Newsroom

The 7314ATDBD+2KL10AC3 Bearing: Design, Performance, and Industrial Applications

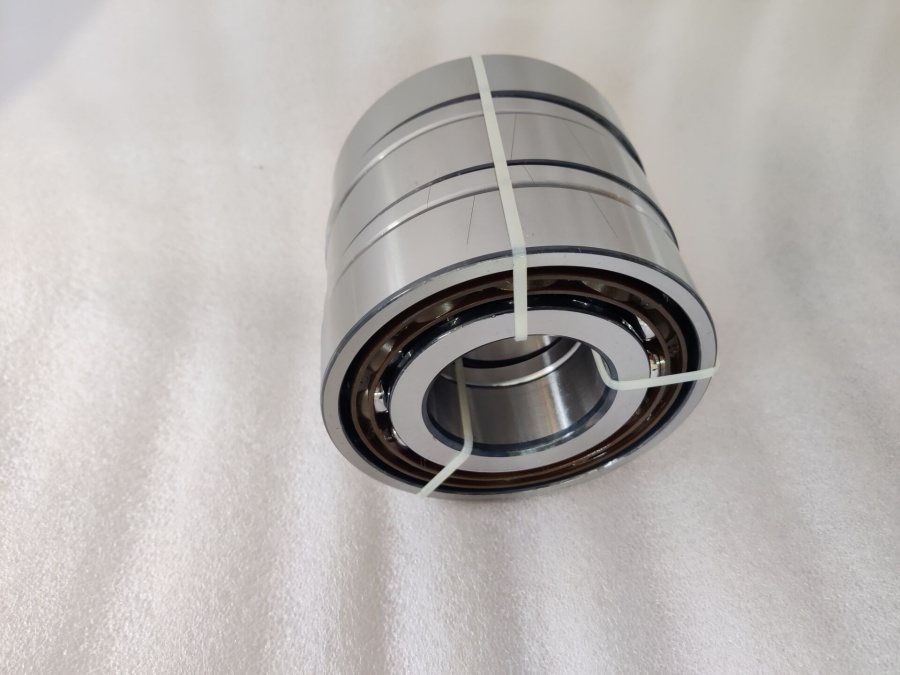

2024-01-20In the realm of industrial machinery, bearings serve as the unsung heroes that enable smooth rotation, reduce friction, and support axial and radial loads. Among the diverse range of bearing models available, the 7314ATDBD+2KL10AC3 stands out as a high-performance solution tailored for demanding industrial environments. This article delves into the structural design, key features, material selection, application scenarios, and maintenance considerations of the 7314ATDBD+2KL10AC3 bearing, shedding light on why it has become a preferred choice for engineers and manufacturers across various sectors.

To understand the 7314ATDBD+2KL10AC3 bearing, it is essential to decode its model number, as each alphanumeric segment conveys critical information about its design and specifications. The prefix “7” indicates that it belongs to the angular contact ball bearing category, a type renowned for its ability to handle both radial and axial loads simultaneously. Angular contact ball bearings are distinguished by their contact angle, which determines their load-carrying capacity and operational characteristics. The following “3” denotes the bearing’s series, signifying its dimensional proportions—specifically, a medium cross-sectional height that balances load capacity and compactness. The numbers “14” represent the bore diameter, calculated as 14 × 5 = 70 millimeters, a standard size that facilitates compatibility with a wide range of shafts and machinery components.

Moving on to the suffixes, “A” specifies a contact angle of 30 degrees, a configuration that optimizes the bearing’s performance for applications requiring high axial load capacity while maintaining stable radial load support. The “TDBD” suffix indicates a double-row, back-to-back mounting arrangement. In back-to-back mounting, the outer rings of the two bearing rows are positioned opposite each other, which enhances the bearing’s rigidity and resistance to tilting moments. This design is particularly advantageous in high-speed rotating machinery where stability and precision are paramount. The “+2KL10AC3” segment refers to the bearing’s accessories and precision class: “2KL10” denotes the inclusion of two locking collars with a 10-millimeter width, enabling easy and secure installation on the shaft, while “AC3” signifies a precision class that ensures tight tolerances and smooth operation, making it suitable for high-precision applications.

The structural design of the 7314ATDBD+2KL10AC3 bearing is a result of meticulous engineering, aimed at maximizing performance and durability. The double-row angular contact configuration provides several advantages over single-row bearings. By incorporating two rows of balls, the bearing distributes loads more evenly, reducing stress on individual components and extending service life. The back-to-back mounting further enhances rigidity, as the distance between the bearing rows creates a longer moment arm, effectively resisting bending and tilting forces. This makes the bearing ideal for applications such as machine tool spindles, where minimal runout and high rigidity are essential for achieving precise machining results.

Material selection is another critical factor that contributes to the 7314ATDBD+2KL10AC3 bearing’s exceptional performance. The inner and outer rings, as well as the balls, are typically manufactured from high-carbon chromium bearing steel (e.g., SUJ2 or 100Cr6). This material is chosen for its high hardness, excellent wear resistance, and superior fatigue strength—properties that are vital for withstanding the repetitive stresses of high-speed rotation. The bearing’s cages, which separate and guide the balls, are often made from brass or polyamide. Brass cages offer high strength and heat resistance, making them suitable for high-temperature and high-speed applications, while polyamide cages provide lower friction and quieter operation, ideal for environments where noise reduction is a priority. Additionally, the bearing may feature a steel shield or rubber seal to prevent the ingress of contaminants such as dust, dirt, and moisture, which can significantly reduce bearing life if left unaddressed.

The 7314ATDBD+2KL10AC3 bearing is engineered to deliver outstanding performance under a wide range of operating conditions. It has a high radial load capacity, typically around 55–65 kN, and an axial load capacity of approximately 35–45 kN, depending on the operating speed and lubrication conditions. The bearing is capable of operating at high speeds, with a limiting speed of up to 6,000–8,000 rpm (revolutions per minute) when properly lubricated and installed. This high-speed capability is attributed to its optimized contact angle, precision manufacturing, and high-quality materials. Furthermore, the bearing exhibits excellent temperature resistance, with a maximum operating temperature of 120°C (248°F) for standard models, and can be customized to withstand higher temperatures with specialized materials and lubricants.

Due to its robust design and versatile performance, the 7314ATDBD+2KL10AC3 bearing finds applications in a variety of industrial sectors. One of its primary uses is in machine tool spindles, where it provides the necessary rigidity and precision to ensure accurate cutting and machining operations. Machine tools such as lathes, milling machines, and grinding machines rely on bearings like the 7314ATDBD+2KL10AC3 to maintain stable rotation even under heavy cutting loads. Another key application area is in industrial pumps and compressors, where the bearing must withstand high speeds and varying load conditions. The back-to-back mounting configuration ensures that the bearing can handle the axial thrust generated by these machines, while its sealing features protect it from the harsh fluids and contaminants commonly found in pump and compressor environments.

Additionally, the 7314ATDBD+2KL10AC3 bearing is used in electric motors, especially high-power motors used in industrial drives and automation systems. In these applications, the bearing’s high-speed capability and low friction help to improve motor efficiency and reduce energy consumption. It is also employed in heavy machinery such as construction equipment and mining machinery, where it must endure extreme loads and harsh operating conditions. The bearing’s durable construction and high load-carrying capacity make it well-suited for these demanding applications.

Proper maintenance is crucial to ensuring the long-term performance and reliability of the 7314ATDBD+2KL10AC3 bearing. One of the most important maintenance tasks is regular lubrication. Lubrication reduces friction between the bearing components, dissipates heat, and prevents corrosion. The type of lubricant used should be selected based on the operating speed, temperature, and load conditions. For high-speed applications, a low-viscosity grease or oil is recommended, while high-temperature applications may require synthetic lubricants with superior thermal stability. It is also important to maintain the correct lubricant level, as insufficient lubrication can lead to increased friction and premature wear, while over-lubrication can cause overheating.

Another key maintenance consideration is contamination control. The 7314ATDBD+2KL10AC3 bearing’s seals or shields should be inspected regularly to ensure they are intact and functioning properly. Any damage to the seals can allow contaminants to enter the bearing, leading to abrasion and premature failure. In addition, the bearing should be inspected periodically for signs of wear, such as excessive noise, vibration, or temperature rise. If any of these signs are detected, the bearing should be replaced promptly to prevent damage to other machinery components. Proper installation is also essential for maximizing bearing life—installing the bearing with excessive interference or misalignment can cause increased stress and reduce performance.

In conclusion, the 7314ATDBD+2KL10AC3 bearing is a high-performance, versatile component that plays a critical role in a wide range of industrial applications. Its double-row angular contact design, back-to-back mounting configuration, and high-quality materials make it capable of handling both radial and axial loads, while its precision manufacturing ensures stable and reliable operation at high speeds. From machine tool spindles to industrial pumps and electric motors, this bearing delivers the rigidity, durability, and precision that modern industrial machinery demands. By understanding its design features, application requirements, and maintenance needs, engineers and manufacturers can fully leverage the capabilities of the 7314ATDBD+2KL10AC3 bearing, ensuring optimal performance and extending the service life of their machinery. As industrial technology continues to advance, the demand for high-performance bearings like the 7314ATDBD+2KL10AC3 is expected to grow, further solidifying its position as a key component in the global industrial supply chain.