Newsroom

What is a thrust bearing?

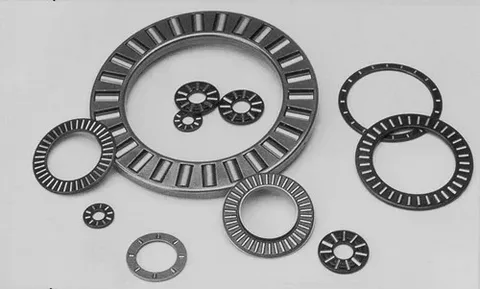

2024-12-04Thrust bearings are generally composed of two thrust washers or more thrust washers and several rolling elements. Generally, thrust washers are divided into shaft washers and housing washers. The most common type of rolling elements is usually an integral combination formed by iron or copper cages. The most common type of this kind of bearing is the ball thrust bearing.

Definition

A thrust bearing is a special bearing specifically designed to bear axial forces, that is, the forces in the direction parallel to the axis. Thrust bearings are also called axial thrust bearings.

Working Principle

The thrust ball bearing is a separable type of bearing. The shaft ring and the housing ring can be separated from the assembly of the cage and the steel balls. The shaft ring is the ring that mates with the shaft, and the housing ring is the ring that mates with the bearing housing bore and has a clearance with the shaft. The thrust ball bearing can only bear axial loads.

The single-direction thrust ball bearing can only bear the axial load in one direction.

The double-direction thrust ball bearing can bear the axial loads in two directions.

The thrust ball bearing cannot limit the radial displacement of the shaft and has a very low limiting rotational speed.

The single-direction thrust ball bearing can limit the axial displacement of the shaft and the housing in one direction.

The double-direction bearing can limit the axial displacement in two directions.

The thrust roller bearing is mainly used to bear the combined axial and radial loads with the axial load as the main component, but the radial load should not exceed 55% of the axial load. Compared with other thrust roller bearings, this kind of bearing has a lower friction coefficient, a higher rotational speed, and self-aligning performance.

The rollers of the 29000-type bearing are asymmetric spherical rollers, which can reduce the relative sliding between the rollers and the raceway during operation. Moreover, the rollers are long, have a large diameter, there are a large number of rollers, and the load-carrying capacity is high. Usually, oil lubrication is adopted, and grease lubrication can be used in individual low-speed cases. It should be preferentially selected during design and selection.

The 80000-type thrust cylindrical roller bearing, the 90000-type thrust tapered roller bearing, and the AXK-type thrust needle roller bearing can bear the unidirectional axial load. Their axial load-carrying capacity is much greater than that of the thrust ball bearing, and they have high rigidity and occupy a small axial space.

The thrust cylindrical roller bearing and the thrust needle roller bearing are suitable for occasions with low rotational speeds, and the rotational speed of the thrust tapered roller bearing is slightly higher than that of the thrust cylindrical roller bearing.

Application Classification

Thrust bearings are divided into thrust ball bearings and thrust roller bearings.

The thrust ball bearings are further divided into thrust ball bearings and thrust angular contact ball bearings. The raceway ring that mates with the shaft and is composed of washers with raceways, balls, and cage assemblies is called the shaft ring, and the raceway ring that mates with the housing is called the housing ring. For double-direction bearings, the intermediate ring mates with the shaft. Single-direction bearings can bear unidirectional axial loads, and double-direction bearings can bear bidirectional axial loads. Bearings with spherical mounting surfaces on the housing rings have self-aligning performance and can reduce the impact of installation errors. Such bearings are mainly applied in automobile steering mechanisms and machine tool spindles.

The thrust roller bearings are divided into thrust cylindrical roller bearings, thrust self-aligning roller bearings, thrust tapered roller bearings, and thrust needle roller bearings. The thrust cylindrical roller bearings are mainly applied in oil drilling rigs and iron and steel manufacturing machinery. The thrust self-aligning roller bearings are mainly applied in hydroelectric generators, vertical motors, ship propeller shafts, tower cranes, and extruders. The main applications of the thrust tapered roller bearings are as follows: Unidirectional: crane hooks, swivels of oil drilling rigs. Bidirectional: roll necks of rolling mills. The flat thrust bearing mainly bears axial loads in the assembly and is widely used.

Although the installation and operation of thrust bearings are relatively simple, errors still often occur during actual maintenance. That is, the installation positions of the tight ring and the loose ring of the bearing are incorrect, resulting in the bearing losing its function and the shaft neck being quickly worn. When the tight ring is installed on the end face of the stationary part, it is a wrong assembly. The inner ring of the tight ring has a transition fit with the shaft neck. When the shaft rotates, it drives the tight ring and generates friction with the end face of the stationary part. When subjected to the axial acting force (Fx), the friction torque will be greater than the resistance torque of the inner diameter fit, causing the mating surface of the tight ring and the shaft to rotate forcibly and aggravating the wear of the shaft neck.

Precautions

The following points should be noted when installing thrust bearings:

(1) Distinguish the tight ring and the loose ring of the bearing (judged according to the inner diameter size of the bearing, with a difference in hole diameter of 0.1 - 0.5 mm).

(2) Distinguish the stationary parts of the mechanism (that is, the parts that do not move, mainly referring to the assembly).

(3) In any case, the loose ring of the bearing should always be against the end face of the stationary part.

About QIBR: Founded in 2002 and based in Luoyang, QIBR is a leading manufacturer specializing in the production of high-precision bearings. The company is recognized for its commitment to quality, innovation, and providing tailored bearing solutions for diverse industries worldwide. With advanced manufacturing capabilities and a strong international presence, QIBR continues to be a key player in the global bearing market.