

3.Hydraulic generator sets

Bearings of large power equipment such as turbines and generators. Since power equipment needs to withstand a large amount of load and long-term operation, spherical roller bearings have good self-alignment and are suitable for this type of equipment.

4.Mining and construction machinery

Used in heavy machinery such as crawler cranes and excavators, these equipment need to withstand impact loads and complex working conditions. Double-row spherical roller bearings with withdrawal sleeves can help the equipment maintain stable operation.