Newsroom

Two Mounting Methods for Cylindrical Roller Bearings

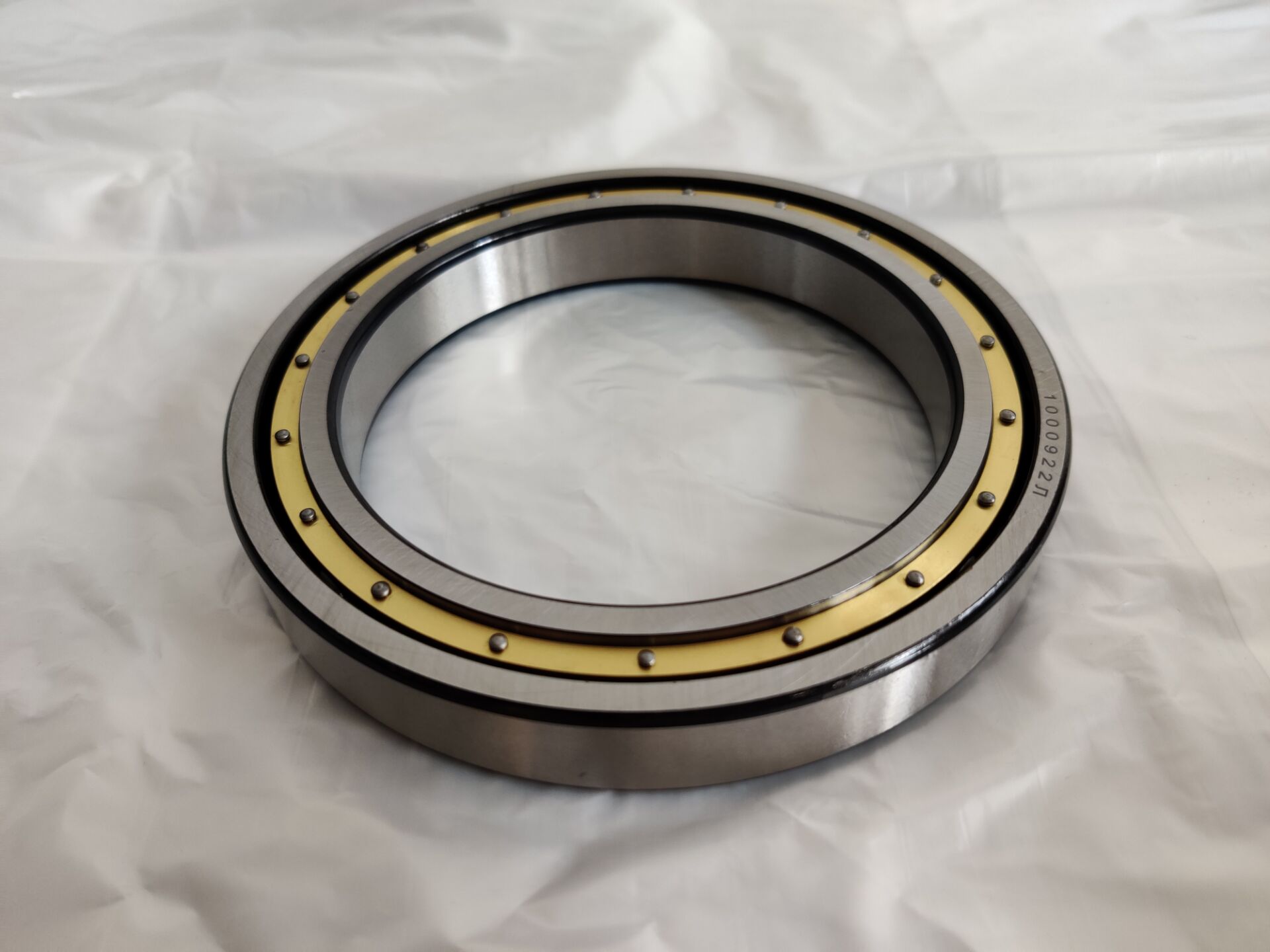

Cylindrical roller bearings feature line contact between the rollers and raceways, boasting a high load-carrying capacity and being mainly designed to bear radial loads. With minimal friction between the rolling elements and the ring ribs, they are suitable for high-speed rotation. According to the presence or absence of ribs on the rings, cylindrical roller bearings are classified into single-row types such as NU, NJ, NUP, N and NF, and double-row types such as NNU and NN. This type of bearing adopts a separable structure for the inner and outer rings. Common models include SKF NJ2216ECM/C3, INA SL1818/500-E, INA LSL192334-TB, etc.

Cylindrical roller bearings without ribs on either the inner or outer ring allow axial relative movement between the inner and outer rings, making them applicable as free-end bearings. Cylindrical roller bearings with double ribs on one side of the inner/outer ring and a single rib on the mating ring can withstand a certain level of axial load in one direction. Generally, they use steel plate stamped cages or solid cages machined from copper alloy, while some also adopt polyamide molded cages.

In the actual installation of cylindrical roller bearings, incorrect mounting methods often lead to bearing damage and subsequent malfunction. It is hereby emphasized that mastering the correct mounting method for cylindrical roller bearings is an extremely critical step.

There are two common correct mounting methods for cylindrical roller bearings: cold mounting and hot mounting.

1. Cold Mounting

For small bearings with a non-tight fit, the bearing can be fitted into the proper position by gently striking a sleeve with a hammer. The impact force should be applied evenly on the bearing ring as much as possible to prevent the bearing from tilting or skewing. Most cylindrical roller bearings are installed via the press-fitting method. When pressing both the inner and outer rings of a cylindrical roller bearing onto the shaft and into the housing simultaneously, it is essential to apply equal pressure to the inner and outer rings at the same time, with the contact surfaces of the mounting tool kept on the same plane.

2. Hot Mounting

Typically, heating the bearing or bearing housing is a prerequisite for mounting large-sized bearings, as the required mounting force increases with the rise of bearing dimensions. The temperature difference between the bearing ring and the shaft/housing for hot mounting mainly depends on the interference fit and the diameter of the bearing mating surface. The heating temperature of open bearings must not exceed 120°C. It is not recommended to heat cylindrical roller bearings with seals and dust covers above 80°C (the temperature shall be ensured not to exceed the allowable temperature of the seals and lubricating grease). During the heating process, the bearing must be heated uniformly, and local overheating is strictly prohibited.