Newsroom

5 Ways to Reduce Costs with Joint Bearings

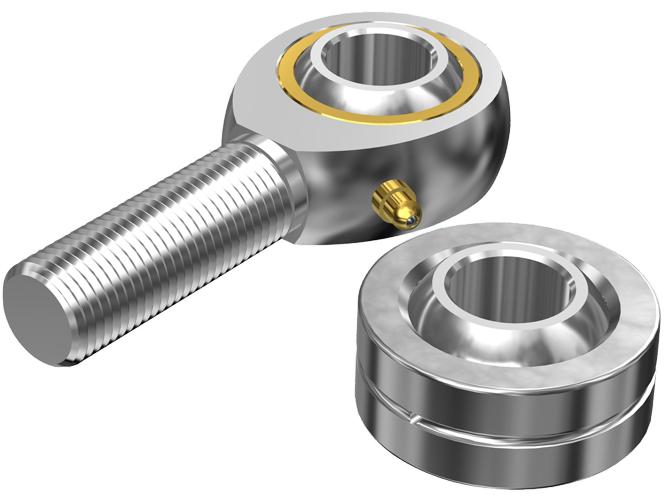

2025-11-14Joint bearings are widely used in industrial machinery, hydraulic equipment, construction vehicles, agricultural machines, and automation systems. With the right selection and maintenance approach, joint bearings can significantly lower operating costs while improving equipment performance and reliability.

Below are five effective cost-saving strategies to help you maximize value when using joint bearings.

1.Choose the Right Bearing Material to Reduce Purchasing Costs

Selecting a suitable bearing material—such as bronze, PTFE composite, engineered plastics, or steel-backed materials—allows you to match performance with actual application needs. This avoids over-specification and helps reduce initial material and procurement costs.

2. Improve Lubrication Efficiency to Extend Service Life

By using appropriate lubricants and optimizing lubrication intervals, you can reduce friction and wear, extend operating life, and avoid premature failure.

Maintenance-free PTFE-lined bearings can further cut down on grease consumption and labor expenses.

3.Simplify Installation to Lower Assembly and Replacement Costs

Many joint bearings support direct press-fit installation, which simplifies assembly, reduces labor time, and minimizes the risk of installation-related damage.

A simple structure means quicker replacement and less downtime.

4.Reduce Surface Treatment and Hardening Costs

Because joint bearings have large contact surfaces and distribute loads evenly, they often require less surface hardening or finishing on the shaft or housing.

This can significantly cut machining costs and shorten production cycles.

5.Use Predictive Maintenance to Avoid Unplanned Shutdowns

Regular monitoring of bearing condition—such as temperature, friction, and abnormal wear—helps you detect problems early and prevent sudden failures.

Predictive maintenance reduces unexpected downtime, lowers repair costs, and keeps production stable.

Conclusion: A Smart Way to Lower Operating Costs

With proper material selection, efficient lubrication, simplified installation, reduced machining requirements, and the use of predictive maintenance, joint bearings offer a highly economical solution for many industrial applications.

Applying these five methods can help your equipment run more efficiently, more reliably, and at a lower long-term cost.