Newsroom

How to Install Crossed Roller Bearings for Optimal Rotation Performance

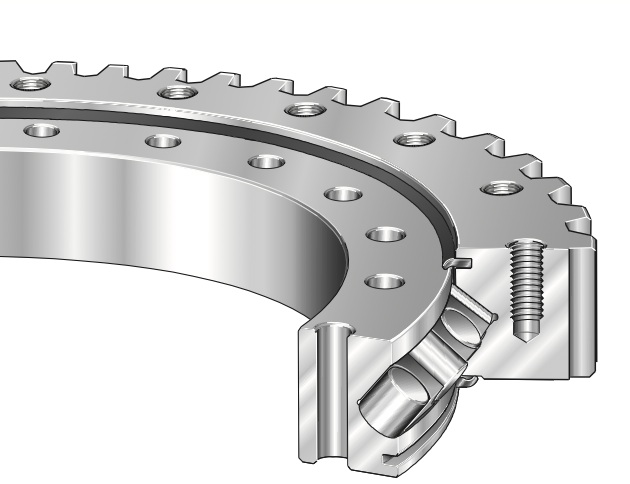

The rolling elements of crossed roller bearing are generally arranged in a crisscross pattern on a single raceway, using tapered rollers or cylindrical rollers to achieve rotation. A correct installation method can promote better rotation performance of crossed roller bearings. Let's learn how to install crossed roller bearing to achieve optimal rotation performance!

1. Control and selection of shaft tolerance and bearing housing

If the shaft size is too large and its tolerance decreases, the bearing will have a significant inflexible rotation phenomenon. The cross roller bearing will lack flexibility after rotational compression, and there will be an obvious sandy feeling after the bearing is pressed. For a good bearing tolerance and shaft center control, the roundness of the bearing should be well controlled. Excessive roundness of the steering shaft or improper shaft tolerance will affect the flexibility of the bearing.

2. Bearing assembly mode

Since crossed roller bearing are high-precision products, improper assembly can easily damage the bearing raceway, leading to bearing damage. The thrust of the crossed roller bearing is only a small circle. Therefore, when installing the bearing, a special mold must be used for press-fitting, or pressure or hydraulic pressure can be applied. During extrusion and pressing, it must first be separated from the guide ring; otherwise, the roller bearing will be damaged.

3. Prevent foreign objects during assembly

Iron filings are easily generated when balancing the rotor during bearing installation. The interior of the bearing must be kept in dynamic balance before installation. No oil or grease should be applied to the bearing housing. If non-coating control is required, assembly should be done indoors.

4. Prevent paint rust

The characteristic of paint rust is that on a motor, if the motor is stored in a warehouse for a long time, the motor will produce abnormal noise, causing severe rusting of the bearing. Many manufacturers used to regard this as a problem with the crossed roller bearing itself. Now, many people have realized that the problem lies in the varnish. However, the volatile acid in the insulating varnish, under certain temperature and humidity conditions, will cause metal corrosion and form corrosive substances, resulting in corrosion damage to the bearing. It is necessary to choose a good quality paint and then assemble after a period of air-drying.