Newsroom

The XIU15/560 Cross Cylindrical Roller Slewing Bearing: Engineering Marvel for Heavy-Duty Rotation

In the world of heavy machinery and precision engineering, the ability to facilitate smooth, controlled, and reliable rotation under immense loads is paramount. At the heart of many such applications lies a critical component: the slewing bearing. Among the various types available, the cross cylindrical roller slewing bearing represents a pinnacle of design for handling complex load scenarios. The XIU15/560 model is a specific embodiment of this technology, engineered to deliver exceptional performance in the most demanding environments. This article delves into the design, operating principles, advantages, and typical applications of this robust bearing.

Understanding the Slewing Bearing

A slewing bearing, also known as a turntable bearing, is a large-scale rolling-element bearing that seamlessly facilitates rotational movement between two structures. Unlike standard bearings that primarily handle radial or axial loads, slewing bearings are uniquely designed to manage a combination of loads simultaneously: axial forces (parallel to the axis of rotation), radial forces (perpendicular to the axis), and tilting moments (which cause a tipping force). They are integral to machines that require a part to rotate relative to its base, such as cranes, excavators, wind turbines, and medical scanners.

The Cross Cylindrical Roller Design: A Standout Feature

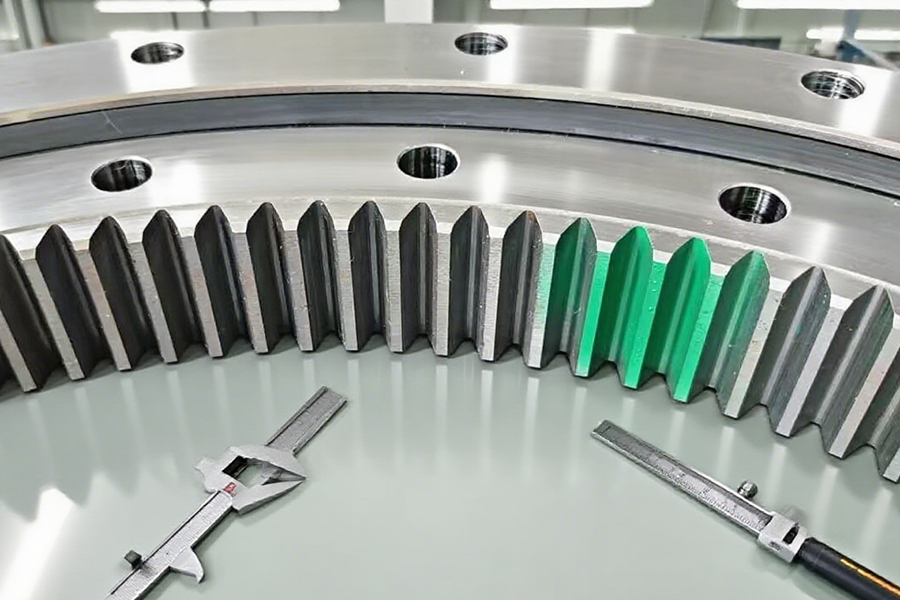

The XIU15/560 belongs to a specialized category known as cross cylindrical roller slewing bearings. Its name is derived from its internal structure. Within the bearing, there are two rows of cylindrical rollers. The key innovation is their orientation: the rollers in one row are arranged perpendicularly (at a 90-degree angle) to the rollers in the adjacent row. This crossed configuration is the bearing's defining characteristic and the source of its superior capabilities.

This design allows the XIU15/560 to independently and efficiently handle loads from all directions. One row of rollers is optimized to carry high axial loads and tilting moments, while the perpendicular row is specifically designed to accommodate high radial loads. This separation of duties within a single, compact unit is a significant advantage over single-row ball or roller slewing bearings, which often struggle with combined load scenarios.

Decoding the Model: XIU15/560

The nomenclature provides insights into the bearing's specifications:

XIU: This is likely the manufacturer's series or type code, commonly indicating a cross roller slewing bearing with an internal gear ring. The "U" often denotes a four-point contact design, but in this context, it aligns with the crossed roller principle.

15: This figure typically represents the bearing's core design and sealing system.

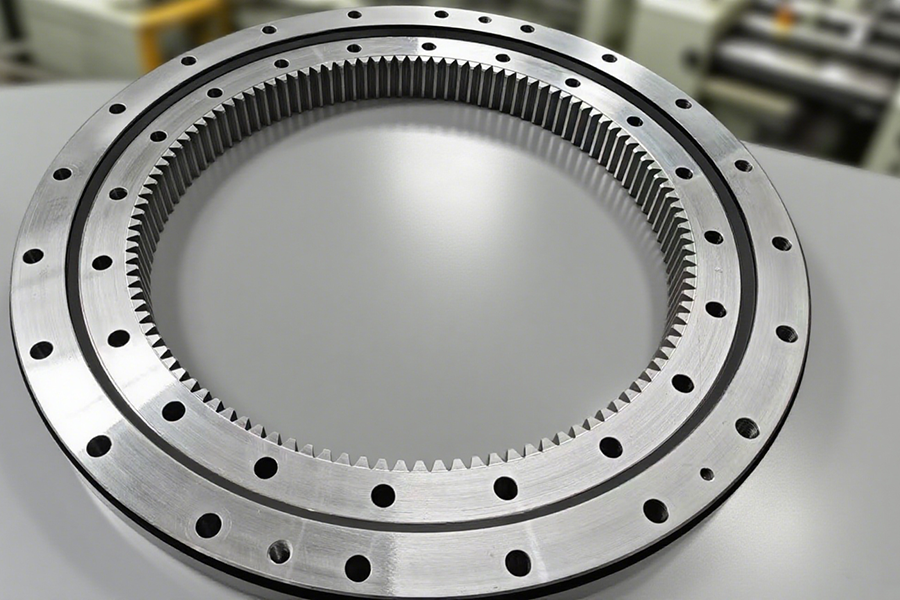

560: This is the most critical dimension, indicating the bearing's pitch diameter in millimeters. The pitch diameter is the diameter of the circle through the centers of the rollers. A 560mm pitch diameter places this bearing in the medium-to-large size category, suitable for substantial machinery.

Based on this size, we can infer other approximate dimensions (e.g., an outer diameter of ~650mm-700mm, an inner diameter of ~480mm-520mm) and a significant load-carrying capacity.

Technical Advantages and Performance Characteristics

The XIU15/560 cross cylindrical roller slewing bearing offers several compelling benefits:

1.High Load Capacity and Rigidity: The line contact of cylindrical rollers (as opposed to the point contact of balls) provides a vastly larger contact area with the raceways. This translates into an exceptionally high load capacity for both axial and radial forces, as well as superior rigidity. The bearing exhibits minimal elastic deformation under load, ensuring precision and stability in operation.

2.High Rotational Accuracy: The precision-ground raceways and rollers, combined with the rigid structure, result in extremely low runout and precise rotational movement. This makes the XIU15/560 ideal for applications where positioning accuracy is critical, such as in robotic arms or indexing tables.

3.Compact and Space-Saving Design: Despite its high performance, the cross-roller design is remarkably compact. By efficiently managing all load types in a single row, it eliminates the need for multiple stacked bearings, saving valuable space and reducing the overall weight and complexity of the machinery.

4.Smooth and Efficient Operation: The optimized roller geometry and high-quality manufacturing ensure low friction torque and smooth, consistent rotation. This efficiency can contribute to reduced power requirements for the drive motor.

5.Integrated Gearing: The XIU15/560 model is typically available with an internal gear machined into the bearing's inner or outer ring. This allows for direct meshing with a pinion gear, simplifying the drive system design and creating a fully integrated rotational mechanism.

Common Applications

The unique combination of strength, precision, and compactness makes the XIU15/560 bearing a preferred choice in numerous industries:

Construction Machinery: Excavators, mobile cranes, and concrete pumpers use these bearings in their slewing platforms to handle the massive digging forces, loads, and dynamic moments.

Material Handling: Stacker cranes, robotic palletizers, and automated warehousing systems rely on them for precise and reliable rotation.

Industrial Automation: They are found in the joints of heavy-duty robotic arms, welding positioners, and large indexing tables used in manufacturing lines.

Medical Equipment: High-precision imaging devices like CT and MRI scanners may utilize scaled-down versions of this technology for their gantry rotation, requiring smoothness and accuracy to eliminate artifacts.

Military and Aerospace: In radar antenna platforms, missile launch systems, and gun turrets, where unwavering reliability and accuracy under extreme conditions are non-negotiable.

Installation and Maintenance Considerations

Proper handling is crucial for maximizing the service life of a XIU15/560 bearing. Installation requires a rigid, machined mounting surface with high flatness and stiffness to prevent pre-loading and distortion. The bearing is typically secured with high-strength pre-tensioned bolts.

Maintenance primarily involves protecting it from its environment. Although it comes with integral seals (often denoted by the "15" in the model number), regular inspection of these seals is necessary. For applications in harsh conditions, re-lubrication via the built-in grease fittings is essential to flush out contaminants and ensure the rollers and raceways are always protected by a fresh film of high-quality, extreme-pressure grease.

Conclusion

The XIU15/560 cross cylindrical roller slewing bearing is far more than a simple component; it is a sophisticated engineering system that enables modern heavy machinery to perform its rotational feats with power, precision, and reliability. Its intelligent crossed-roller design efficiently solves the complex challenge of managing multi-directional loads in a compact and robust package. As machinery continues to evolve, demanding greater performance from smaller footprints, the principles embodied by the XIU15/560 will remain at the forefront of rotational solution design, proving that sometimes, the most powerful innovations are found in the components that work quietly at the core.