QIBR angular contact ceramic ball bearings excel in the turbochargers of renowned Chinese new energy vehicle brands

- Industry

- New energy vehicle manufacturing

- Location

- China

- Goals

- Improved the turbocharger bearings to maximize their adaptability to various environments

Products used

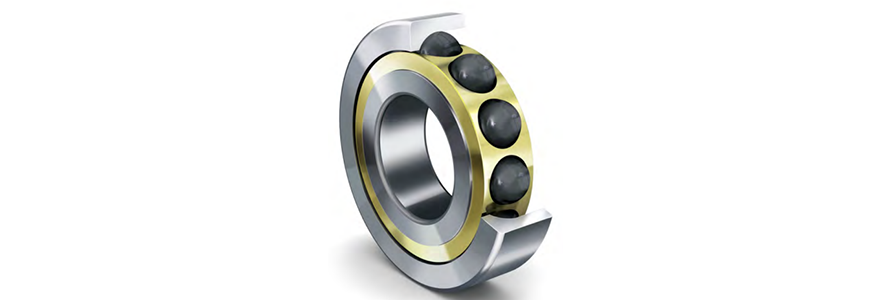

QIBR angular contact ceramic ball bearings excel in the turbochargers of renowned Chinese new energy vehicle brands

- Renowned Chinese new energy vehicle brands have chosen QIBR angular contact ceramic ball bearings for their new turbochargers after extensive comparative testing

Customer introduction:

The customer is a well-known Chinese company focused on the research, development, and production of new energy vehicle technology, dedicated to promoting a more environmentally friendly and efficient automotive industry. This company has a strong technical foundation and rich market experience in the new energy vehicle sector, with products that lead the industry in range, power performance, and environmental standards. As market competition intensifies, the customer’s performance requirements for new energy vehicle turbochargers continue to increase in order to further enhance overall vehicle performance and driving experience.

a) Challenges(Problems that exist and why they are not solved)

In electric vehicles, particularly, the turbochargers in the engine can reach temperatures of up to 150 degrees Celsius or higher during operation. The efficient performance of electric motors can create harsher conditions for turbochargers. The quality of turbochargers plays a crucial role in the engines of new energy vehicles.

Internal bearings within turbochargers experience significant forces and inertial forces during high-speed rotation. To ensure long-term stable operation, the selection of bearings is crucial.

In the working environment of automotive engines, turbochargers may come into contact with corrosive gases, liquids, or chemicals. Therefore, bearing materials need to have excellent chemical stability to cope with potential challenges.

Moreover, new energy vehicles emphasize lightweight design and energy efficiency optimization. Turbochargers, as key components for enhancing engine efficiency, require lightweight bearings to reduce energy losses.

b) Solution (How QIBR Solves the Problem)

QIBR addresses the aforementioned challenges by employing advanced angular contact ceramic ball bearing technology, providing a comprehensive solution:

- Optimized Material Selection: Angular contact ball bearings are manufactured using hybrid materials. The steel material has a density of 7.8–7.85 g/cm³, a thermal expansion coefficient of 11.5, hardness of NV 10 of 700, and is non-electrically insulating. The ceramic material has a density of 3.2–3.25 g/cm³, a thermal expansion coefficient of 3.2, hardness of NV 10 of 1600, and is electrically insulating. This material composition allows angular contact ceramic ball bearings to achieve speeds up to 10% higher compared to steel rolling element bearings.

- Design Optimization: Utilizing an angular contact design with a 15-degree contact angle improves the bearing’s load capacity and stability, meeting high precision requirements and high-speed rotational environments.

- Surface Treatment: Special surface coatings or treatment technologies are applied to enhance the wear resistance and chemical stability of the bearings.

- Lightweight Design: Leveraging the lightweight properties of ceramic angular contact ball bearings reduces the overall weight of the turbocharger, enhancing the vehicle's energy efficiency performance.

Through continuous improvement, QIBR developed bearings that meet customer needs. Experimental testing of the designed bearings yielded data, resulting in the final model 360010, made from material 11414881, with bearing dimensions of 130*200*33 and a weight of 3.86 kg.

c) Results

- Improved High-Temperature Resistance and Stability of the Turbocharger

- Extended Bearing Lifespan and Overall System Reliability

- Reduced Maintenance Requirements and Downtime, Lowered Operating Costs:

- Improved Engine Efficiency and Environmental Adaptability

- Decreased Turbocharger Damage Rate in Harsh Environments, Increased Engine Profitability

Testimonials

QIBR's technical experts provided us with an advanced angular contact ceramic ball bearing solution, thoroughly analyzing and optimizing the issues we faced with high temperatures, high speeds, and chemical corrosion in our new energy vehicle engine turbocharger applications. Their products have not only significantly improved the stability and durability of our equipment but also effectively reduced our operating costs and maintenance frequency. We conducted preliminary simulation tests with various bearings and found that the data for QIBR angular contact ceramic ball bearings was comparable to that of bearings purchased from SMS Group in Germany and Morgan in the United States. In comparison, QIBR bearings offer excellent value for money!

Through this collaboration, we have developed a strong appreciation for QIBR's professional products and services, and we will continue to choose them as our partner.

Their products have not only significantly improved the stability and durability of our equipment but also effectively reduced our operating costs and maintenance frequency.