52210

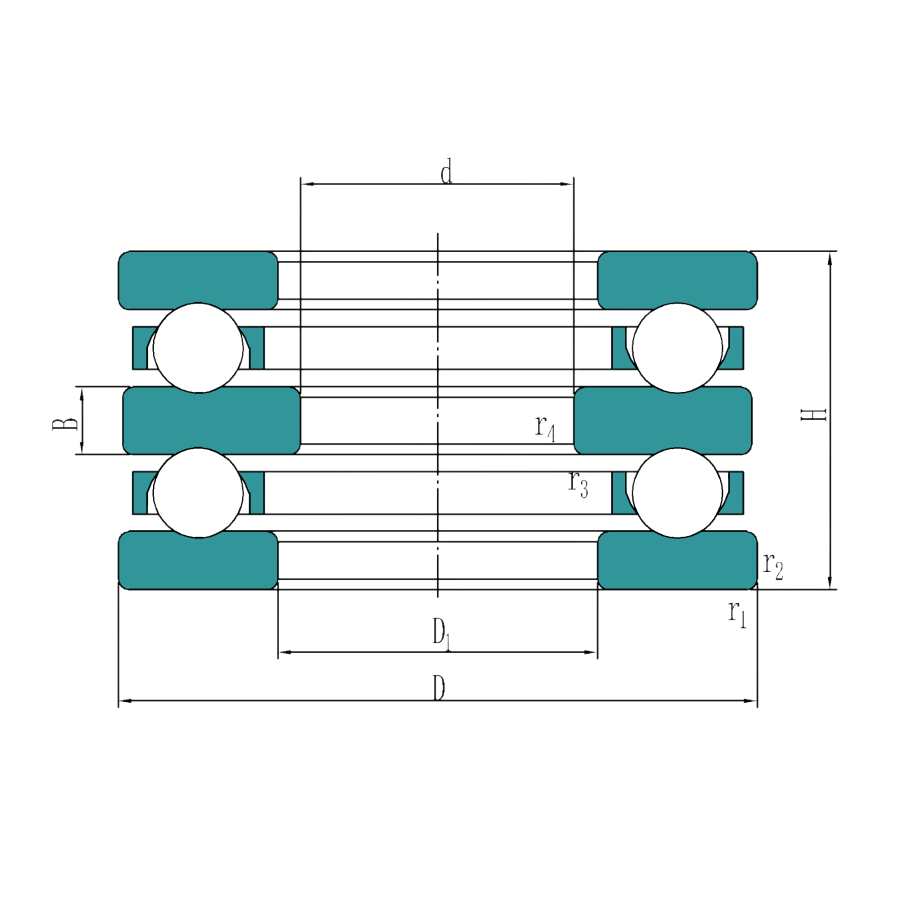

- Inner diameter:

- 40 mm

- Outer diameter:

- 78 mm

- Width:

- 39 mm

- Mass:

- 0.71 kg

We will provide you with the most suitable solution.

Image may differ from product. See technical specification for details.

Specifications

Seris - 52210

Description

QIBR - 52210 Thrust Ball Bearing Advantages and Applications

52210Thrust Ball Bearing, high axial load capacity, low friction, Inner diameter (d) is 40 mm, Outer diameter (D) is 78 mm, Width (H) is 39 mm, Mass is 0.71 kg, suitable for industrial robot joints, transmission systems and mixers, etc., and is the most widely used bearing in working conditions with high load-bearing capacity requirements.

QIBR - 52210 Thrust Ball Bearing Characteristics

52210Thrust Ball Bearing, long life, easy to install and maintain. 52210Thrust Ball Bearing, can withstand unidirectional or bidirectional axial loads, suitable for mechanical equipment with high stability requirements.

52210 Thrust Ball Bearings Features and Advantages

Designed for Axial Loads: Thrust ball bearings are specifically designed to support axial loads, providing unique advantages in this area.

Self-Aligning Capability: They can reduce the impact of installation errors and accommodate a certain degree of axial displacement.

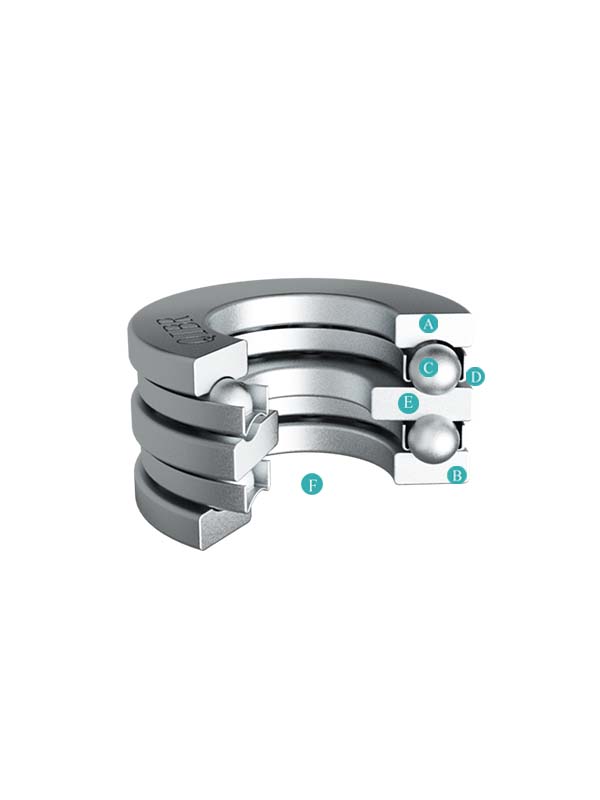

Separable Design: The shaft rings, housing rings, and cage components can be separated, making the installation and disassembly of the bearings more convenient.

Long Service Life: These bearings can withstand a certain amount of wear and scratches, improving overall operational efficiency and offering a longer lifespan.

Application: Thrust ball bearings are widely used in cranes, vertical pumps, vertical centrifuges, jacks, low-speed reducers, machine tools, automobiles, motors, and aerospace applications.

QIBR - 52210 Thrust Ball Bearings Optimization

Precision Levels: Bearings can be provided in precision grades of P4, P6, and P5 based on customer requirements.

Cage Selection: The type of cage can be chosen according to customer needs, such as stamped cages and copper alloy machined cages.

Further Customization: QIBR can design and optimize thrust ball bearings according to customer usage conditions and requirements.

QIBR - 52210 Thrust Ball Bearings Quality Control

Dimension measurement: Multiple high-precision instruments are used to measure various dimensions of the bearing, with an accuracy of up to 0.001mm.

Rotation accuracy: A micrometer measures small surface defects or deviations, with a measurement precision of up to 0.001mm.

Hardness measurement: A hardness tester measures the surface hardness of the bearings, with a precision of ±0.5HRC.

Metallographic analysis: Professional metallographic microscopes analyze the internal metallographic structure of the metals.

Geometric tolerance: A profile projector measures the geometric shape and relative position of the bearings.

Noise monitoring: Vibration meters monitor the vibration conditions during operation to obtain noise data.

Raw material control: Steel and parts are sourced from ISO 14001-certified suppliers, ensuring product stability while promoting sustainable development.

Features & Benefits

When your application calls for precision axial load-carrying capacity, there’s nothing better than thrust bearings. A thrust bearing is a rotary bearing designed to support axial loads on rotating shafts, which permits smooth rotation under high thrust loads at low and medium speeds. The axial load from the rotating shaft is absorbed into the stationary housings or mounts within which the thrust bearing turns.

Downloads