Newsroom

Deep Groove Ball Bearing 61810 2RZ A Versatile Workhorse for Precision Applications

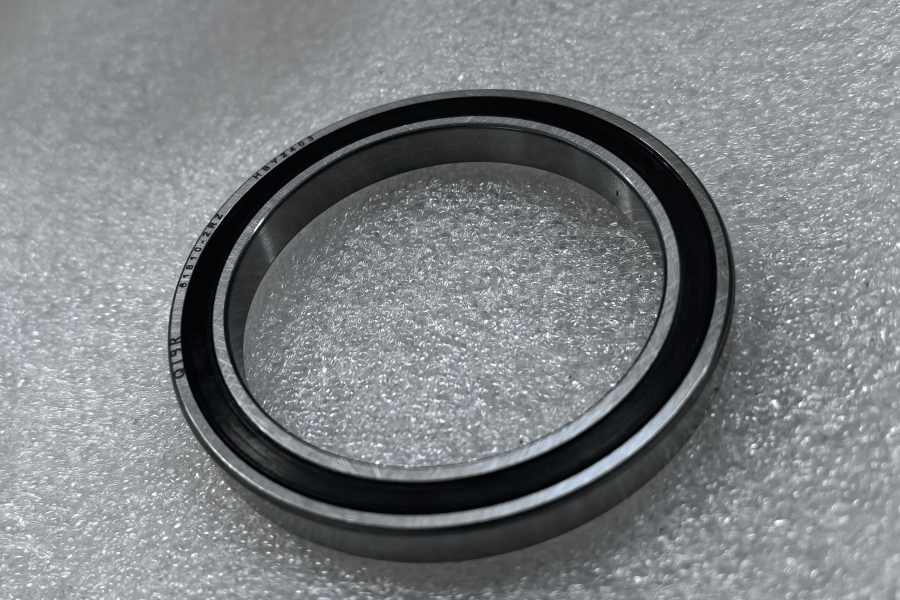

Deep groove ball bearings stand as the most widely used bearing type across industries, celebrated for their simplicity, reliability, and adaptability to diverse operating conditions. Among this category, the 61810 2RZ model emerges as a standout choice for applications demanding high speed, low friction, and effective contamination protection. Designed with precision engineering and tailored to meet rigorous industrial standards, this bearing balances performance, durability, and cost-effectiveness, making it indispensable in sectors ranging from machinery manufacturing to aerospace. This article delves into the core features, specifications, working principles, applications, and maintenance of the 61810 2RZ deep groove ball bearing, shedding light on why it remains a preferred component for engineers and manufacturers worldwide.

Basic Specifications and Design Fundamentals

The 61810 2RZ derives its model number from standardized bearing nomenclature, which encodes key design attributes. The prefix “6” identifies it as a deep groove ball bearing, the most common bearing category due to its ability to accommodate both radial and axial loads (in both directions). The “18” denotes the “18” series, a subset of thin-walled deep groove ball bearings characterized by a small cross-section—ideal for applications where space is constrained. The “10” indicates the bore diameter, which translates to 50 millimeters (a critical dimension for shaft mounting). The suffix “2RZ” specifies the sealing configuration: double-sided (2) non-contact rubber seals (RZ) pre-lubricated with grease.

Key dimensional parameters of the 61810 2RZ adhere to ISO standards (ISO 3408), ensuring interchangeability across manufacturers. The bearing has an outer diameter of 65 millimeters, a width of 7 millimeters, and a bore diameter of 50 millimeters—creating a compact profile that fits into tight assemblies. Its radial internal clearance typically follows the C3 class as standard, though other clearance classes (e.g., C2, C4) are available for specialized temperature or load requirements. Precision grades range from P0 (standard precision) to P5 or P6 for high-precision applications, with geometric tolerances tightly controlled to minimize runout and ensure smooth operation.

Structural Features and Material Composition

Core Components

The 61810 2RZ comprises four primary components, each engineered for optimal performance:

Inner and Outer Rings: Manufactured from high-carbon chromium bearing steel (GCr15, equivalent to AISI 52100), these rings feature precision-ground raceways with a deep groove profile. The material offers exceptional hardness (HRC 60–64 after heat treatment), wear resistance, and fatigue strength, enabling the bearing to withstand repeated load cycles.

Rolling Elements: Typically 10–12 spherical steel balls (GCr15 or ceramic, depending on application), polished to a mirror finish to reduce friction and prevent surface damage. Ceramic balls (e.g., silicon nitride) are an optional upgrade for high-speed or corrosive environments, offering lower density and higher temperature resistance.

Cage: A non-separable component that separates and guides the rolling elements, preventing collision and ensuring uniform load distribution. The standard cage material is phenolic resin (glass fiber-reinforced), which balances strength, low friction, and compatibility with grease lubrication. Brass cages are available for high-temperature or heavy-load applications.

Sealing Shields (2RZ): Double-sided rubber seals (usually nitrile rubber NBR or fluororubber FKM) attached to the outer ring, with a small clearance from the inner ring to avoid contact. This non-contact design minimizes friction while blocking dust, dirt, and moisture from entering the bearing interior. The seals are pre-filled with high-performance grease, eliminating the need for initial lubrication and reducing maintenance requirements.

Sealing Advantage of 2RZ Configuration

The 2RZ sealing system is a defining feature of this bearing, distinguishing it from open (no seals) or metal-shielded (ZZ) variants. Unlike contact seals (e.g., 2RS), which rub against the inner ring and increase friction, the non-contact RZ seals maintain a tiny gap (typically 0.1–0.3 mm) that reduces heat generation—critical for high-speed operation. This design preserves the bearing’s high rotational speed capability while providing effective protection against contaminants. The pre-lubricated grease within the sealed cavity ensures consistent lubrication over extended periods, reducing downtime for re-lubrication and extending service life. For applications involving extreme temperatures (above 120°C), FKM seals are recommended, as they offer better heat and chemical resistance than NBR.

Working Principle and Performance Capabilities

Operational Mechanism

Deep groove ball bearings operate on the principle of converting sliding friction into rolling friction. When radial load is applied, the rolling elements (steel balls) roll between the inner and outer ring raceways, distributing the load evenly across the contact points. The deep groove design allows the bearing to also absorb axial loads (thrust loads) in both directions, as the raceways are curved to match the curvature of the balls. This dual-load capacity eliminates the need for additional thrust bearings in many applications, simplifying assembly and reducing costs.

The 2RZ seal’s non-contact design plays a key role in performance: by avoiding direct contact between the seal and inner ring, it minimizes friction torque, allowing the bearing to achieve higher rotational speeds. The maximum operating speed of the 61810 2RZ (at standard temperature and grease lubrication) is approximately 12,000 rpm—significantly higher than contact-sealed alternatives. This makes it ideal for high-speed equipment such as electric motors, spindle drives, and centrifuges.

Load and Temperature Limits

The 61810 2RZ is rated for moderate radial and axial loads. Its basic dynamic radial load rating (C) is typically 9.8 kN, and the basic static radial load rating (C0) is 7.2 kN. Axial load capacity depends on the contact angle (standard deep groove bearings have a contact angle of 0°), with the bearing capable of handling axial loads up to 20–30% of the radial load. For applications requiring higher axial capacity, angular contact ball bearings may be a better alternative, but the 61810 2RZ excels in scenarios where balanced radial and axial loads are present.

Operating temperature range is another key performance metric. With NBR seals and standard grease, the bearing can operate between -20°C and 120°C. For low-temperature applications (-40°C to 80°C), silicone rubber seals are available, while FKM seals extend the upper temperature limit to 180°C. Beyond these ranges, special lubricants (e.g., synthetic grease) or open bearings with external lubrication may be necessary.

Key Applications Across Industries

The compact size, high speed, and sealed design of the 61810 2RZ make it suitable for a wide array of industrial and commercial applications. Its versatility stems from its ability to perform reliably in both general-purpose and precision environments:

1. Electric Motors and Generators

Small to medium-sized electric motors (e.g., HVAC motors, fractional horsepower motors, and industrial drive motors) rely on the 61810 2RZ for smooth, high-speed operation. The bearing’s compact width fits within motor housings, while the 2RZ seals protect against dust and moisture—common in industrial or outdoor settings. The pre-lubricated design also reduces maintenance, a critical factor for motors in hard-to-reach locations.

2. Machine Tools and Spindles

Precision machine tools (e.g., CNC lathes, milling machines, and grinding machines) require bearings that minimize runout and support high rotational speeds. The 61810 2RZ (in P5 or P6 precision grades) meets these demands, providing the accuracy needed for tight tolerances in machining operations. Its thin-walled design also helps reduce spindle diameter, improving rigidity and machining precision.

3. Medical Equipment

Medical devices such as centrifuges, diagnostic scanners, and surgical tools demand bearings that are quiet, reliable, and contamination-free. The 61810 2RZ’s sealed design prevents lubricant leakage and blocks particulate matter, ensuring compliance with strict medical hygiene standards. Its low noise operation is also critical for equipment used in clinical settings.

4. Aerospace and Automotive Components

In aerospace, the 61810 2RZ is used in auxiliary systems (e.g., cabin air compressors, hydraulic pumps) where weight and space are at a premium. The automotive industry employs it in small motors (e.g., windshield wipers, power windows) and transmission components, leveraging its durability and resistance to vibration.

5. General Industrial Machinery

From conveyor systems and pumps to printing presses and packaging equipment, the 61810 2RZ serves as a cost-effective solution for general rotating applications. Its ability to handle mixed loads and resist contamination makes it a workhorse in manufacturing facilities, where reliability and low maintenance are key to productivity.

Installation, Maintenance, and Troubleshooting

Proper installation and maintenance are critical to maximizing the service life of the 61810 2RZ. Incorrect handling or neglect can lead to premature failure, costly downtime, and safety risks.

Installation Best Practices

Shaft and Housing Fit: The inner ring should be mounted with a transition or interference fit (typically H7/k6 for the shaft), while the outer ring uses a clearance or transition fit (H7/h6 for the housing). Excessive interference can distort the bearing raceways, reducing performance and lifespan.

Mounting Tools: Use a press or sleeve to apply force evenly to the ring being fitted (inner ring for shaft mounting, outer ring for housing mounting). Avoid tapping the bearing directly with a hammer, as this can damage the raceways or rolling elements.

Alignment: Ensure the shaft and housing are properly aligned to prevent misalignment loads, which cause uneven wear and increased friction. Misalignment exceeding 2° can drastically reduce bearing life.

Maintenance Guidelines

Lubrication: The 2RZ bearing is pre-lubricated with grease, but re-lubrication may be required for long-term or high-temperature operation. Use grease compatible with the seal material (e.g., lithium-based grease for NBR seals) and follow the manufacturer’s recommendations for re-lubrication intervals.

Contamination Control: Inspect the seals regularly for damage (e.g., cracks, wear) and replace the bearing if seals are compromised. Keep the surrounding area clean during maintenance to prevent debris from entering the bearing.

Temperature Monitoring: Abnormal temperature rise (exceeding 80°C under normal load) indicates potential issues such as insufficient lubrication, misalignment, or overloading. Monitor temperatures during operation and address anomalies promptly.

Common Troubleshooting

Noise or Vibration: Often caused by misalignment, contaminated lubricant, or worn rolling elements. Check alignment, replace grease, and inspect the bearing for damage.

Leakage: Damaged seals or over-greasing can cause grease leakage. Replace seals if worn and ensure proper grease volume during re-lubrication.

Premature Wear: Typically due to overloading, improper fit, or inadequate lubrication. Verify load ratings, adjust shaft/housing fits, and follow lubrication guidelines.

Advantages and Competitive Edge

The 61810 2RZ offers several key advantages that set it apart from other bearing types and configurations:

Compact Design: Its thin-walled 18-series profile makes it ideal for space-constrained applications, where larger bearings would not fit.

High Speed Capability: The non-contact 2RZ seals minimize friction, enabling higher rotational speeds than contact-sealed bearings.

Dual Load Capacity: Accommodates both radial and axial loads, reducing the need for multiple bearings in assembly.

Low Maintenance: Pre-lubricated and sealed design eliminates frequent re-lubrication and protects against contamination, lowering operating costs.

Interchangeability: Compliance with ISO standards ensures compatibility across manufacturers, simplifying replacement and inventory management.

Compared to open bearings, the 61810 2RZ offers superior contamination protection without sacrificing speed. Compared to metal-shielded (ZZ) bearings, it provides better sealing against moisture and fine particles, making it suitable for harsh environments. While contact-sealed (2RS) bearings offer tighter sealing, they generate more friction and limit speed—making the 2RZ a better choice for high-speed applications.

Conclusion

The 61810 2RZ deep groove ball bearing exemplifies the perfect balance of precision, performance, and practicality. Its standardized design, compact profile, and versatile performance make it a cornerstone component in countless industrial and commercial applications, from electric motors to medical equipment. By understanding its specifications, structural features, and maintenance requirements, engineers and manufacturers can leverage the 61810 2RZ to optimize equipment reliability, reduce downtime, and lower operating costs. As industries continue to demand smaller, faster, and more durable components, the 61810 2RZ remains a trusted solution that meets the evolving needs of modern technology.

Would you like me to create a detailed technical data sheet for the 61810 2RZ, including exact load ratings, speed limits, and material specifications, to complement this article?