Image may differ from product. See technical specification for details.

Search for the bearing model you need

Standard

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Material

52100/100Cr6/SUJ2/Stainless Steel

Brand

QIBR/OEM/Neutral

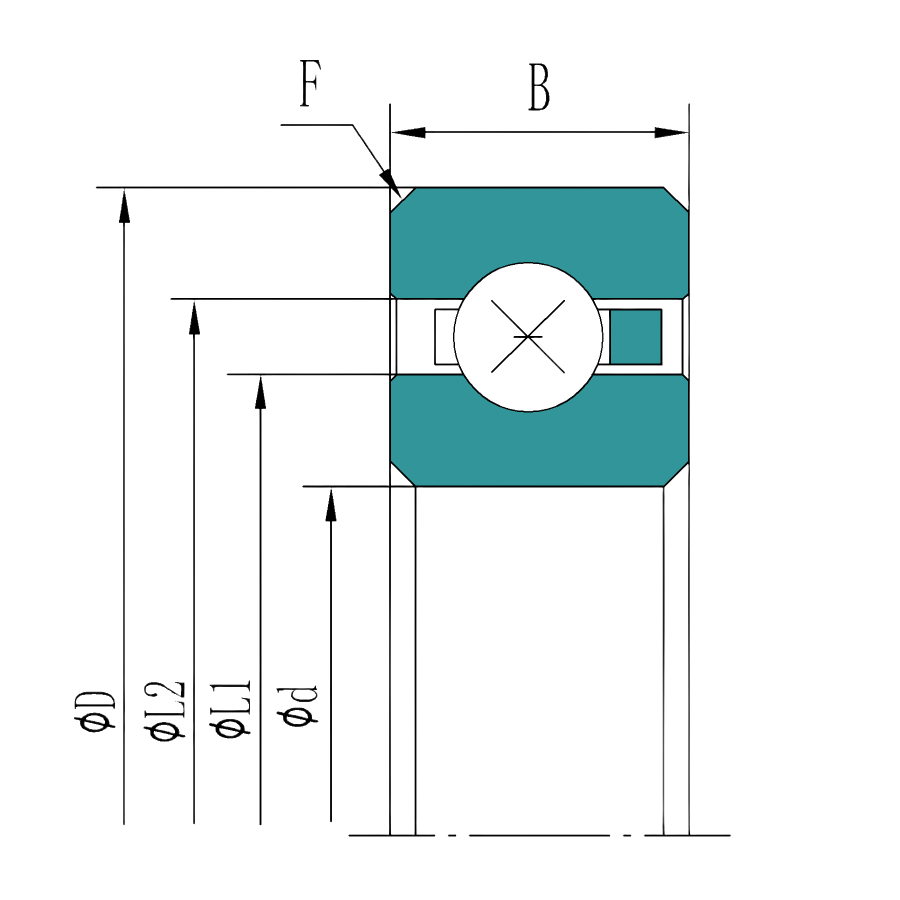

Shaft abutment diameter (das)

QIBR/Standard Industrial Package/OEM

Inner diameter

25.4000~762.0000mm

Outer diameter

34.9250~787.4000mm

Applications

Aerospace Industry, Robotics, Medical Devices, Semiconductor Manufacturing Equipment, Optical Equipment, Industrial Machinery, Automotive, etc

| NO. | Product | Product Number | Inner diameter (d) | Land diameters (L1) | Land diameters (L2) | Mass | Outer diameter (D) | Width (B) |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

KAA10XL0 | 1.000 inch | 1.140 inch | 1.235 inch | 0.026 lbs | 1.375 inch | 0.1875 inch |

| 2 |

|

KAA15XL0 | 1.500 inch | 1.640 inch | 1.735 inch | 0.039 lbs | 1.875 inch | 0.1875 inch |

| 3 |

|

KAA17XL0 | 1.750 inch | 1.890 inch | 1.985 inch | 0.045 lbs | 2.125 inch | 0.1875 inch |

| 4 |

|

KA020XD0 | 2.000 inch | 2.186 inch | 2.314 inch | 0.10 lbs | 2.500 inch | 0.250 inch |

| 5 |

|

KA020XD6 | 2.000 inch | 2.186 inch | 2.314 inch | 0.10 lbs | 2.500 inch | 0.250 inch |

| 6 |

|

KA020XL0 | 2.000 inch | 2.186 inch | 2.314 inch | 0.10 lbs | 2.500 inch | 0.250 inch |

| 7 |

|

KA020XL6 | 2.000 inch | 2.186 inch | 2.314 inch | 0.10 lbs | 2.500 inch | 0.250 inch |

| 8 |

|

KA020XP0 | 2.000 inch | 2.186 inch | 2.314 inch | 0.10 lbs | 2.500 inch | 0.250 inch |

| 9 |

|

KA020XP0A | 2.000 inch | 2.186 inch | 2.314 inch | 0.10 lbs | 2.500 inch | 0.250 inch |

| 10 |

|

KA020XP0L | 2.000 inch | 2.186 inch | 2.314 inch | 0.10 lbs | 2.500 inch | 0.250 inch |

| 11 |

|

KA020XP0M | 2.000 inch | 2.186 inch | 2.314 inch | 0.10 lbs | 2.500 inch | 0.250 inch |

| 12 |

|

KA020XP6 | 2.000 inch | 2.186 inch | 2.314 inch | 0.10 lbs | 2.500 inch | 0.250 inch |

| 13 |

|

KA025XD0 | 2.500 inch | 2.686 inch | 2.814 inch | 0.13 lbs | 3.000 inch | 0.250 inch |

| 14 |

|

KA025XD6 | 2.500 inch | 2.686 inch | 2.814 inch | 0.13 lbs | 3.000 inch | 0.250 inch |

| 15 |

|

KA025XL0 | 2.500 inch | 2.686 inch | 2.814 inch | 0.13 lbs | 3.000 inch | 0.250 inch |

| 16 |

|

KA025XL6 | 2.500 inch | 2.686 inch | 2.814 inch | 0.13 lbs | 3.000 inch | 0.250 inch |

| 17 |

|

KA025XP0 | 2.500 inch | 2.686 inch | 2.814 inch | 0.13 lbs | 3.000 inch | 0.250 inch |

| 18 |

|

KA025XP0A | 2.500 inch | 2.686 inch | 2.814 inch | 0.13 lbs | 3.000 inch | 0.250 inch |

| 19 |

|

KA025XP0K | 2.500 inch | 2.686 inch | 2.814 inch | 0.13 lbs | 3.000 inch | 0.250 inch |

| 20 |

|

KA025XP0L | 2.500 inch | 2.686 inch | 2.814 inch | 0.13 lbs | 3.000 inch | 0.250 inch |

| 21 |

|

KA025XP0M | 2.500 inch | 2.686 inch | 2.814 inch | 0.13 lbs | 3.000 inch | 0.250 inch |

| 22 |

|

KA025XP6 | 2.500 inch | 2.686 inch | 2.814 inch | 0.13 lbs | 3.000 inch | 0.250 inch |

| 23 |

|

KA030XD0 | 3.000 inch | 3.186 inch | 3.314 inch | 0.15 lbs | 3.500 inch | 0.250 inch |

| 24 |

|

KA030XD6 | 3.000 inch | 3.186 inch | 3.314 inch | 0.15 lbs | 3.500 inch | 0.250 inch |

| 25 |

|

KA030XL0 | 3.000 inch | 3.186 inch | 3.314 inch | 0.15 lbs | 3.500 inch | 0.250 inch |

| 26 |

|

KA030XL6 | 3.000 inch | 3.186 inch | 3.314 inch | 0.15 lbs | 3.500 inch | 0.250 inch |

| 27 |

|

KA030XP0 | 3.000 inch | 3.186 inch | 3.314 inch | 0.15 lbs | 3.500 inch | 0.250 inch |

| 28 |

|

KA030XP0A | 3.000 inch | 3.186 inch | 3.314 inch | 0.15 lbs | 3.500 inch | 0.250 inch |

| 29 |

|

KA030XP0K | 3.000 inch | 3.186 inch | 3.314 inch | 0.15 lbs | 3.500 inch | 0.250 inch |

| 30 |

|

KA030XP0L | 3.000 inch | 3.186 inch | 3.314 inch | 0.15 lbs | 3.500 inch | 0.250 inch |

| 31 |

|

KA030XP0M | 3.000 inch | 3.186 inch | 3.314 inch | 0.15 lbs | 3.500 inch | 0.250 inch |

| 32 |

|

KA030XP6 | 3.000 inch | 3.186 inch | 3.314 inch | 0.15 lbs | 3.500 inch | 0.250 inch |

| 33 |

|

KA035XD0 | 3.500 inch | 3.686 inch | 3.814 inch | 0.18 lbs | 4.000 inch | 0.250 inch |

| 34 |

|

KA035XD6 | 3.500 inch | 3.686 inch | 3.814 inch | 0.18 lbs | 4.000 inch | 0.250 inch |

| 35 |

|

KA035XL0 | 3.500 inch | 3.686 inch | 3.814 inch | 0.18 lbs | 4.000 inch | 0.250 inch |

| 36 |

|

KA035XL6 | 3.500 inch | 3.686 inch | 3.814 inch | 0.18 lbs | 4.000 inch | 0.250 inch |

| 37 |

|

KA035XP0 | 3.500 inch | 3.686 inch | 3.814 inch | 0.18 lbs | 4.000 inch | 0.250 inch |

| 38 |

|

KA035XP0A | 3.500 inch | 3.686 inch | 3.814 inch | 0.18 lbs | 4.000 inch | 0.250 inch |

| 39 |

|

KA035XP0K | 3.500 inch | 3.686 inch | 3.814 inch | 0.18 lbs | 4.000 inch | 0.250 inch |

| 40 |

|

KA035XP0L | 3.500 inch | 3.686 inch | 3.814 inch | 0.18 lbs | 4.000 inch | 0.250 inch |

| 41 |

|

KA035XP0M | 3.500 inch | 3.686 inch | 3.814 inch | 0.18 lbs | 4.000 inch | 0.250 inch |

| 42 |

|

KA035XP6 | 3.500 inch | 3.686 inch | 3.814 inch | 0.18 lbs | 4.000 inch | 0.250 inch |

| 43 |

|

KA040XD0 | 4.000 inch | 4.186 inch | 4.314 inch | 0.19 lbs | 4.500 inch | 0.250 inch |

| 44 |

|

KA040XD6 | 4.000 inch | 4.186 inch | 4.314 inch | 0.19 lbs | 4.500 inch | 0.250 inch |

| 45 |

|

KA040XL0 | 4.000 inch | 4.186 inch | 4.314 inch | 0.19 lbs | 4.500 inch | 0.250 inch |

| 46 |

|

KA040XL6 | 4.000 inch | 4.186 inch | 4.314 inch | 0.19 lbs | 4.500 inch | 0.250 inch |

| 47 |

|

KA040XP0 | 4.000 inch | 4.186 inch | 4.314 inch | 0.19 lbs | 4.500 inch | 0.250 inch |

| 48 |

|

KA040XP0A | 4.000 inch | 4.186 inch | 4.314 inch | 0.19 lbs | 4.500 inch | 0.250 inch |

| 49 |

|

KA040XP0K | 4.000 inch | 4.186 inch | 4.314 inch | 0.19 lbs | 4.500 inch | 0.250 inch |

| 50 |

|

KA040XP0L | 4.000 inch | 4.186 inch | 4.314 inch | 0.19 lbs | 4.500 inch | 0.250 inch |

| 51 |

|

KA040XP0M | 4.000 inch | 4.186 inch | 4.314 inch | 0.19 lbs | 4.500 inch | 0.250 inch |

| 52 |

|

KA040XP6 | 4.000 inch | 4.186 inch | 4.314 inch | 0.19 lbs | 4.500 inch | 0.250 inch |

| 53 |

|

KA042XD0 | 4.250 inch | 4.436 inch | 4.564 inch | 0.20 lbs | 4.750 inch | 0.250 inch |

| 54 |

|

KA042XD6 | 4.250 inch | 4.436 inch | 4.564 inch | 0.20 lbs | 4.750 inch | 0.250 inch |

| 55 |

|

KA042XL0 | 4.250 inch | 4.436 inch | 4.564 inch | 0.20 lbs | 4.750 inch | 0.250 inch |

| 56 |

|

KA042XL6 | 4.250 inch | 4.436 inch | 4.564 inch | 0.20 lbs | 4.750 inch | 0.250 inch |

| 57 |

|

KA042XP0 | 4.250 inch | 4.436 inch | 4.564 inch | 0.20 lbs | 4.750 inch | 0.250 inch |

| 58 |

|

KA042XP0A | 4.250 inch | 4.436 inch | 4.564 inch | 0.20 lbs | 4.750 inch | 0.250 inch |

| 59 |

|

KA042XP0K | 4.250 inch | 4.436 inch | 4.564 inch | 0.20 lbs | 4.750 inch | 0.250 inch |

| 60 |

|

KA042XP0L | 4.250 inch | 4.436 inch | 4.564 inch | 0.20 lbs | 4.750 inch | 0.250 inch |

| 61 |

|

KA042XP0M | 4.250 inch | 4.436 inch | 4.564 inch | 0.20 lbs | 4.750 inch | 0.250 inch |

| 62 |

|

KA042XP6 | 4.250 inch | 4.436 inch | 4.564 inch | 0.20 lbs | 4.750 inch | 0.250 inch |

| 63 |

|

KA045XD0 | 4.500 inch | 4.686 inch | 4.814 inch | 0.22 lbs | 5.000 inch | 0.250 inch |

| 64 |

|

KA045XD6 | 4.500 inch | 4.686 inch | 4.814 inch | 0.22 lbs | 5.000 inch | 0.250 inch |

| 65 |

|

KA045XL0 | 4.500 inch | 4.686 inch | 4.814 inch | 0.22 lbs | 5.000 inch | 0.250 inch |

| 66 |

|

KA045XL6 | 4.500 inch | 4.686 inch | 4.814 inch | 0.22 lbs | 5.000 inch | 0.250 inch |

| 67 |

|

KA045XP0 | 4.500 inch | 4.686 inch | 4.814 inch | 0.22 lbs | 5.000 inch | 0.250 inch |

| 68 |

|

KA045XP0A | 4.500 inch | 4.686 inch | 4.814 inch | 0.22 lbs | 5.000 inch | 0.250 inch |

| 69 |

|

KA045XP0K | 4.500 inch | 4.686 inch | 4.814 inch | 0.22 lbs | 5.000 inch | 0.250 inch |

| 70 |

|

KA045XP0L | 4.500 inch | 4.686 inch | 4.814 inch | 0.22 lbs | 5.000 inch | 0.250 inch |

| 71 |

|

KA045XP0M | 4.500 inch | 4.686 inch | 4.814 inch | 0.22 lbs | 5.000 inch | 0.250 inch |

| 72 |

|

KA045XP6 | 4.500 inch | 4.686 inch | 4.814 inch | 0.22 lbs | 5.000 inch | 0.250 inch |

| 73 |

|

KA047XD0 | 4.936 inch | 5.064 inch | 0.23 lbs | 4.750 inch | 5.250 inch | 0.250 inch |

| 74 |

|

KA047XD6 | 4.936 inch | 5.064 inch | 0.23 lbs | 4.750 inch | 5.250 inch | 0.250 inch |

| 75 |

|

KA047XL0 | 4.936 inch | 5.064 inch | 0.23 lbs | 4.750 inch | 5.250 inch | 0.250 inch |

| 76 |

|

KA047XL6 | 4.936 inch | 5.064 inch | 0.23 lbs | 4.750 inch | 5.250 inch | 0.250 inch |

| 77 |

|

KA047XP0 | 4.936 inch | 5.064 inch | 0.23 lbs | 4.750 inch | 5.250 inch | 0.250 inch |

| 78 |

|

KA047XP0A | 4.936 inch | 5.064 inch | 0.23 lbs | 4.750 inch | 5.250 inch | 0.250 inch |

| 79 |

|

KA047XP0K | 4.936 inch | 5.064 inch | 0.23 lbs | 4.750 inch | 5.250 inch | 0.250 inch |

| 80 |

|

KA047XP0L | 4.936 inch | 5.064 inch | 0.23 lbs | 4.750 inch | 5.250 inch | 0.250 inch |

| 81 |

|

KA047XP0M | 4.936 inch | 5.064 inch | 0.23 lbs | 4.750 inch | 5.250 inch | 0.250 inch |

| 82 |

|

KA047XP6 | 4.936 inch | 5.064 inch | 0.23 lbs | 4.750 inch | 5.250 inch | 0.250 inch |

| 83 |

|

KA050XD0 | 5.000 inch | 5.186 inch | 5.314 inch | 0.24 lbs | 5.500 inch | 0.250 inch |

| 84 |

|

KA050XD6 | 5.000 inch | 5.186 inch | 5.314 inch | 0.24 lbs | 5.500 inch | 0.250 inch |

| 85 |

|

KA050XL0 | 5.000 inch | 5.186 inch | 5.314 inch | 0.24 lbs | 5.500 inch | 0.250 inch |

| 86 |

|

KA050XL6 | 5.000 inch | 5.186 inch | 5.314 inch | 0.24 lbs | 5.500 inch | 0.250 inch |

| 87 |

|

KA050XP0 | 5.000 inch | 5.186 inch | 5.314 inch | 0.24 lbs | 5.500 inch | 0.250 inch |

| 88 |

|

KA050XP0A | 5.000 inch | 5.186 inch | 5.314 inch | 0.24 lbs | 5.500 inch | 0.250 inch |

| 89 |

|

KA050XP0K | 5.000 inch | 5.186 inch | 5.314 inch | 0.24 lbs | 5.500 inch | 0.250 inch |

| 90 |

|

KA050XP0L | 5.000 inch | 5.186 inch | 5.314 inch | 0.24 lbs | 5.500 inch | 0.250 inch |

| 91 |

|

KA050XP0M | 5.000 inch | 5.186 inch | 5.314 inch | 0.24 lbs | 5.500 inch | 0.250 inch |

| 92 |

|

KA050XP6 | 5.000 inch | 5.186 inch | 5.314 inch | 0.24 lbs | 5.500 inch | 0.250 inch |

| 93 |

|

KA055XD0 | 5.500 inch | 5.686 inch | 5.814 inch | 0.25 lbs | 6.000 inch | 0.250 inch |

| 94 |

|

KA055XD6 | 5.500 inch | 5.686 inch | 5.814 inch | 0.25 lbs | 6.000 inch | 0.250 inch |

| 95 |

|

KA055XL0 | 5.500 inch | 5.686 inch | 5.814 inch | 0.25 lbs | 6.000 inch | 0.250 inch |

| 96 |

|

KA055XL6 | 5.500 inch | 5.686 inch | 5.814 inch | 0.25 lbs | 6.000 inch | 0.250 inch |

| 97 |

|

KA055XP0 | 5.500 inch | 5.686 inch | 5.814 inch | 0.25 lbs | 6.000 inch | 0.250 inch |

| 98 |

|

KA055XP0A | 5.500 inch | 5.686 inch | 5.814 inch | 0.25 lbs | 6.000 inch | 0.250 inch |

| 99 |

|

KA055XP0K | 5.500 inch | 5.686 inch | 5.814 inch | 0.25 lbs | 6.000 inch | 0.250 inch |

| 100 |

|

KA055XP0L | 5.500 inch | 5.686 inch | 5.814 inch | 0.25 lbs | 6.000 inch | 0.250 inch |

QIBR Standard Inch Thin Section Ball Bearing Series -Open Type X features and advantages

QIBR Standard Inch Thin-Wall Ball Bearing Series -Open Type X has a number of significant features and advantages, which solve key problems in various fields, mainly reflected in the following aspects:

1. QIBR standard inch thin wall ball bearing series -Open Type X has the characteristics of high rigidity and high load carrying capacity

QIBR Standard Inch Thin Wall Ball Bearing Series -Open Type X Despite the lightweight design of this series of bearings, the open A type bearings still provide good rigidity and load carrying capacity, suitable for high loads and high-speed running applications.

2. QIBR Standard Inch Thin Wall Ball Bearing Series – Open Type X has the characteristics of optimized open structure design

QIBR Standard Inch Thin Wall Ball Bearing Series – Open Type X bearing design allows good lubrication and heat dissipation, suitable for use in environments not exposed to pollution. Standard Inch Thin Wall Ball Bearing Series – Open Type X is more adaptable and can provide different internal clearances, lubrication methods and cage structures according to the needs of different customers to meet diverse usage requirements.

3. QIBR Standard Inch Thin Section Ball Bearing Series -Open Type X has the characteristics of low friction and high efficiency

QIBR Standard Inch Thin Section Ball Bearings -Open Type X are designed to reduce the frictional torque of the bearings and are suitable for use where low driving torque is required, thus improving the overall operating efficiency of the equipment.

4. QIBR Standard Inch Thin Wall Ball Bearing Series -Open Type X customized service

QIBR Standard Inch Thin Wall Ball Bearing Series -Open Type X usually provides customized service, which can design the bearings according to the specific needs and meet the special requirements and working conditions of different industries.

QIBR Standard Inch Thin Wall Ball Bearing Series –Open Type X Performance Improvement and Solutions

1. Effectively improve material performance and enhance high load-bearing capacity

The Standard Inch Thin Wall Ball Bearing Series –Open Type X is made of high-quality steel to manufacture inner and outer rings and balls. The surface hardness and material properties are improved through vacuum heat treatment and other processes, thereby improving the load capacity and service life of the bearing. The design of the Standard Inch Thin Wall Ball Bearing Series –Open Type X allows for a larger number of balls and provides a higher load-bearing capacity. For example, the use of thin-wall design can reduce material usage and improve economy while maintaining strength.

2. Low friction characteristics

The open design of the Standard Inch Thin Wall Ball Bearing Series –Open Type X reduces the friction torque and improves the overall operating efficiency of the bearing. It is suitable for use in applications that require low drive torque. This feature is particularly important at high speeds, helping to reduce the energy consumption of the equipment and extend the service life of the equipment.

3. Improve manufacturing accuracy and load capacity

The production of Standard Inch Thin Wall Ball Bearing Series –Open Type X adopts advanced foreign processing equipment and processes, such as precision grinding, super-fine grinding, etc., to improve the geometric accuracy of the inner and outer rings and balls, reduce processing errors, and thus improve the rotation accuracy and operation stability of the bearings.

4. Personalized design

According to the application requirements of standard inch thin-walled ball bearing series -Open Type X in different occasions, personalized structural size solutions are provided to meet specific performance requirements. This approach not only enriches the standards of bearings, but also provides effective guidance for manufacturers to meet the personalized needs of users.

In short, by optimizing materials, manufacturing accuracy, personalized design and other measures, the performance of standard inch thin-walled ball bearing series -Open Type X can be significantly improved to meet the increasingly demanding application requirements.

QIBR Standard Inch Thin Wall Ball Bearing Series - main areas of application for Open Type X

Aerospace/astronomical instruments

X-type thin section bearings are widely used in the field of aerospace and astronomical instrumentation because of their lightweight design and wide range of load carrying capacity.

Machine Tools

X-type thin section bearings are commonly used in applications such as machine tool spindles to provide precision positioning and high rigidity.

Medical equipment

X-type thin section bearings are used in medical equipment, such as surgical robotic joints, where lightweight and high precision are required.

Optical Scanning Equipment

X-type thin section bearings provide precision rotary support in optical scanning equipment.

Robotics

X-type thin section bearings are widely used in robotic joints to provide precision positioning and high rigidity.

Semiconductor Manufacturing Equipment

Type X thin section bearings are used as precision rotary bearings in semiconductor manufacturing equipment.

In general, the standard inch thin section ball bearing series -Open Type X is mainly used in applications requiring light weight, high rigidity and high precision rotary support, such as aerospace, machine tools, medical, optical, robotics and semiconductor manufacturing. Their small cross section and multiple load carrying capacities make them ideal for these applications.