Newsroom

Methods for Maintaining Slewing Bearings

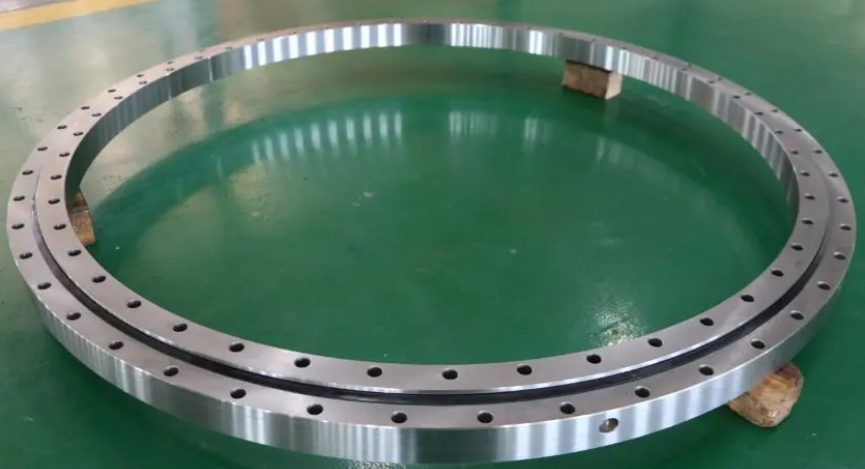

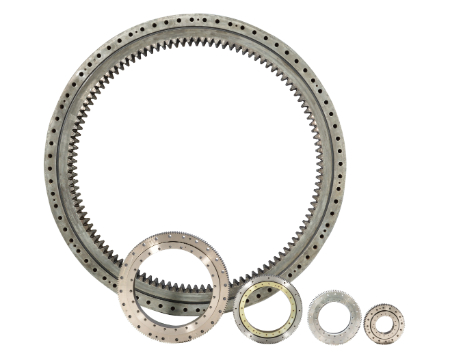

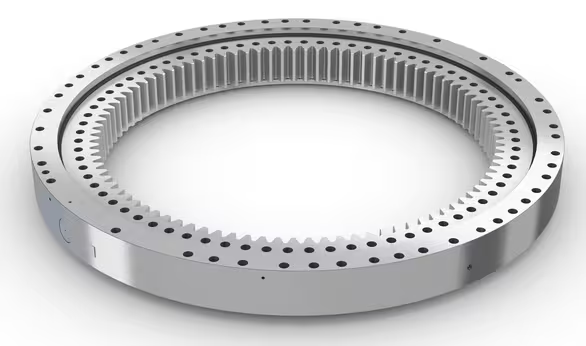

Slewing bearings are large-sized bearings with a special structure. They can simultaneously withstand large axial loads, radial loads, and overturning moments, and have multiple functions such as supporting, rotating, transmitting, and fixing. Common models include: ZYS 1-LGL, ZYS 1-HSB345, ZYS CL-1926, etc. Therefore, we must do a good job in the relevant inspection work for the installation of slewing bearing, or pay attention to the matters needing attention during installation. For such large-sized bearings, we must do a good job in maintenance, storage, etc., to avoid the following damages to the slewing bearing, which may cause them to fail to work normally.

1. Installation of slewing bearing: Before installing the slewing bearing, the installation surface of the host should be inspected. The supporting parts should have sufficient strength, and the connecting surface should be machined. The surface should be smooth, without impurities and burrs. For those that cannot be machined to the required flatness, special plastic with high injection strength can be used as filler to ensure the accuracy of the installation plane and reduce vibration.

The slewing bearing ring has a quenched soft zone, and "s" is marked on the outer ring surface. During installation, the position of the soft zone should be placed in the non-load zone or non-frequently loaded zone (the plug hole is always located on the soft zone). When installing the slewing bearing, radial positioning should be carried out first, the mounting bolts should be tightened crosswise, and the rotation of the bearing should be checked. When tightening the bolts, there should be sufficient pre-tightening force, which should be 70% of the yield limit of the bolt material. The mounting bolts use tempered flat washers instead of spring washers.

2. Overhaul of slewing bearing: After the slewing bearing is installed and runs continuously for 100 hours, check whether the pre-tightening torque of the mounting bolts meets the requirements, and then repeat the above check every 500 hours of continuous operation. After the slewing bearing is installed, an appropriate amount of grease should be added. When adding, the bearing should be rotated to make the grease evenly distributed. After the slewing bearing works for a period of time, it will inevitably lose part of the grease. Therefore, during normal operation, the slewing bearing should be replenished with grease every 50-100 hours.

3. Transportation and storage of slewing bearing: During transportation, the bearings should be placed horizontally on the vehicle, and measures should be taken to prevent sliding and vibration. If necessary, auxiliary supports should be added.