Newsroom

A Comprehensive Overview of the RUS 26102 Bearing

In the realm of mechanical engineering, bearings serve as the unsung heroes that enable smooth rotational motion while reducing friction between moving parts. Among the diverse range of bearing models available today, the RUS 26102 stands out as a reliable and versatile option, widely used in various industrial and automotive applications. This article aims to provide a detailed analysis of the RUS 26102 bearing, covering its design features, material composition, performance characteristics, application areas, installation and maintenance requirements, as well as its market positioning and future development trends.

Product Overview and Design Features

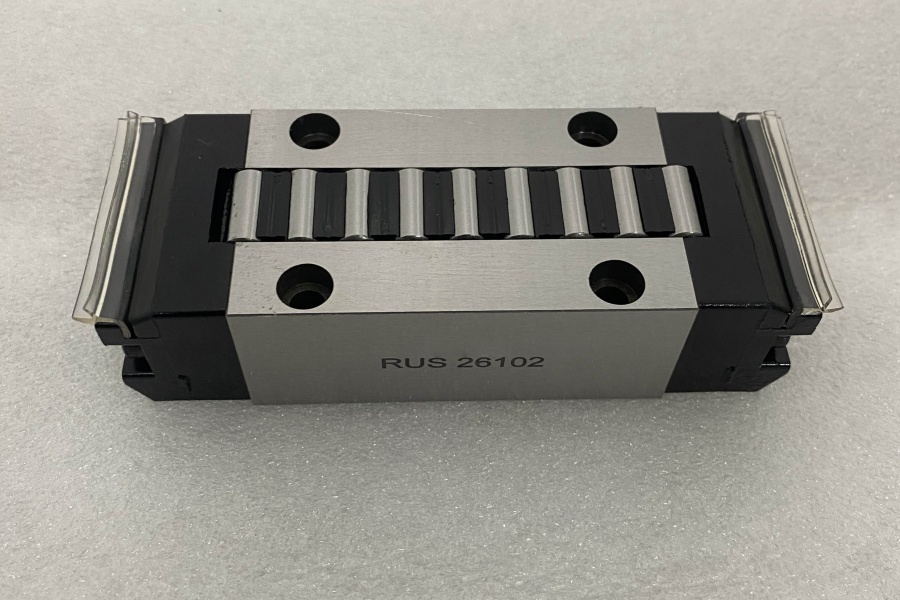

The RUS 26102 is a type of needle roller bearing, a category known for its compact structure and high load-carrying capacity relative to its size. Unlike traditional ball bearings that use spherical rolling elements, needle roller bearings employ long, thin cylindrical rollers (needles) that have a large surface area in contact with the raceways. This unique design allows the RUS 26102 to withstand significant radial loads while occupying minimal space, making it an ideal choice for applications where space constraints are a critical consideration.

One of the key design features of the RUS 26102 is its integrated inner ring. Unlike some needle roller bearings that rely on the shaft itself to act as the inner raceway, the RUS 26102 comes with a dedicated inner ring made of high-quality bearing steel. This design not only simplifies the installation process but also ensures consistent performance and extends the service life of both the bearing and the shaft. The bearing also features a precision-machined outer ring with a smooth raceway, which works in tandem with the needles to minimize friction and wear.

Another notable design element of the RUS 26102 is its cage. The cage, typically made of either stamped steel or engineering plastic (such as polyamide), is responsible for guiding and separating the needle rollers, preventing them from rubbing against each other. Stamped steel cages offer high strength and durability, making them suitable for high-temperature and high-load applications. On the other hand, plastic cages are lighter, quieter, and more resistant to corrosion, making them a preferred choice for applications where noise reduction and chemical resistance are important.

Material Composition and Manufacturing Process

The performance and durability of a bearing are largely determined by the materials used in its construction, and the RUS 26102 is no exception. The inner and outer rings of the RUS 26102 are typically made of high-carbon chromium bearing steel, such as AISI 52100 or SUJ2 (Japanese standard). This type of steel is known for its excellent hardness, wear resistance, and fatigue strength, which are essential properties for bearing components that are subjected to repeated loads and high rotational speeds.

The needle rollers of the RUS 26102 are also manufactured from high-carbon chromium bearing steel, but they undergo additional heat treatment processes to further enhance their mechanical properties. The heat treatment process typically involves quenching (rapid cooling) and tempering (heating to a specific temperature and holding it for a certain period), which results in a martensitic microstructure that provides high hardness and toughness. This ensures that the needle rollers can withstand the high contact pressures generated during operation without deforming or breaking.

In addition to the bearing steel components, the RUS 26102 may also include other materials such as seals or shields to protect the internal components from contamination. Common seal materials include nitrile rubber (NBR), fluororubber (FKM), and polytetrafluoroethylene (PTFE). NBR seals are cost-effective and offer good resistance to oil and water, making them suitable for general-purpose applications. FKM seals, on the other hand, have excellent high-temperature and chemical resistance, making them ideal for harsh environments such as those found in the automotive and aerospace industries. PTFE seals are known for their low friction coefficient and high wear resistance, making them a good choice for applications where low friction and long service life are required.

The manufacturing process of the RUS 26102 involves several precision steps, including forging, turning, heat treatment, grinding, and assembly. The forging process is used to shape the raw steel into the approximate form of the inner and outer rings, which helps to improve the material's density and mechanical properties. After forging, the components undergo turning to achieve the desired dimensions and surface finish. Heat treatment is then performed to enhance the hardness and durability of the components, followed by precision grinding to ensure the raceways and rollers have a smooth surface and accurate dimensions. Finally, the components are assembled, and the bearing is tested to ensure it meets the required performance standards.

Performance Characteristics and Technical Parameters

The RUS 26102 bearing offers excellent performance characteristics that make it suitable for a wide range of applications. One of its key performance metrics is its load-carrying capacity. Due to its needle roller design and high-quality materials, the RUS 26102 can withstand significant radial loads. The basic dynamic load rating (C) and basic static load rating (C0) are important parameters used to quantify the bearing's load-carrying capacity. For the RUS 26102, the basic dynamic load rating typically ranges from 25 to 35 kN, while the basic static load rating ranges from 35 to 50 kN, depending on the specific design and manufacturing specifications.

Another important performance characteristic of the RUS 26102 is its speed capability. The maximum rotational speed of a bearing is determined by several factors, including the type of bearing, the material of the cage, the lubrication method, and the operating temperature. The RUS 26102 is designed to operate at moderate to high speeds, with a maximum rotational speed of approximately 8,000 to 12,000 rpm under normal operating conditions. However, this speed can be reduced if the bearing is subjected to high loads, high temperatures, or poor lubrication.

Friction and wear are also critical performance factors for bearings, as they directly affect the efficiency and service life of the bearing. The RUS 26102 is designed to minimize friction through its precision-machined raceways and smooth needle rollers. The use of high-quality lubricants further reduces friction and wear, ensuring that the bearing operates efficiently for an extended period. The friction coefficient of the RUS 26102 is typically in the range of 0.001 to 0.003, which is comparable to that of other high-performance needle roller bearings.

In terms of operating temperature range, the RUS 26102 can operate in a wide range of temperatures, depending on the material of the seals and the lubricant used. With standard NBR seals and mineral oil lubricants, the bearing can operate at temperatures ranging from -30°C to 120°C. For high-temperature applications, FKM seals and synthetic lubricants can be used to extend the operating temperature range up to 200°C or higher.

Other important technical parameters of the RUS 26102 include its dimensions. The bearing typically has an inner diameter (d) of 15 mm, an outer diameter (D) of 28 mm, and a width (B) of 12 mm. These dimensions make it a compact bearing that can fit into tight spaces, making it suitable for applications such as small electric motors, automotive transmissions, and household appliances.

Application Areas

The RUS 26102 bearing's compact size, high load-carrying capacity, and reliable performance make it suitable for a wide range of applications across various industries. One of the primary application areas of the RUS 26102 is the automotive industry. In automobiles, the bearing is used in various components such as transmissions, differential gears, and steering systems. In transmissions, the RUS 26102 helps to support the rotating shafts and gears, ensuring smooth gear shifting and efficient power transmission. In differential gears, the bearing withstands the radial loads generated during cornering, while in steering systems, it enables smooth rotation of the steering column.

Another important application area of the RUS 26102 is the industrial machinery sector. The bearing is commonly used in small electric motors, pumps, compressors, and conveyors. In electric motors, the RUS 26102 supports the motor shaft, reducing friction and ensuring efficient operation. In pumps and compressors, the bearing withstands the radial loads generated by the rotating impellers, while in conveyors, it helps to support the conveyor rollers, enabling smooth movement of materials.

The RUS 26102 is also used in household appliances such as washing machines, dryers, and vacuum cleaners. In washing machines, the bearing is used in the drum assembly, supporting the rotating drum and reducing noise and vibration. In dryers, it helps to support the dryer drum, ensuring efficient drying performance. In vacuum cleaners, the bearing is used in the motor, enabling the motor to operate at high speeds with minimal friction.

In addition to these applications, the RUS 26102 is also used in the aerospace industry, although to a lesser extent. In aerospace applications, the bearing is used in small auxiliary components such as fuel pumps and hydraulic systems, where its compact size and high reliability are essential.

Installation and Maintenance Guidelines

Proper installation and maintenance are crucial for ensuring the optimal performance and long service life of the RUS 26102 bearing. When installing the bearing, it is important to follow the manufacturer's guidelines to avoid damaging the bearing or the associated components.

Before installation, the bearing and the mounting surfaces (shaft and housing) should be thoroughly cleaned to remove any dirt, debris, or contaminants. Contaminants such as dust, dirt, and metal particles can cause premature wear and failure of the bearing. The mounting surfaces should also be inspected for any scratches, dents, or other defects that could affect the bearing's performance. If any defects are found, they should be repaired or the components should be replaced.

The bearing should be installed with the correct interference fit. The interference fit between the inner ring and the shaft, and between the outer ring and the housing, is important for ensuring that the bearing is securely mounted and can withstand the applied loads. The amount of interference fit depends on the type of bearing, the material of the components, and the operating conditions. The manufacturer's specifications should be consulted to determine the correct interference fit for the specific application.

When installing the bearing, it is important to apply the correct amount of force. Excessive force can damage the bearing's raceways or rollers, while insufficient force can result in a loose fit, which can cause the bearing to rotate on the shaft or in the housing, leading to premature wear. The bearing can be installed using a press, a hammer with a soft face (such as a brass hammer), or a bearing puller, depending on the size and type of the bearing.

After installation, the bearing should be lubricated properly. Lubrication helps to reduce friction and wear, dissipate heat, and protect the bearing from corrosion. The type of lubricant used depends on the operating conditions, such as temperature, speed, and load. For the RUS 26102 bearing, mineral oil lubricants or lithium-based greases are commonly used. The lubricant should be applied in the correct amount, as too much lubricant can cause increased friction and temperature rise, while too little lubricant can result in insufficient lubrication and premature wear.

Regular maintenance is also essential for the RUS 26102 bearing. Maintenance activities include periodic inspection, lubrication, and replacement of worn components. The bearing should be inspected regularly for signs of wear, such as noise, vibration, temperature rise, or leakage of lubricant. If any signs of wear are detected, the bearing should be removed and inspected further to determine the cause of the wear. If necessary, the bearing should be replaced.

Lubrication should be replenished at regular intervals, depending on the operating conditions and the type of lubricant used. The manufacturer's guidelines should be consulted to determine the recommended lubrication interval. In addition, the bearing should be kept clean and free from contaminants to prevent premature wear and failure.

Market Positioning and Future Development Trends

In the global bearing market, the RUS 26102 occupies a niche position as a mid-range, high-performance needle roller bearing. It competes with similar products from other major bearing manufacturers, such as SKF, NSK, Timken, and Schaeffler. The RUS 26102 is known for its excellent (cost-performance ratio), offering reliable performance at a relatively affordable price. This makes it a popular choice among small and medium-sized enterprises (SMEs) that are looking for high-quality bearings without the high cost associated with premium brands.

The market demand for the RUS 26102 is driven by several factors, including the growth of the automotive and industrial machinery industries. The increasing production of automobiles, especially electric vehicles (EVs), is expected to drive the demand for bearings, as EVs require more bearings than traditional internal combustion engine (ICE) vehicles. The growth of the industrial machinery industry, particularly in emerging economies such as China, India, and Brazil, is also expected to contribute to the demand for the RUS 26102.

In terms of future development trends, the RUS 26102 is likely to undergo several improvements to meet the changing needs of the market. One of the key trends in the bearing industry is the development of more energy-efficient bearings. To meet this trend, manufacturers of the RUS 26102 may focus on reducing friction through improved design and the use of advanced materials. For example, the use of ceramic materials for the needle rollers could reduce friction and weight, while also improving the bearing's resistance to corrosion and high temperatures.

Another trend in the bearing industry is the integration of smart technologies. Smart bearings are equipped with sensors that can monitor various parameters such as temperature, vibration, and load, providing real-time data on the bearing's performance. This data can be used to predict maintenance needs, prevent unexpected failures, and optimize the performance of the bearing. In the future, the RUS 26102 may be available in a smart version, which could appeal to customers in industries such as automotive and aerospace, where reliability and safety are critical.

The development of environmentally friendly bearings is also a growing trend in the industry. Manufacturers are increasingly focusing on reducing the environmental impact of their products through the use of sustainable materials, such as recycled steel, and the development of lubricants that are biodegradable. The RUS 26102 may also be adapted to meet these environmental requirements, making it a more attractive choice for customers who are committed to sustainability.

Conclusion

The RUS 26102 bearing is a versatile and reliable needle roller bearing that offers excellent performance characteristics, making it suitable for a wide range of applications across various industries. Its compact design, high load-carrying capacity, and affordable price make it a popular choice among customers looking for a cost-effective bearing solution. By following proper installation and maintenance guidelines, the RUS 26102 can provide long service life and reliable performance.

As the global bearing market continues to evolve, the RUS 26102 is likely to undergo further improvements to meet the changing needs of customers. The integration of advanced materials, smart technologies, and environmentally friendly features will help to ensure that the RUS 26102 remains a competitive and relevant product in the years to come. Whether used in automotive transmissions, industrial machinery, or household appliances, the RUS 26102 is sure to continue playing an important role in enabling smooth and efficient rotational motion in various mechanical systems.