Newsroom

Do You Know the Functions and Precautions for Tapered Roller Bearings?

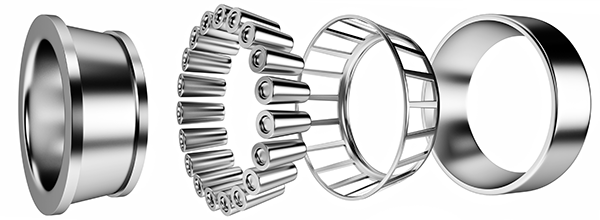

Tapered roller bearings feature conical inner and outer ring raceways, with tapered rollers arranged between them. The projection lines of all conical surfaces converge at the same point on the bearing axis. This design makes tapered roller bearings particularly suitable for withstanding combined (radial and axial) loads. The axial load-carrying capacity of the bearing is largely determined by the contact angle α; the larger the α angle, the higher the axial load capacity. The angle size is represented by the calculation coefficient e; the larger the e value, the larger the contact angle, and the better the bearing's adaptability to axial loads.

Tapered roller bearings are usually separable, meaning the cone assembly (consisting of the inner ring with roller and cage assembly) can be mounted separately from the cup (outer ring).

Tapered roller bearings are widely used in industries such as automotive, rolling mills, mining, metallurgy, and plastic machinery.

The main causes of scratches on tapered roller bearings during installation are: tilting of the inner and outer rings during bearing installation and disassembly; or impact loads generated during installation and disassembly, which lead to scratches on the bearings.

Tapered roller bearings must be installed in accordance with operational specifications; otherwise, many problems will arise. For example, improper installation methods or approaches will cause linear scratches on the bearing's raceway surfaces and rolling surfaces. The installation of deep groove ball bearings directly affects the accuracy, service life and performance of the bearings during operation.

Although tapered roller bearings are excellent in terms of quality and other aspects, rolling bearings are precision components and their use must be carried out with corresponding care. No matter how high-performance a bearing is, it will not deliver the expected high performance if used improperly. The precautions for bearing use are as follows:

1. Keep the tapered roller bearing and its surroundings clean.

Even tiny dust particles invisible to the naked eye can adversely affect the bearing. Therefore, it is necessary to keep the surrounding environment clean to prevent dust from entering the bearing.

2. Handle with care during use.

Subjecting the tapered roller bearing to strong impacts during use will cause scratches and indentations, which can become potential causes of failures. In severe cases, it may lead to cracking or fracture, so caution must be exercised.

3. Use appropriate operating tools.

Avoid substituting with existing tools; appropriate tools must be used.