Newsroom

Surface Strengthening and Heat Treatment of Slewing Bearing Components

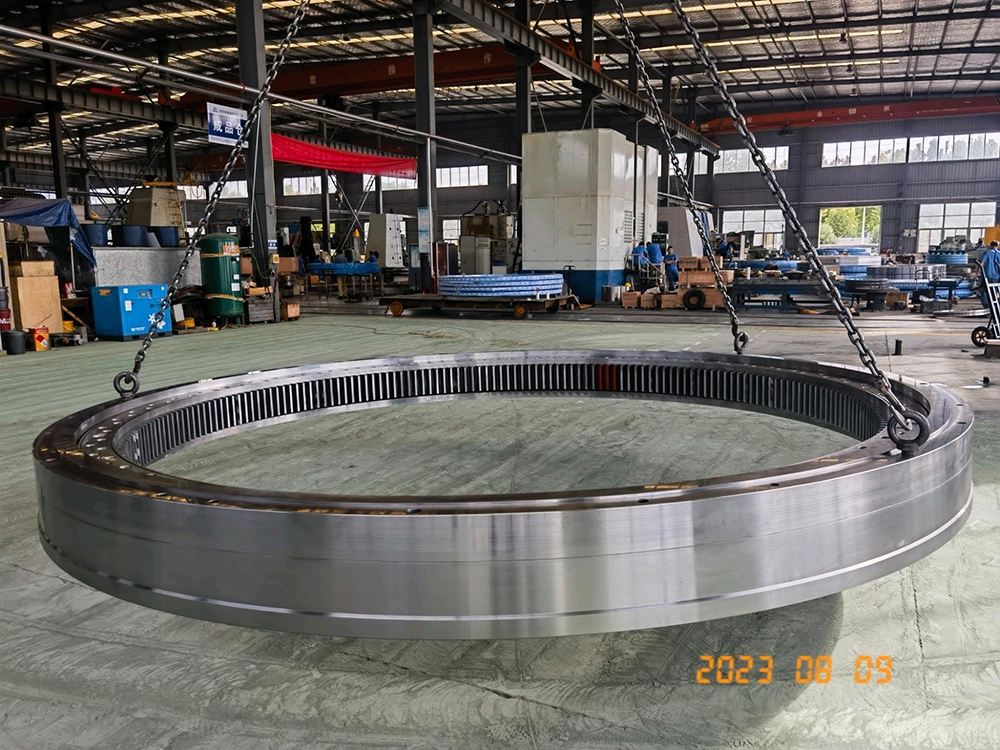

Slewing bearings are large-sized bearings with a special structure. They can simultaneously withstand significant axial loads, radial loads, and overturning moments, and possess multiple functions such as supporting, rotating, transmitting power, and fixing.

There are considerable differences between the working surface and the core of slewing bearing components in terms of state, structure, and performance requirements. However, integral heat treatment often fails to fully consider these two aspects, and the potential of the material cannot be fully exploited. The application of material surface strengthening technology can not only resolve the structural and requirement differences between the surface and the core but also improve the surface to obtain some special working properties, thereby meeting the operational requirements of bearings under specific conditions. This is of great significance for the development of modern science and technology. Traditional surface strengthening methods fall within the scope of heat treatment. Modern surface strengthening technologies developed in recent times, such as laser, electron beam, and ion beam techniques, not only apply a number of high and new technologies to material surface strengthening but also have transcended the scope of traditional heat treatment, forming a new technical field. Therefore, current surface strengthening technologies can be classified in various ways from different perspectives. Based on their physical and chemical processes, they can be roughly divided into five categories: surface deformation strengthening, surface heat treatment strengthening, chemical heat treatment strengthening, surface metallurgical strengthening, and surface film strengthening.

1. The Surface of Slewing Bearings Deformation Strengthening

This process involves plastic deformation of the metal surface layer to form a hardened layer with high hardness and strength. This surface strengthening method is also known as surface hardening. It includes shot peening, sandblasting, cold extrusion, rolling, cold rolling, impact hardening, explosive shock strengthening, etc. The key features of these methods are: increasing the dislocation density of the strengthened layer, refining the subgrain structure, thereby improving hardness and strength, reducing surface roughness, significantly enhancing surface fatigue strength, and lowering fatigue notch sensitivity. There is no obvious boundary between the hardened layer and the substrate, with a coherent structure that is not prone to peeling during service. Most of these methods have been applied in the bearing industry: impact strengthening of rolling element surfaces is a typical application, and precision rolling has become a new method for the processing and strengthening of ring components.

2. The Surface of Slewing Bearings Heat Treatment Strengthening

This refers to the process of quenching the surface layer of components through solid-state transformation using rapid heating methods, known as surface heat treatment or commonly as surface quenching. It includes flame heating quenching, high (medium) frequency induction quenching, laser heating quenching, electron beam heating quenching, etc. Its characteristics are: local heating and quenching of the surface, resulting in minimal workpiece deformation; high heating speed and productivity; short heating time, leading to slight surface oxidation and decarburization.